Preparation method of molybdenum disulfide/carbon nano-fiber hybrid material

A technology of carbon nanofibers and hybrid materials, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, can solve the problems of unfavorable electrocatalytic materials and poor electrical conductivity, and achieve high catalytic activity, good stability and repeatability, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

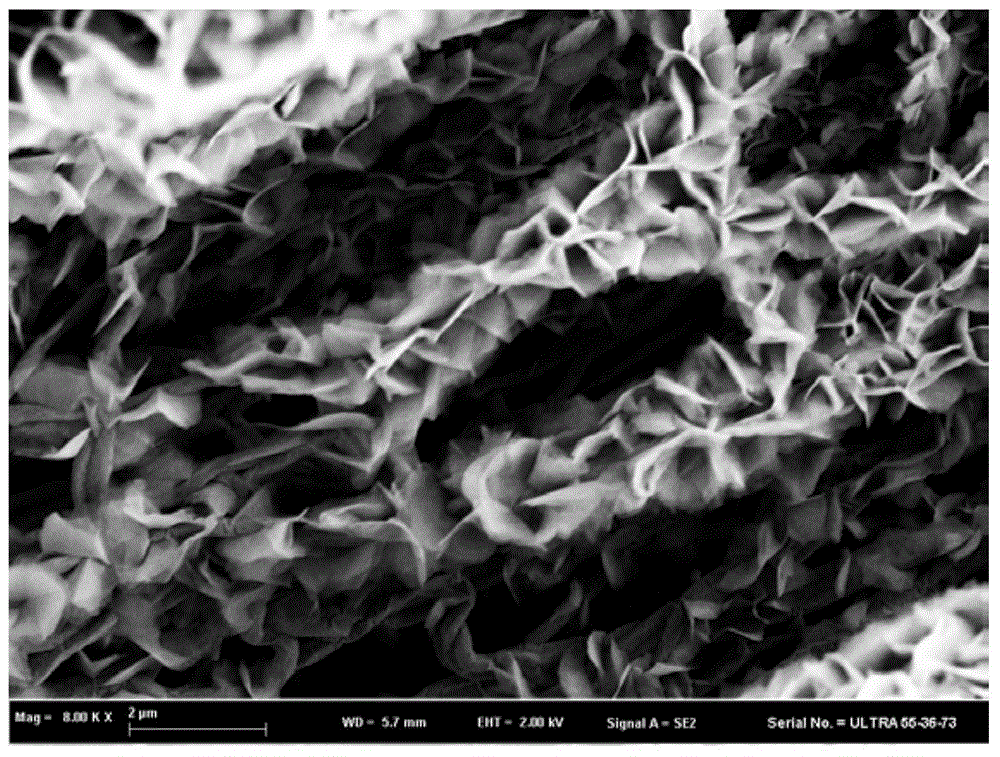

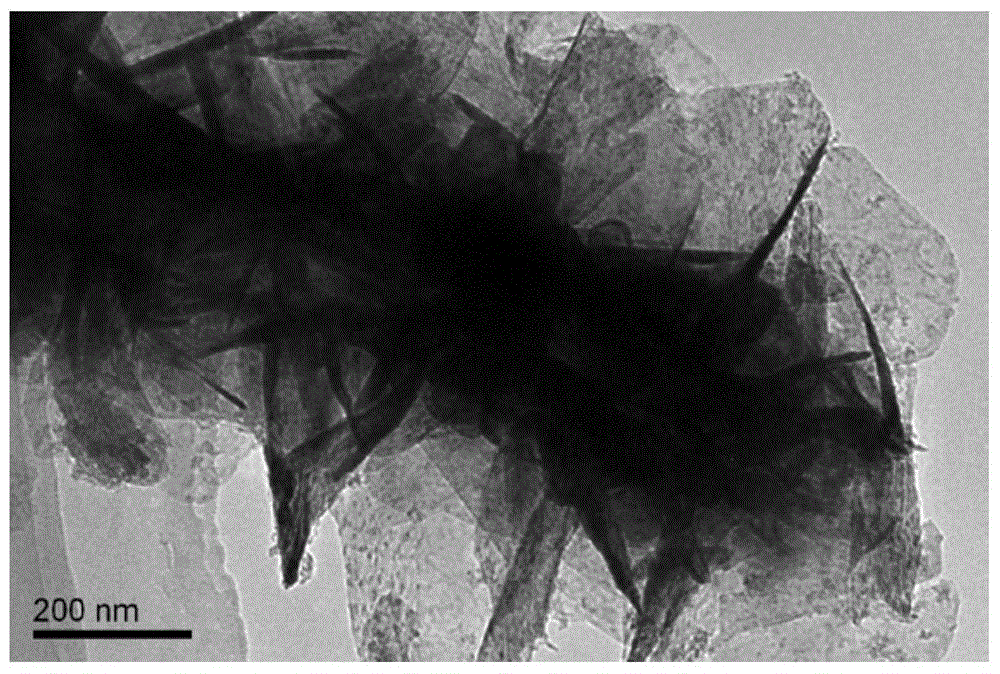

[0018] Embodiment 1: get 5g polyacrylonitrile powder, make the solution that mass concentration is 5% with dimethyl sulfoxide, then adopt electrospinning method to spin this solution, control spinning voltage to be 4kV, receiving device arrives The distance between the spinning needles is 5 cm (that is, the receiving distance is 5 cm), and the flow rate of the solution is 0.01 mL / min, that is, polyacrylonitrile ultrafine fibers with a diameter of 100-800 nm are obtained.

[0019] Place the obtained ultrafine fibers in a muffle furnace or tube furnace, pre-oxidize in air at 200°C for 8 hours, then keep them at 800°C in an argon atmosphere for 20 hours, and finally cool to room temperature in an argon atmosphere, to obtain carbon nanofibers.

[0020] Put 0.5g of manganese dioxide, 1g of molybdenum trioxide and 0.5g of carbon nanofiber into three corundum boats respectively, and then place all three corundum boats in the middle of the tube furnace; add 1g of sulfur powder into an...

Embodiment 2

[0021] Embodiment 2: get 5g cellulose, make the solution that mass concentration is 15% with dimethyl sulfoxide, then adopt electrospinning method to spin this solution, control the spinning voltage to be 18kV, receive device to spin The distance between the needles is 20cm, and the flow rate of the solution is 0.01mL / min, that is, ultrafine fibers with a diameter of 100-800nm are obtained.

