Efficient CrOx/mesoporous CaO catalyst for preparing isobutene by oxidative dehydrogenation of iso-butane and preparation method thereof

A technology for oxidative dehydrogenation and isobutene production, which is applied in the field of catalysis, can solve problems such as no chromium oxide catalyst, and achieve the effect of good oxidation-reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

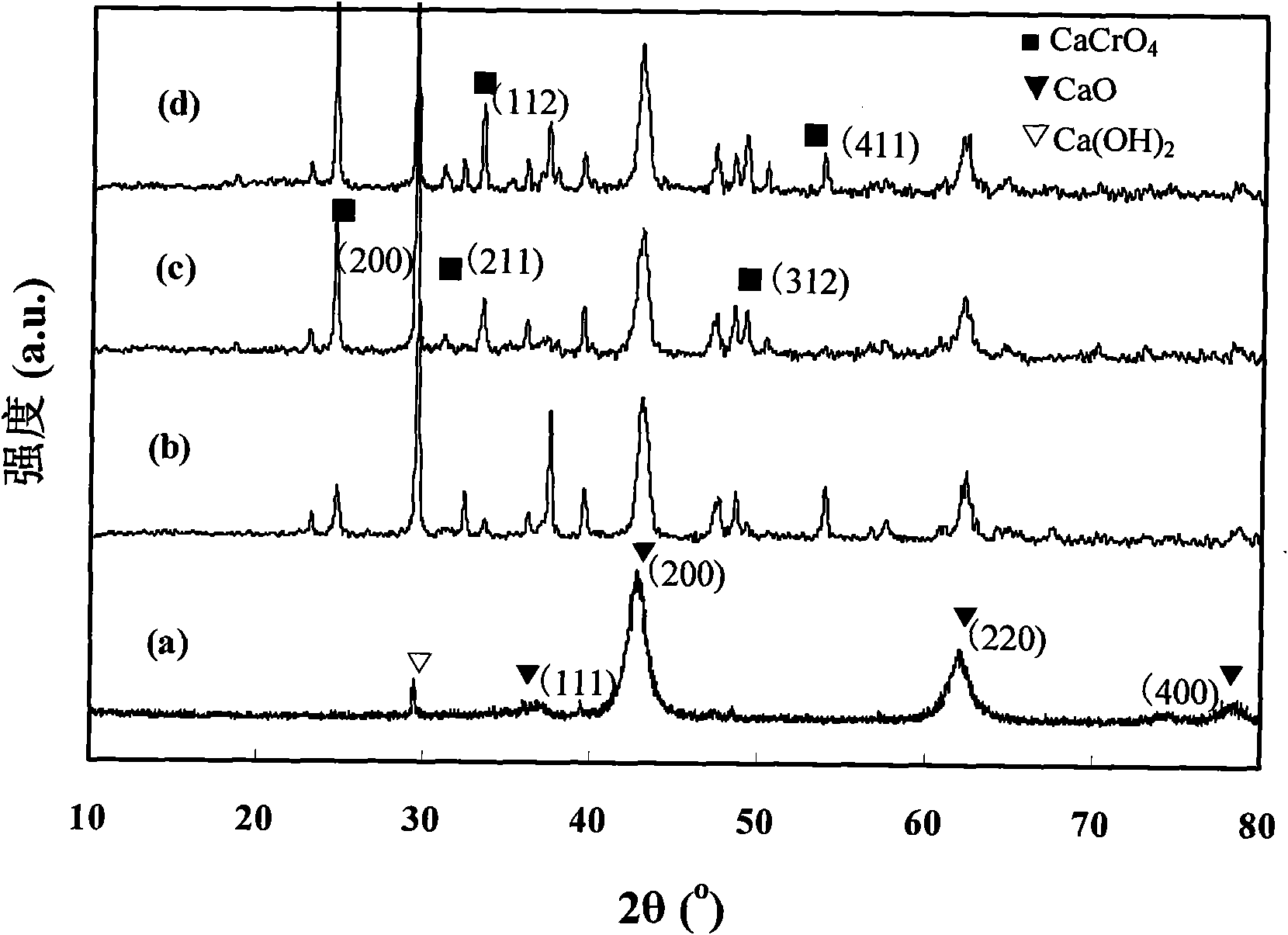

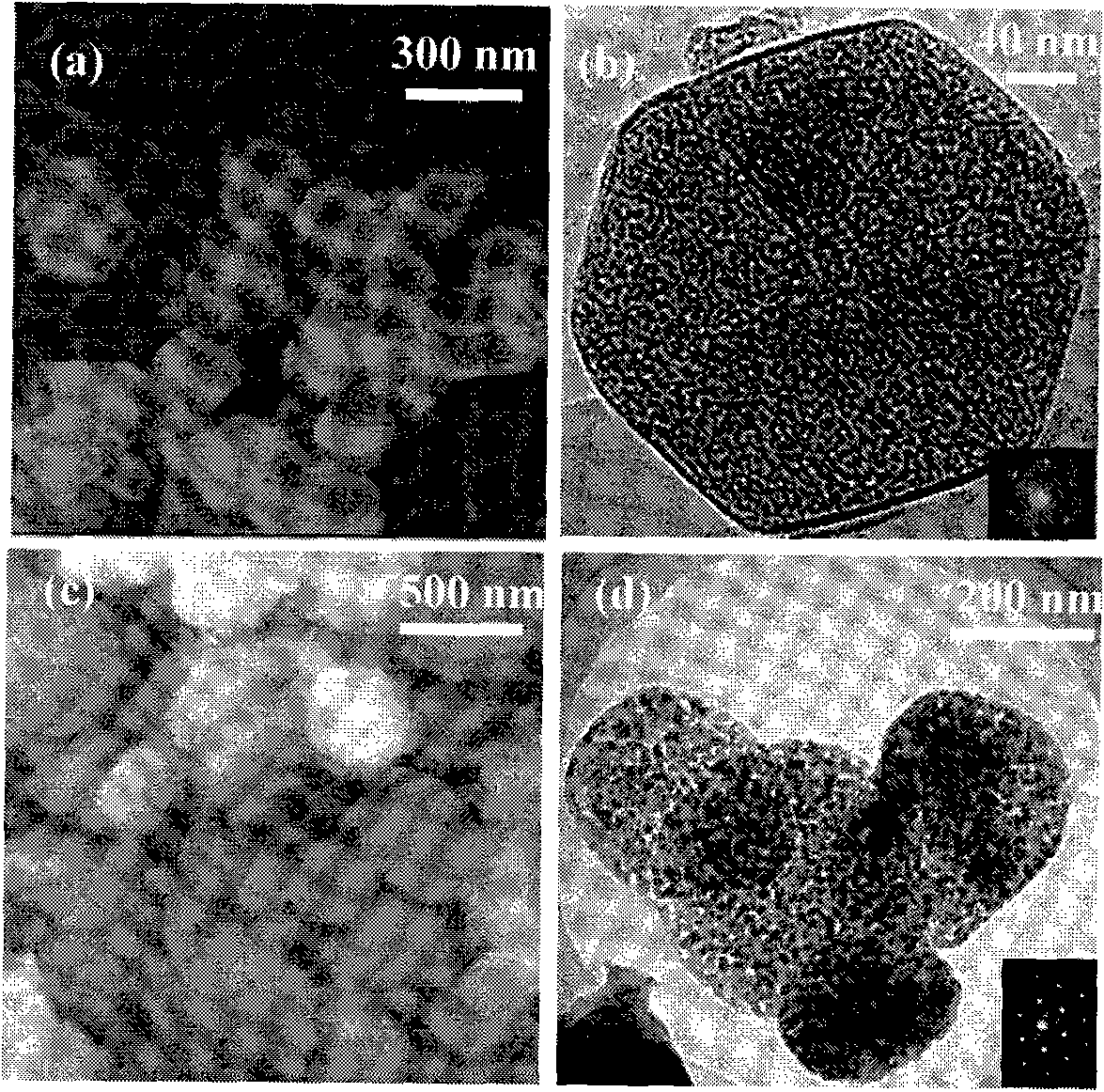

[0020] 1) Prepare mesoporous CaO carrier with reference to the method disclosed in CN101187055: dissolve 3.1g polyethylene glycol in 120mL deionized water, add 2.24g CaO powder, stir evenly at room temperature, transfer to autoclave and place in oven , hydrothermally treated at 240°C for 72 hours, the product was taken out and naturally cooled to room temperature, filtered, washed, and dried to obtain a white powder, which was put into a muffle furnace and raised from room temperature to Burn at 600°C for 5 hours to obtain CaO single crystal particles with wormhole-like mesoporous cubic crystal structure, that is, mesoporous CaO carrier, and dry at 100°C for 1 hour;

[0021] 2) Weigh 0.4386g of chromium nitrate and dissolve it in absolute ethanol equal in volume to 2.0000g of mesoporous CaO;

[0022] 3) Add the solution prepared in step 2) to 2.0000 g of the dried mesoporous CaO powder in step 1), and after fully stirring, dry at 120°C for 12 hours, grind the obtained powder e...

Embodiment 2

[0024] 1) with embodiment 1 step 1);

[0025] 2) Weigh 1.1700g of chromium nitrate and dissolve it in absolute ethanol equal in volume to 2.0000g of mesoporous CaO;

[0026] 3) Add the solution prepared in step 2) to 2.0000 g of the dried mesoporous CaO powder in step 1), and after fully stirring, dry at 120°C for 12 hours, grind the obtained powder evenly and transfer it to a muffle furnace, In the air atmosphere, the temperature was raised to 550°C at a rate of 1°C / min for 3 hours to obtain CrO x / mesoporous CaO catalyst, wherein, the active component CrO x The load of Cr 2 o 3 The mass percentage content of is counted as 10%.

