Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142results about How to "Minimized contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

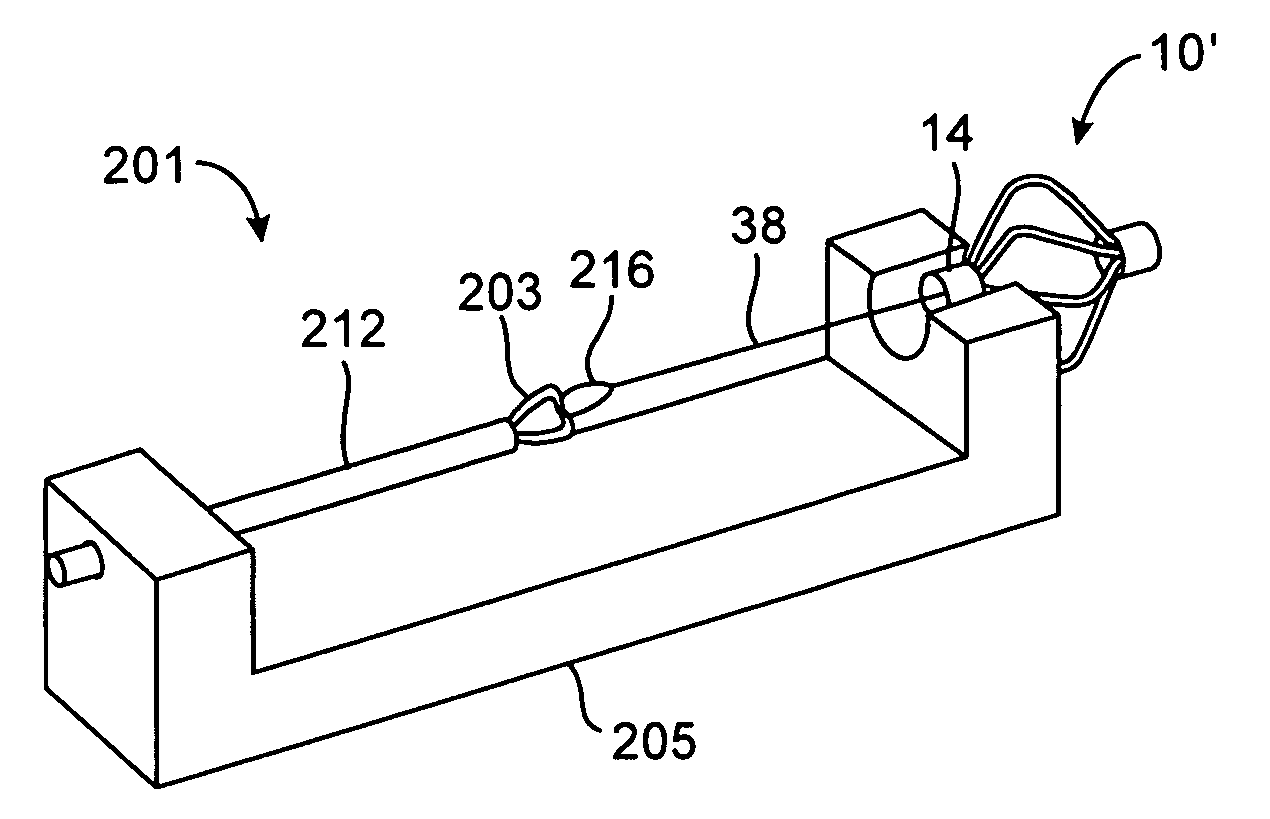

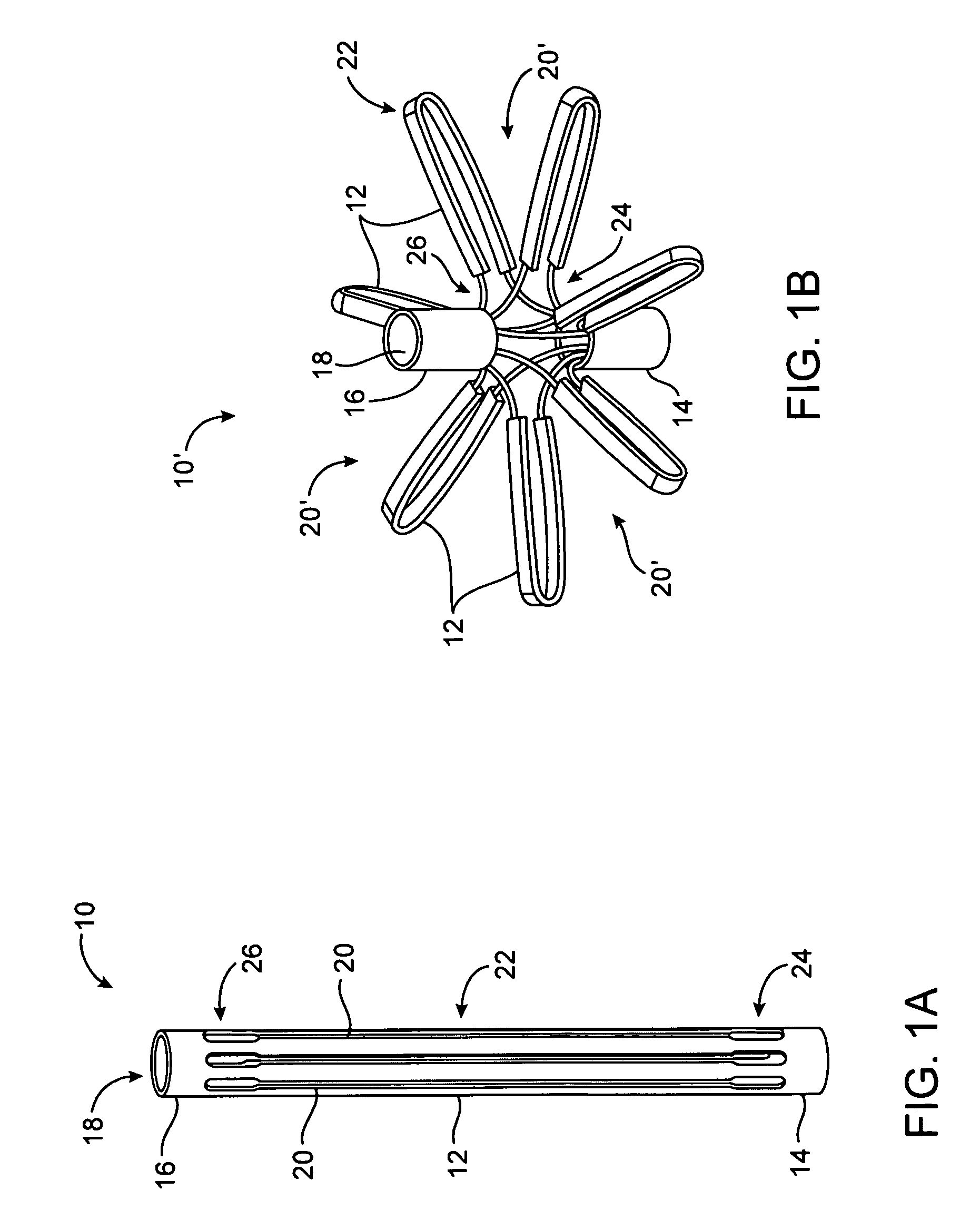

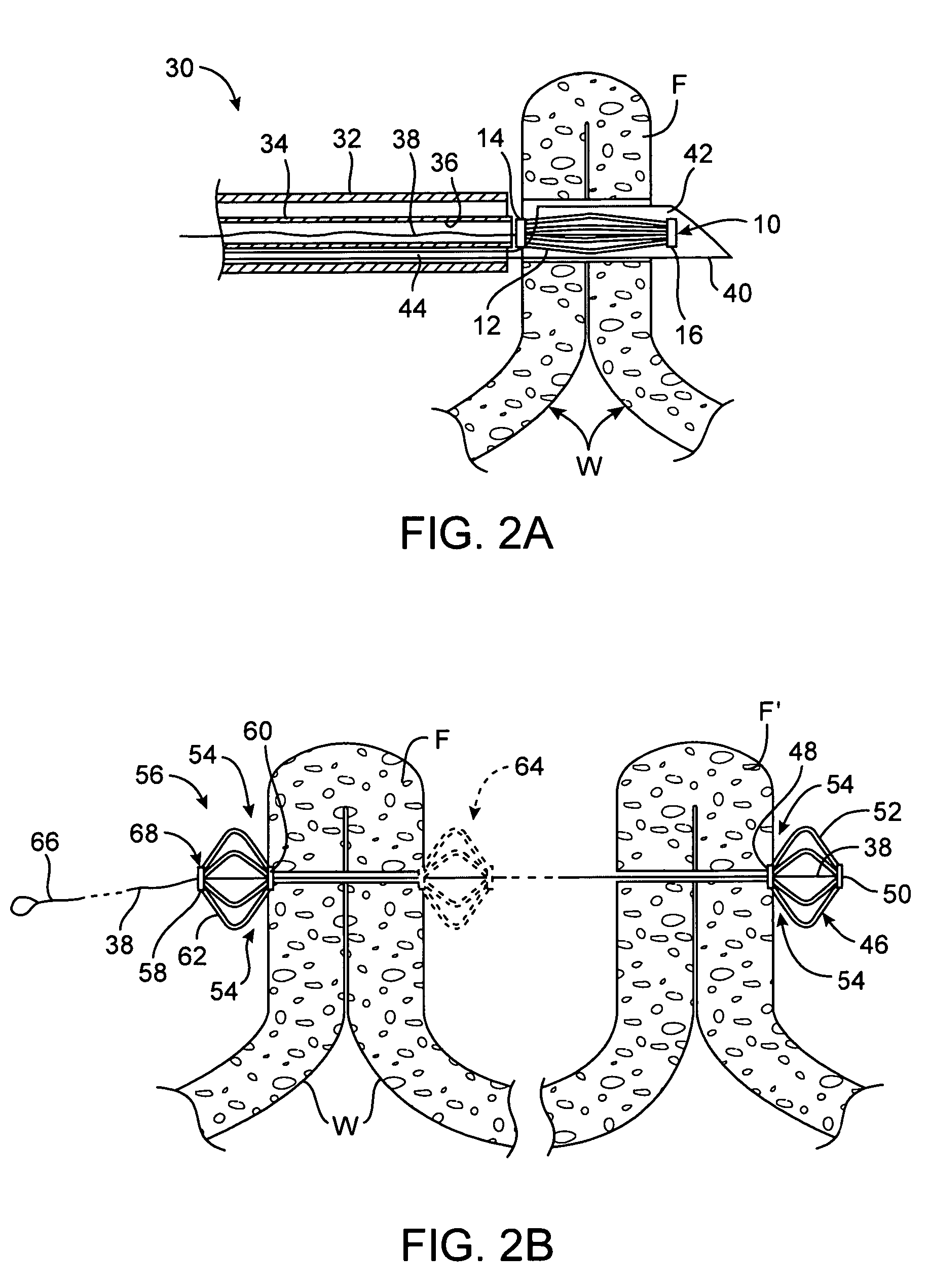

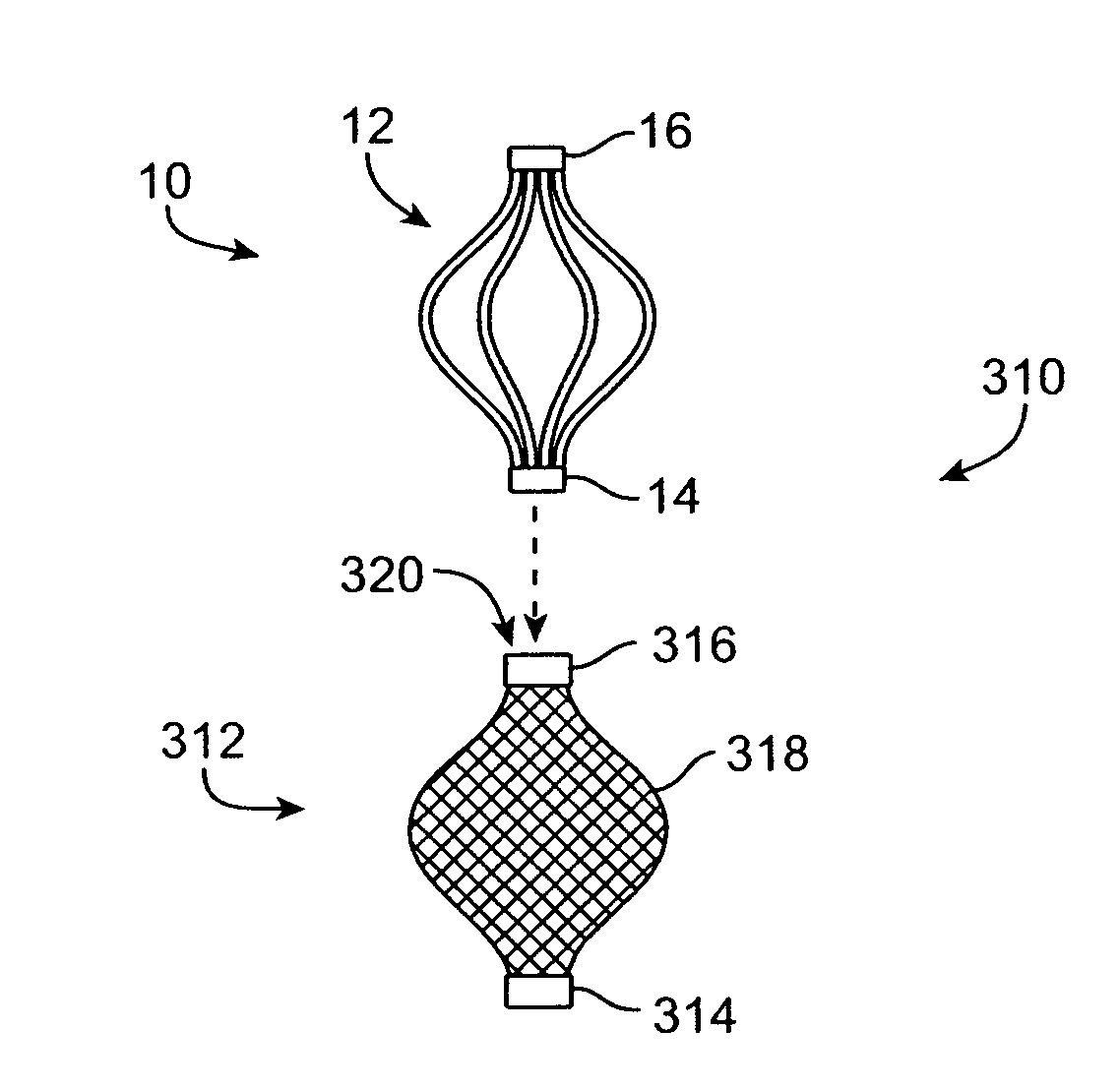

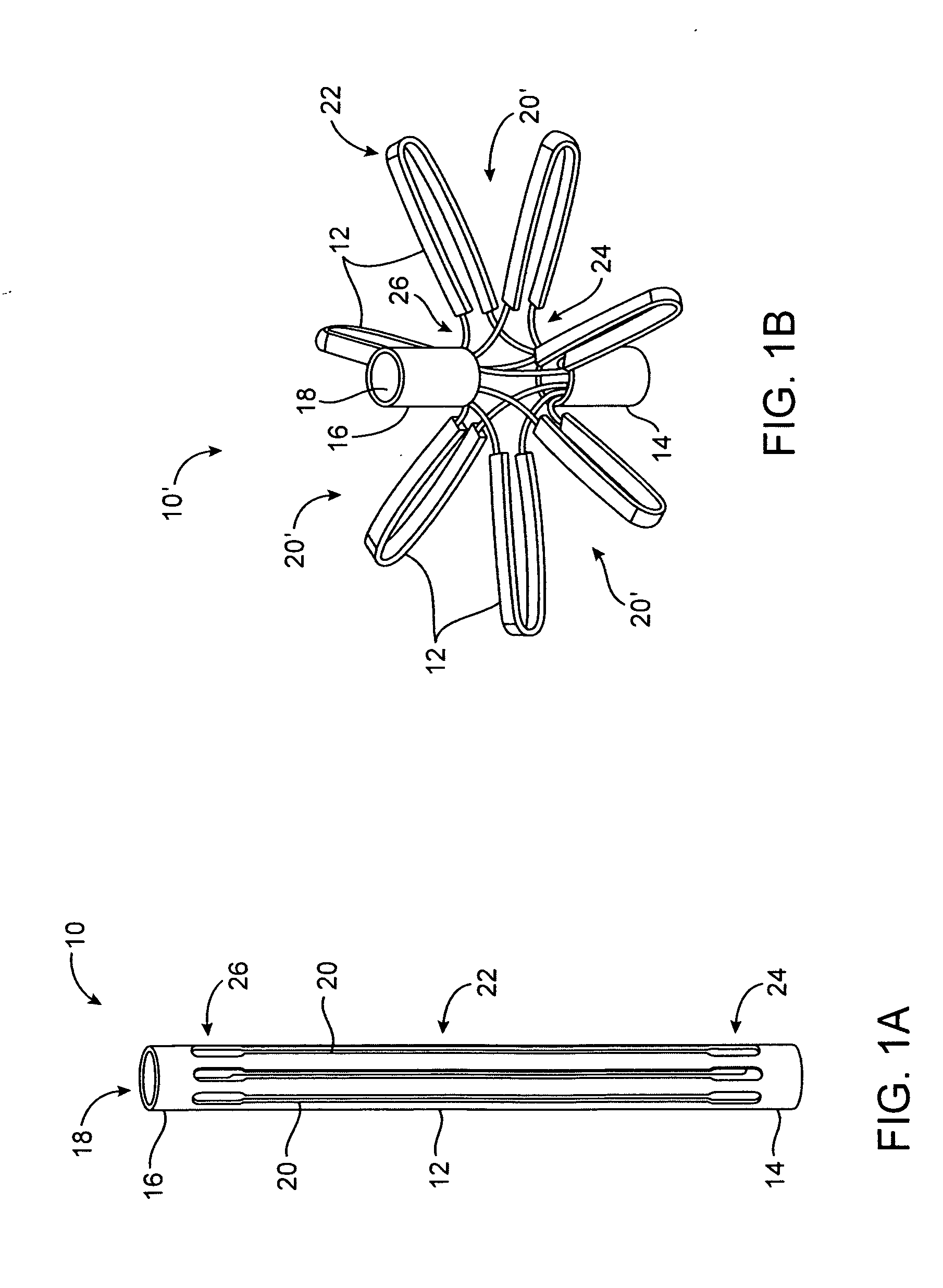

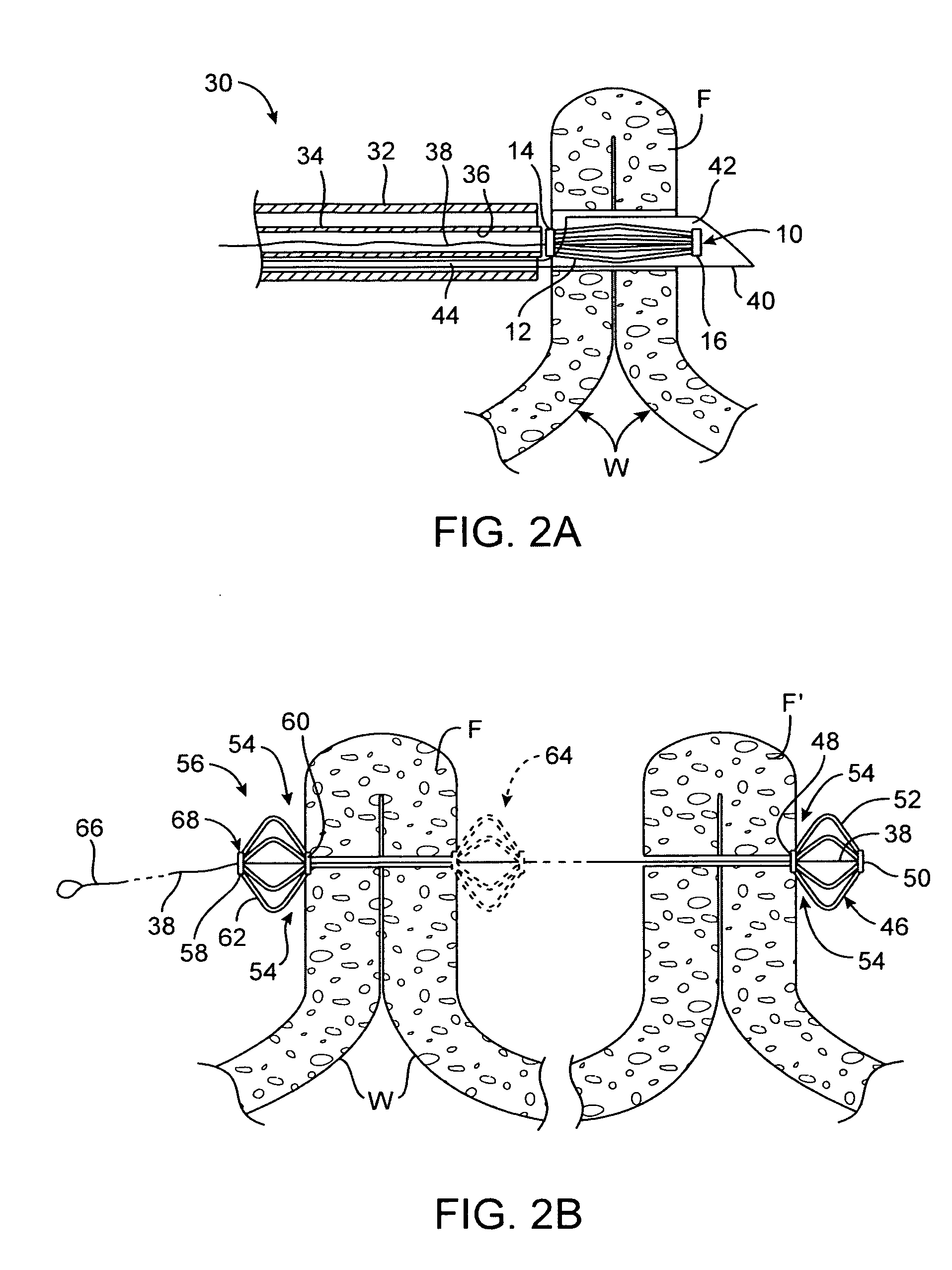

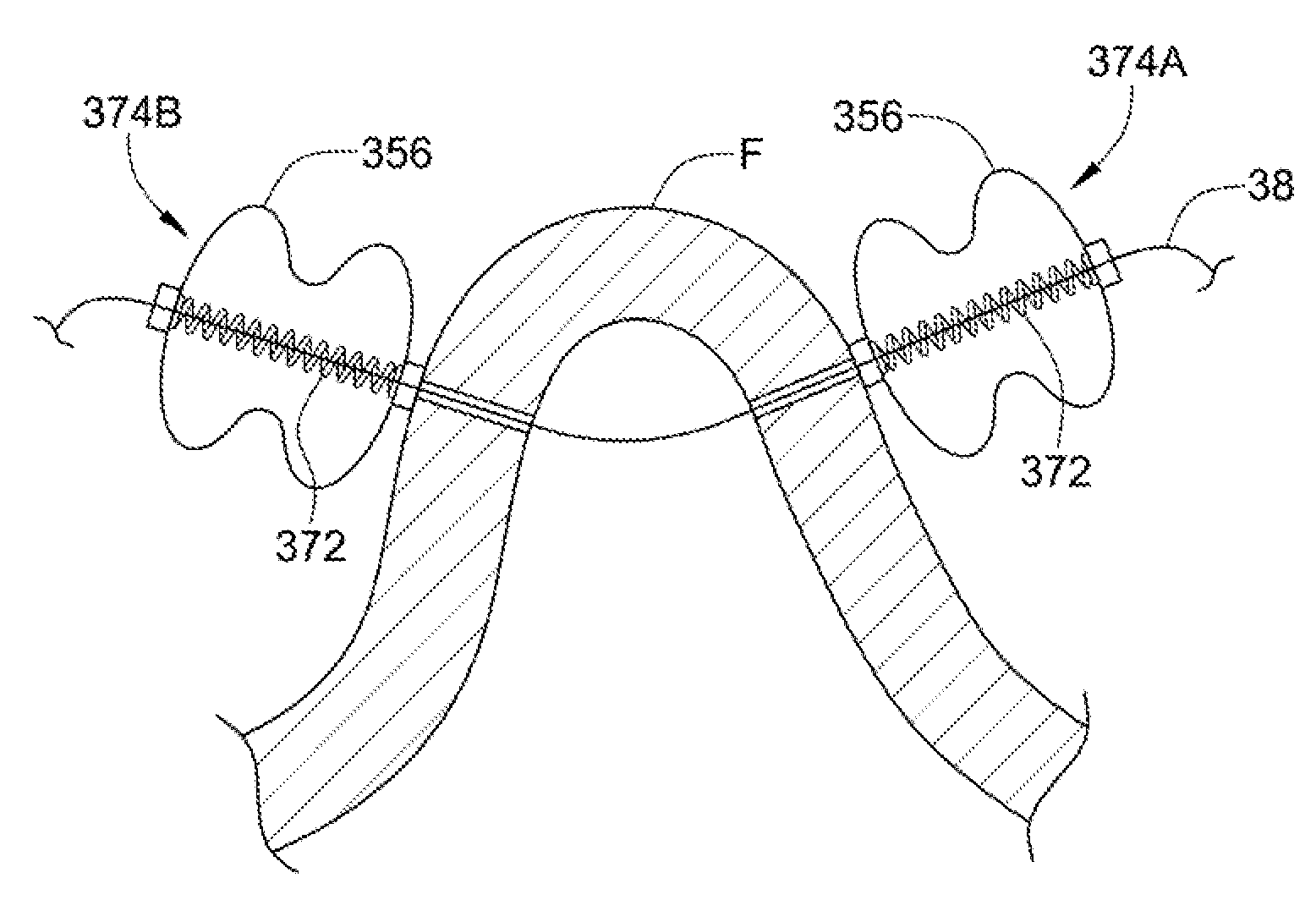

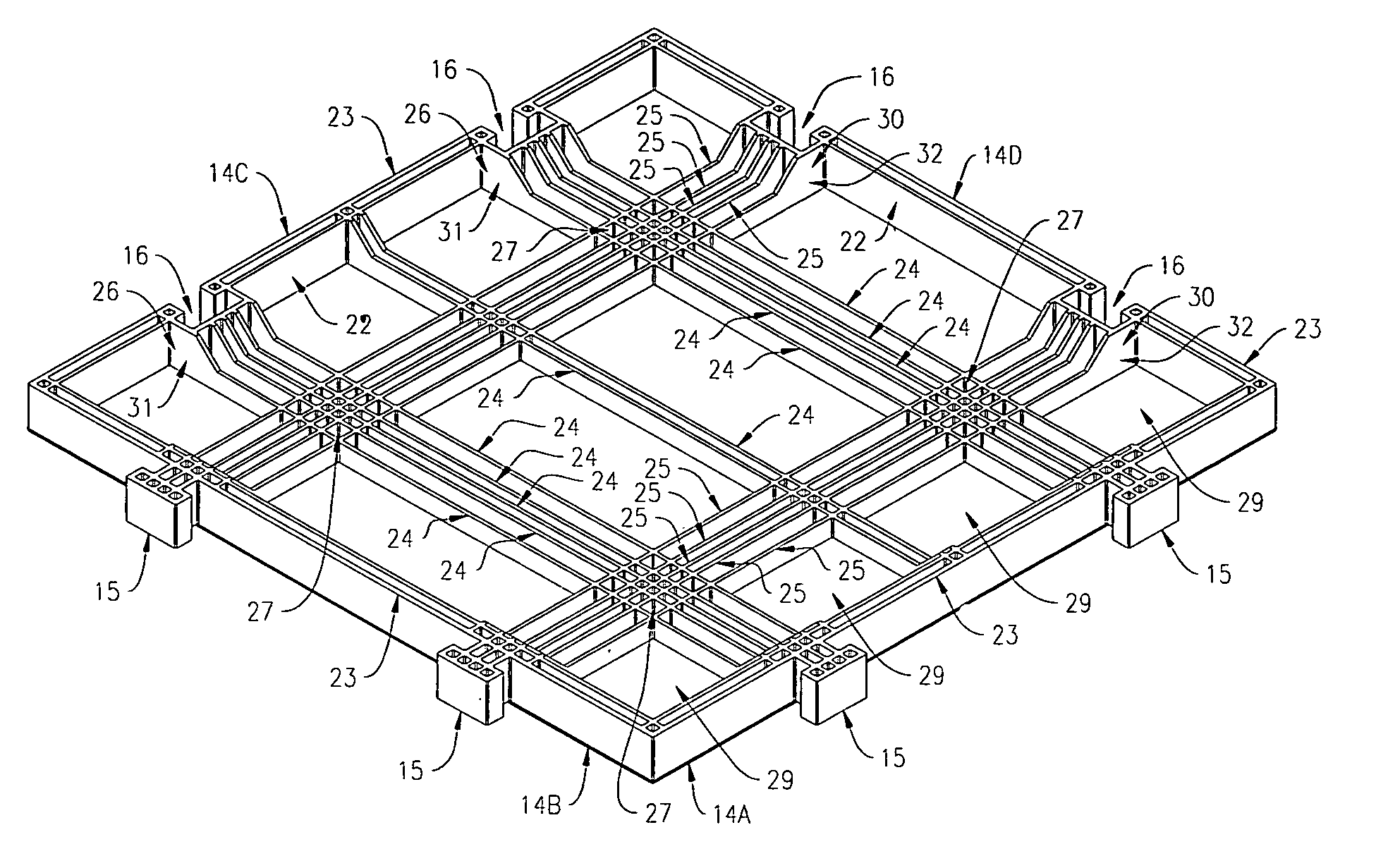

System for optimizing anchoring force

ActiveUS7695493B2Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

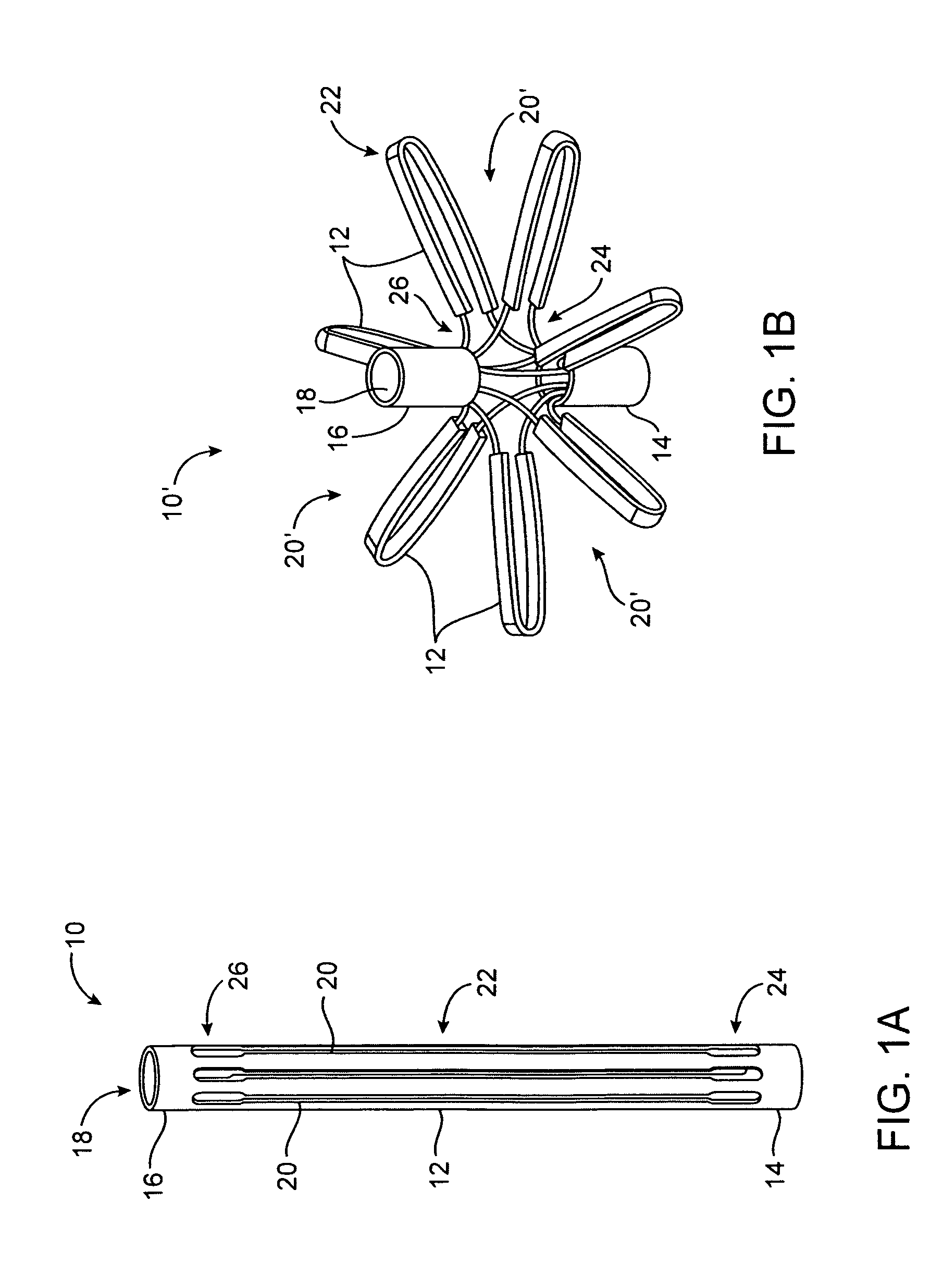

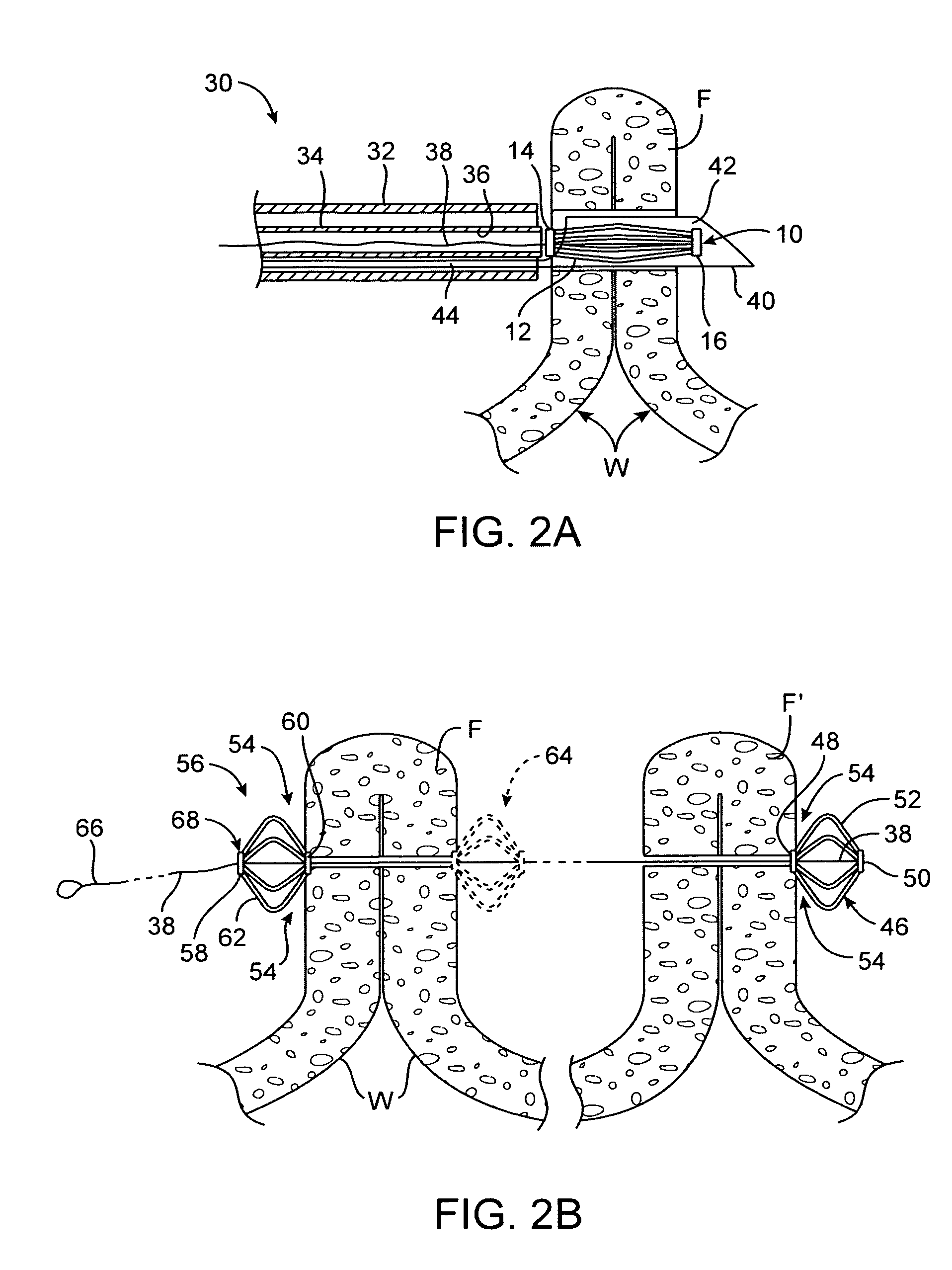

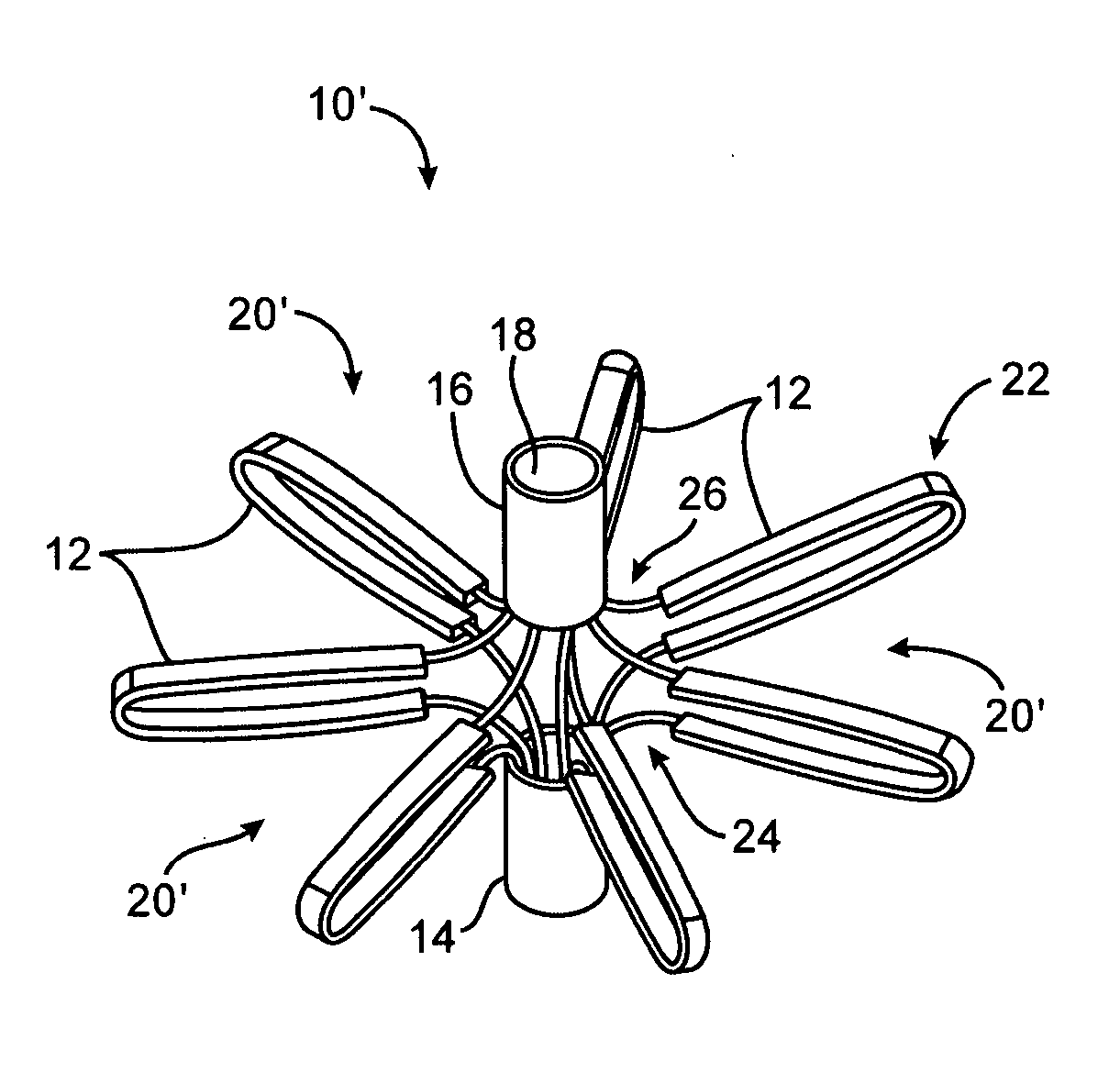

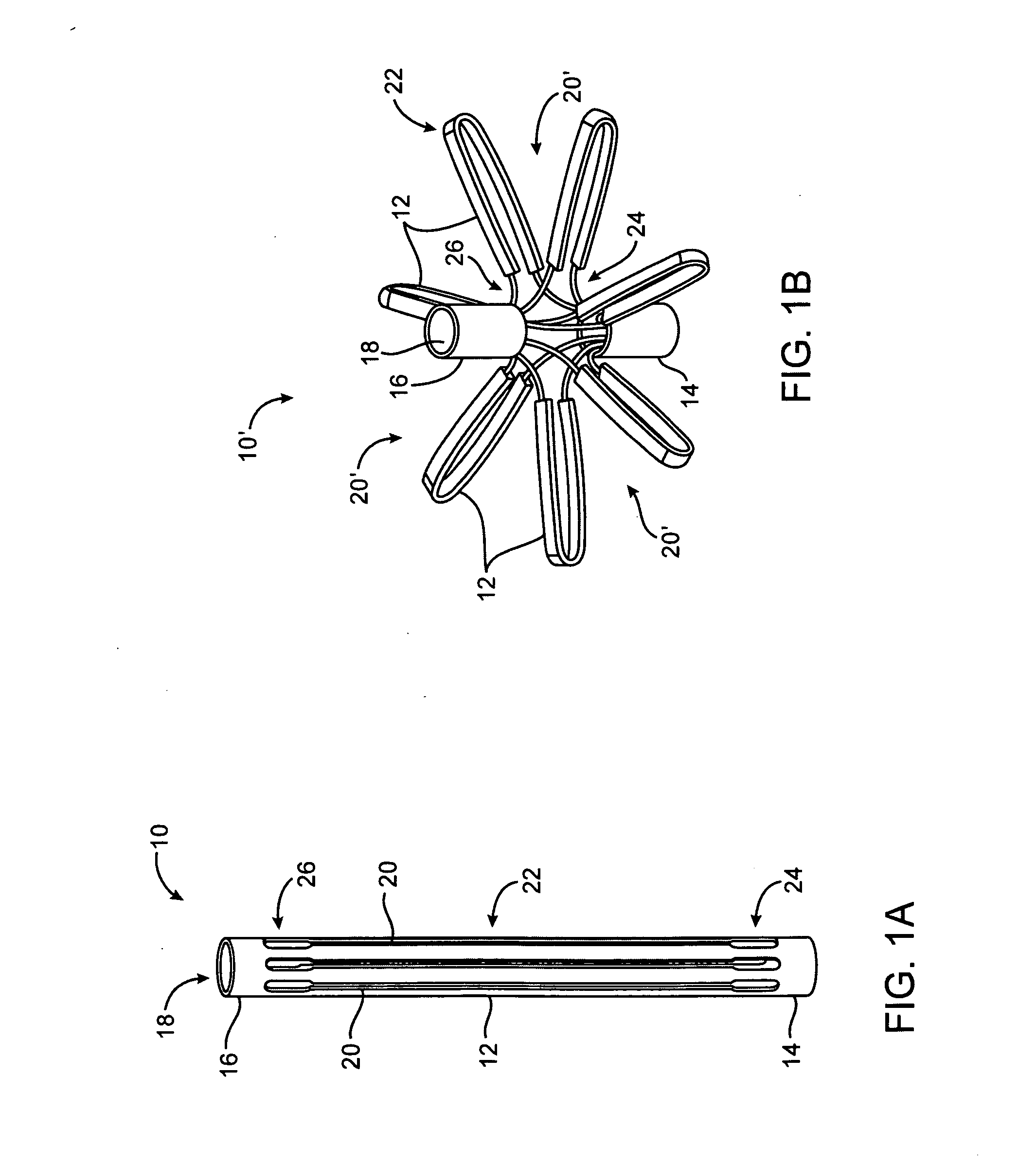

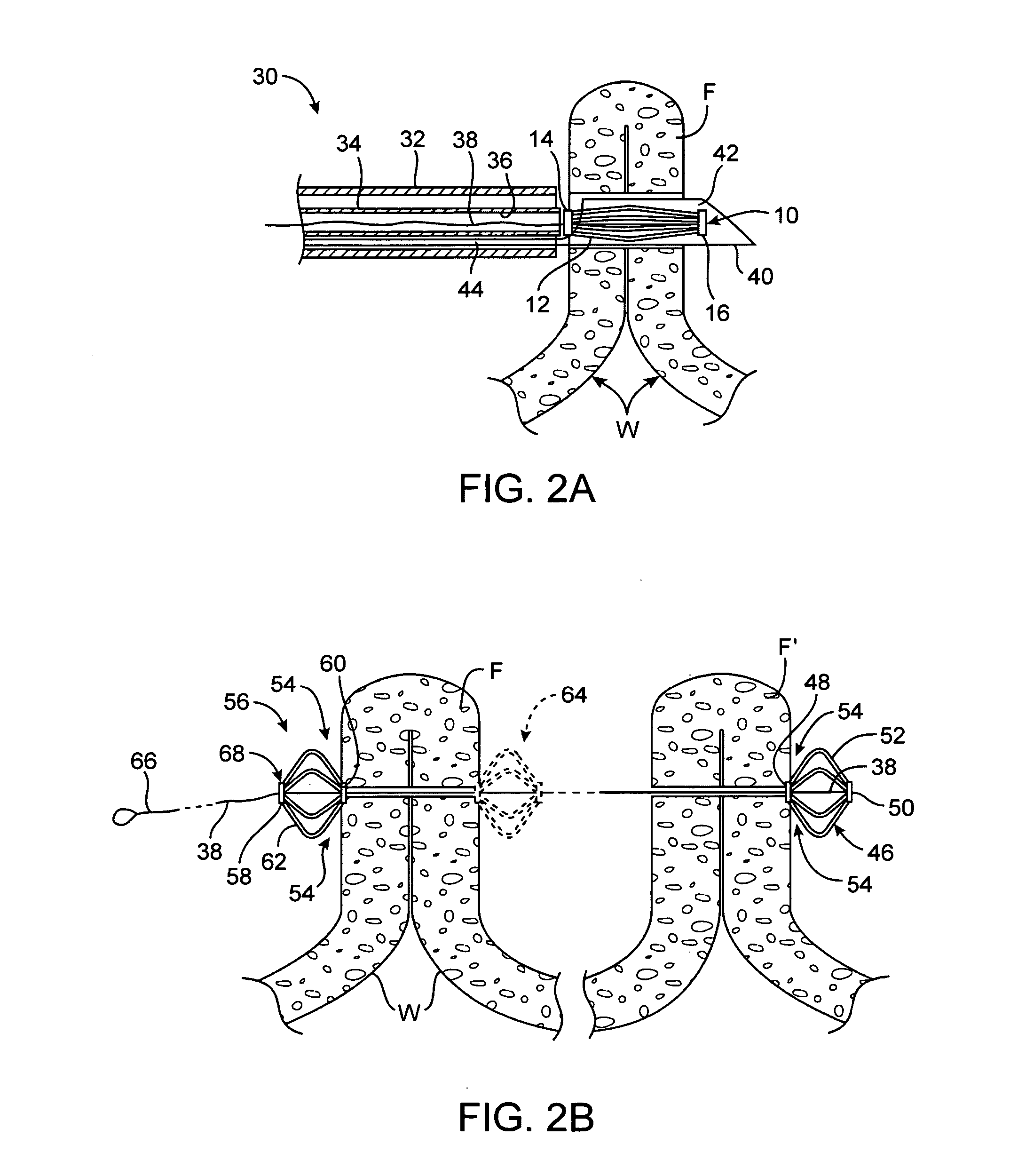

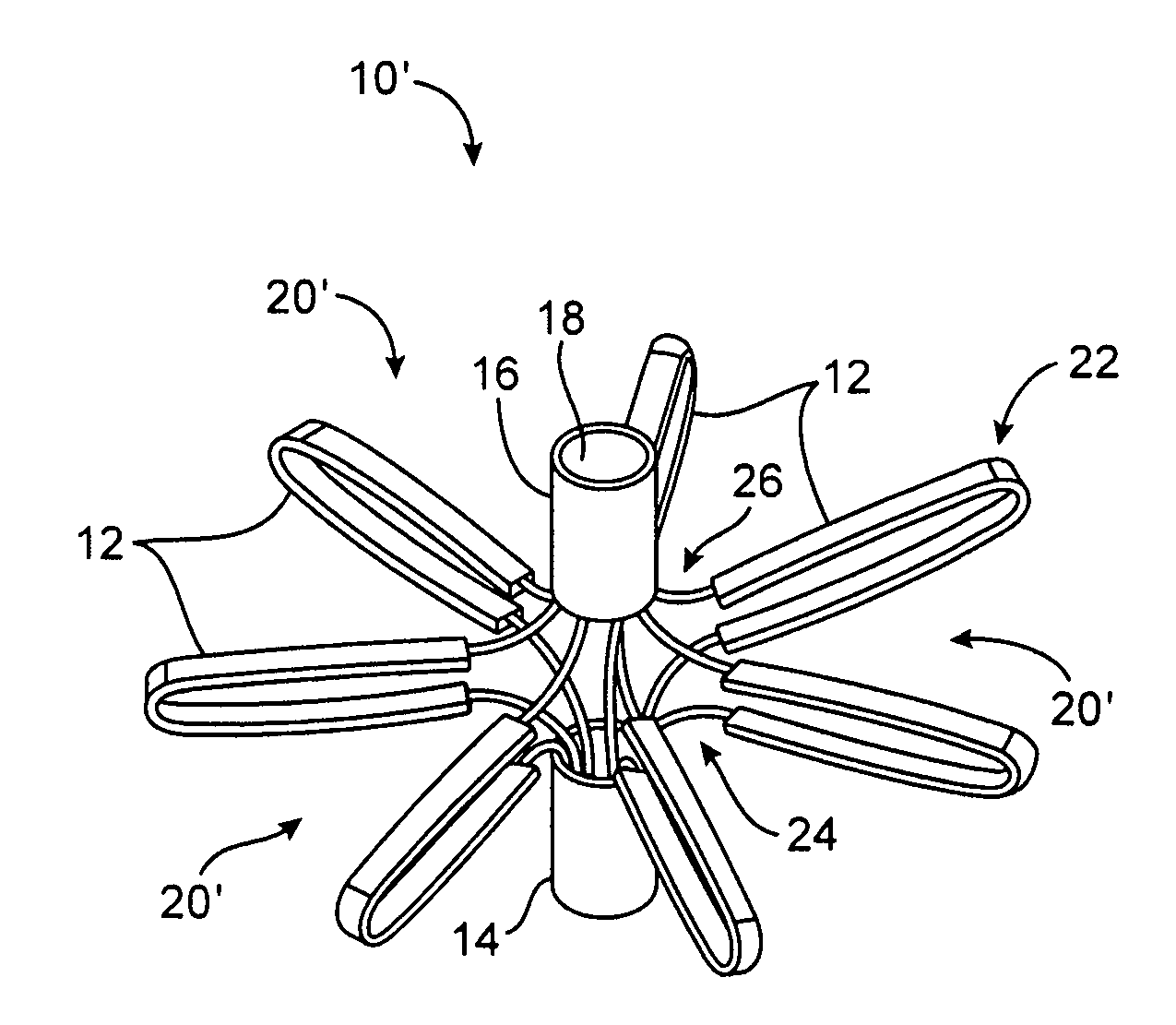

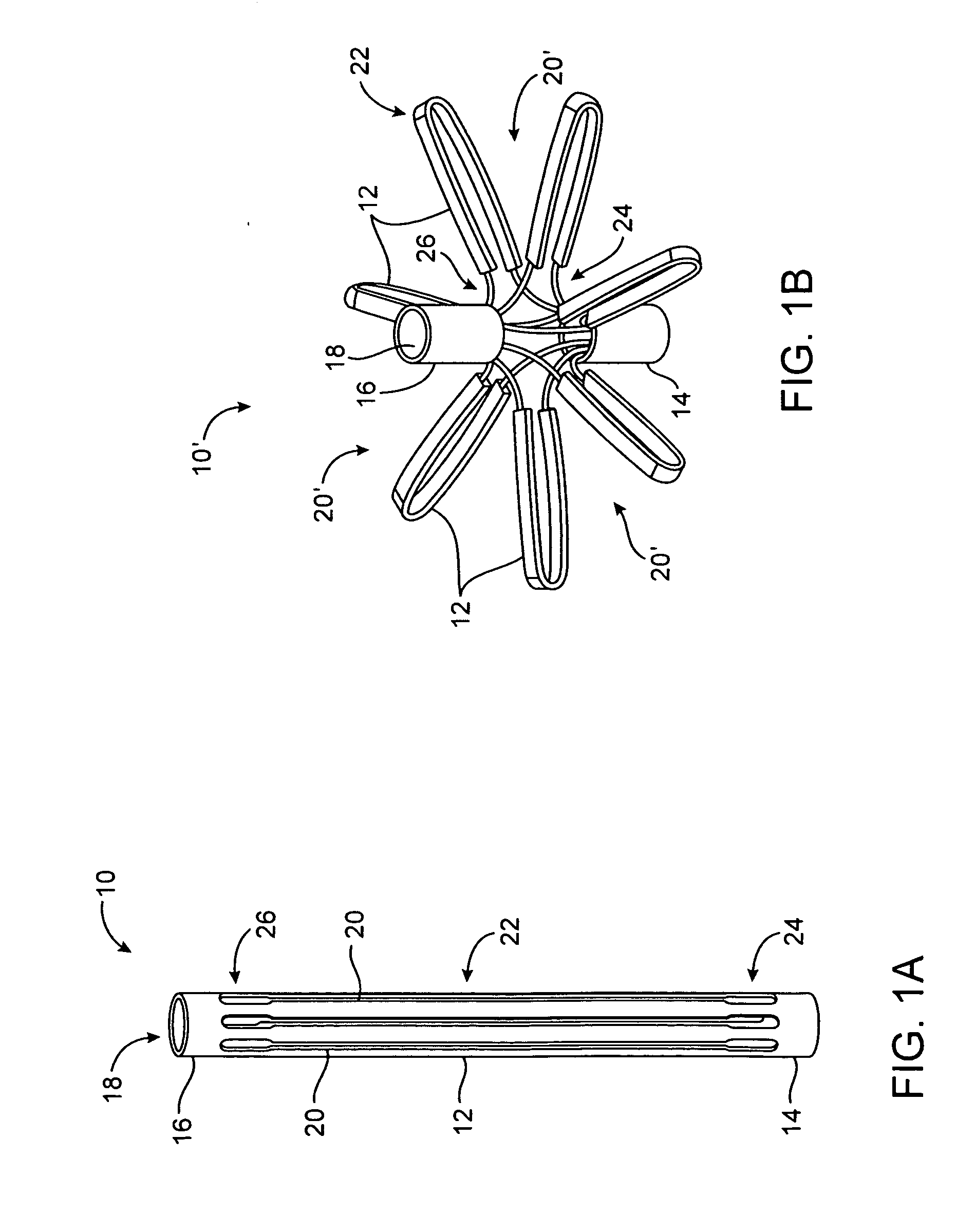

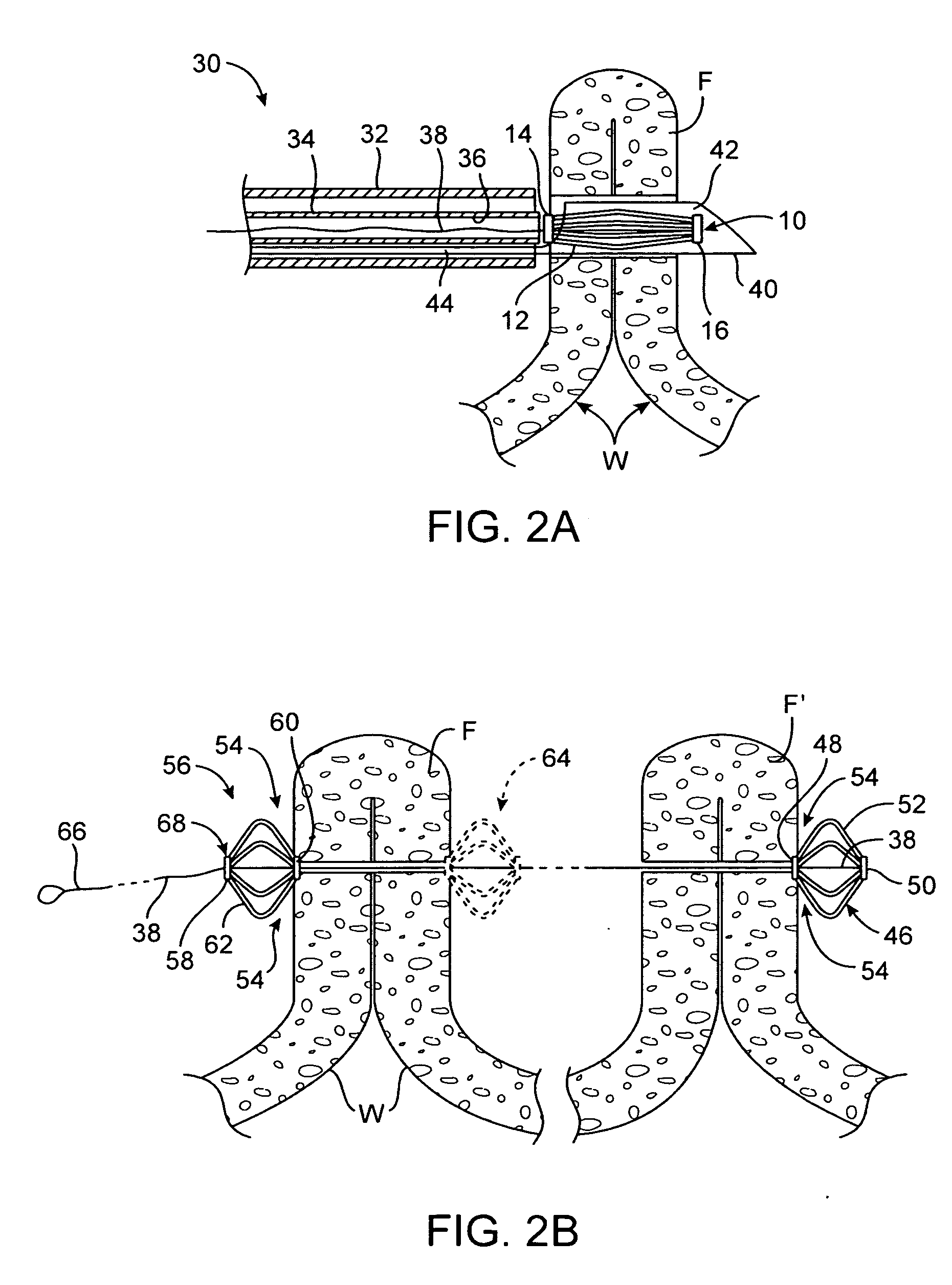

