Automatic feeding system of fine blanking bar stock and using method thereof

An automatic feeding and strip material technology, which is applied to metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of poor accuracy, high labor intensity, and low work efficiency, and achieve high accuracy and low labor intensity , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

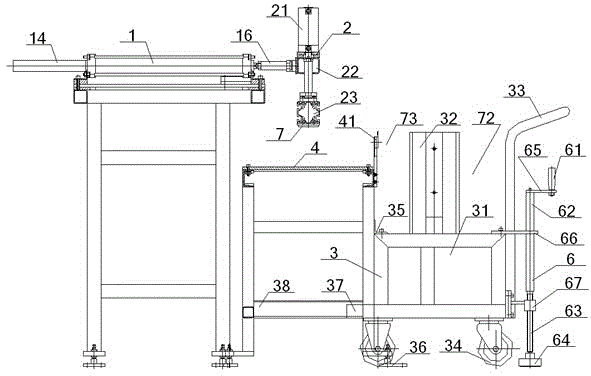

[0065] see figure 1 – image 3 , an automatic feeding system for fine blanking strips, the automatic feeding system includes a material moving device 1, a material lifting device 2 and a strip car 3, the material moving device 1 moves back and forth along a horizontal line, and the material lifting device 2 moves along a horizontal line The vertical line moves up and down, the output end of the material shifting device 1 is connected with the material lifting device 2, and a strip material 7 is placed in the strip car 3;

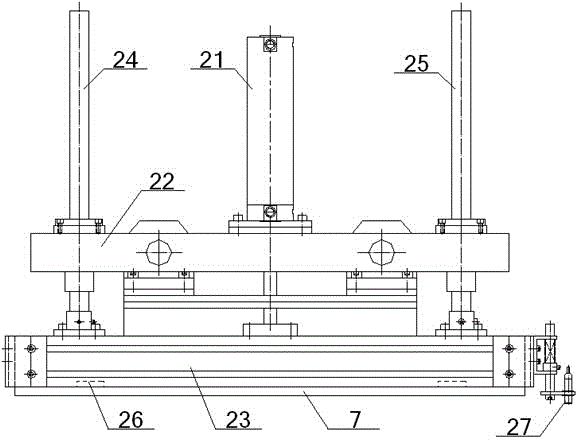

[0066] The material lifting device 2 includes a material lifting cylinder 21, a support plate 22 and a profile 23, the left side (i.e. the back side) of the support plate 22 is connected to the output end of the material moving device 1, and the center of the top of the support plate 22 is provided with Lifting material cylinder 21, the two ends of support plate 22 tops are provided with No. 1 material lifting slide bar 24, No. 2 lifting material sliding ba...

Embodiment 2

[0071] Basic content is the same as embodiment 1, the difference is:

[0072] see figure 1 , the outside of the armrest 33 is provided with a manual fixing device 6, the manual fixing device 6 includes a rotary handle 61, a rotary shaft 62, a rotary screw 63 and a fixing part 64, the bottom end of the rotary handle 61 is connected to the horizontal plate 65 and The top of the rotating shaft 62 is connected, the middle part of the rotating shaft 62 is connected with the top of the underbody frame 31 through the fixed plate 66, the bottom of the rotating shaft 62 is connected with the fixed part 64 after the rotating screw 63, and the rotating screw 63 The part near the bottom of the rotating shaft 62 is covered with a rotating bearing 67 that rotates with the rotating screw 63. The periphery of the rotating bearing 67 is connected with the bottom of the armrest 33; Braking device 36 is arranged, and one end away from armrest 33 on the bottom of the undercarriage frame 31 is co...

Embodiment 3

[0074] Basic content is the same as embodiment 1, the difference is:

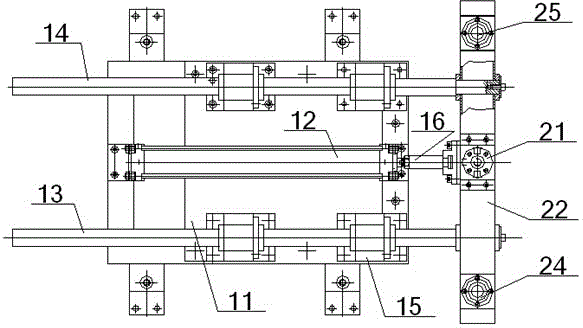

[0075] see figure 1 and figure 2 , the material shifting device 1 comprises a material shifting platform 11 and two parallel No. The front ends of the rod 13 and the No. 2 material-moving slide bar 14 respectively pass through the bearing housing 15 and are connected to the back of the support plate 22, and the middle part of the back of the support plate 22 is connected to the output end of the material-moving cylinder 12 through the connecting shaft 16, and The material transfer cylinder 12 is located between the No. 1 material transfer slide bar 13 and the No. 2 material transfer slide bar 14 .

[0076] When in use, the output end of the material transfer cylinder 12 drives the support plate 22 to do horizontal reciprocating motion through the connecting shaft 16. At the same time, the No. The support plate 22 is driven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com