Corrosion-resistant polymer waterproof mortar

A waterproof mortar and polymer technology, applied in the field of building materials, can solve the problems of easy aging, low strength, and poor corrosion resistance of polymer waterproof mortar, and achieve the effect of excellent corrosion resistance and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

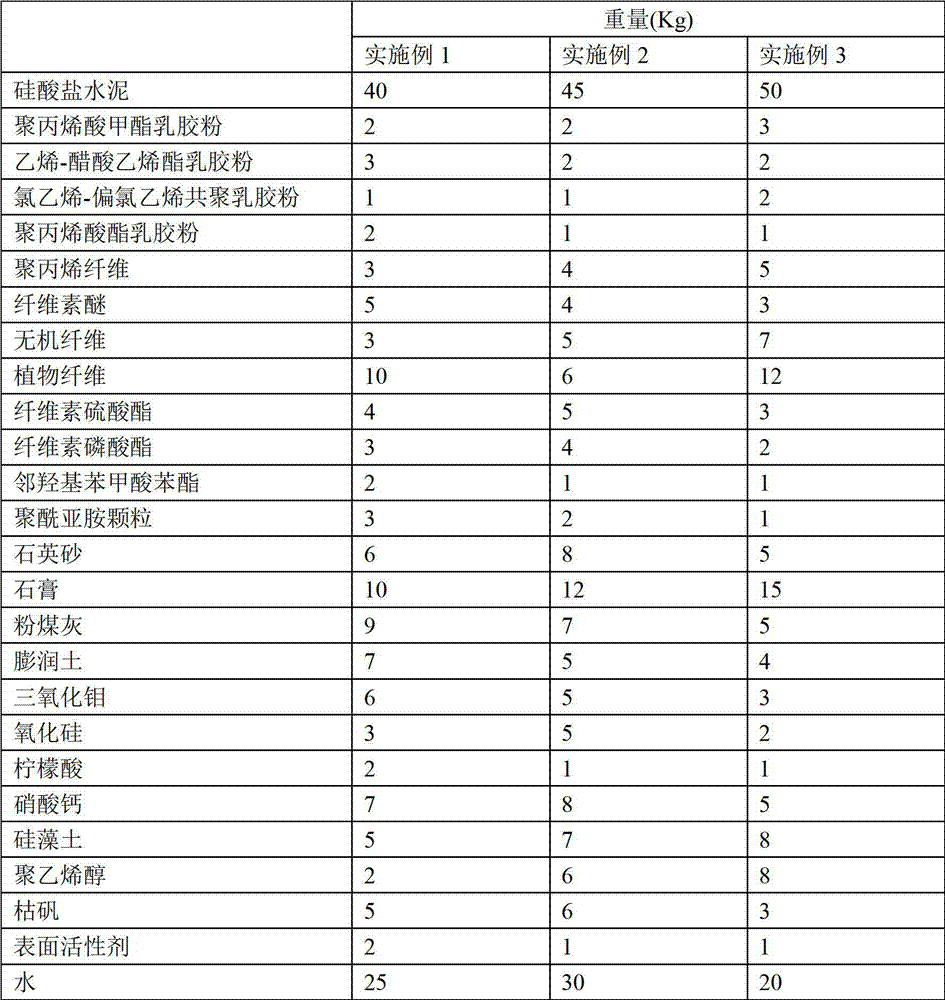

[0026] The components were prepared in the weight ratios shown in Table 1.

[0027] The weight proportion of table 1 embodiment 1~embodiment 3

[0028]

[0029] In the above embodiments, aluminum silicate fiber is used as the inorganic fiber; corn stalk is used as the plant fiber, and its length is less than 0.3 cm; the length of polypropylene fiber is in the range of 1-20 mm; hydroxypropyl methyl cellulose ether is used as the cellulose ether.

[0030] The preparation method is:

[0031] S1: Mix portland cement, polymethyl acrylate latex powder, ethylene-vinyl acetate latex powder, vinyl chloride-vinylidene chloride copolymer latex powder, and polyacrylate latex powder evenly to form mixture A;

[0032] S2: Mix polypropylene fiber, cellulose ether, inorganic fiber, plant fiber, cellulose sulfate, cellulose phosphate, phenyl o-hydroxybenzoate, and polyimide particles uniformly to form a mixture B;

[0033] S3: Mix mixture A, mixture B, quartz sand, gypsum, fly ash, benton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com