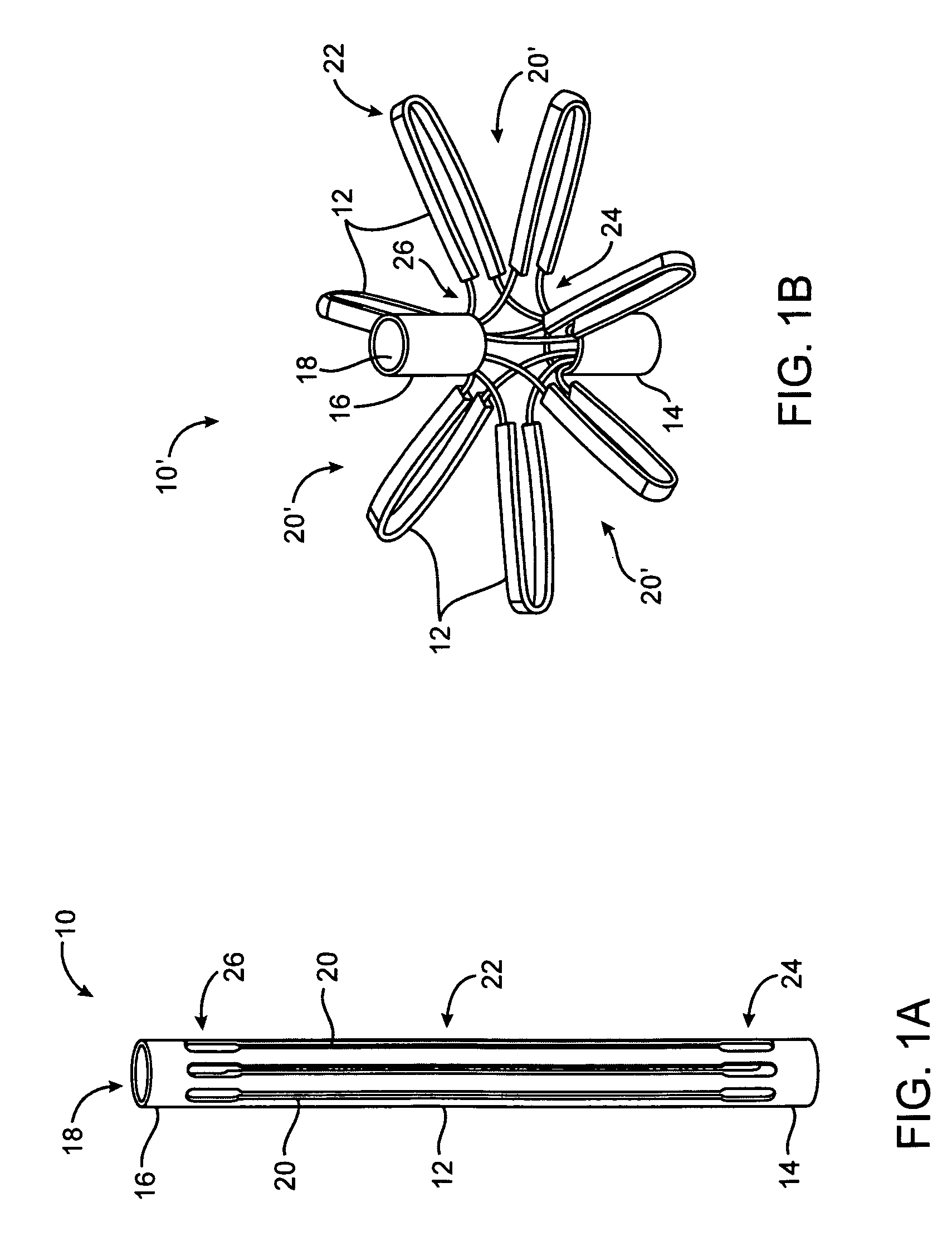

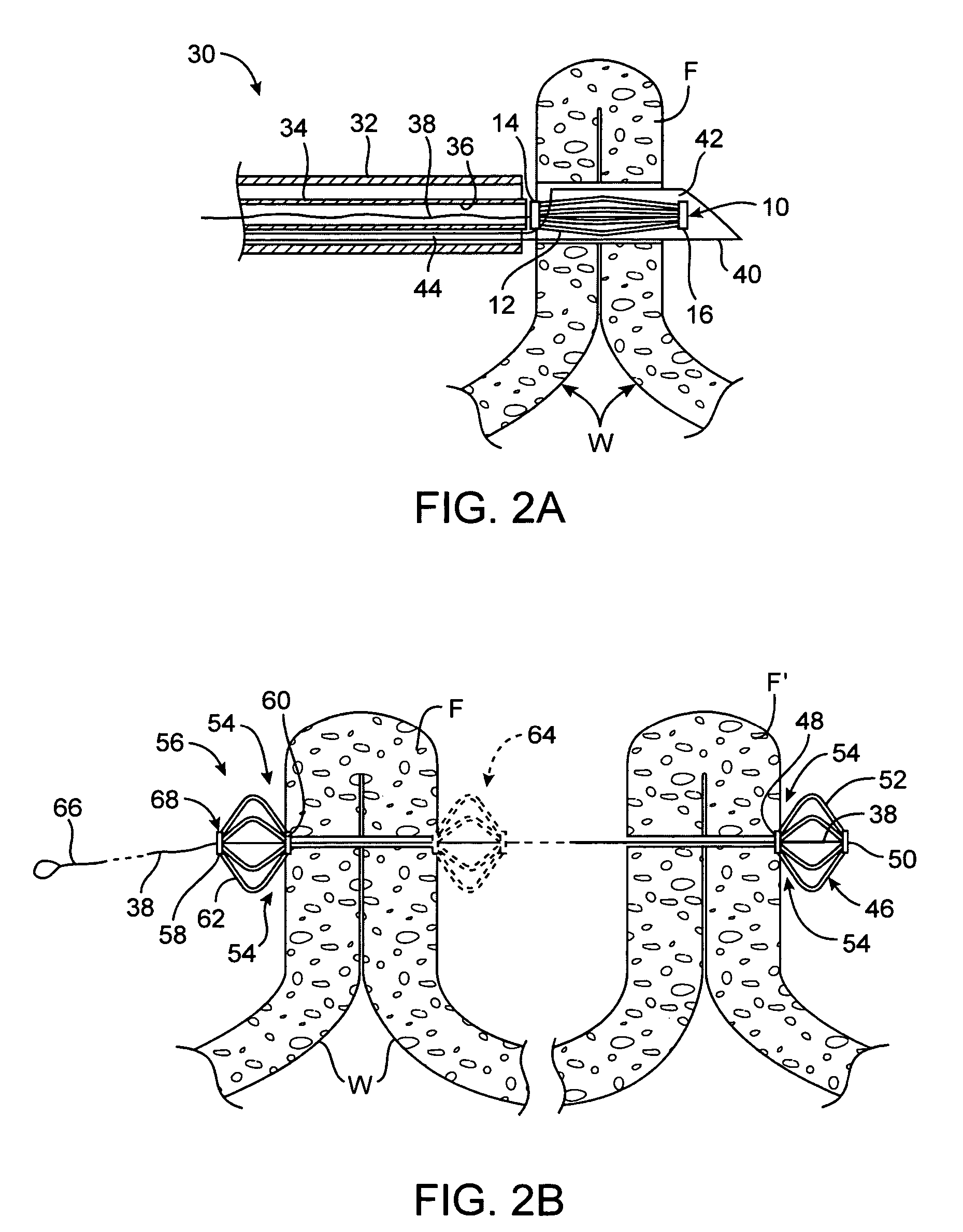

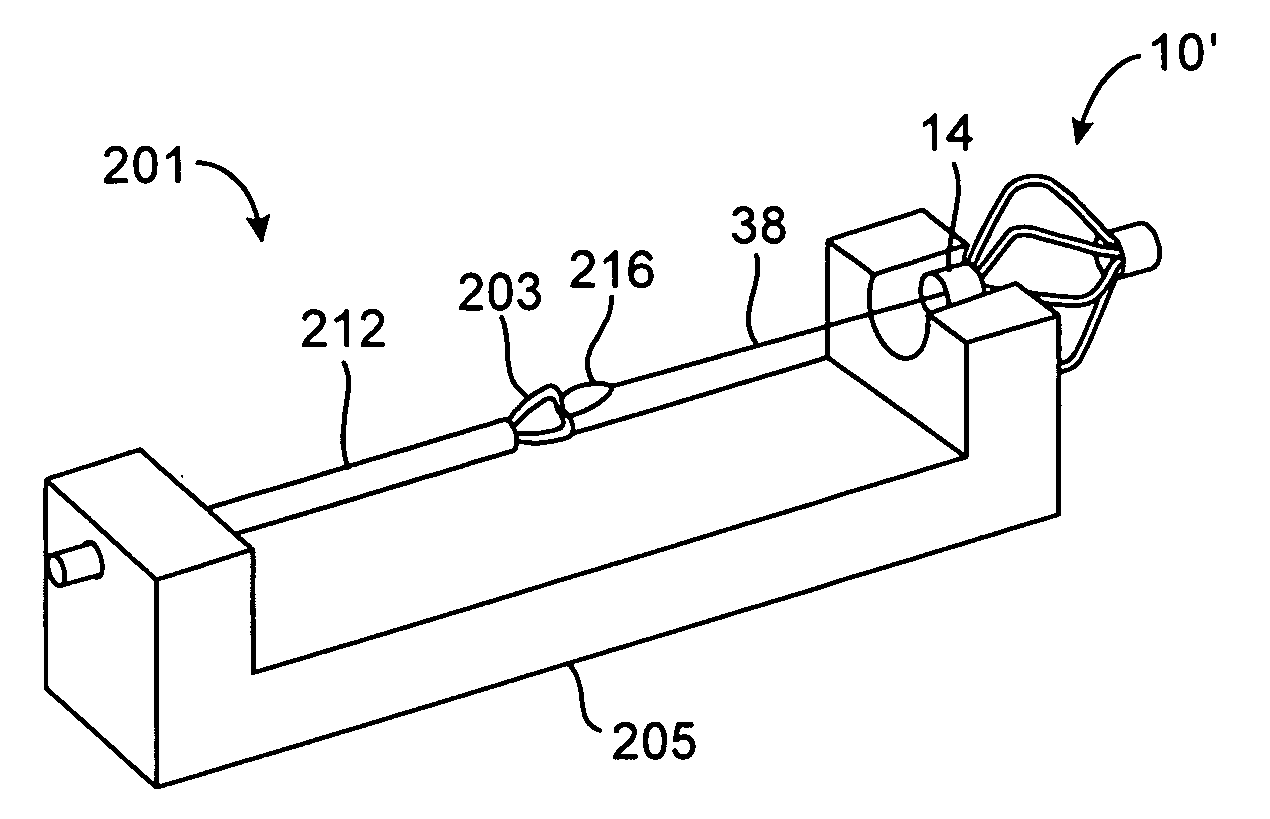

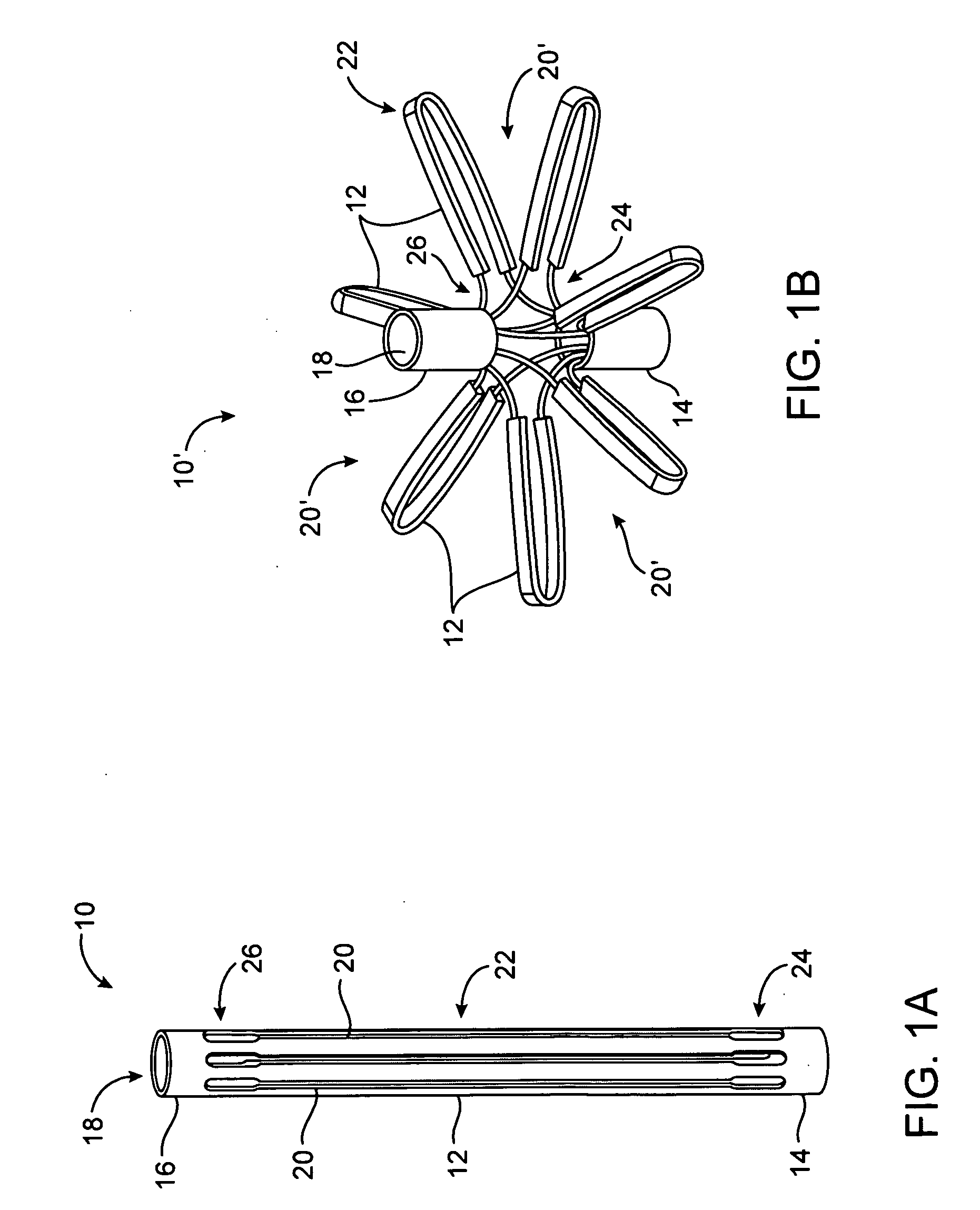

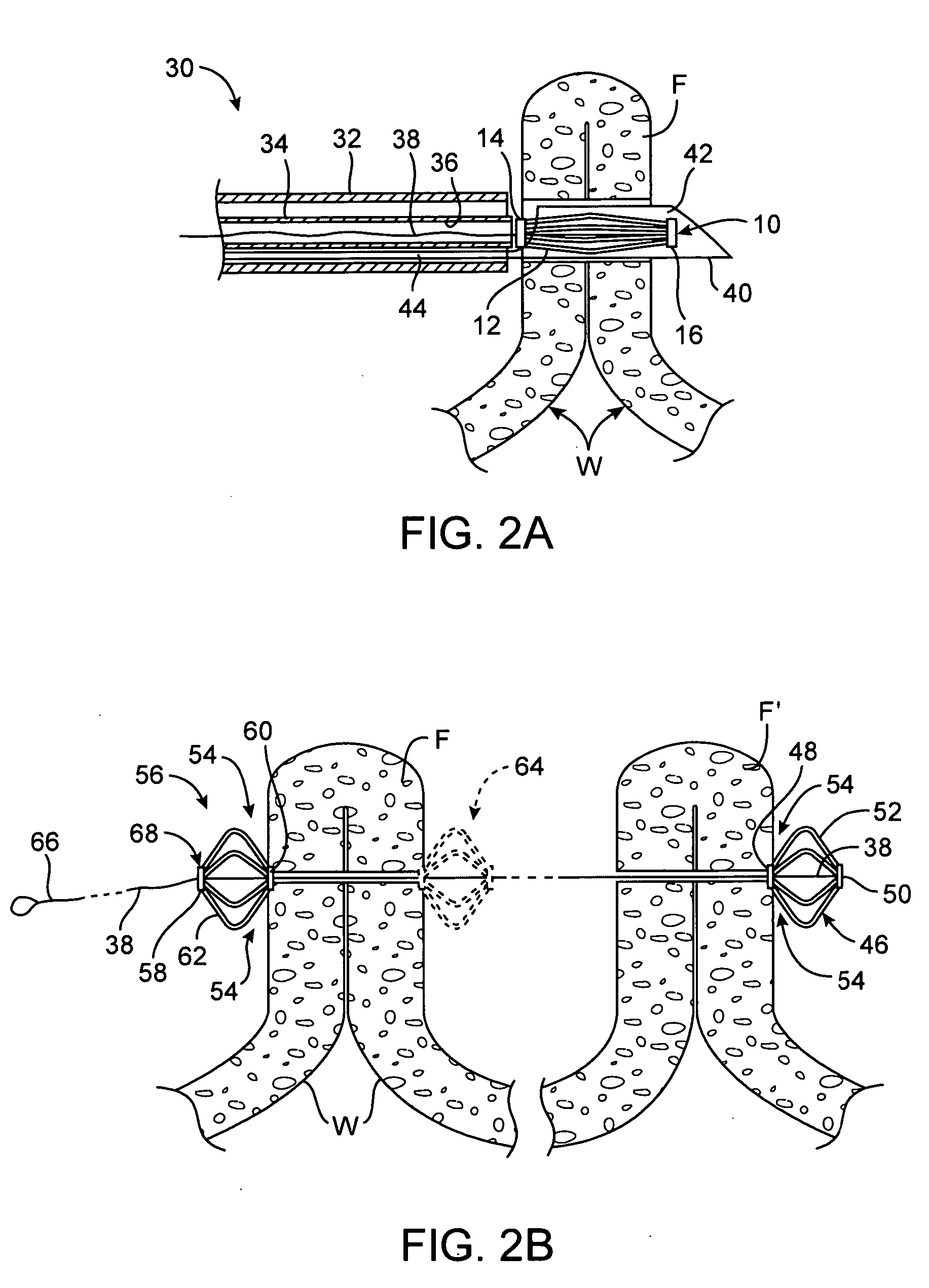

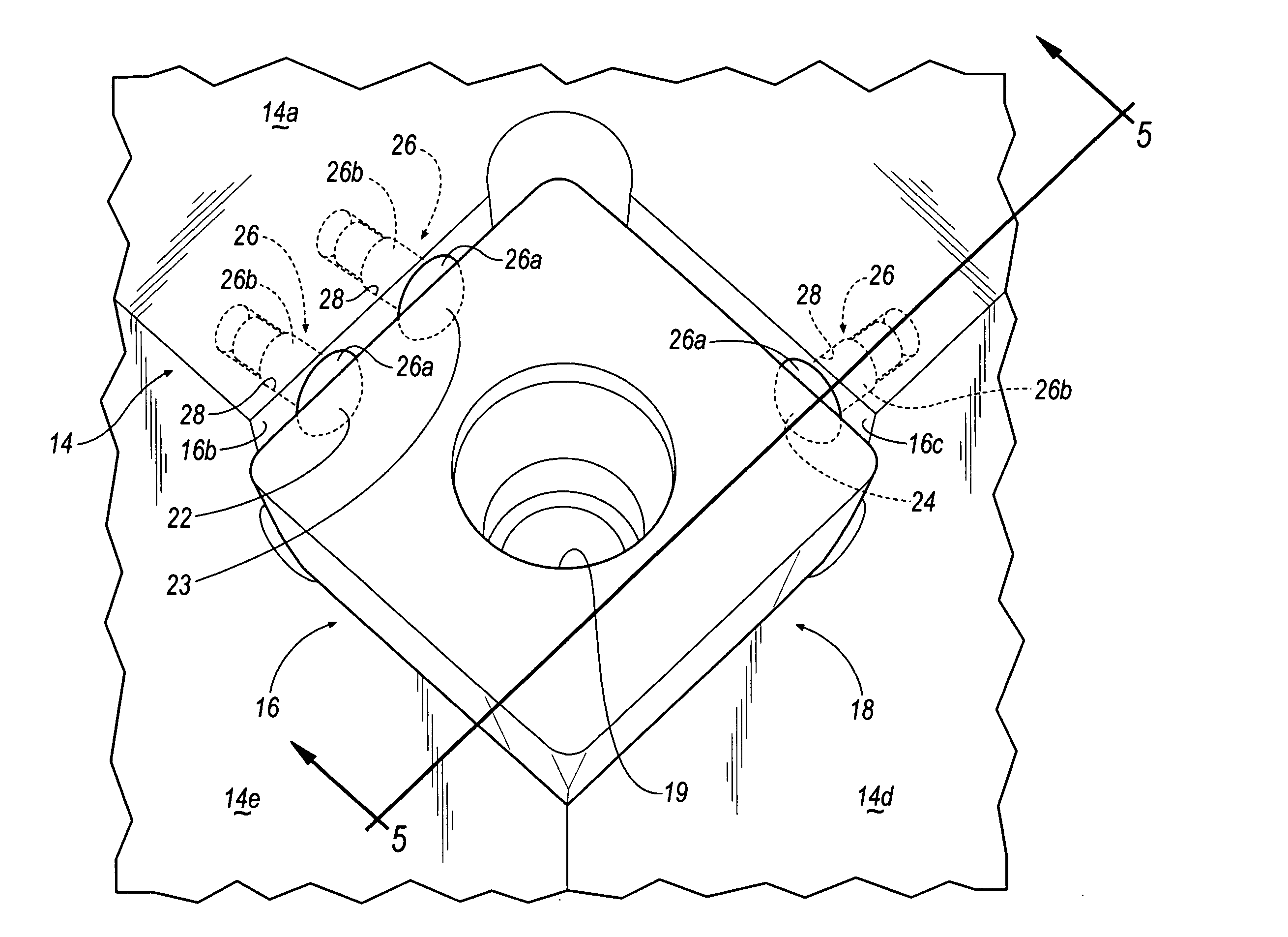

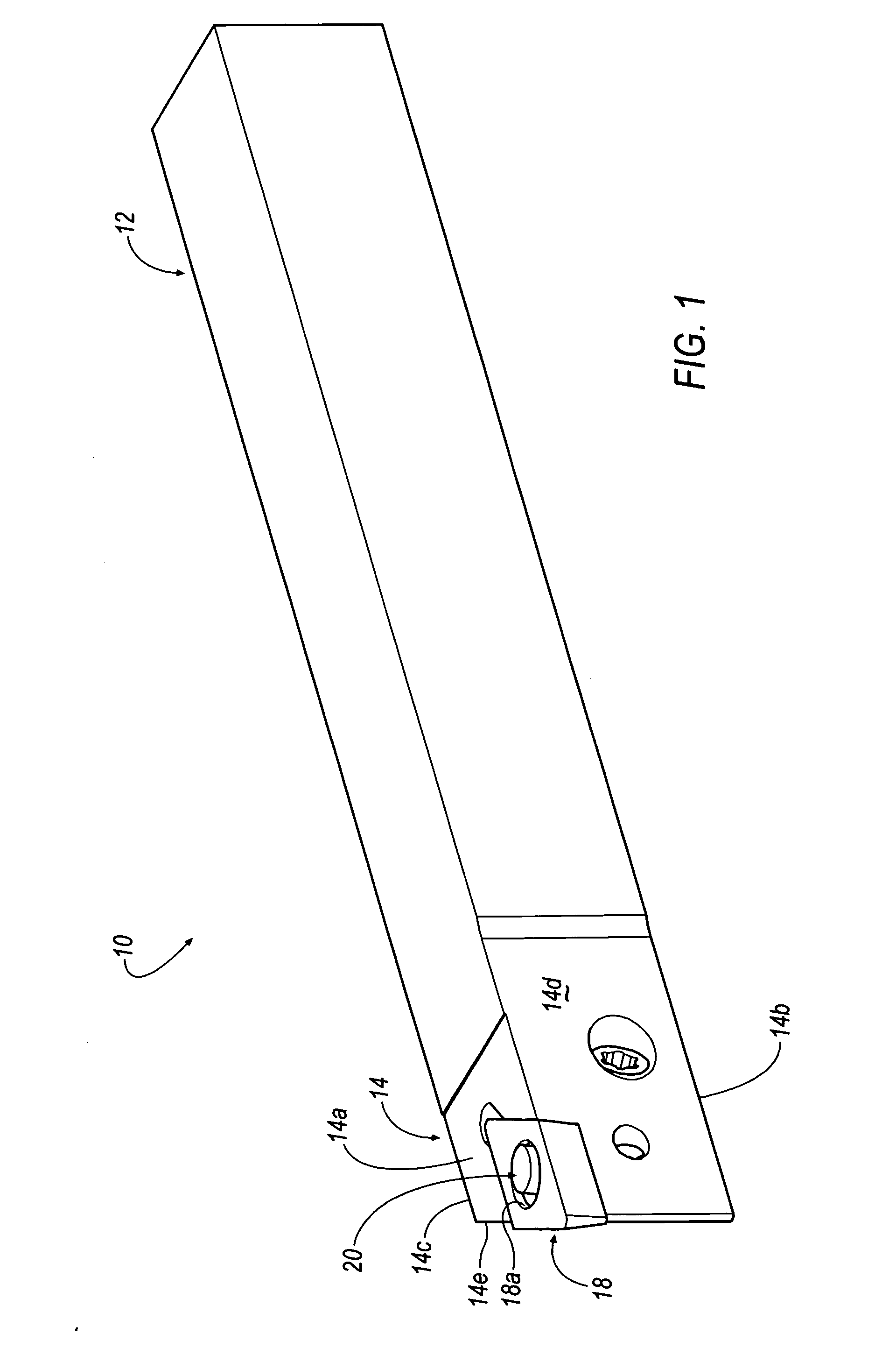

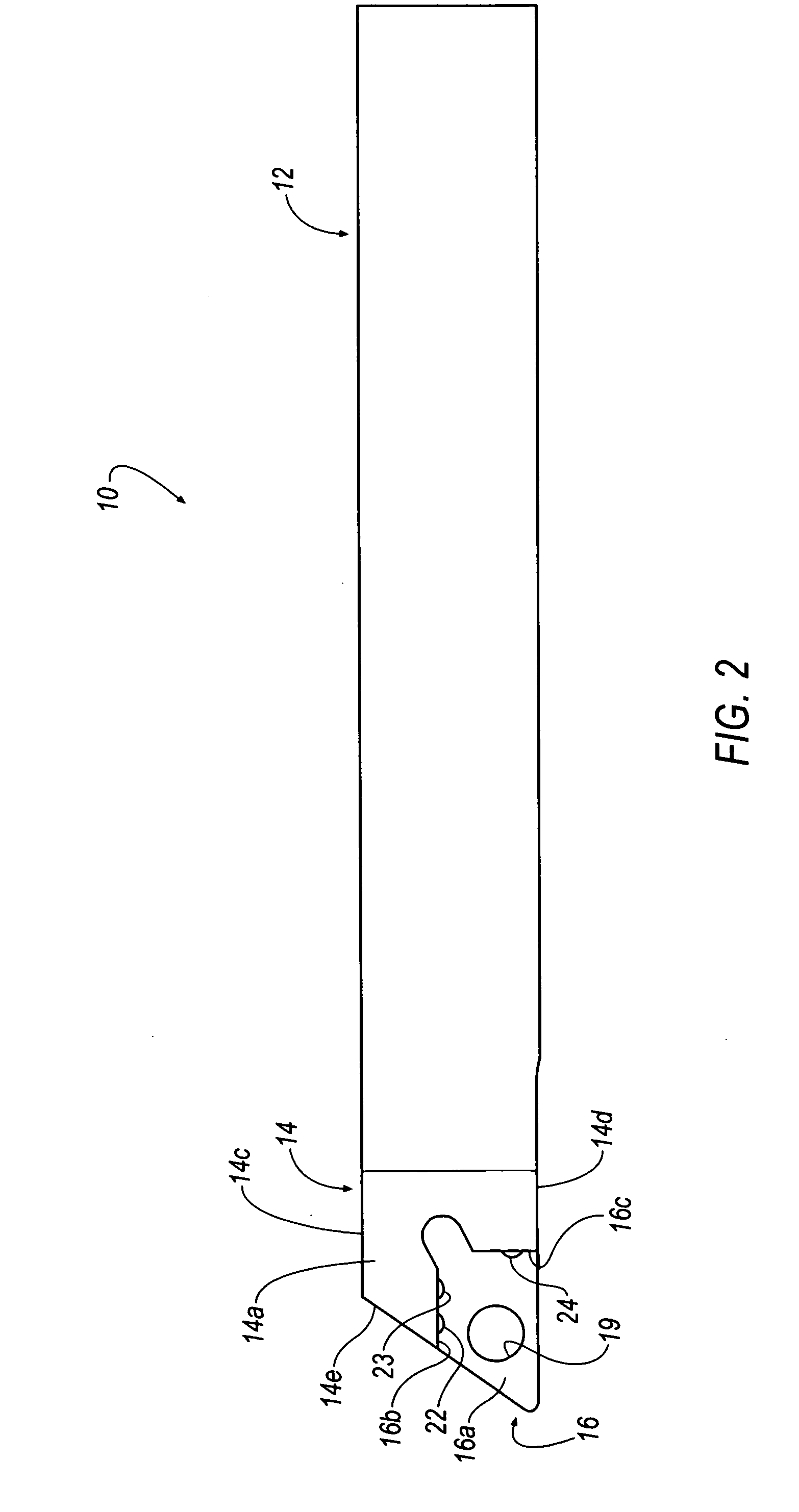

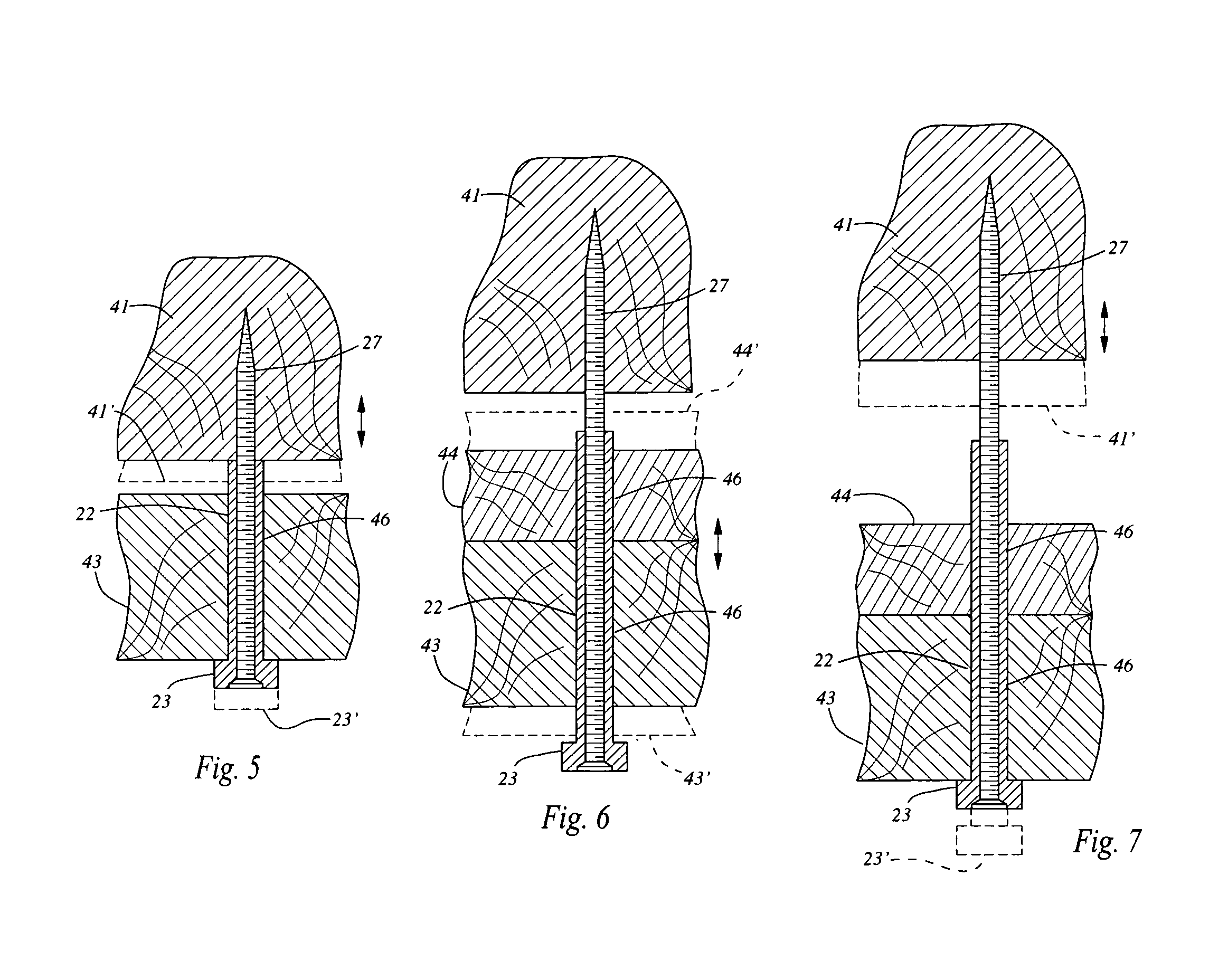

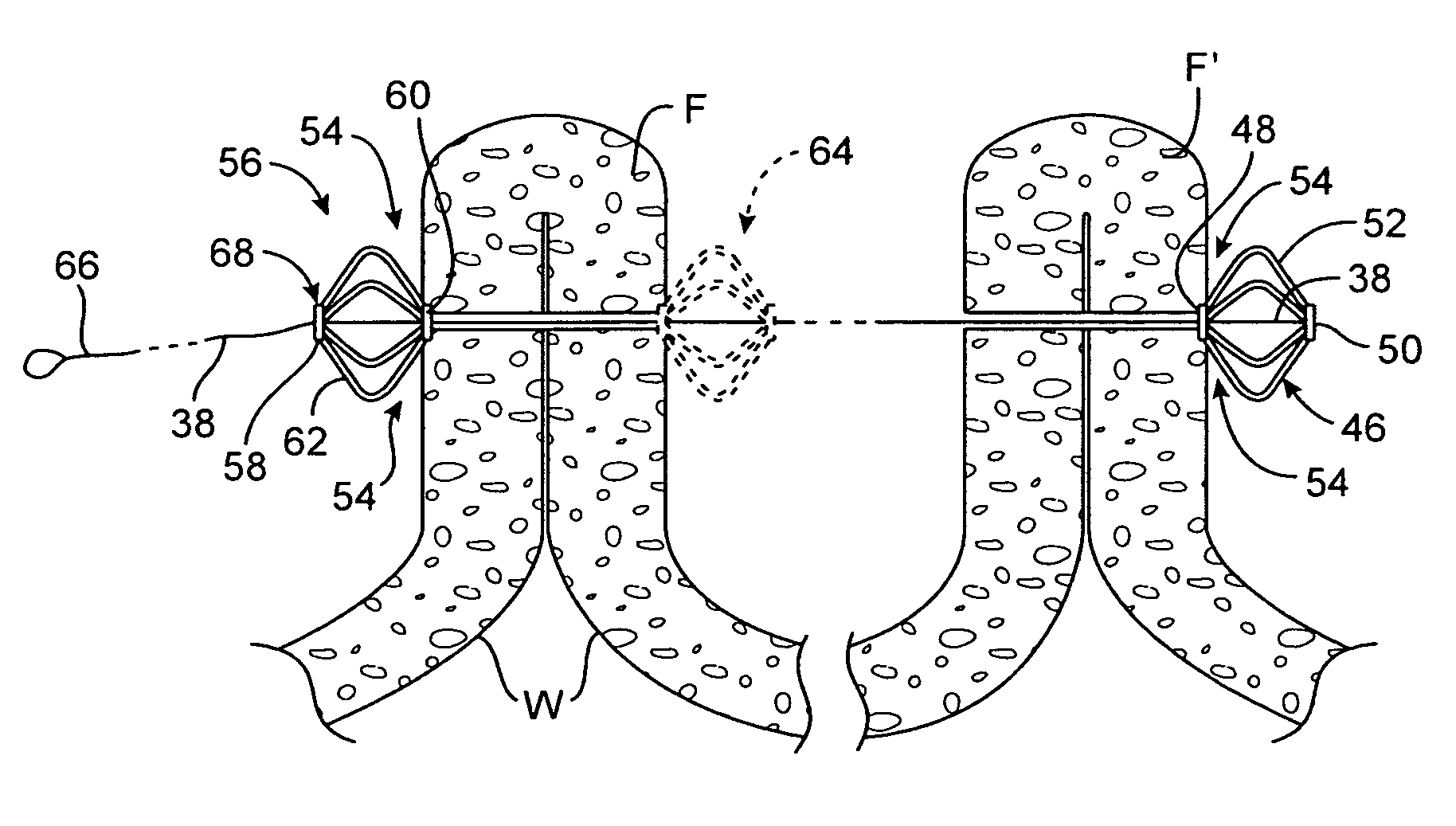

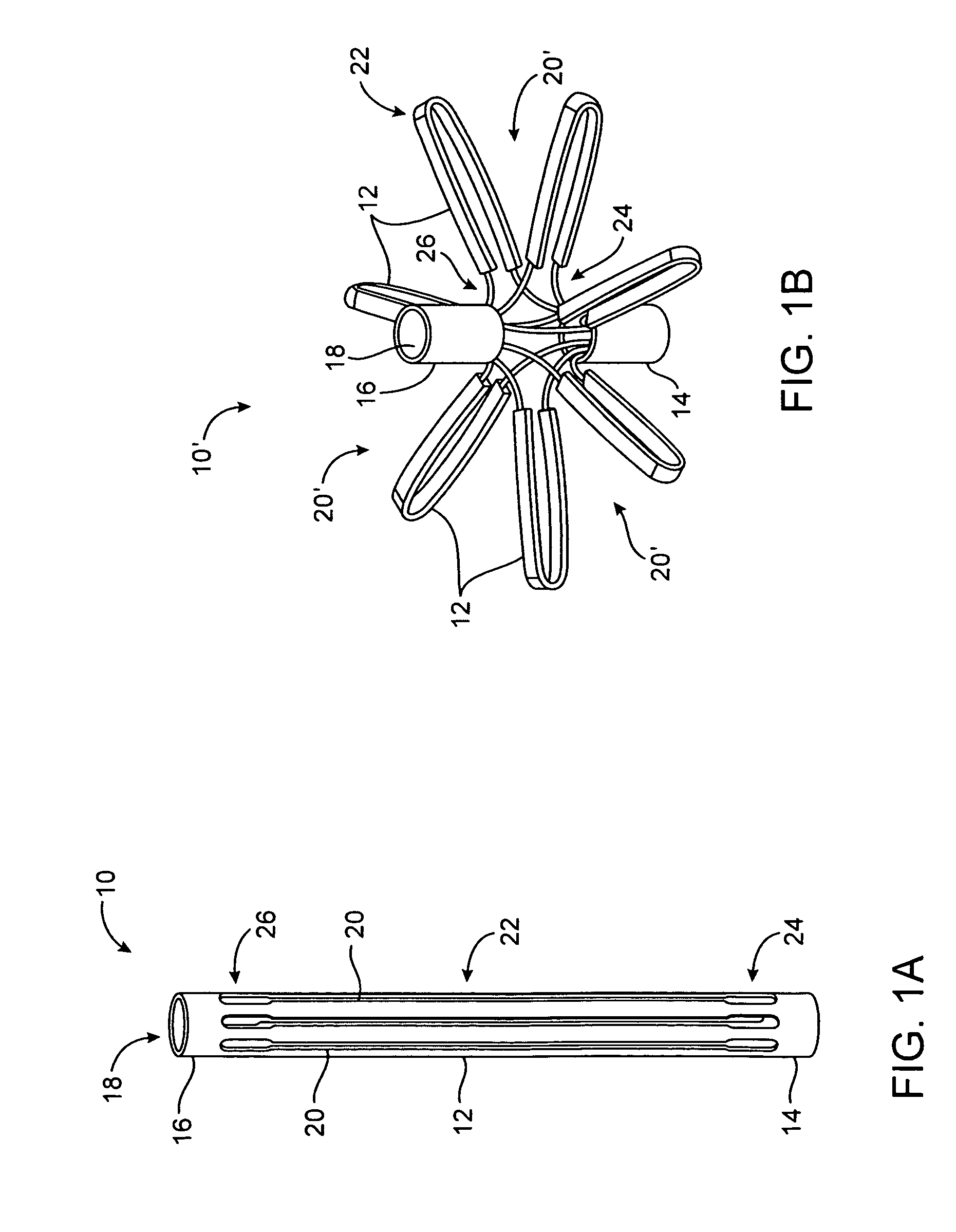

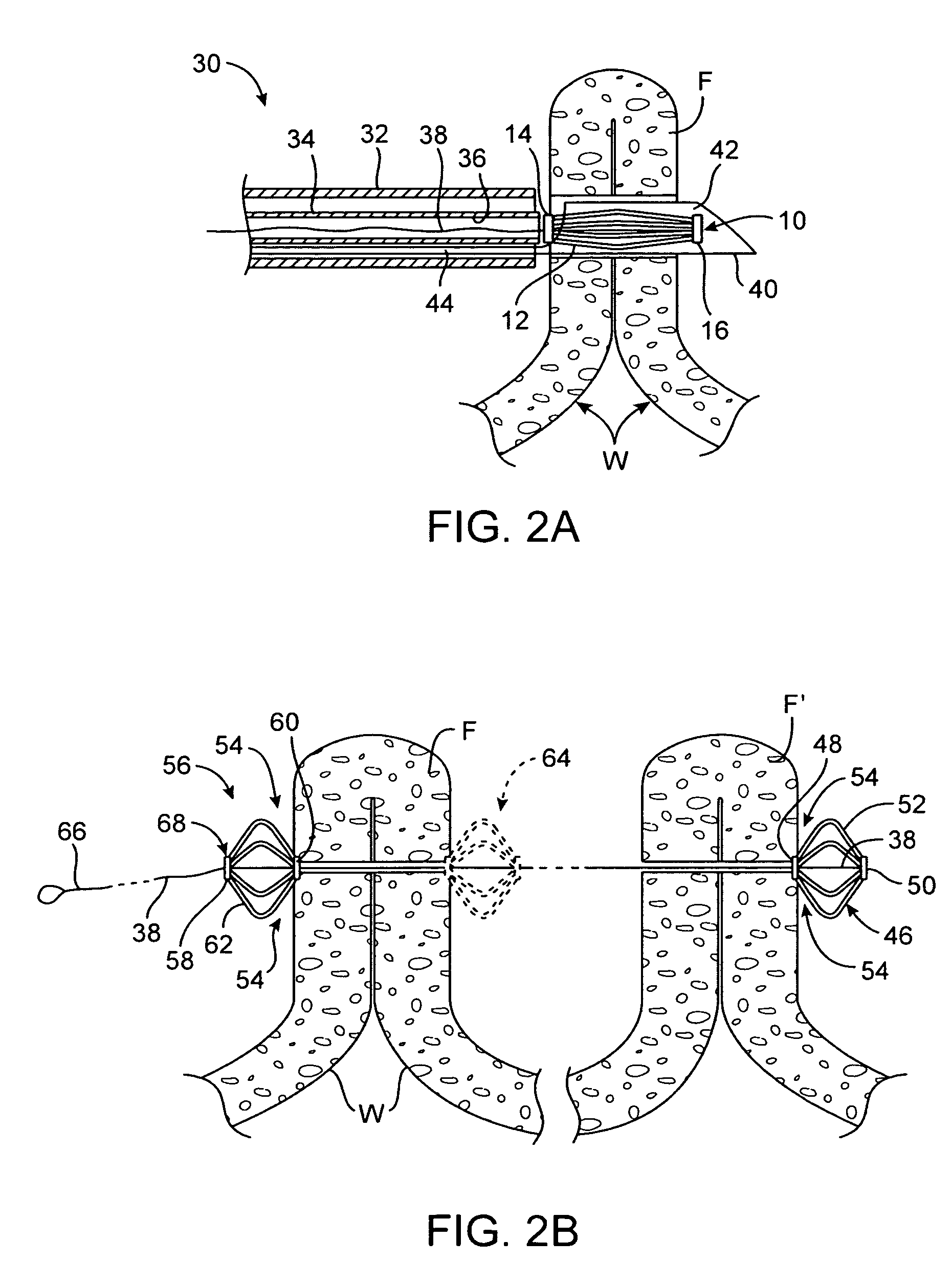

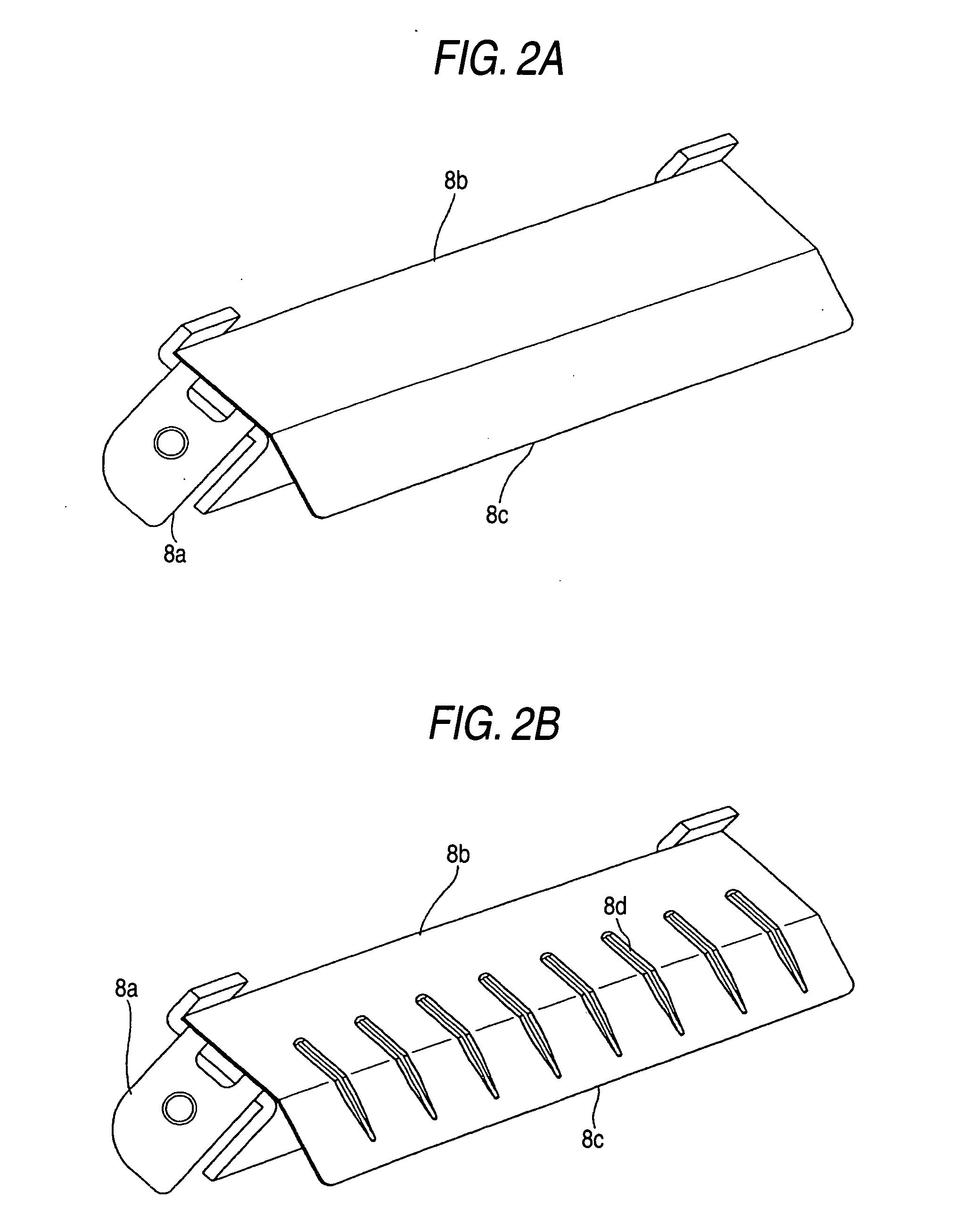

Systems for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

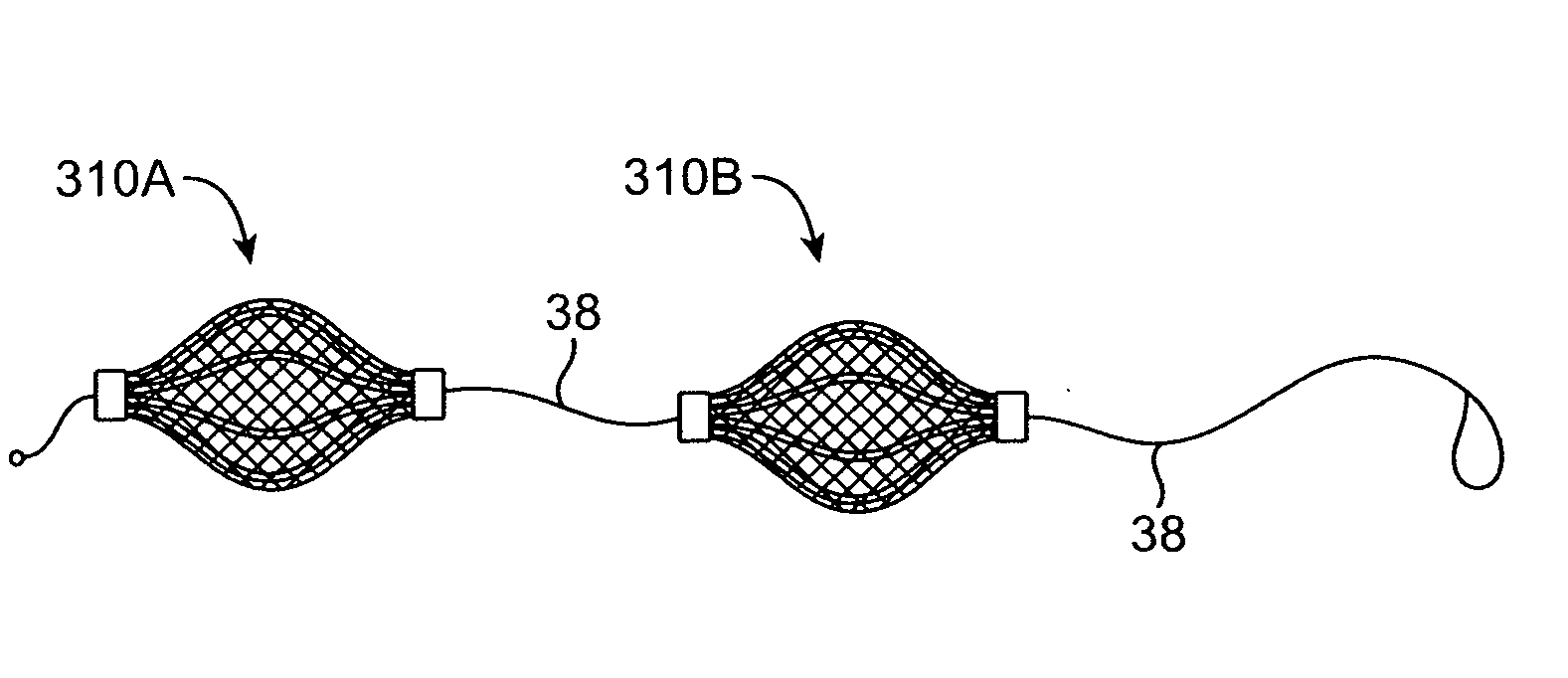

Compressible tissue anchor assemblies

ActiveUS7736379B2Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

Apparatus & methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Compressible tissue anchor assemblies

