Servo mechanical press

A technology for servo machinery and presses, applied in the field of six-link servo mechanical presses, can solve the problems of inability to adapt to the servo stamping process, and the slider can only change speed, and achieves simple structure, large force increase stroke, and reduced manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

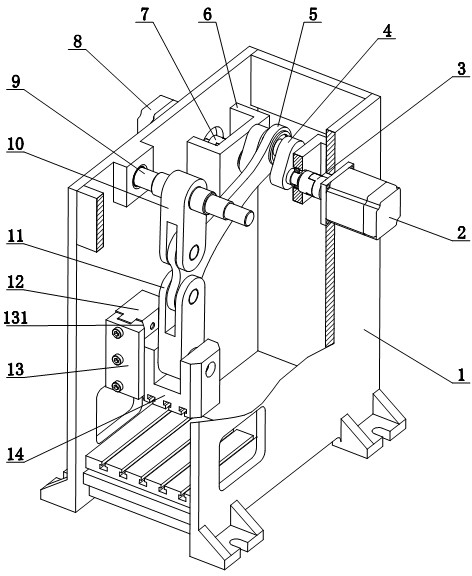

[0021] Such as figure 1 As shown, a servo mechanical press includes a frame 1, and the frame 1 is in a frame shape; the present invention is characterized in that it also includes a synchronous first servo motor 2, a second servo motor 8, a first reduction mechanism, a second Two deceleration mechanisms, a six-link working mechanism and a guide structure; wherein the first servo motor 2 and the second servo motor 8 are symmetrically installed on both sides of the frame 1, and the first deceleration mechanism and the second The reduction mechanism is symmetrically installed on both sides of the frame 1; the six-link working mechanism is installed in the frame of the frame 1; the input end of the first reduction mechanism is coaxial with the output shaft of the first servo motor 2, The output end of the first reduction mechanism is fixedly connected with the crankshaft right input end of the six-link working mechanism, the input end of the second reduction mechanism is coaxial w...

Embodiment 2

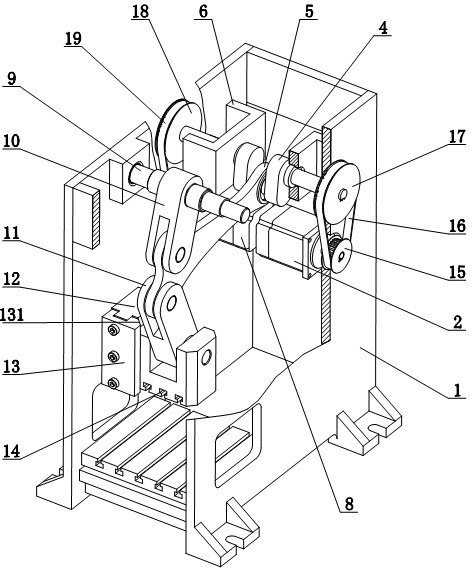

[0027] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that: the structure of the first deceleration mechanism is the same as that of the second deceleration mechanism, and the first deceleration mechanism includes a first small synchronous pulley 15, a first synchronous belt 16 And the first large synchronous pulley 17, the first small synchronous pulley 15 is installed on the output shaft of the first servo motor 2, the first large synchronous pulley 17 is coaxial with crankshaft 4, the first synchronous belt 16 Set on the first small synchronous pulley 15 and the first large synchronous pulley 17, the first small synchronous pulley 15 drives the first large synchronous pulley 17 through the first synchronous belt 16; the second reduction mechanism includes the second small synchronous pulley (not shown), the second synchronous belt 19 and the second large synchronous pulley 18, the second small synchronous pulley is i...

Embodiment 3

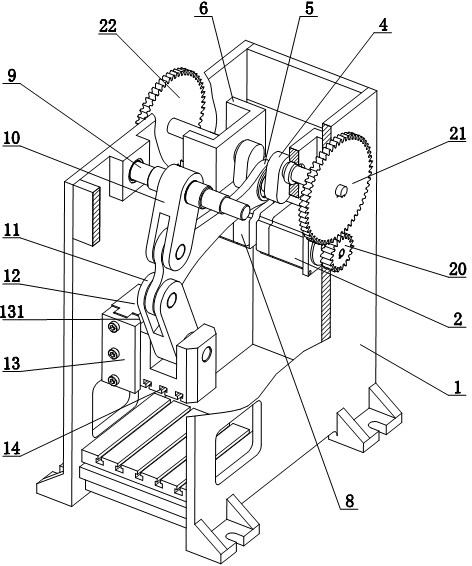

[0029] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that: the structure of the first reduction mechanism and the second reduction mechanism are the same, and the first reduction mechanism includes a first small gear 20 and a first large gear 21, so The first small gear 20 is installed on the output shaft of the first servo motor 2, the first large gear 21 is coaxial with the crankshaft 4, and the first small gear 20 meshes with the first large gear 21; the second reduction mechanism includes the first Two small gears (not shown in the figure) and the second large gear 22, the second small gear is installed on the output shaft of the second servo motor 8, the second large gear 22 is coaxial with the crankshaft 4, the second The pinion meshes with the second large gear 22 . In addition, the first servo motor 2 and the second servo motor 8 are symmetrically arranged and installed on two inner sides of the frame 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com