Graphene-coated mesoporous metallic oxide, and preparation method and use thereof

A technology of alkene-coated mesoporous and mesoporous silica, applied in the field of nanocomposite materials and electrode materials, can solve the problems of poor cycle performance, low charge and discharge rate, etc., to improve charge and discharge capacity, improve cycle performance and rate performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of mesoporous silica SBA-15 template

[0031] 4.0g triblock copolymer P123 (EO 20 PO 70 EO 20 ) was dissolved in 130mL deionized water and 20mL hydrochloric acid (37%, HCl) mixed solution; 8.5g tetraethyl orthosilicate (TEOS) was added dropwise in a water bath at 35-40°C; after stirring for 24 hours, at 100-130°C Keep the temperature constant for 2-3 days; filter, wash, and dry, heat at 550°C for 5 hours, and cool to room temperature to obtain the SBA-15 template.

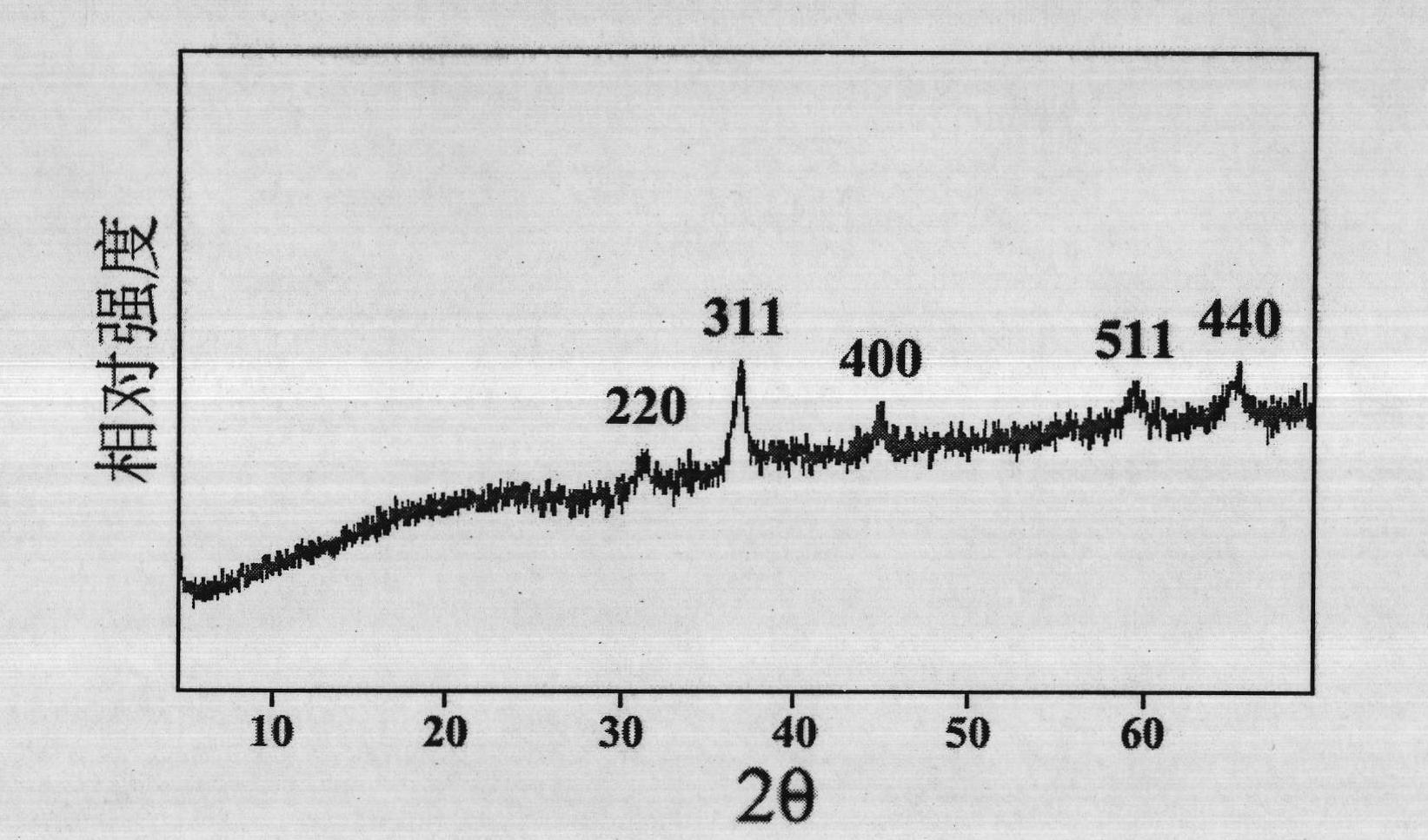

[0032] 2) Preparation of mesoporous cobalt tetroxide (Co 3 o 4 )

[0033] Dissolve 1-4g of cobalt nitrate in 20-30mL of deionized water or ethanol, add 1g of SBA-15 template at room temperature; stir until the solvent evaporates, heat the solid mixture at 300-500°C for 3-5 hours, and cool to room temperature The mixture is added to 1~3mol / L sodium hydroxide (NaOH) solution or 5wt% hydrofluoric acid (HF), stirred for 2~6 hours; after centrifugation, washing and drying, the mesoporous tric...

Embodiment 2

[0042] 1) Preparation of Mesoporous Silica KIT-6 Template

[0043] Dissolve 3.0g of triblock copolymer P123 in 115mL of deionized water and 5mL of hydrochloric acid (37%, HCl) mixture; add 3.0g of butanol dropwise in a water bath at 35-40°C, react for 1 hour, and add dropwise 6.45g Orthoethyl silicate (TEOS); after stirring for 24 hours, keep the temperature at 100-130°C for 2-3 days; filter, wash, and dry, heat at 550°C for 5 hours, and cool to room temperature to obtain the KIT-6 template .

[0044] 2) Preparation of mesoporous manganese dioxide (MnO 2 )

[0045] Dissolve 5-6g of manganese nitrate in 20-30mL of deionized water to make a saturated solution, add 1g of KIT-6 template into 20-30mL of n-hexane to make a suspension; add the saturated solution of manganese nitrate dropwise to the In the suspension, stir overnight, filter and dry to obtain a solid mixture; heat the mixture at 400-500°C for 3-5 hours, and cool to room temperature; add the mixture to 1-3mol / L sodiu...

Embodiment 3

[0052] 1) Preparation of mesoporous silica SBA-16 template

[0053] 2.0g triblock copolymer P127 (EO 106 PO 70 EO 106 ), 4.0g of potassium chloride (KCl) were dissolved in 100mL of deionized water and 20mL of hydrochloric acid (37%, HCl) mixed solution; 8.6g of tetraethyl orthosilicate (TEOS) was added dropwise in a water bath at 35-40°C; stirred After 24 hours, keep the temperature at 100-130°C for 2-3 days; filter, wash, and dry, heat at 550°C for 5 hours, and cool to room temperature to obtain the SBA-16 template.

[0054] 2) Preparation of mesoporous tin dioxide (SnO 2 )

[0055] Grind and mix 1-4g stannous chloride or tin chloride with 1g SBA-16 template for 1-2 hours; heat the mixture at 400-700°C for 3-5 hours and cool to room temperature; add the mixture to 1-3mol / L of sodium hydroxide (NaOH) solution, stirred for 2 to 6 hours; after centrifugation, washing, and drying, the mesoporous tin dioxide (SnO 2 ).

[0056] 3) Preparation of graphene oxide

[0057] Ado...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com