ActiveUS20060217762A1Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsStrain gaugeBiomedical engineering

Apparatus & methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Apparatus and methods for optimizing anchoring force

ActiveUS20050277981A1Avoid exposurePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

Apparatus and methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Compressible tissue anchor assemblies

ActiveUS20050277966A1Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

Apparatus & methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Compressible tissue anchor assemblies

ActiveUS7678135B2Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

Owner:USGI MEDICAL

System for optimizing anchoring force

ActiveUS20050277983A1Avoid exposureConstant force against the tissueSuture equipmentsDiagnosticsConstant forceStrain gauge

Systems for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Tool holder with spherical contact points

InactiveUS20070280790A1Minimized contact areaMinimize overall surface areaMilling cuttersCutting insertsEngineeringTool holder

A tool holder includes a shank portion, a head portion that includes an insert pocket defined by a seat surface, a first or radial support sidewall and a second or axial support sidewall, and a spherical contact point protruding from one of the first and second support sidewalls. The spherical contact point minimizes a contact area between a cutting insert mounted in the insert pocket and one of the first and second support sidewalls of the insert pocket. In one embodiment, the radial support sidewall includes two spherical contact points, and the axial support sidewall includes one spherical contact point. The spherical contact point may be formed by inserting a rivet-like structure into an aperture formed in the support sidewalls of the pocket.