Embodiment 3

[0028] 1) with embodiment 1 step 1);

[0029] 2) Weigh 1.4354g of chromium nitrate and dissolve it in absolute ethanol equal in volume to 2.0000g of mesoporous CaO;

[0030] 3) Add the solution prepared in step 2) to 2.0000 g of the dried mesoporous CaO powder in step 1), and after fully stirring, dry at 120°C for 12 hours, grind the obtained powder evenly and transfer it to a muffle furnace, In the air atmosphere, the temperature was raised to 550°C at a rate of 1°C / min for 3 hours to obtain CrO x / mesoporous CaO catalyst, wherein, the active component CrO x The load of Cr 2 o 3 The mass percent content of is calculated as 12%.

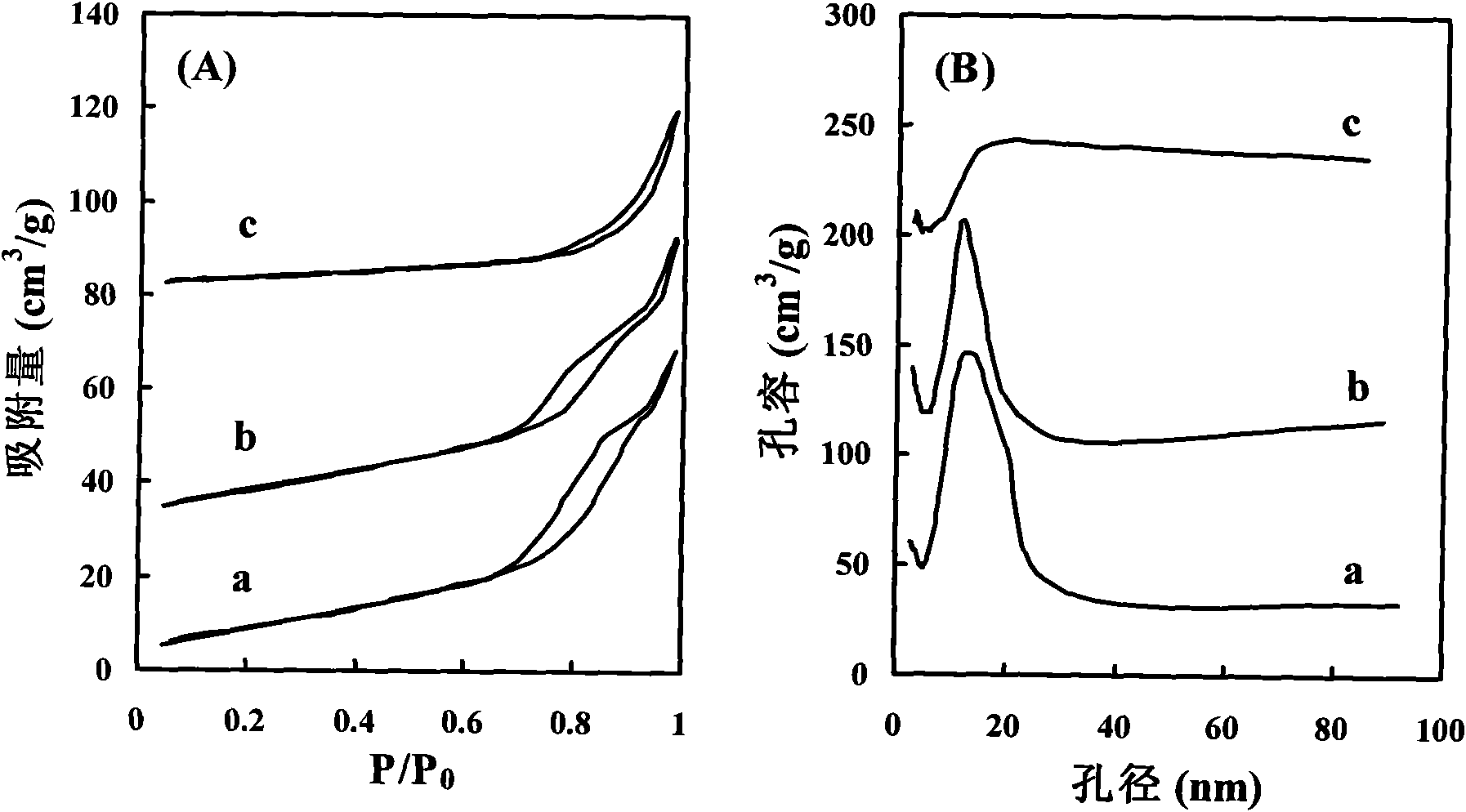

[0031] catalyst

[0032] Mesoporous CaO and CrO prepared by the present invention in table 1 x / Specific surface area, average pore diameter and pore volume of mesoporous CaO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com