High-efficiency difunctional water decomposition electrocatalyst NiCoP and preparation method thereof

An electrocatalyst, dual-function technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problems of poor sustainability, performance degradation, increase the cost of water splitting technology, etc., to improve catalyst efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

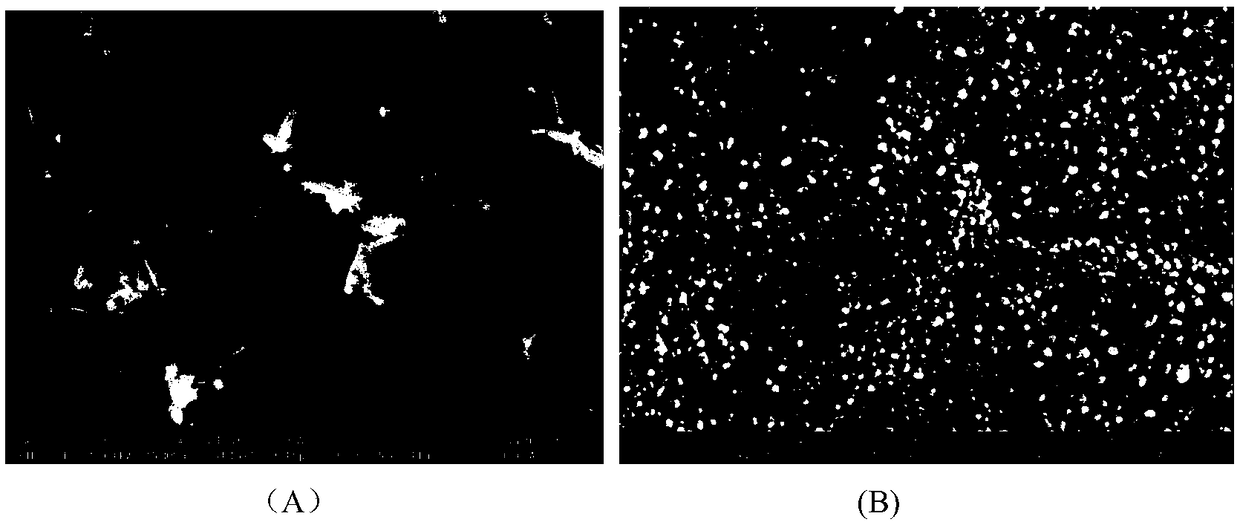

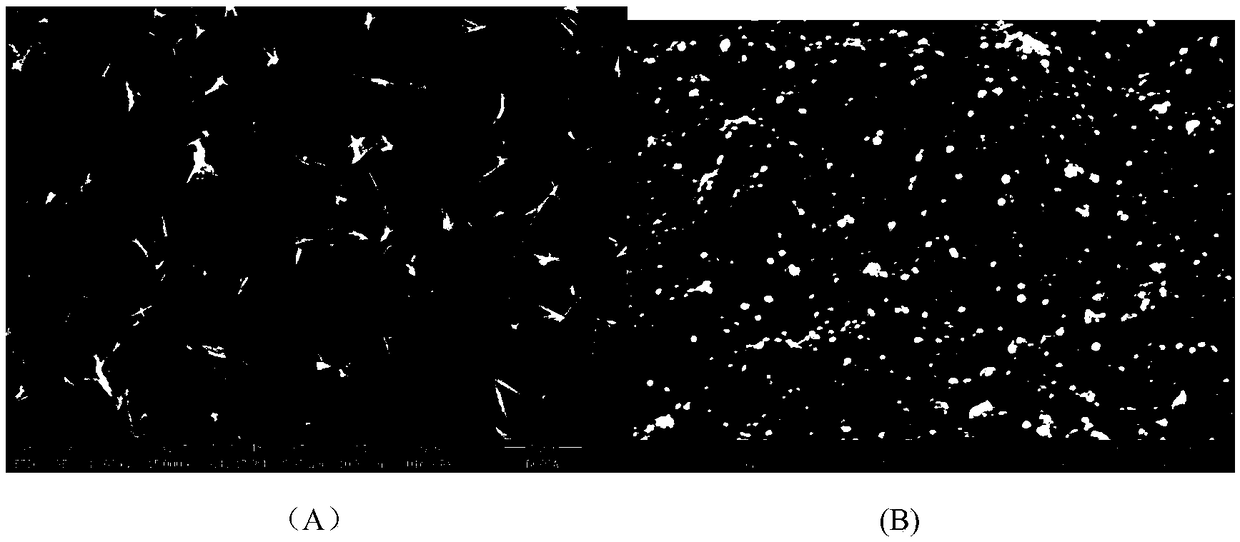

Image

Examples

example 1

[0027] Example 1: Prepare according to the composition of the precursor hydrothermal solution and phosphating hydrothermal solution in Table 1, the precursor hydrothermal time is 8h, and then prepare the sample according to the above process steps.

[0028] Table 1 specific implementation conditions

[0029]

example 2

[0030] Example 2: Prepare according to the composition of the precursor hydrothermal solution and phosphating hydrothermal solution in Table 2, adjust the precursor hydrothermal time to 16h, and then prepare samples according to the above process steps.

[0031] Table 2 specific implementation conditions

[0032]

[0033]

example 3

[0034] Example 3: Prepare according to the composition of the precursor hydrothermal solution and phosphating hydrothermal solution in Table 3, adjust the precursor hydrothermal time to 24h, and then prepare samples according to the above process steps.

[0035] Table 3 specific implementation conditions

[0036]

[0037] The Tafel slopes and current densities corresponding to all examples in Table 4 are 10mA cm -2 overpotential

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com