Owner:KENNAMETAL INC

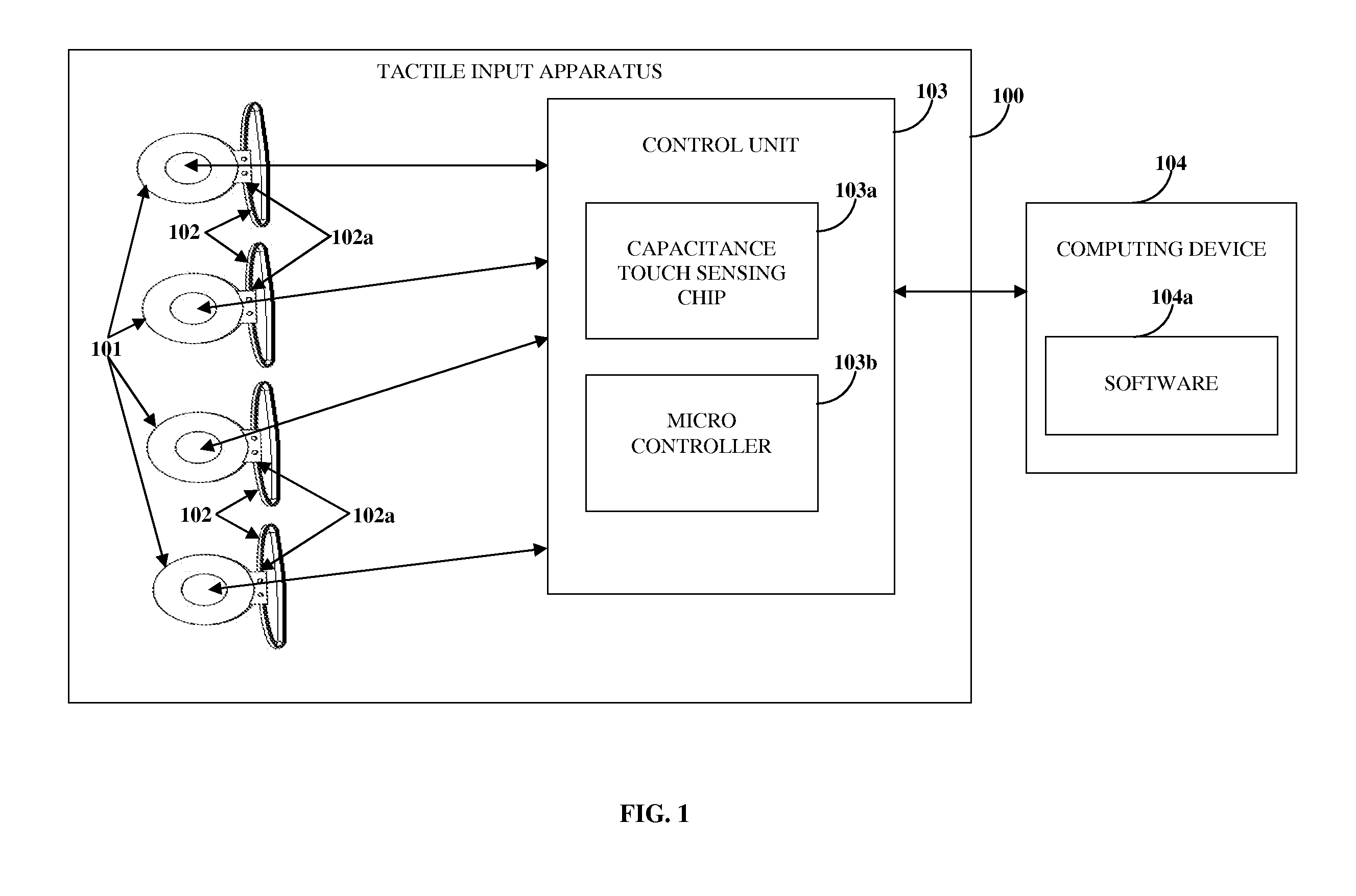

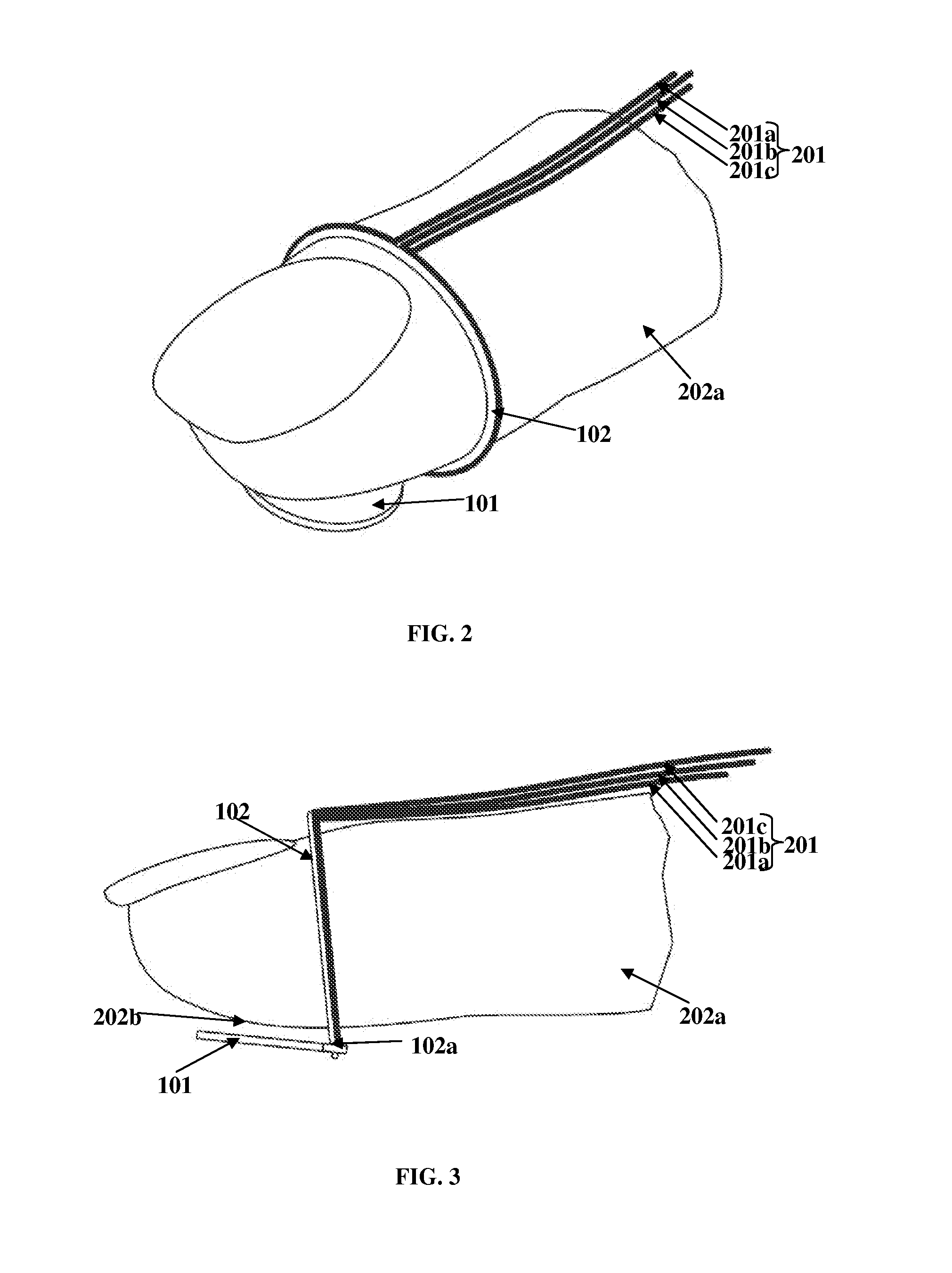

Tactile Input Apparatus

InactiveUS20110187637A1Minimized contact areaReduce perspirationCathode-ray tube indicatorsVideo gamesElectronic communicationEngineering

A tactile input apparatus comprising ring-shaped elements configured to conform to a user's fingers, tactile capacitance sensors operably affixed to periphery of the ring-shaped elements, and a control unit, is provided. Each tactile capacitance sensor is positioned parallel to the underside of each finger and reads a change in capacitance on contacting the user's thumb or palm. The control unit, in wired or wireless electronic communication with each tactile capacitance sensor and with the user's computing device, continuously transmits capacitance readings multiple times per second to a software on the computing device. The software monitors and processes the capacitance readings from the control unit and controls output to the computing device. The software determines logic and then enacts single or multiple custom outputs. The positioning of the tactile capacitance sensors on the periphery of the ring-shaped elements prevents confinement of the user's fingers and allows mobility of the user's fingers.

Owner:NICHOLS DAVID SCOTT

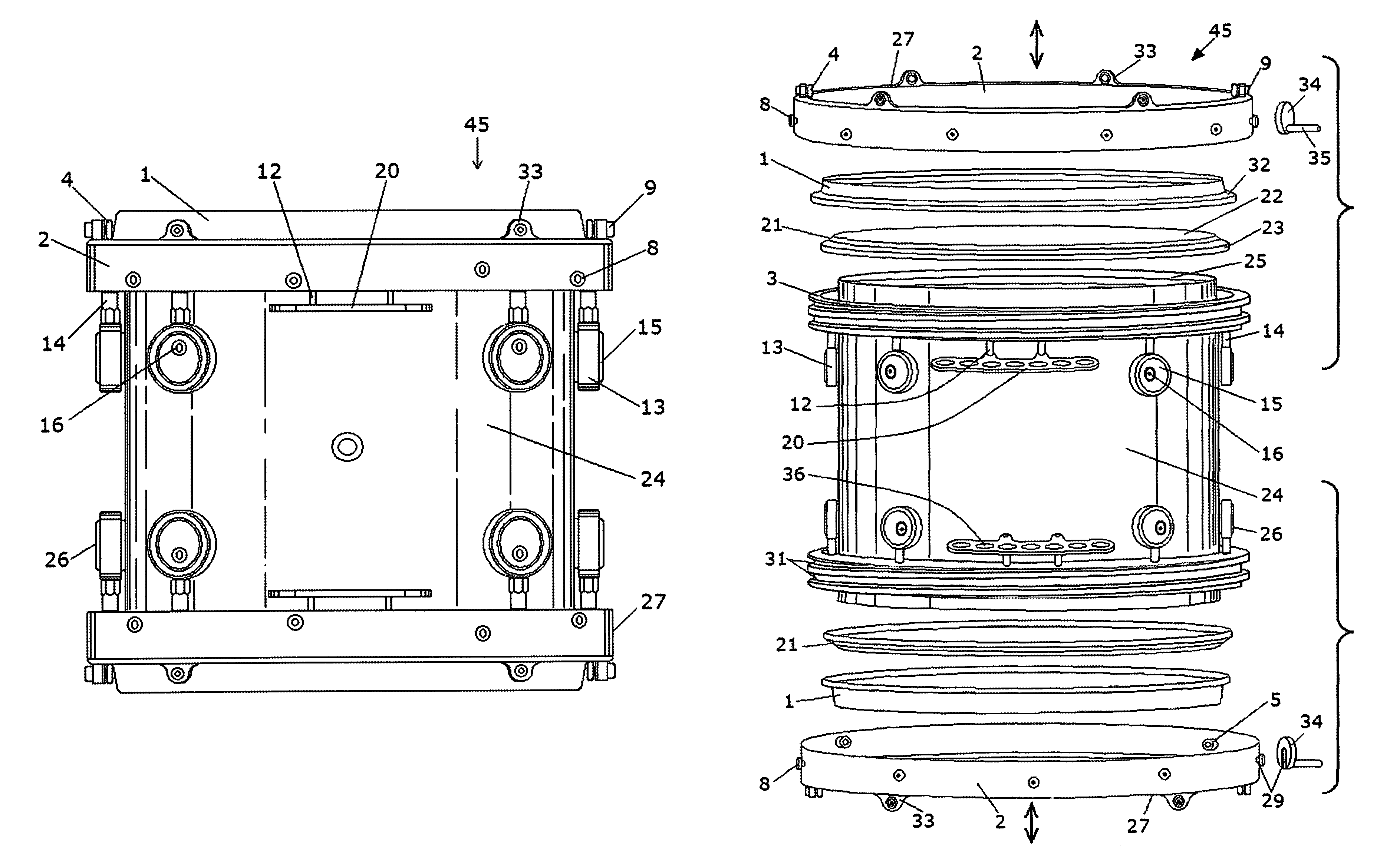

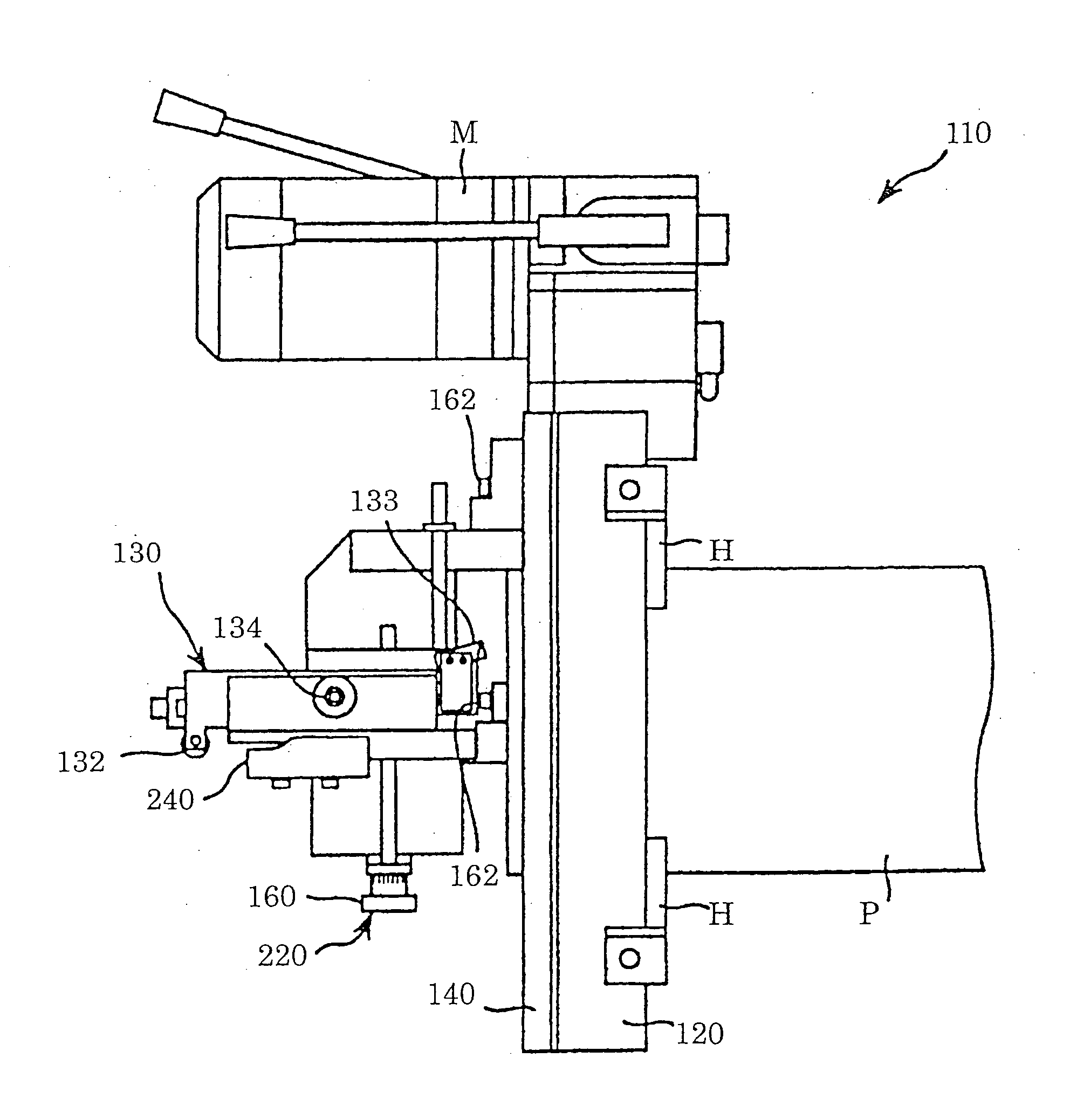

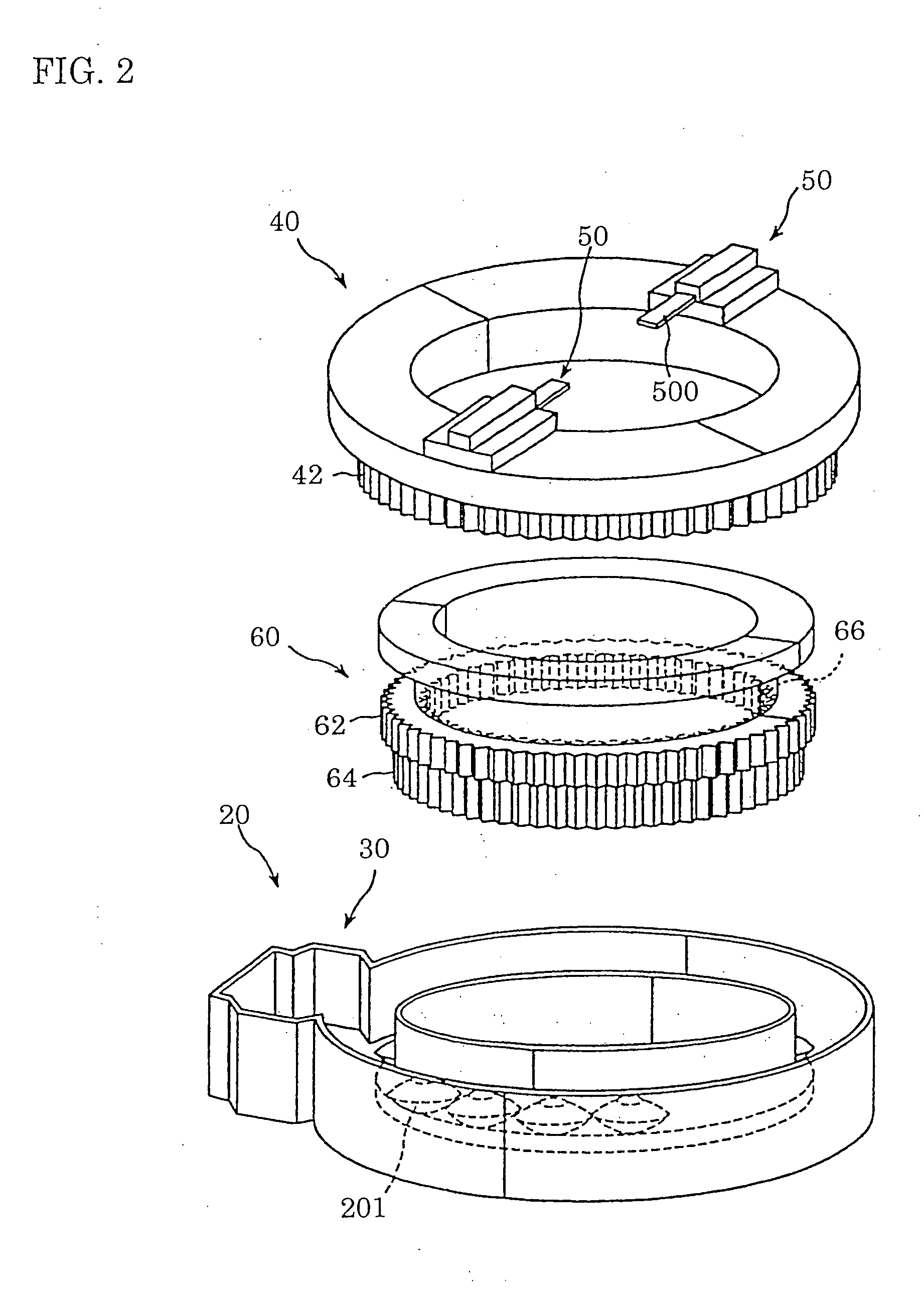

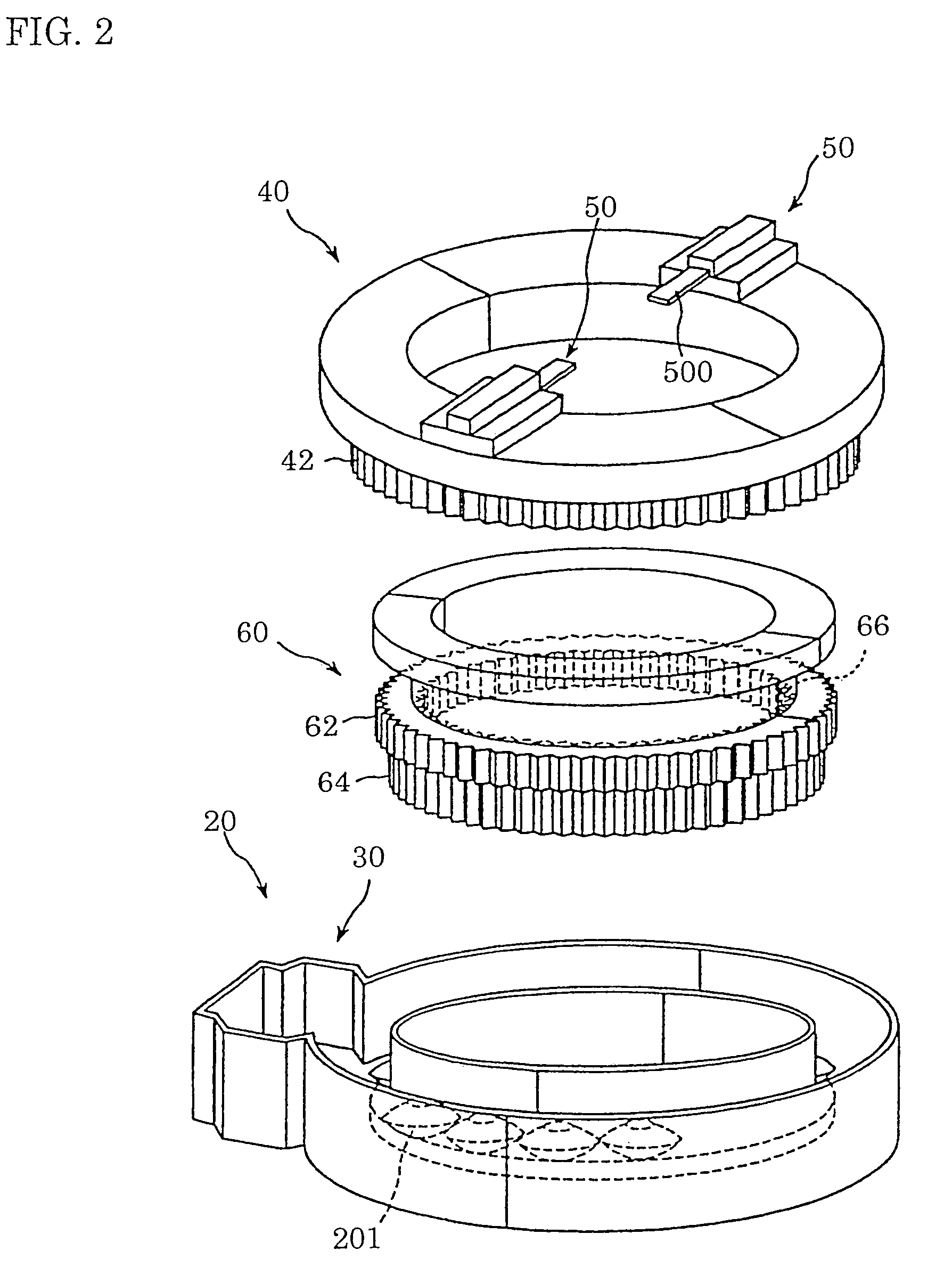

Rotation activated drum tuning system

ActiveUS7501567B1Increased mechanical advantageMinimized contact areaPercussion musical instrumentsBearing downEngineering

A drum tuning system which rotates clockwise or counterclockwise to adjust the tension of a drum head fitted over the open end of a drum body. It utilizes a rotating ring having numerous opposing equally spaced vertically projecting tabs along the top of the body's diameter, each with inward facing wheels that ride on the horizontal surface of a separate inner hoop bearing down on the drum head. The rotating actuator ring is fitted with multiple radial cleats projecting from its outside diameter for grasping it. A radius plate having horizontal holes extends from the drum body, and a tool engages the radial cleats on the rotating actuator ring to facilitate rotation. Multiple adjustable eccentric lugs are used to raise and lower the drum camming mechanism in relation to the open end of the drum body where attached. Horizontal projecting links support the drum attached to suspension mounting systems.

