Lithiation molybdenum trioxide nano band electrode material and its lithiation modifying method

A technology for lithiating molybdenum trioxide and molybdenum trioxide, which is applied in the fields of nanomaterials and nanometers, and achieves the effects of good reproducibility and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

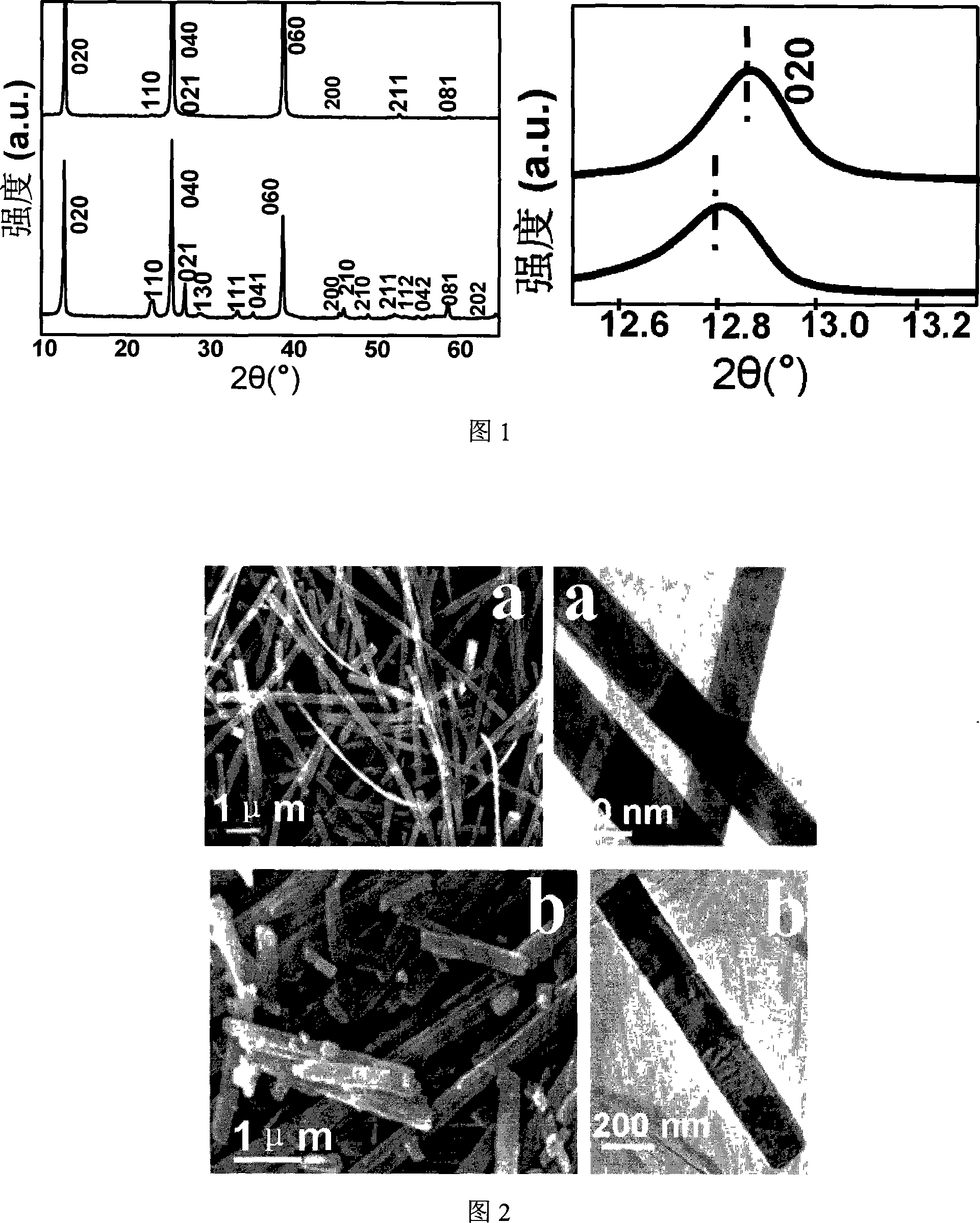

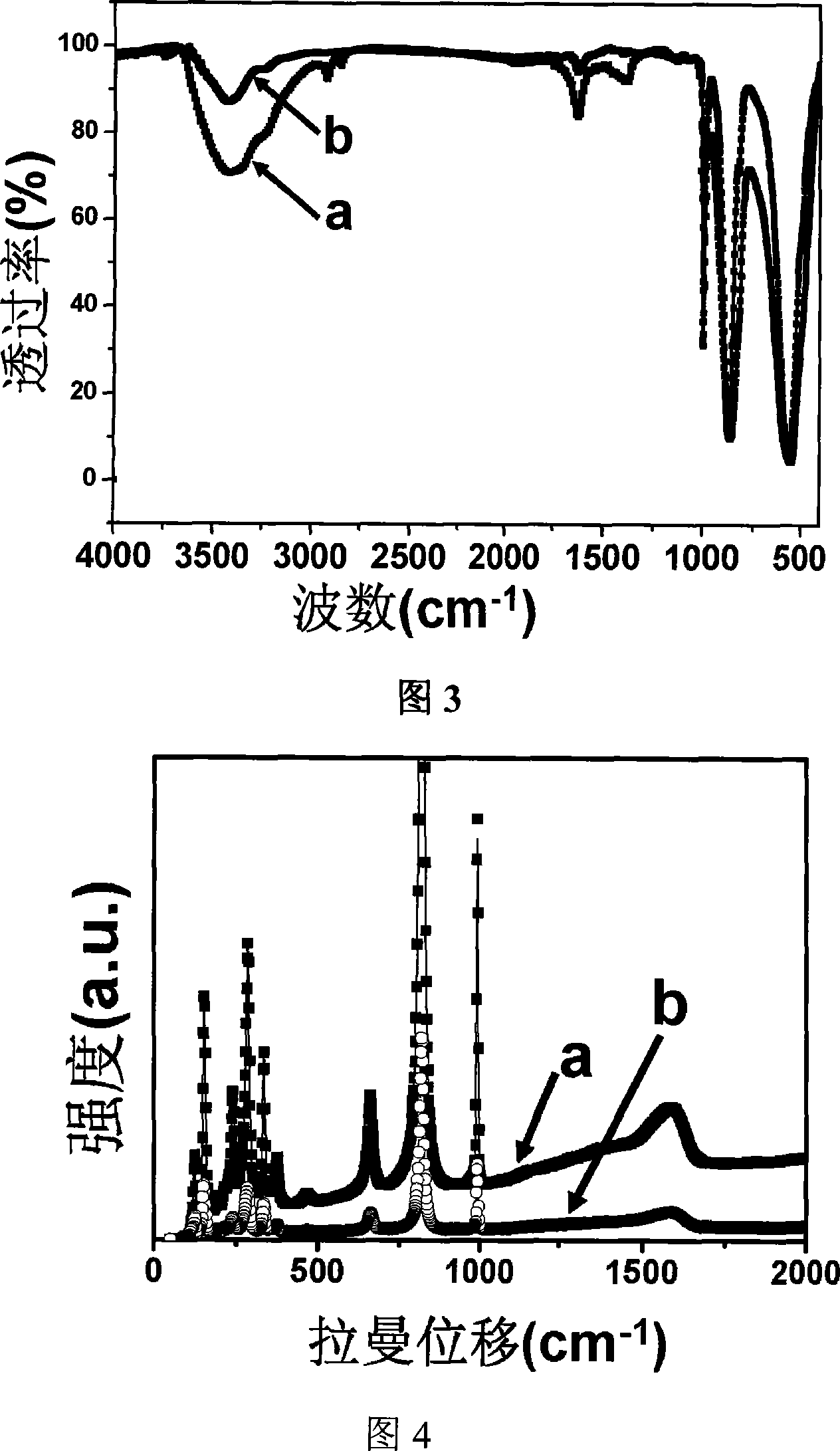

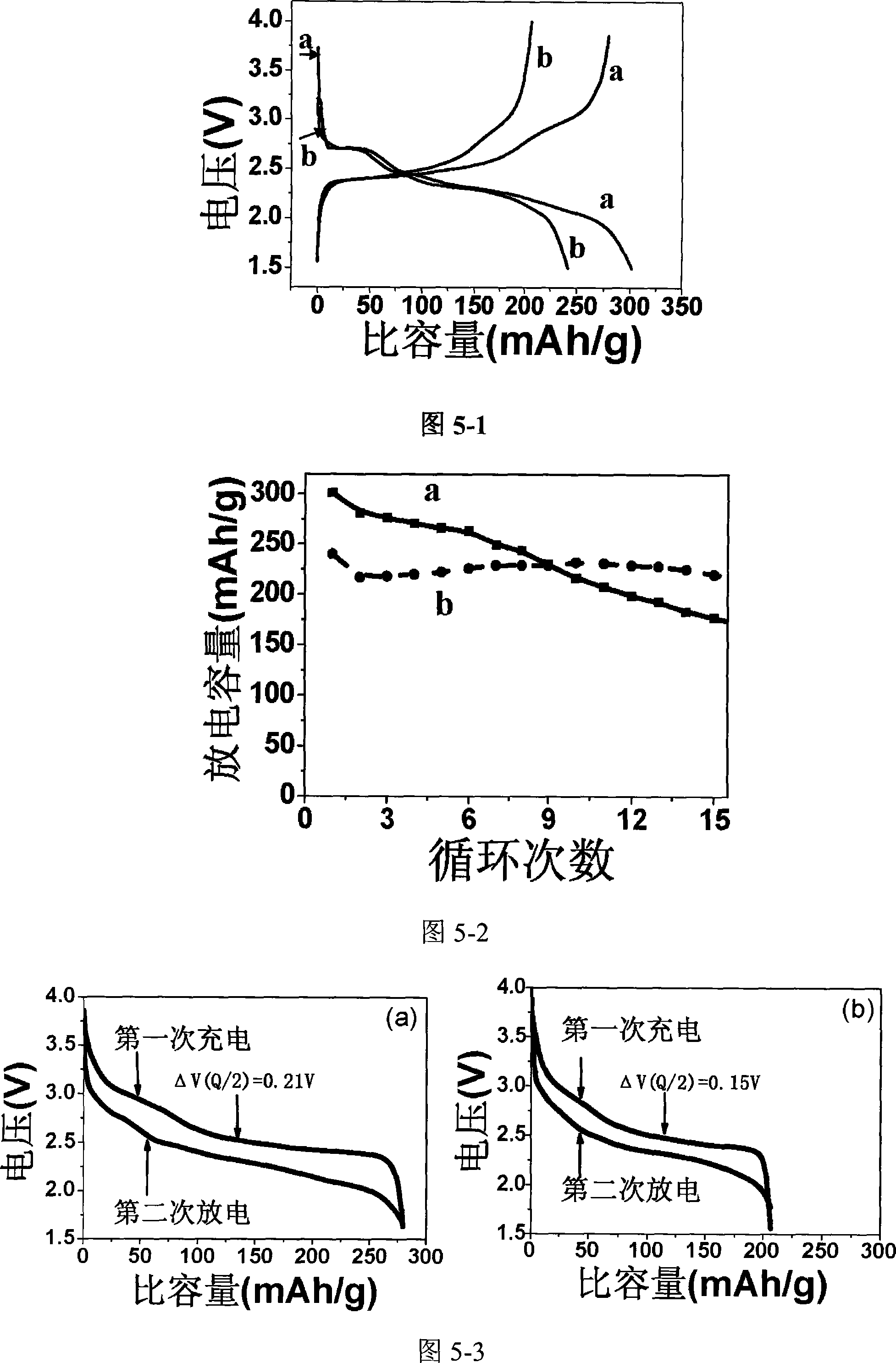

[0030] To prepare lithiated molybdenum trioxide nanobelts, the preparation steps are as follows:

[0031] (1) 4.33 g (NH 4 ) 6 Mo 7 o 24 4H 2 O (≥99.0%) particles were dissolved in 35 milliliters of deionized water; (2) the prepared (NH 4 ) 6 Mo 7 o 24 Solution