Polyamide mold plastic and its use in production of transparent and vapor-disinfectant molding member and extrusion object

A molding compound, polyamide technology, applied in the field of polyamide molding compound, can solve the problems of repeated disinfection of undisclosed products and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

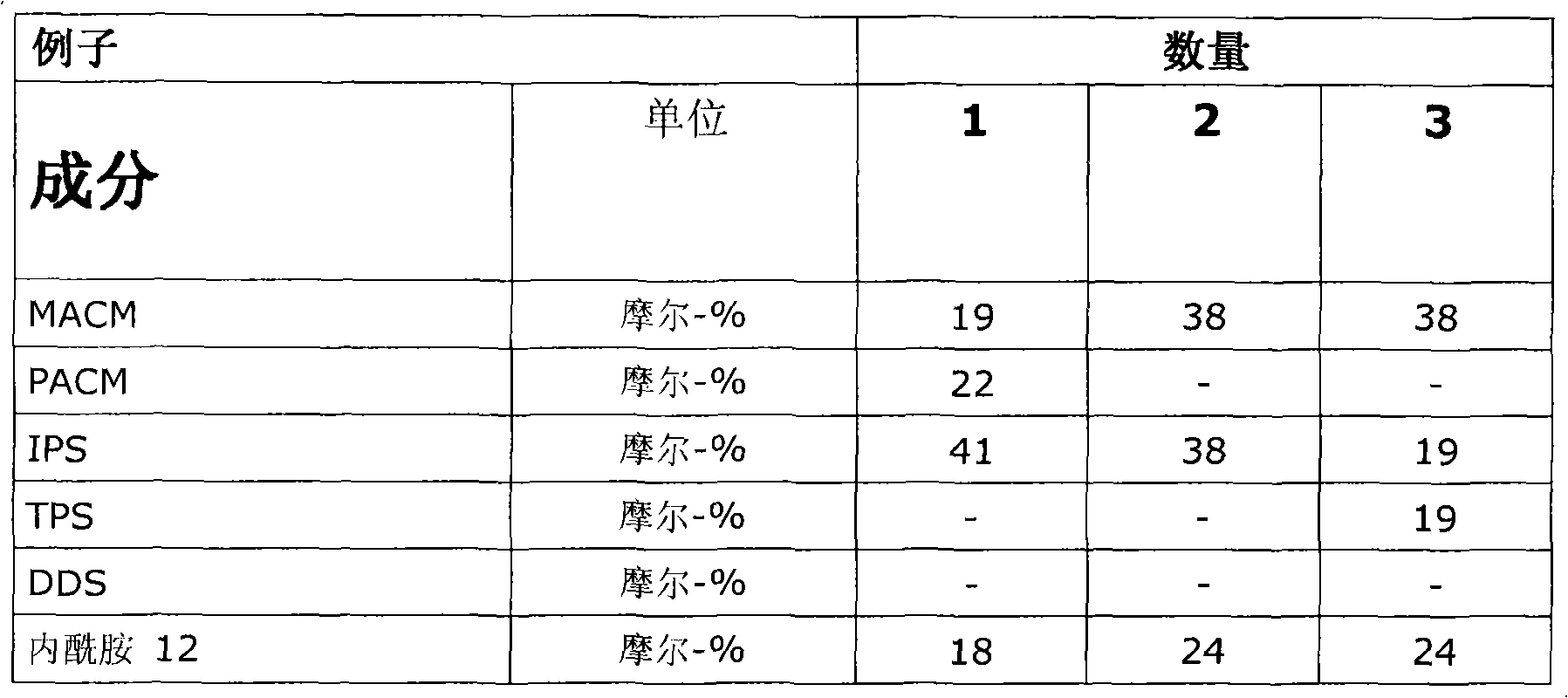

Examples

Embodiment Construction

[0062] The test disinfection method (134 ℃ / 7 minutes) that the present invention uses carries out in the following way:

[0063] 1. Equipment for hot steam sterilization

[0064] The equipment used was an A2549E autoclave from the company Tuttnauer with a chamber volume of 26 I. A four-tiered rack (each with a perforated plate) receiving the specimen is placed inside the circular interior of a horizontally oriented pressure chamber.

[0065] 2. Standard Test Specimen and Pretreatment

[0066] ISO test specimens (standard: ISO / CD3167, type A1, 170 x 20 / 10 x 4 mm) were placed on racks as unpretreated, non-contacting injection molded parts. The autoclave is then closed and screwed down.

[0067] Set the amount of test specimen required according to the planned withdrawal time.

[0068] 3. Perform hot steam sterilization

[0069] The autoclave was heated to 134° C., and the water (about 350 ml) dispensed thereto was evaporated in the autoclave.

[0070] This process lasts 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com