Owner:SPINAZZOLA DAVID MICHAEL

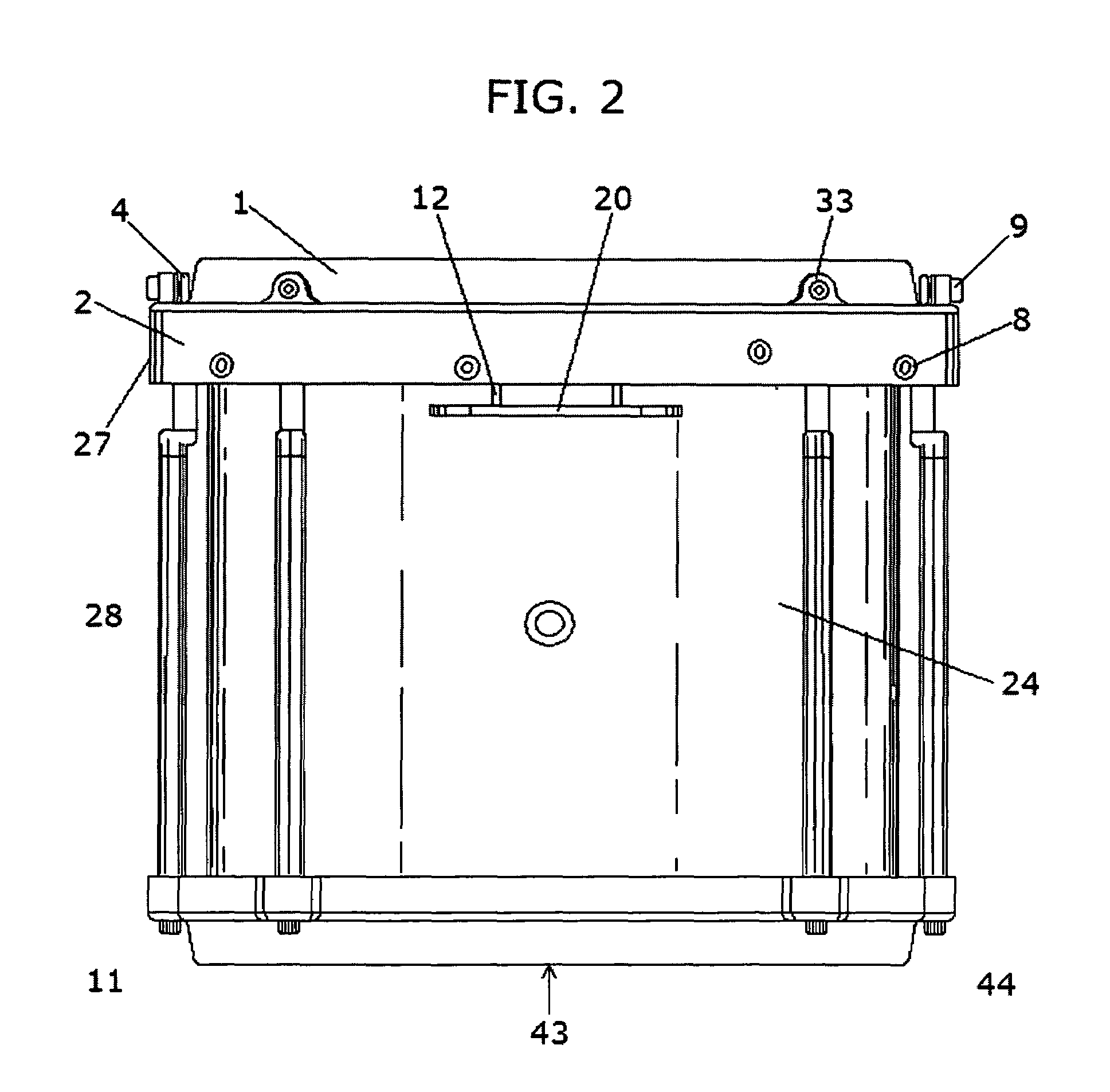

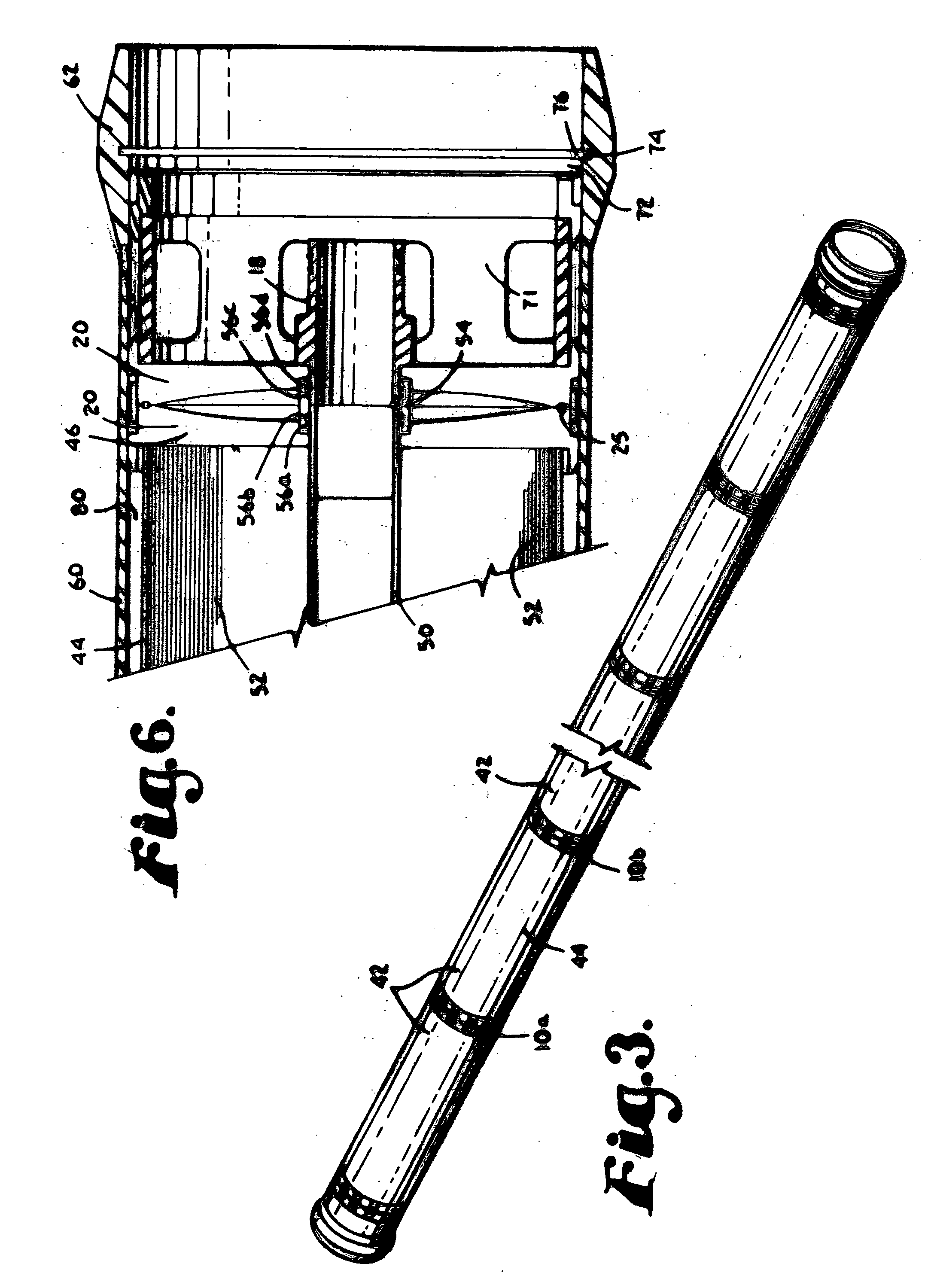

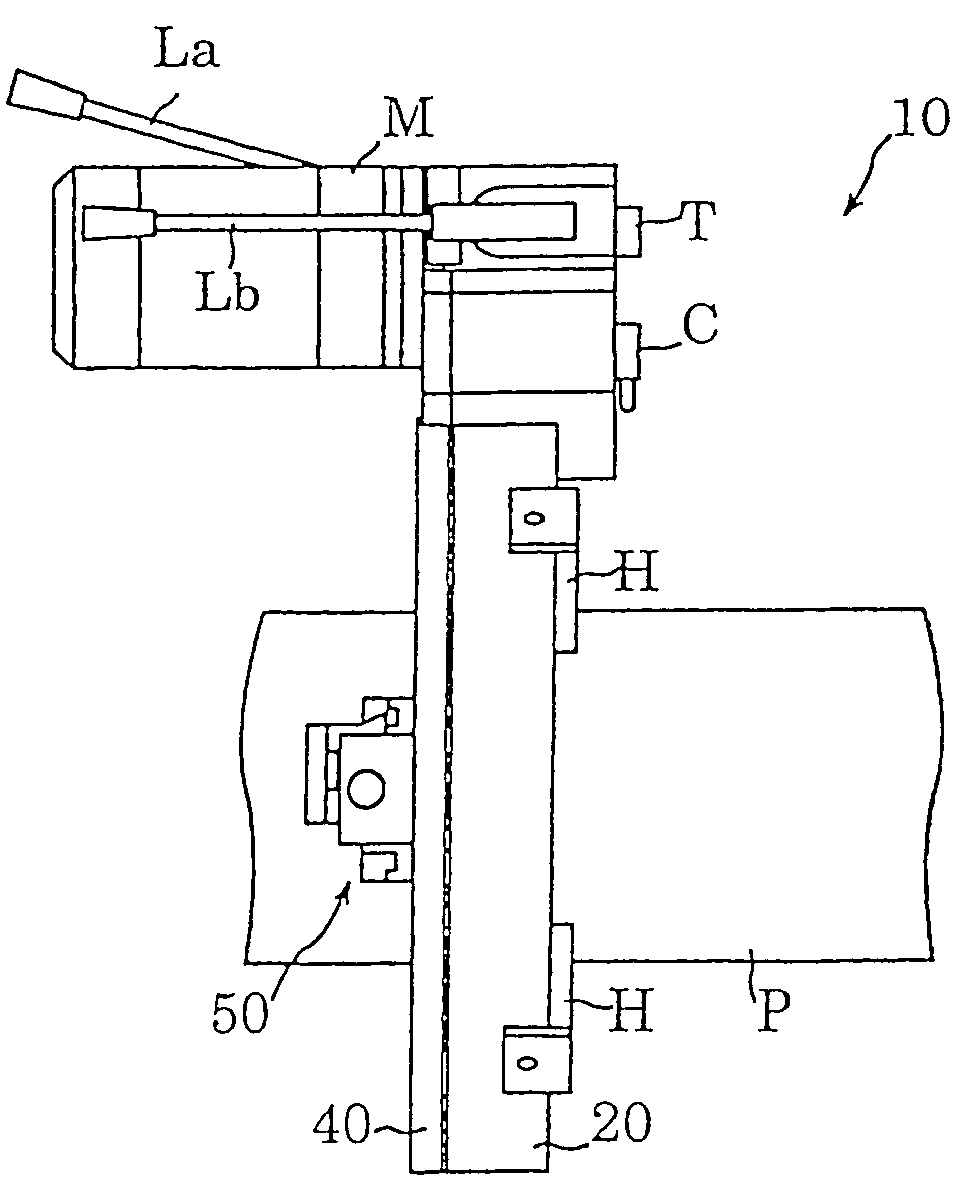

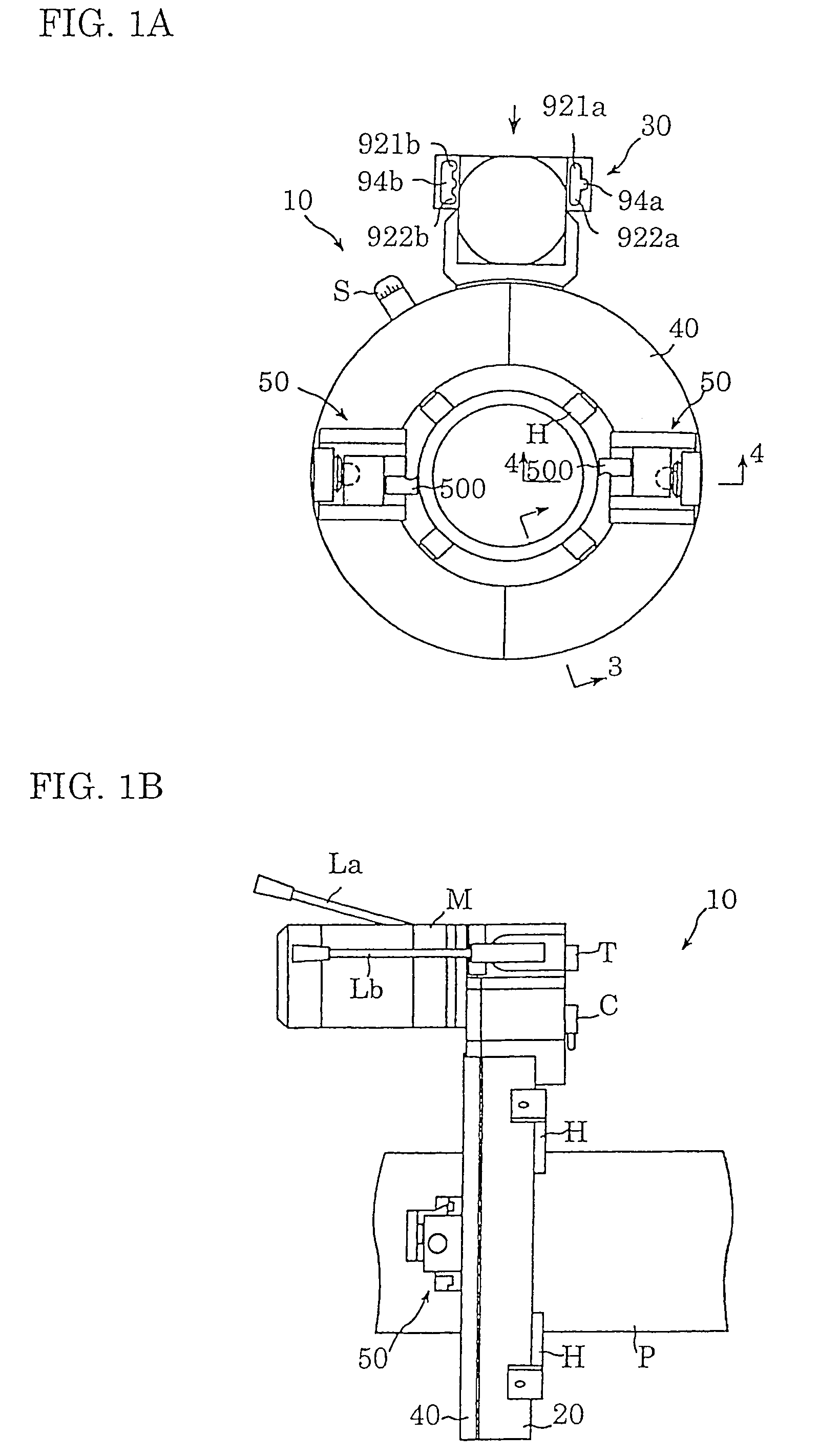

Cutting, profiling, and edge-preparing apparatus

InactiveUS20050247171A1Formed in shape with easeImprove accuracyPortable latheMetal working apparatusEngineeringFeeding mode

An apparatus for cutting and / or profile machining an edge of a pipe is provided. The apparatus includes a housing, a rotatable faceplate mounted on a front surface of the housing, and a tool holder mounted on the faceplate and holding a cutting tool. In a first embodiment, a cutting apparatus includes gearing that permits the tool holder to be moved relative to a surface of a pipe in a rapid-feed mode, a slow-feed mode and a rapid-return mode. In second and third embodiments, a profile machining apparatus includes a carriage having a profiling roller or shaft that advances (or retracts) relative to a pipe along a path defined by a template. The carriage to which the cutting tool is mounted is pivoted about a support shaft permitting the carriage and tool to change its angle and orientation relative to the pipe while advancing or retracting.

Owner:MORI KENICHI

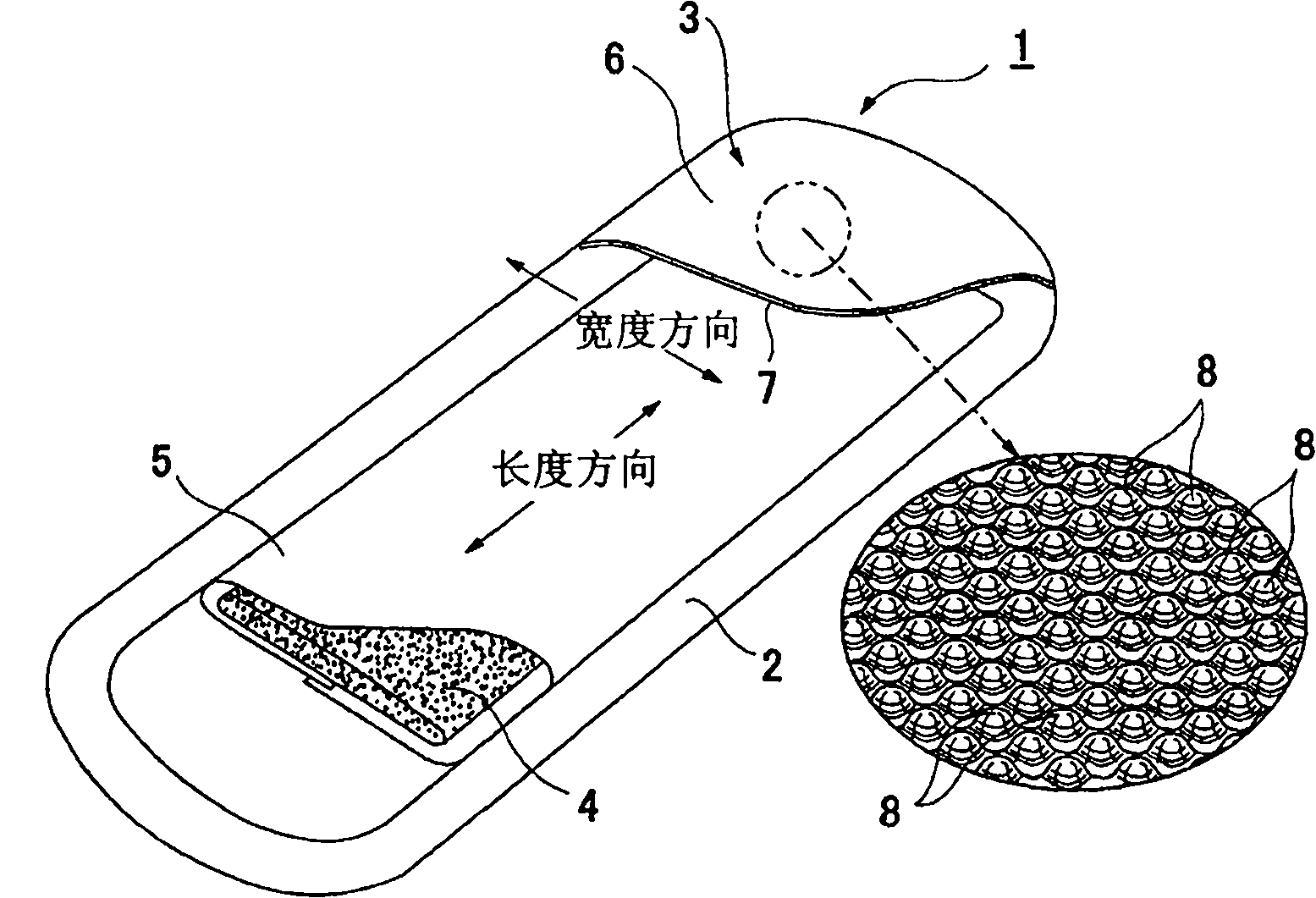

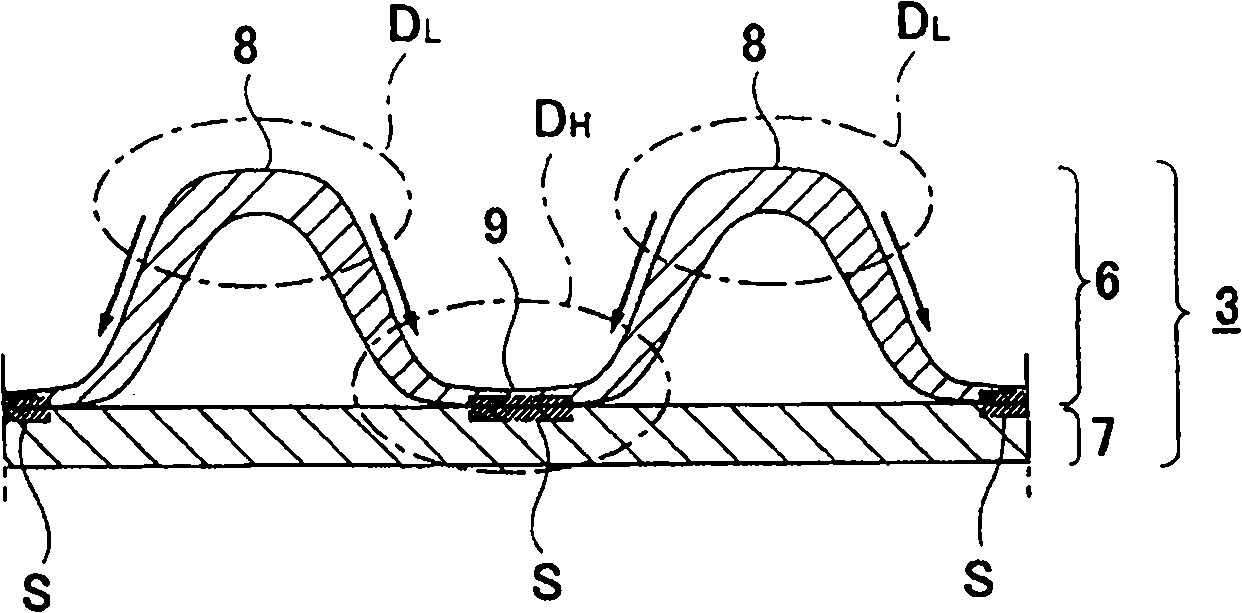

Emboss roller and method for producing surface sheet using emboss roller and absorbent article employing surface sheet

ActiveCN101970211AEliminate stiffnessGood touchLamination ancillary operationsLaminationFiberMechanical engineering

Disclosed is an emboss roller comprising a set of a first emboss roll (11) and a second emboss roll (12) and imparting an irregularly embossed shape onto a surface sheet, wherein a reference surface (14), which has a protrusion (15) protruding outward from the reference surface (14) and a recess (16) recessed from the reference surface (14), the reference surface (14) serving as the boundary, and is smooth to the peripheries of the protrusion (15) and the recess (16), exists on the surface of the first emboss roll (11), and a reference surface (17), which has a protrusion (18) protruding outward from the reference surface (17) to mesh the recess (16) in the first emboss roll (11) and a recess (19) recessed from the reference surface (17) to mesh the protrusion (15) of the first emboss roll (11), the reference surface (17) serving as the boundary, and is smooth to the peripheries of the protrusion (18) and the recess (19), exists on the surface of the second emboss roll (12).

Owner:DAIO PAPER CORP

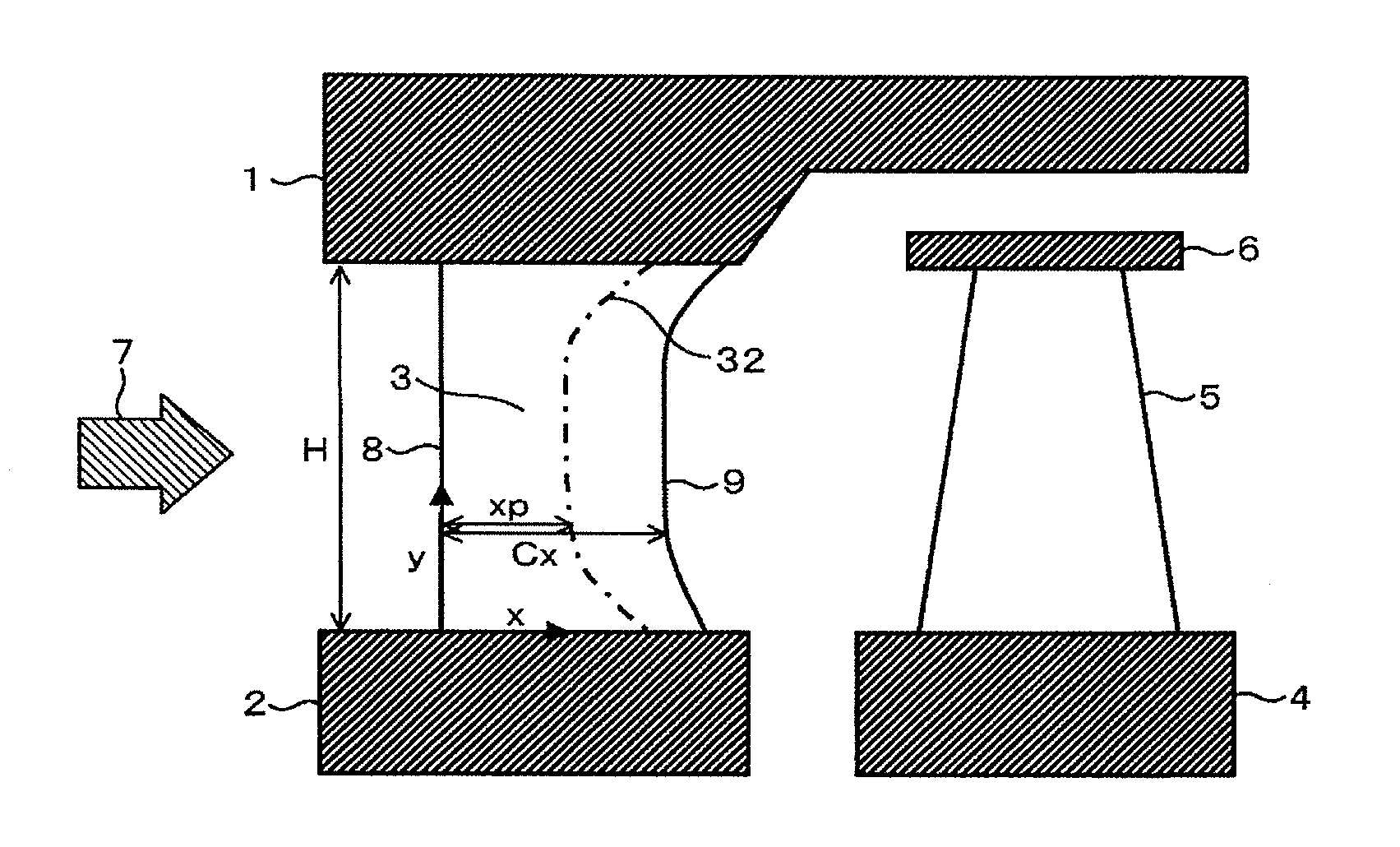

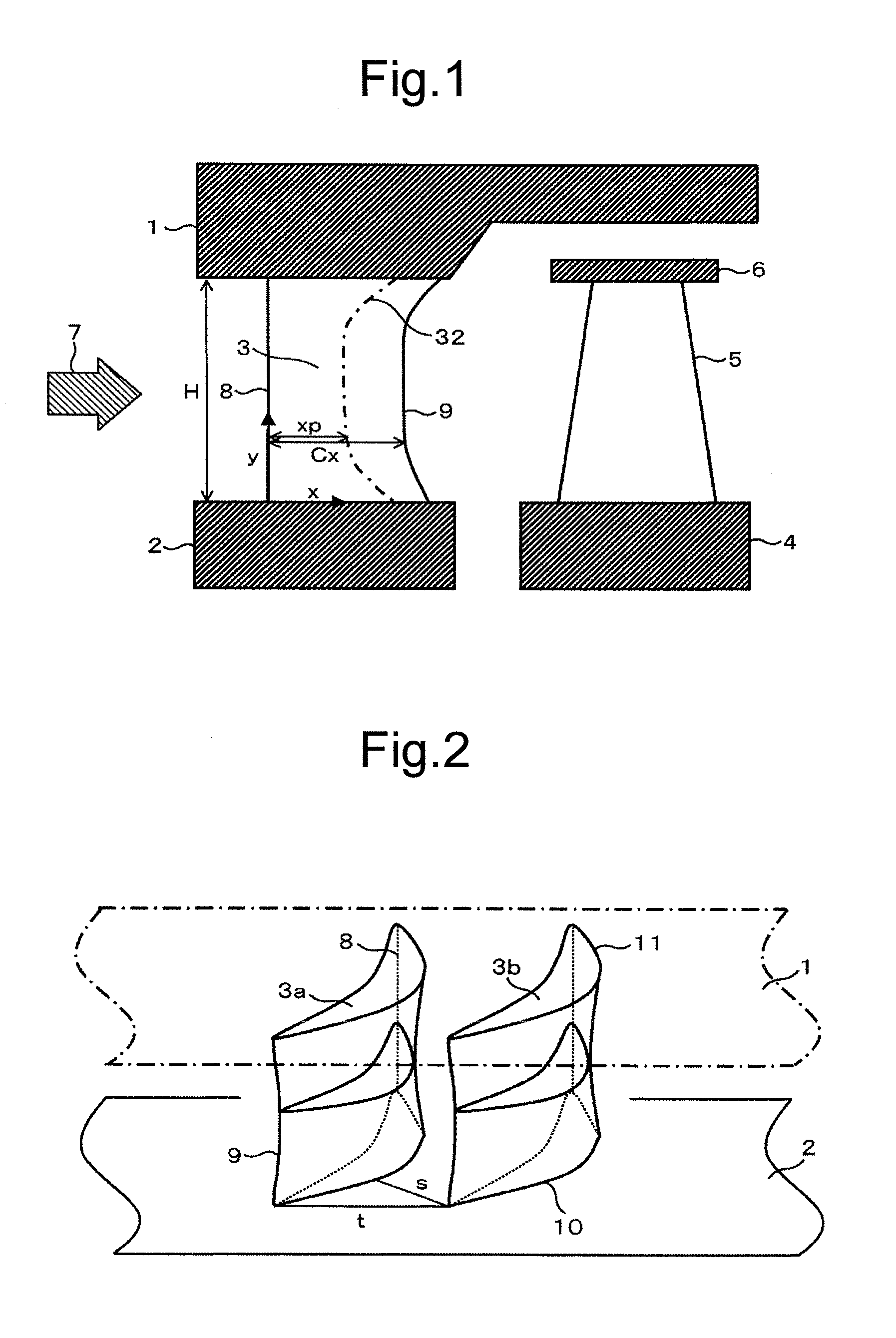

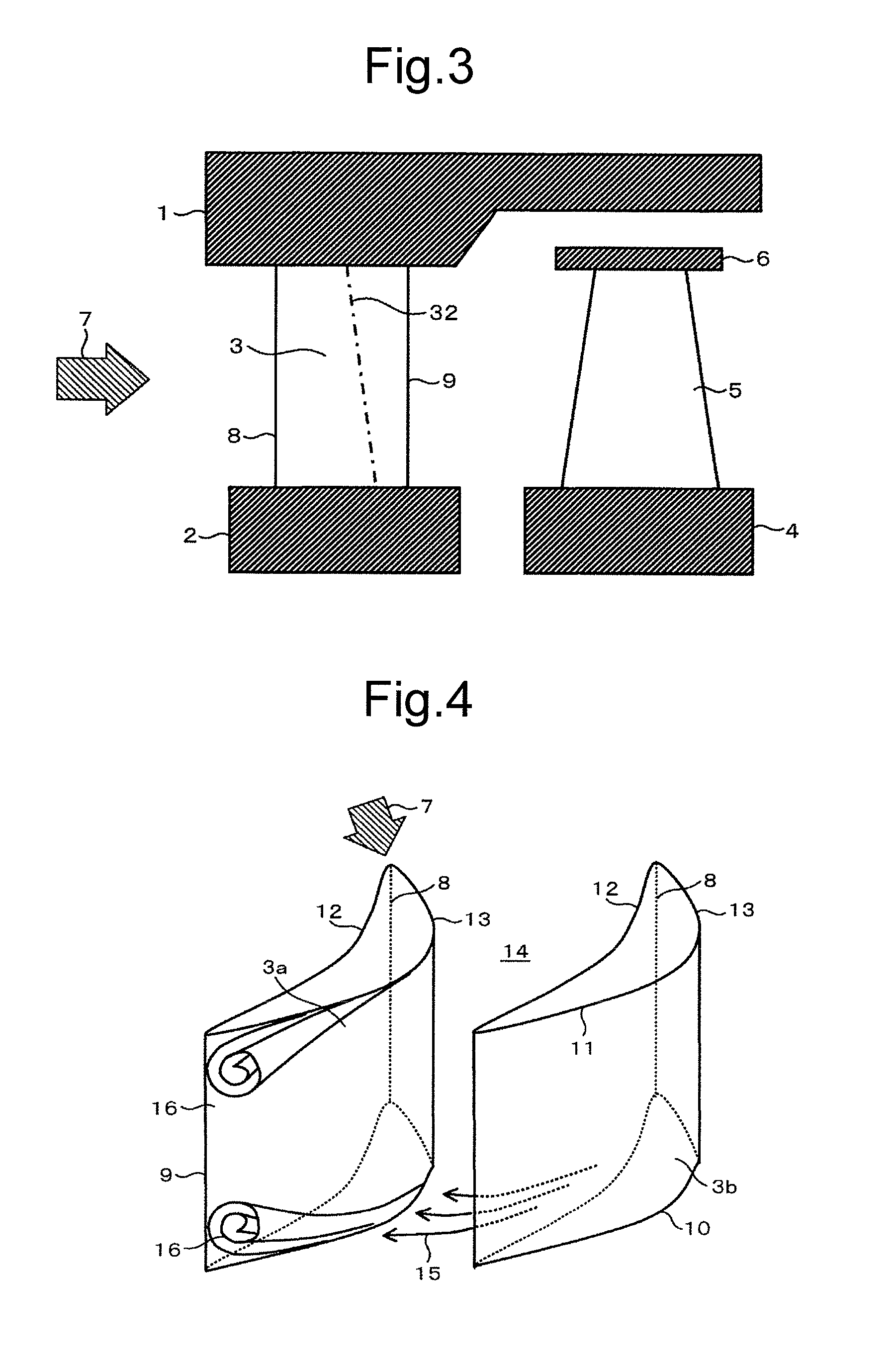

Turbine Nozzle Blade and Steam Turbine Equipment Using Same

InactiveUS20120210715A1Reduce in quantityImproving turbine stage efficiencyBlade accessoriesEfficient propulsion technologiesLeading edgeDifferential pressure