passed through proton exchange resin to obtain bright blue MoO 3 ·nH 2 O sol, the pH value is 2; (3) move the sol to a stainless steel reaction kettle with polytetrafluoroethylene lining, and hydrothermally treat it at 180 ° C for 4 hours; (5) cool and filter, and wash with absolute ethanol and deionized water respectively 3 times, dry at 80°C to obtain light blue molybdenum trioxide nanobelts; (6) Add the obtained molybdenum trioxide nanobelts into deionized water and ultrasonically disperse for 30 minutes, then add LiCl powder, the amount of LiCl added makes the molybdenum trioxide in the system The molar ratio of the element to the lithium element is 1:5, stirring for 2 days; (7) transfer the stirred suspen...

Embodiment 2~ Embodiment 5

[0034] Preparation of Lithiated Molybdenum Trioxide Nanobelts

[0035] The method for preparing molybdenum trioxide nanobelts is basically the same as in Example 1, except that the hydrothermal treatment temperatures of Examples 2, 3, 4, and 5 are respectively 180, 160, 150, and 170°C, and the hydrothermal treatment times are respectively 1, 2, and 2 , 1.5 days.

[0036] The process conditions of molybdenum trioxide nanobelt lithiation with lithium salt are shown in Table 1.

[0037] Table 1:

[0038]

[0039] Lithiated low-dimensional layered nanomaterials can be obtained by referring to the method of Example 1 according to the above experimental parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com