Silver-based flux-cored wire and manufacturing method thereof

A flux-cored wire, silver-based technology, used in manufacturing tools, welding media, welding equipment and other directions, can solve the problems of difficult to accurately control the amount of flux, complex brazing process, low production efficiency, etc., to achieve good welding performance, The effect of long storage time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

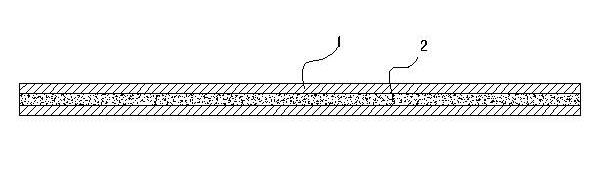

[0009] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0010] As shown in the figure, the silver-based flux-cored welding wire of the present invention includes a tubular welding wire 1 made of silver, copper, and zinc alloy, and a flux 2 filled in the wire tube. The amount of flux 2 is 10-15wt%, and silver, copper, and zinc The amount of alloy is 85-90wt%, the content of silver in silver, copper and zinc alloy is 15-65wt%, the content of copper is 15-65wt%, and the content of zinc is 15-65wt%. The brazing flux includes potassium fluoride, borax and boric acid. The content of potassium fluoride is 15-60 parts by weight, and the content of borax and boric acid is 40-85 parts by weight. The brazing flux also includes boric anhydride, potassium fluoroborate, and potassium fluoride, boric anhydride, and potassium fluoroborate form a potassium fluoride mixture. The amount of the potassium fluoride mixture in the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com