Disclosed is a highly efficient turbine nozzle blade that reduces the number of blades in an axial-flow turbine while reducing secondary-flow loss. In the nozzle blade, when a differential pressure between a pressure side and a suction side of each blade, at the same axial chord position of the blade, is defined as a load of the blade, and a ratio between axial chord length “Cx” of the blade and an axial distance “xp” from a leading edge of the blade at a maximum load position that maximizes the blade load is defined as a maximum load relative position, Cx is greater at a hub and tip than at an intermediate vertical portion, and simultaneously a maximum load relative position at the hub and tip is set to be nearer to a trailing edge thereof than a maximum load relative position of the intermediate vertical portion of the blade.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

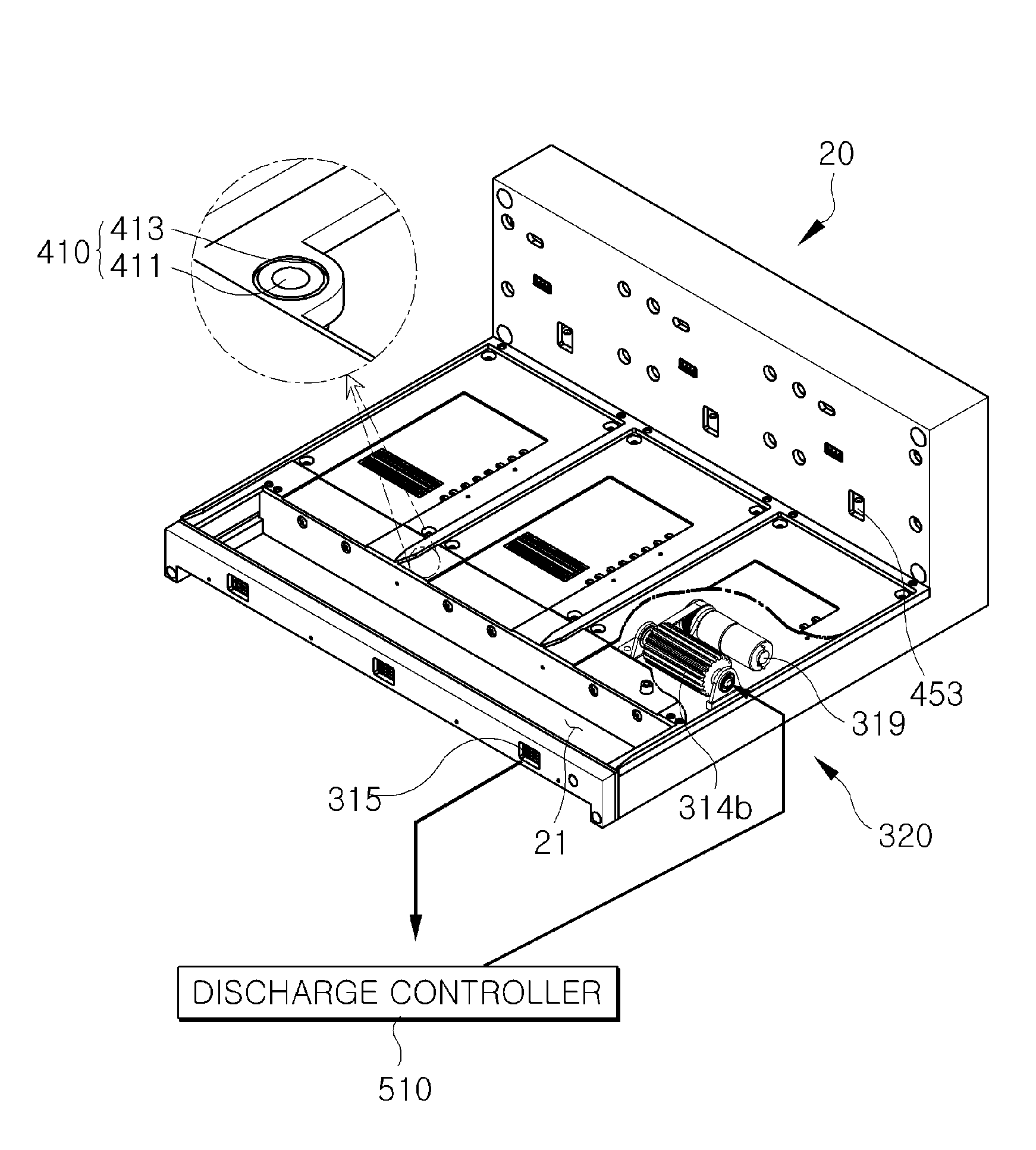

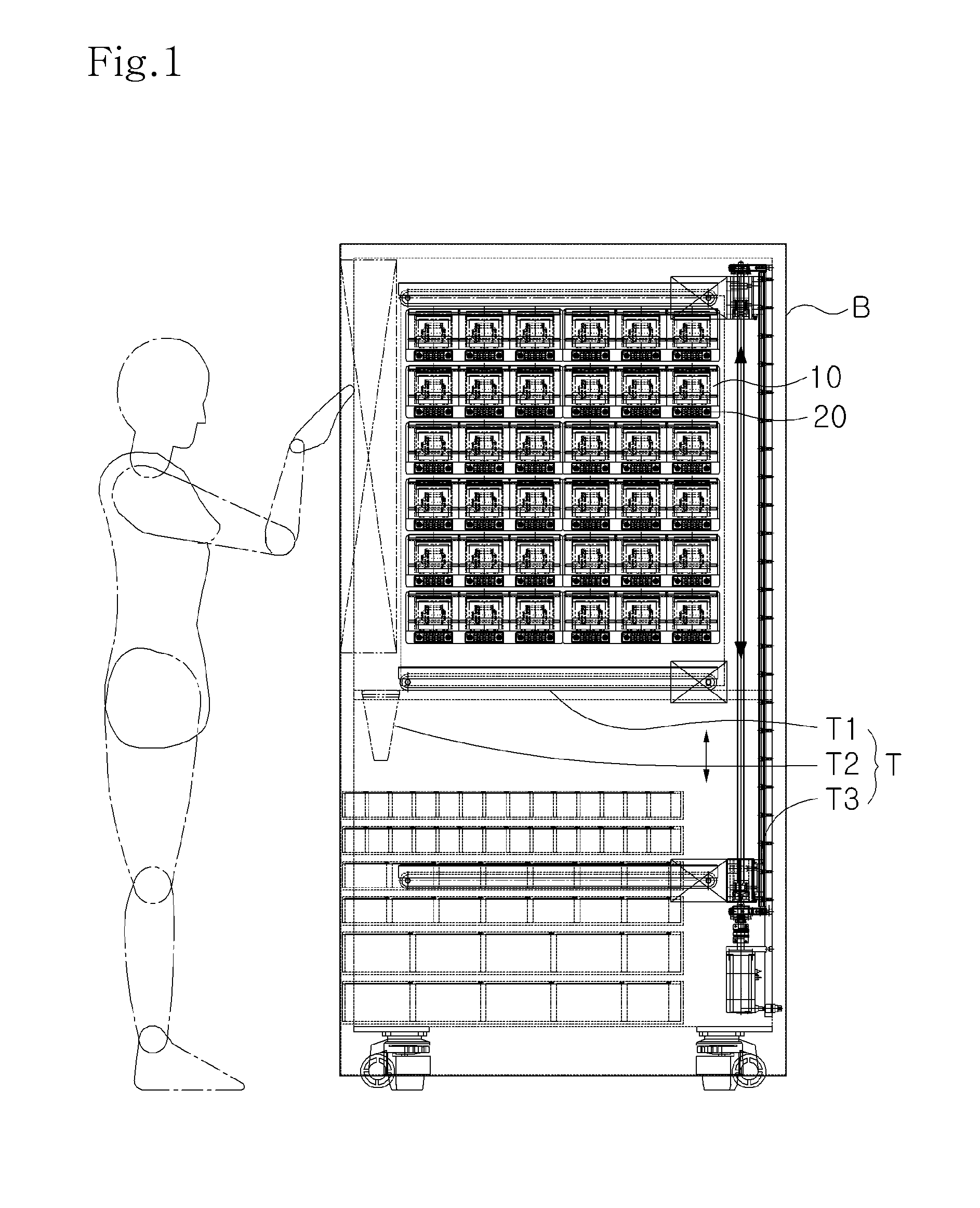

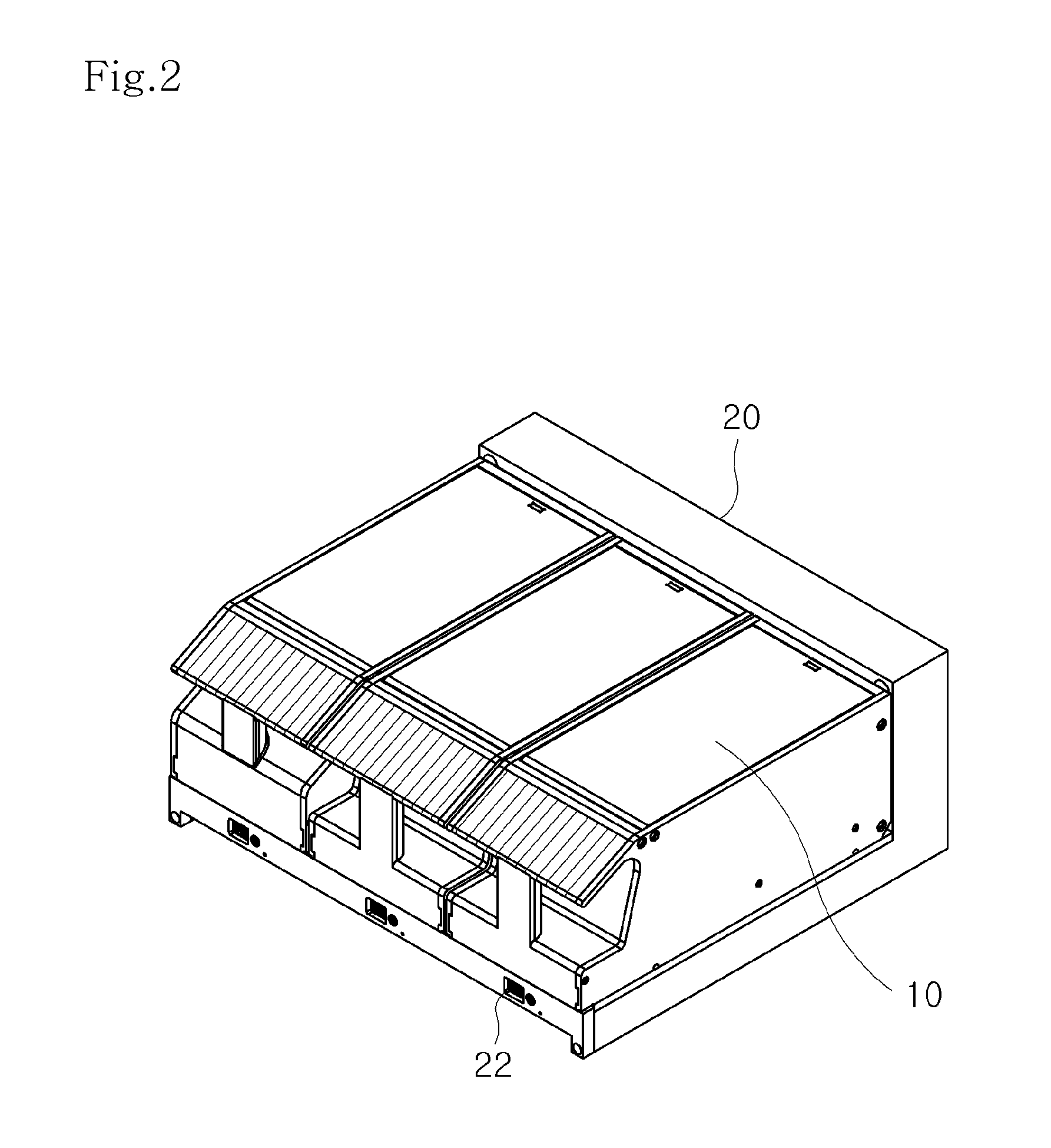

Medicine feeding apparatus

Disclosed is a medicine feeding apparatus. The medicine feeding apparatus includes a medicine cartridge, a cartridge mount, a medicine discharge mechanism, and a discharge drive mechanism. The medicine cartridge has an entrance opening formed in the top thereof, through which a medicine product is put into the medicine cartridge, and a discharge hole formed in a front position of the bottom thereof, through which the medicine product is discharged from the medicine cartridge by operation of the medicine discharge mechanism. The entrance opening is provided with a cover. The medicine cartridge is mounted on an upper surface of the cartridge mount, and the cartridge mount has an outer discharge hole communicating with the discharge hole to discharge the medicine product from the cartridge mount. The discharge drive mechanism is provided at the medicine cartridge and the cartridge mount and serves to drive the medicine discharge mechanism.

Owner:JVM CO LTD

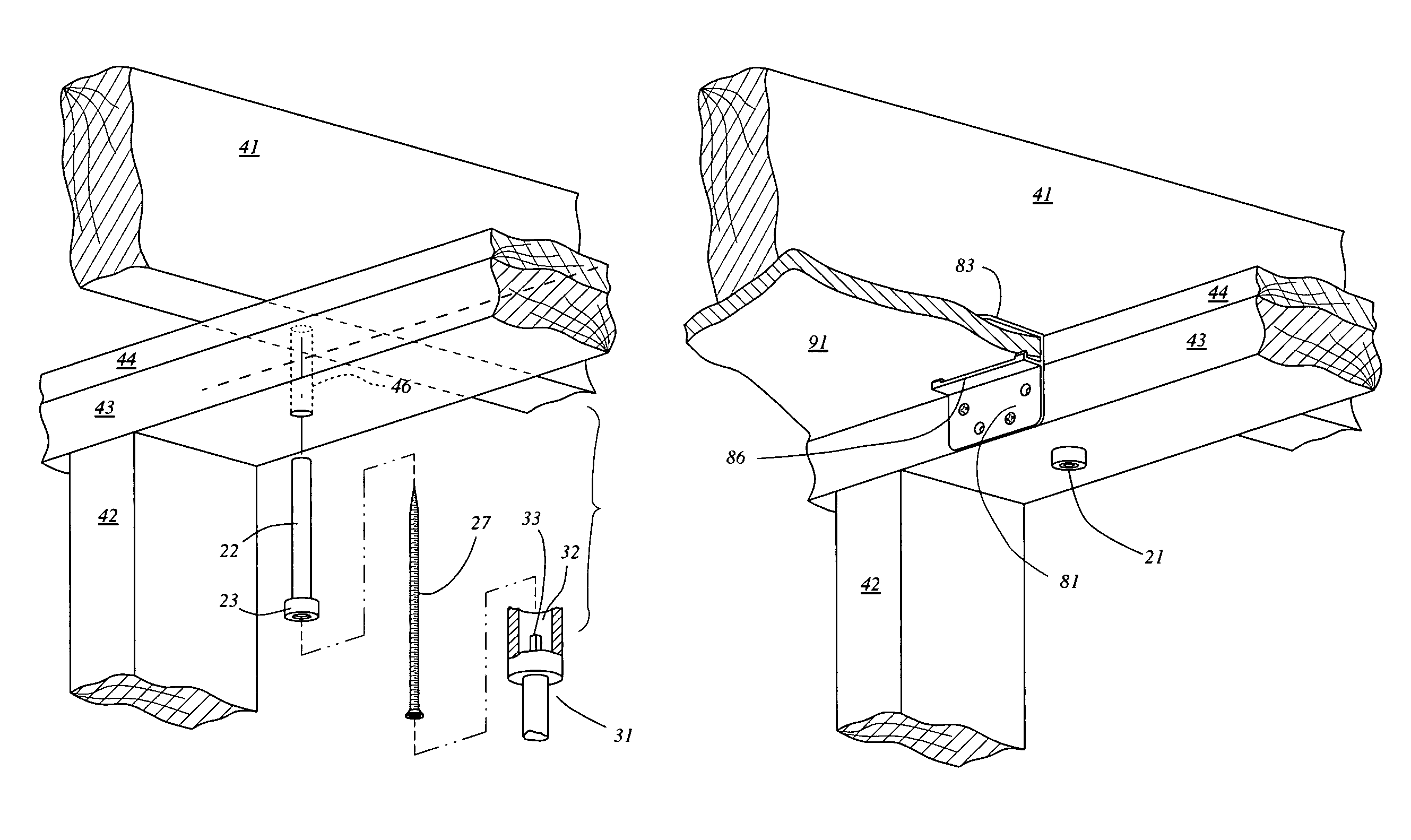

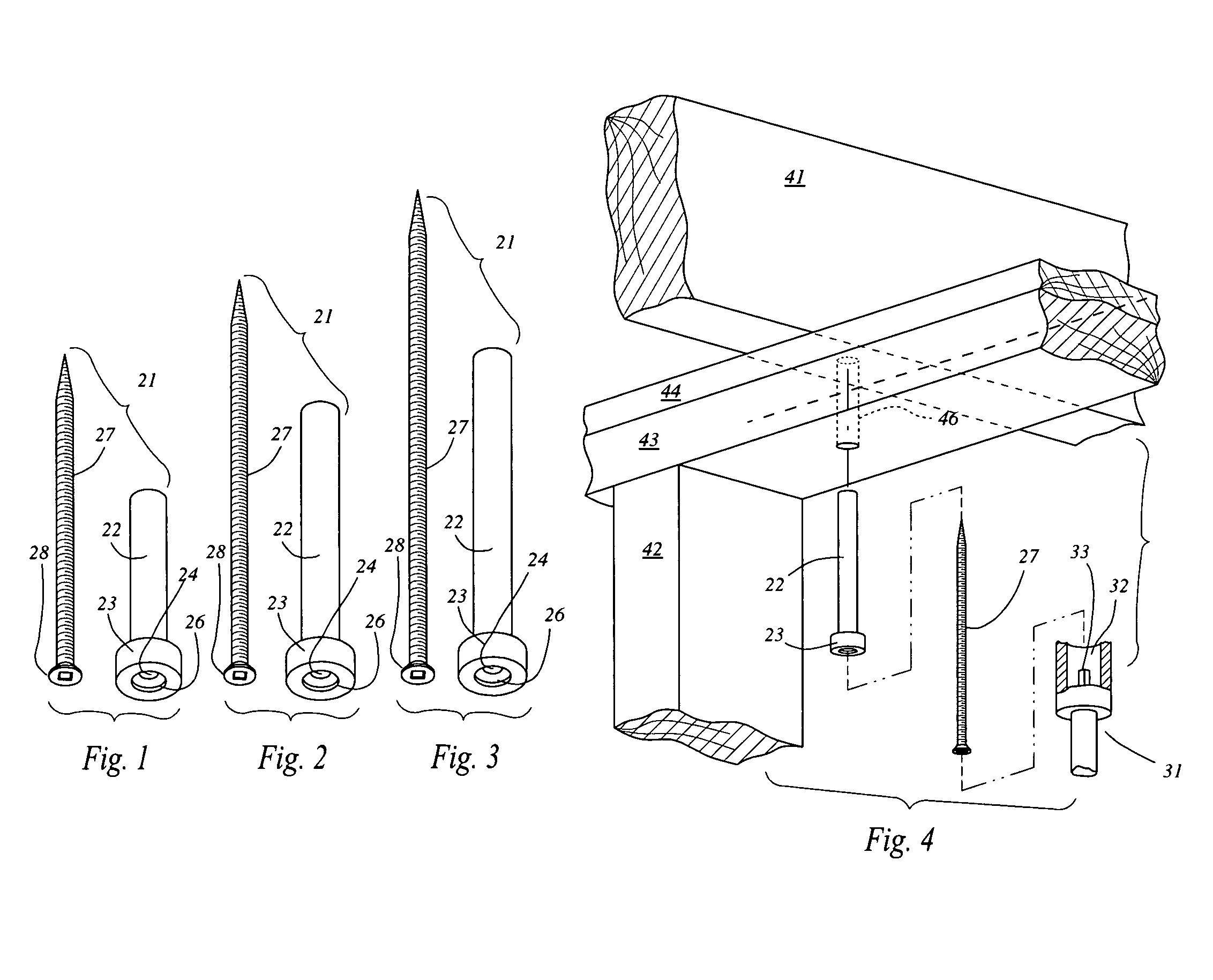

Method and apparatus for securing non-load bearing walls

ActiveUS8458972B1Minimize transmissionGreat acoustic comfortBuilding roofsWallsThreaded fastenerVertical motion

A method and apparatus for securing non-load bearing interior walls in a wood frame structure in a manner that allows for vertical deflection of the frame includes a plurality of sleeved fastener assemblies, each having a threaded fastener extending through a shorter outer sleeve with an enlarged diameter head. The fasteners hold interior non-load bearing walls in place through a predrilled hole in the top plates of the walls, while being capable of accommodating limited vertical movement caused by vertical deflection of the building frame during construction and beyond.