[0022] Place the obtained ultrafine fibers in a muffle furnace or a tube furnace, pre-oxidize in air at 500°C for 3 hours; then keep them warm at 1200°C in an argon atmosphere for 5 hours, and finally cool to room temperature in an argon atmosphere, to obtain carbon nanofibers.

[0023] Put 0.5g of manganese dioxide, 1g of molybdenum trioxide and 0.5g of carbon nanofiber into three corundum boats respectively, and then place all three corundum boats in the middle of the tube furnace; add 1g of sulfur powder into another corundum In the boat, placed upstream of the air flow; after turni...

Embodiment 3

[0024] Embodiment 3: get 10g polyvinylpyrrolidone, make the solution that mass concentration is 10% with dimethyl sulfoxide, then adopt electrospinning method to spin this solution, control the spinning voltage to be 8kV, the receiving device arrives spinning The distance between the silk needles is 15cm, and the flow rate of the solution is 0.01mL / min, that is, ultrafine fibers with a diameter of 100-800nm are obtained.

[0025] Place the obtained ultrafine fibers in a muffle furnace or tube furnace, pre-oxidize in air at 300°C for 5 hours, then keep them at 1000°C in an argon atmosphere for 10 hours, and finally cool to room temperature in an argon atmosphere, to obtain carbon nanofibers.

[0026] Put 0.5g of manganese dioxide, 1g of molybdenum trioxide and 0.5g of carbon nanofiber into three corundum boats respectively, and then place all three corundum boats in the middle of the tube furnace; add 1g of sulfur powder into another corundum In the boat, placed upstream of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com