Preparation method of anti-laser-damage mixed VO<X> phase

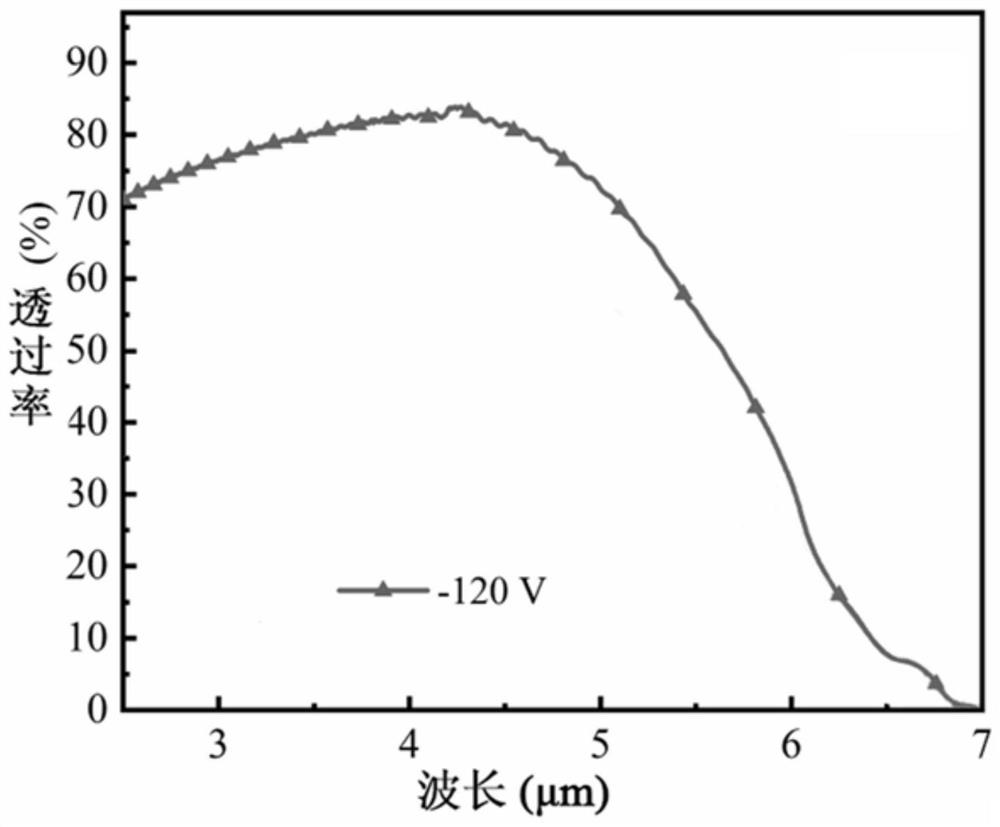

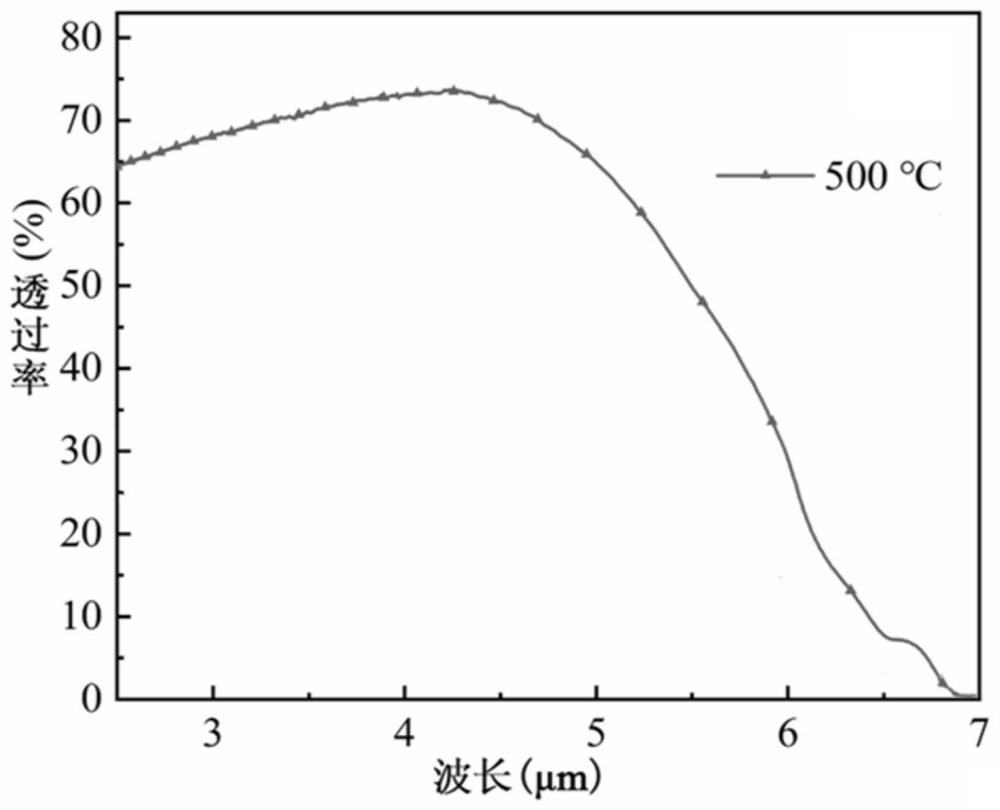

A technology of anti-laser and air pressure control, applied in metal material coating process, vacuum evaporation coating, coating, etc., can solve the problems of uneven optical modulation performance of vanadium oxide thin film, limit thin film laser protection efficiency, etc., and achieve improvement The effect of thin film laser protection efficiency, large application potential, and strong optical modulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0035] Specific implementation mode 1: In this implementation mode, anti-laser damage hybrid VO x The preparation method of phase is implemented according to the following steps:

[0036] 1. For the base material and V respectively 2 o 3 The target is ultrasonically cleaned to obtain the cleaned substrate material and V 2 o 3 target;

[0037] Second, the cleaned V 2 o 3 The target is installed and fixed, and the cleaned base material is placed on the sample stage with a heating system, the distance between the target and the base is adjusted to 5-15 cm, and the door of the vacuum chamber is closed;

[0038] 3. First use the mechanical pump to pre-exhaust the vacuum chamber. When the air pressure is as low as 3.0Pa to 10.0Pa, turn on the molecular pump for further air extraction. At the same time, measure the vacuum degree in the vacuum chamber until the air pressure in the vacuum chamber is as low as 1.0×10 -4 ~1.0×10 - 3 Pa, complete vacuum chamber pumping;

[0039]...

specific Embodiment approach 2

[0041] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the base material described in step one is Al 2 o 3 Substrate (a-side sapphire substrate), SiO 2 Substrate or TiO 2 base.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, deionized water, acetone, ethanol and deionized water are used to clean the base material sequentially.

PUM

| Property | Measurement | Unit |

|---|---|---|

| infrared transmittance | aaaaa | aaaaa |

| infrared transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com