Owner:SIMPSON STRONG TIE

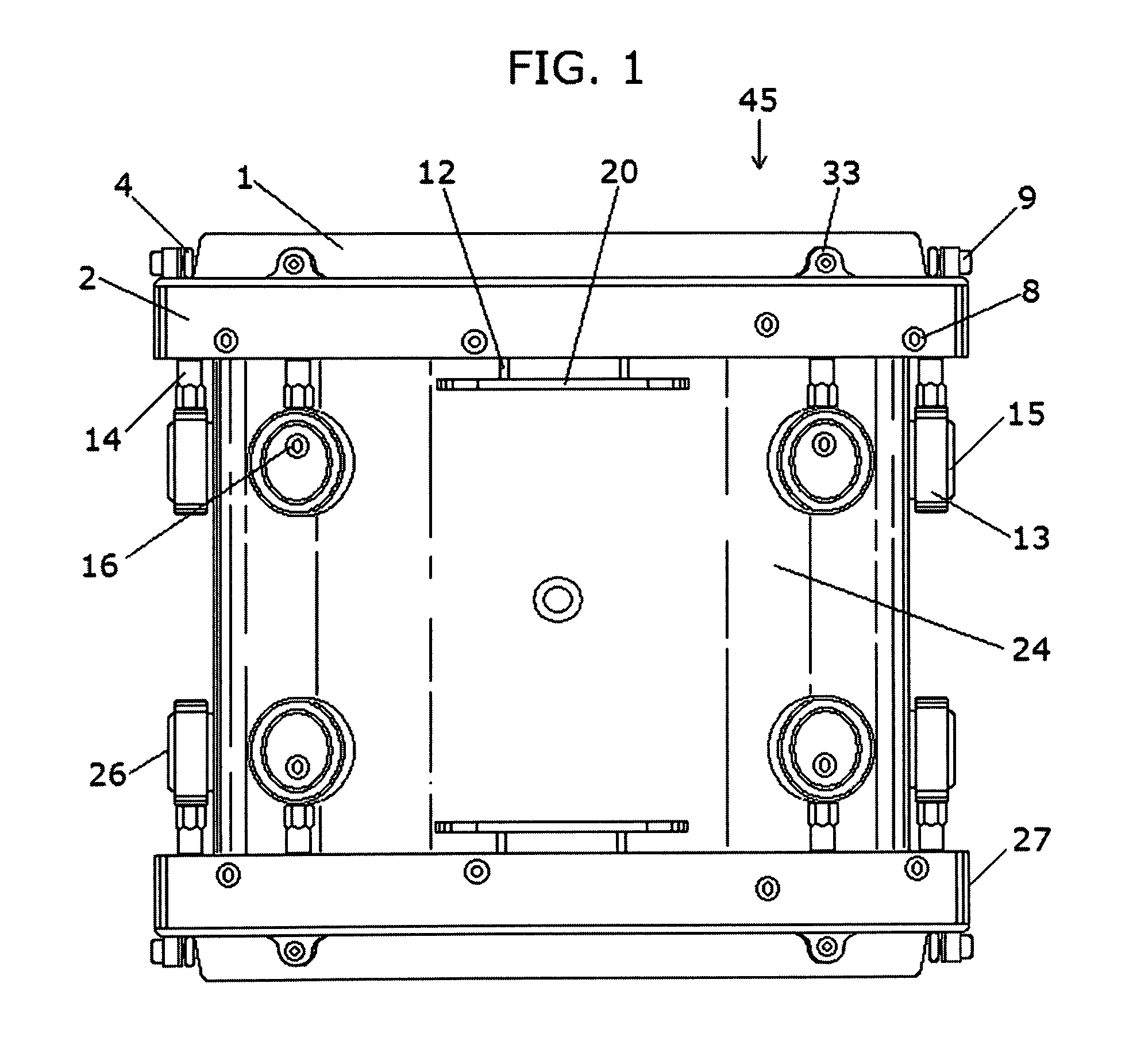

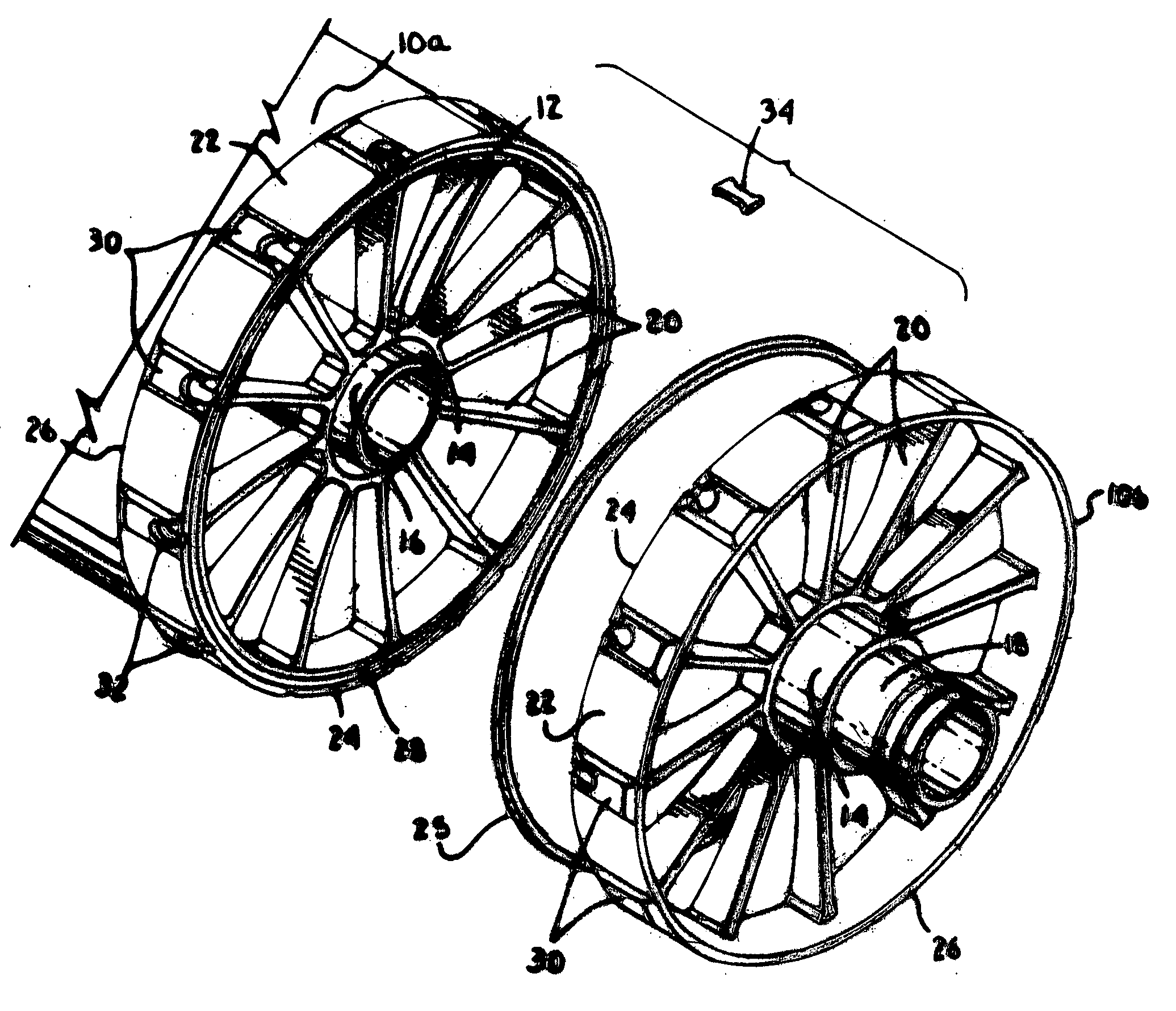

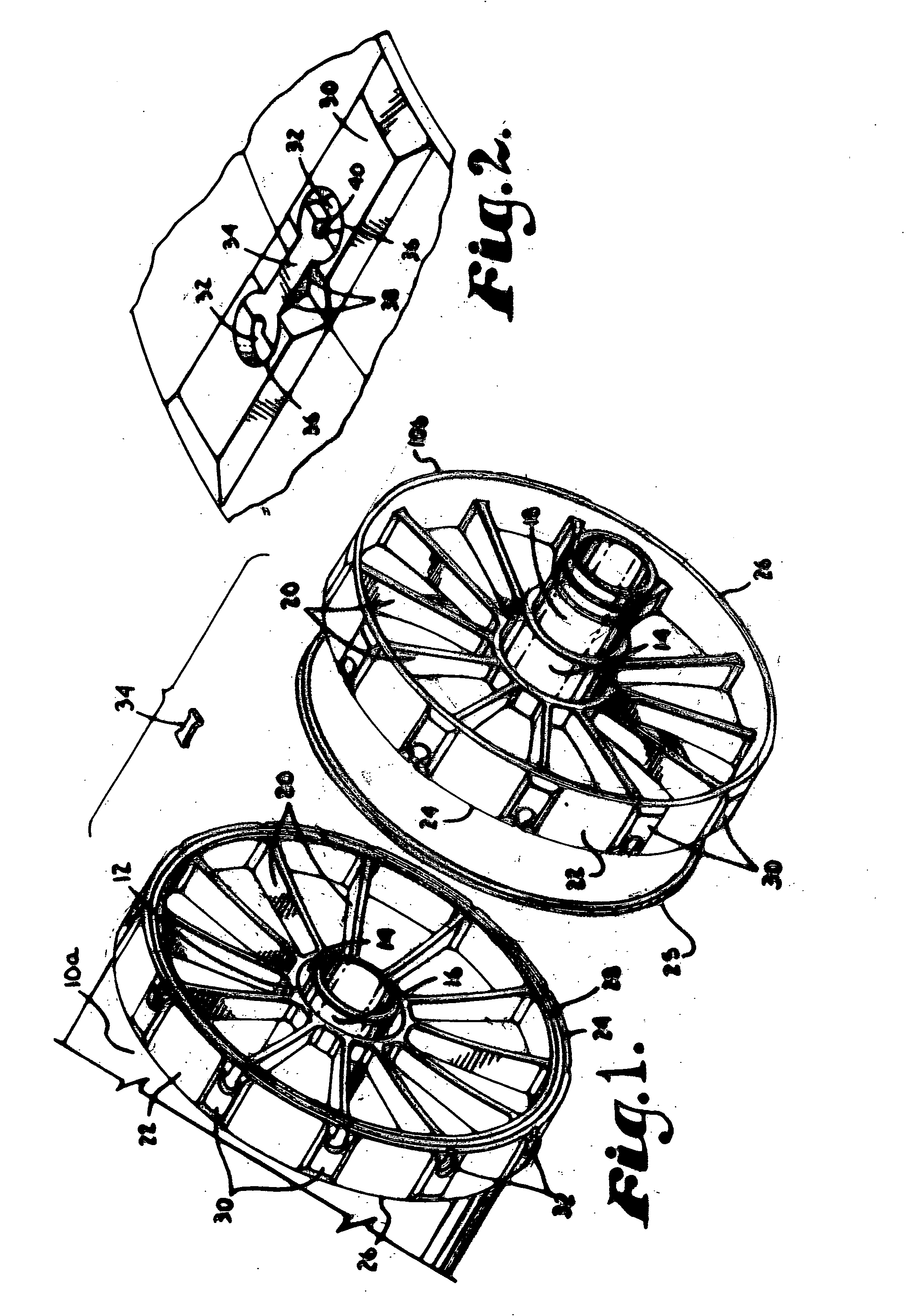

Filtration element and method of constructing a filtration assembly

InactiveUS20050035047A1Easily and securely couplingMinimized contact areaSemi-permeable membranesGeneral water supply conservationEngineeringSpoke

A coupler for a spiral membrane filtration element having a spiral membrane enclosed within a rigid outerwrap includes a center support, a plurality of spokes extending outwardly from the center support, a circular rim coupled with the spokes, with the face of the rim being perpendicular to the axis of the overwrap. The rim includes a channel on its face for receiving a compressible seal, and a plurality of receptacles around its outer surface for joining two face-to-face adjacent couplers when a pair of aligned keepers is place in each receptacle. Exemplary embodiments of the coupler and filtration elements and filtration assemblies are provided, as well as an associated method.

Owner:KOCH MEMBRANE SYST

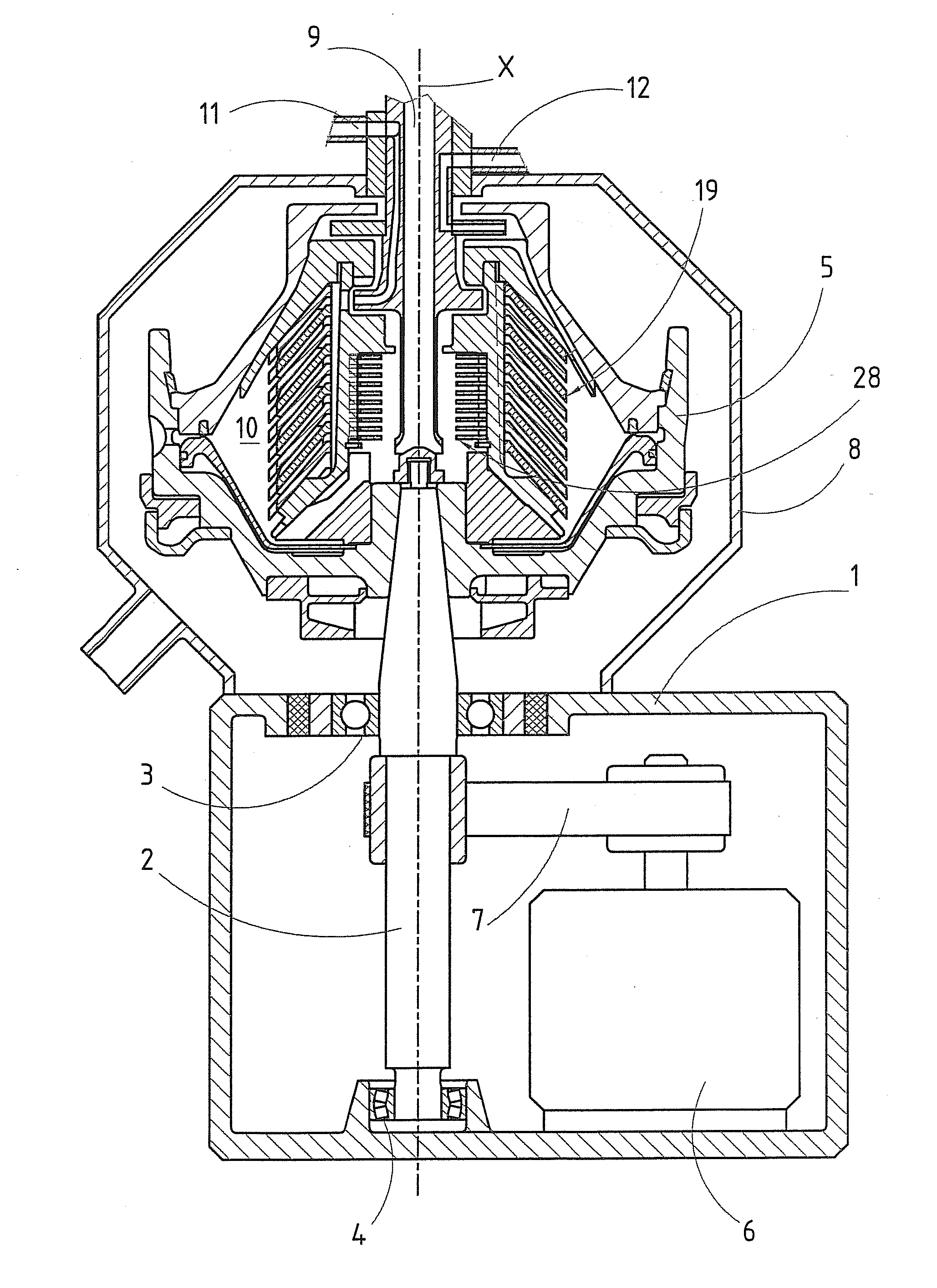

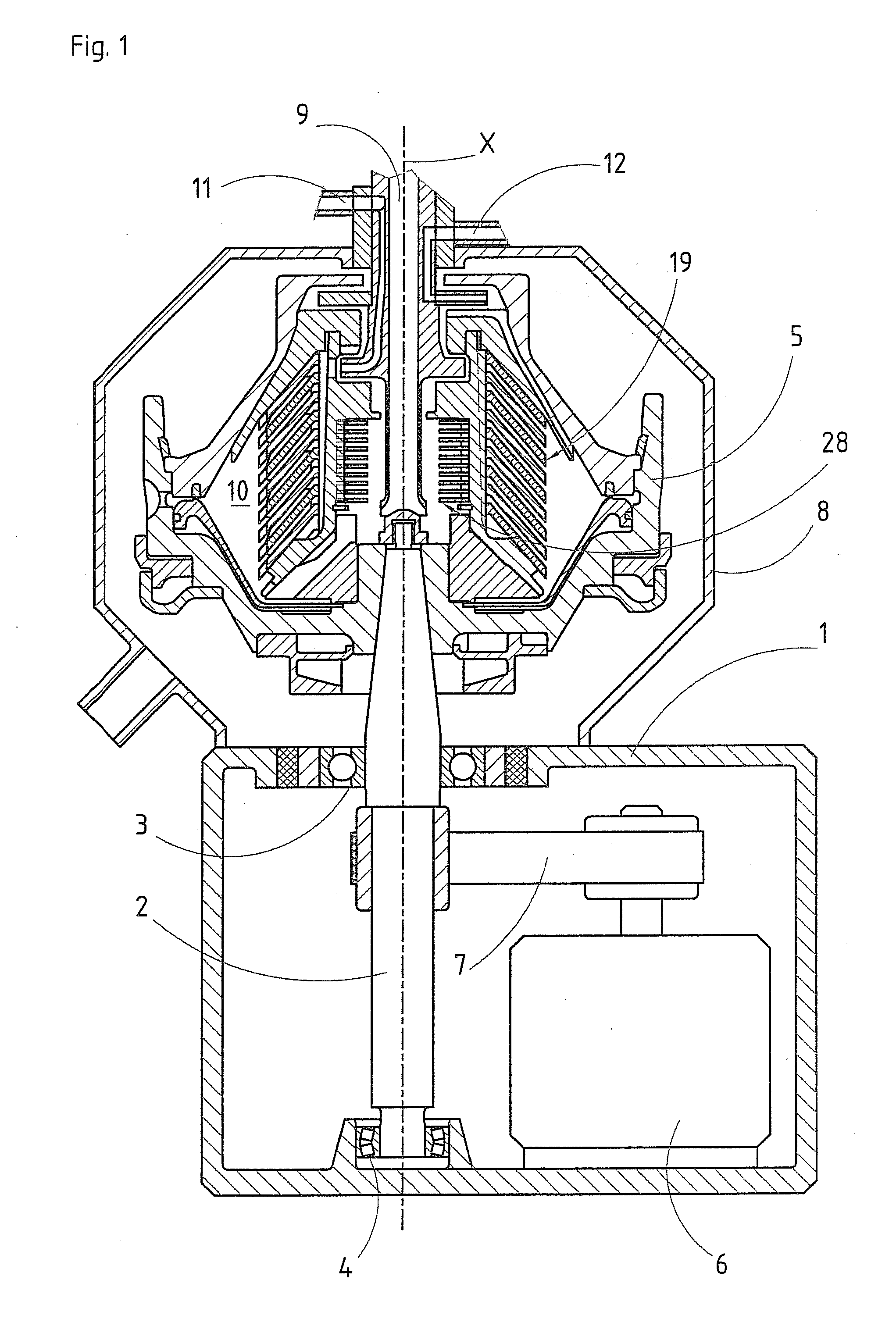

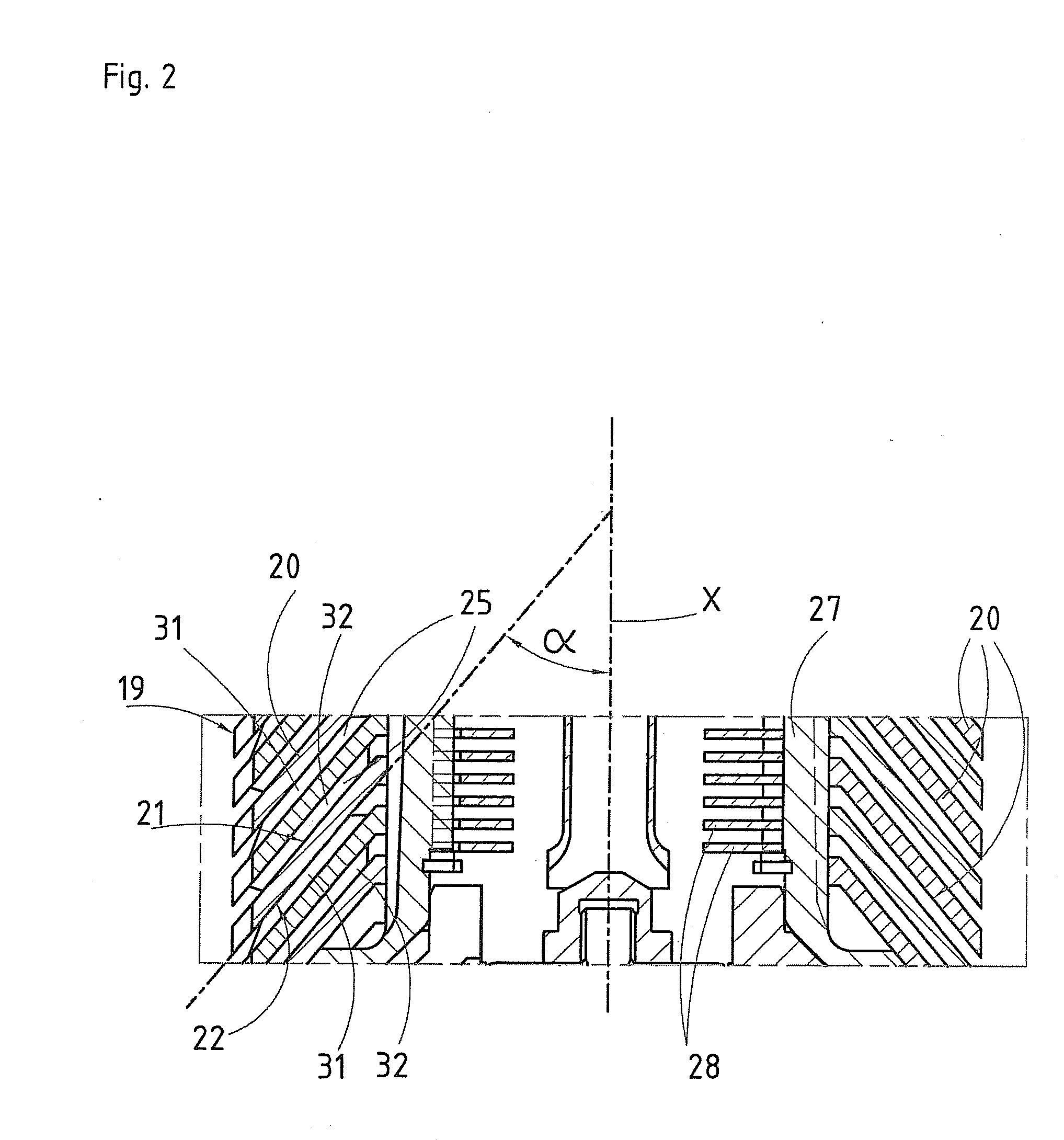

Disk package for a centrifuge rotor

InactiveUS20110237417A1Easy maintenanceGood hygienic propertiesRotary centrifugesEngineeringMechanical engineering

The invention refers to a disk package for a centrifuge. The disk package comprises a plurality of separating disks provided on each other in the disk package. Each separating disk extends around an axis of rotation for the centrifuge rotor and has tapering shape with an inner surface and an outer surface along the axis of rotation. Each separating disk has inner edge, defining a central opening of the separating disk, and outer edge. Each separating disk is manufactured of a material. The separating disks comprise a plurality of first separating disks comprising a number of distance members, which extend away from the inner surface and / or outer surface. Each distance member comprises at least one contact zone abutting an outer surface and inner surface, respectively, of an adjacent separating disk in the disk package. The contact zone has a continuously convex shape seen in a cross section.

Owner:ALFA LAVAL CORP AB

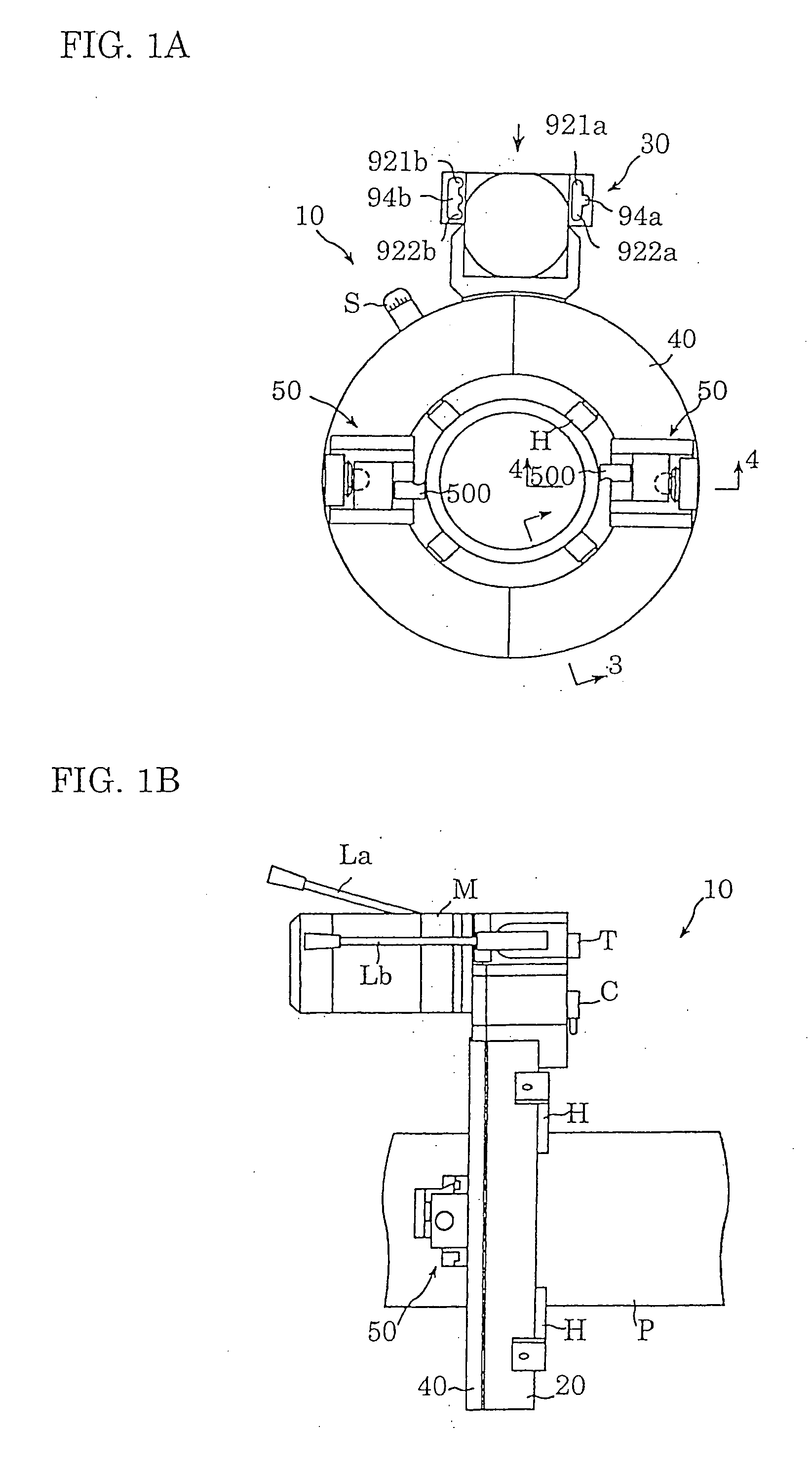

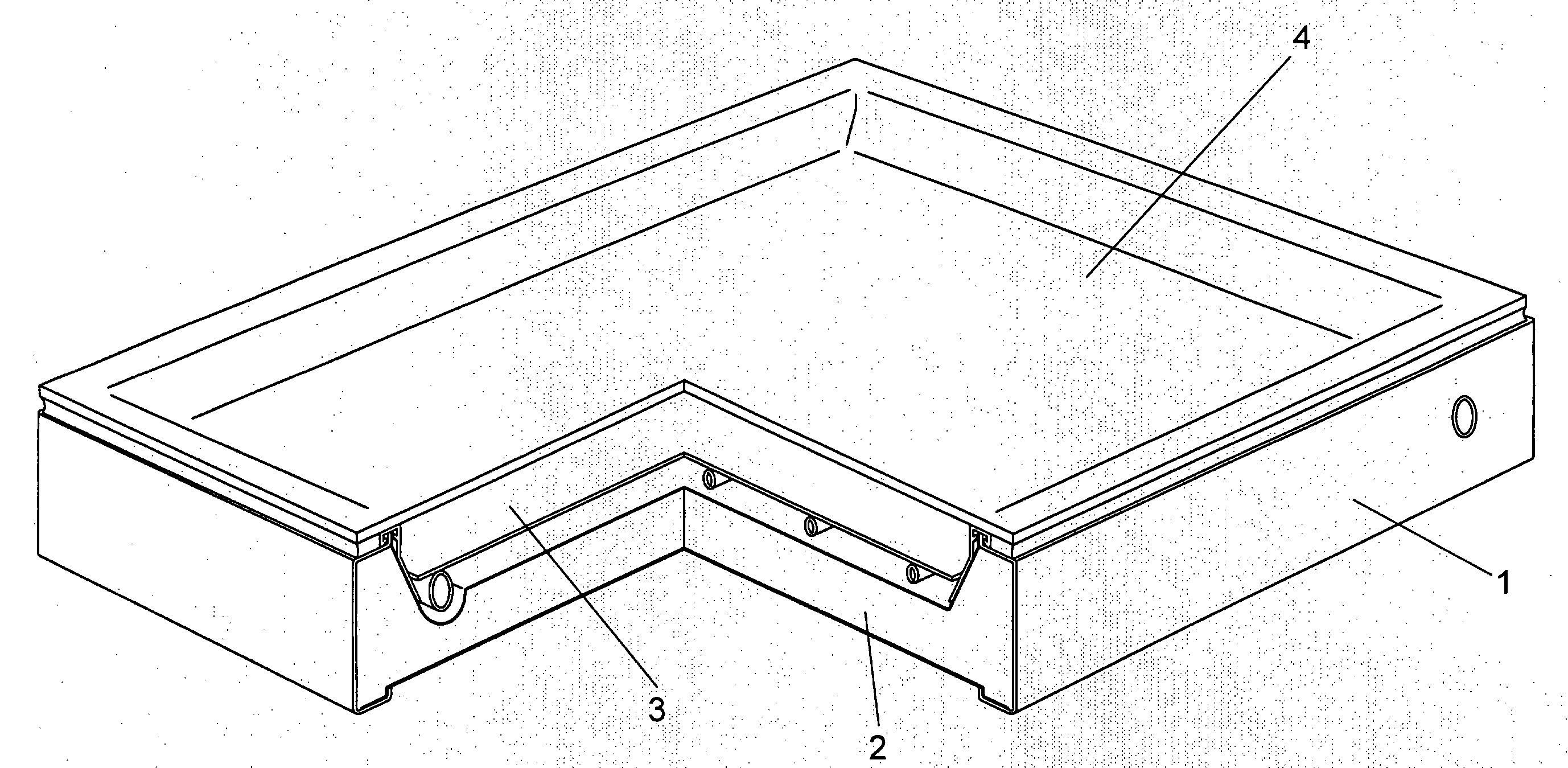

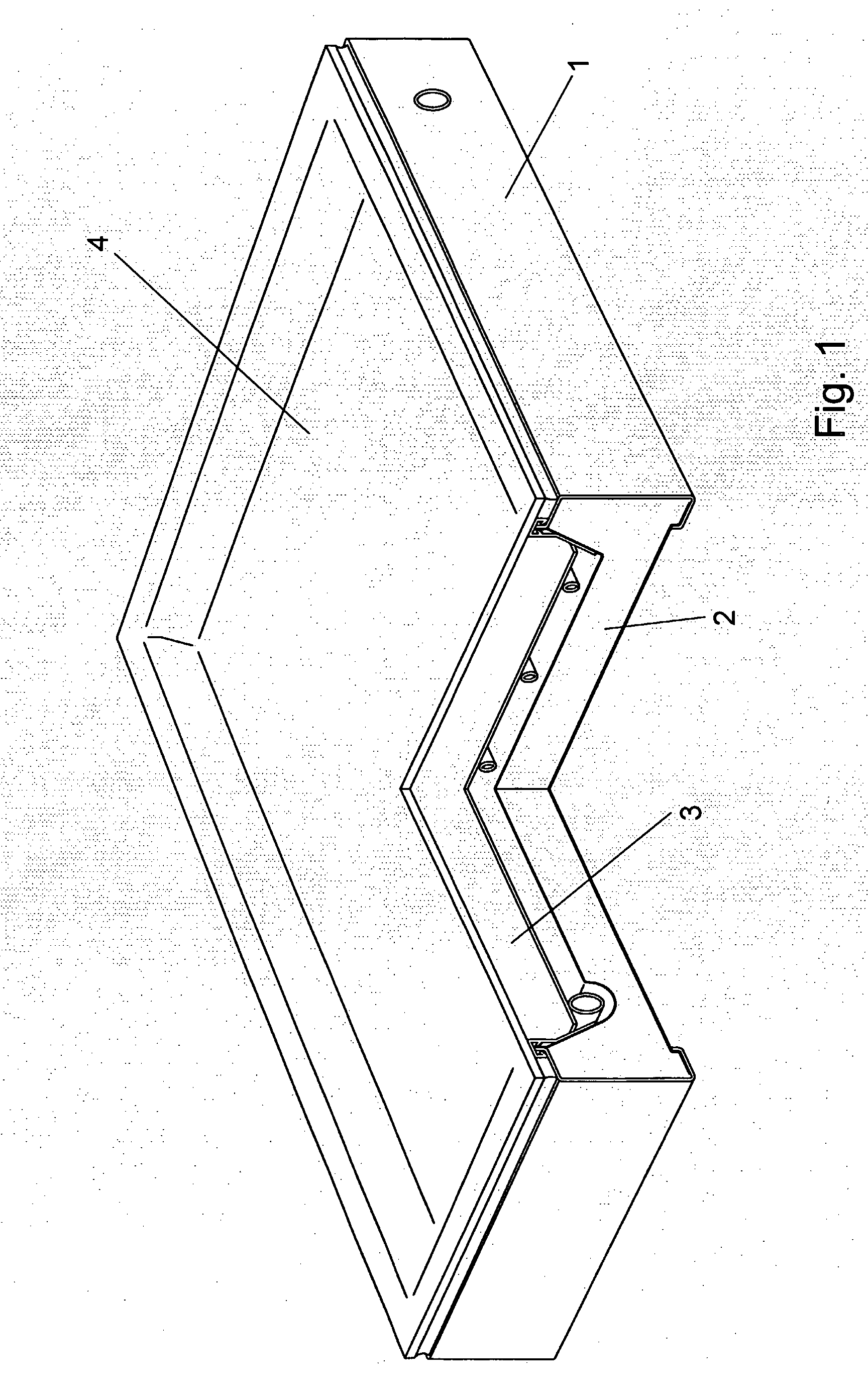

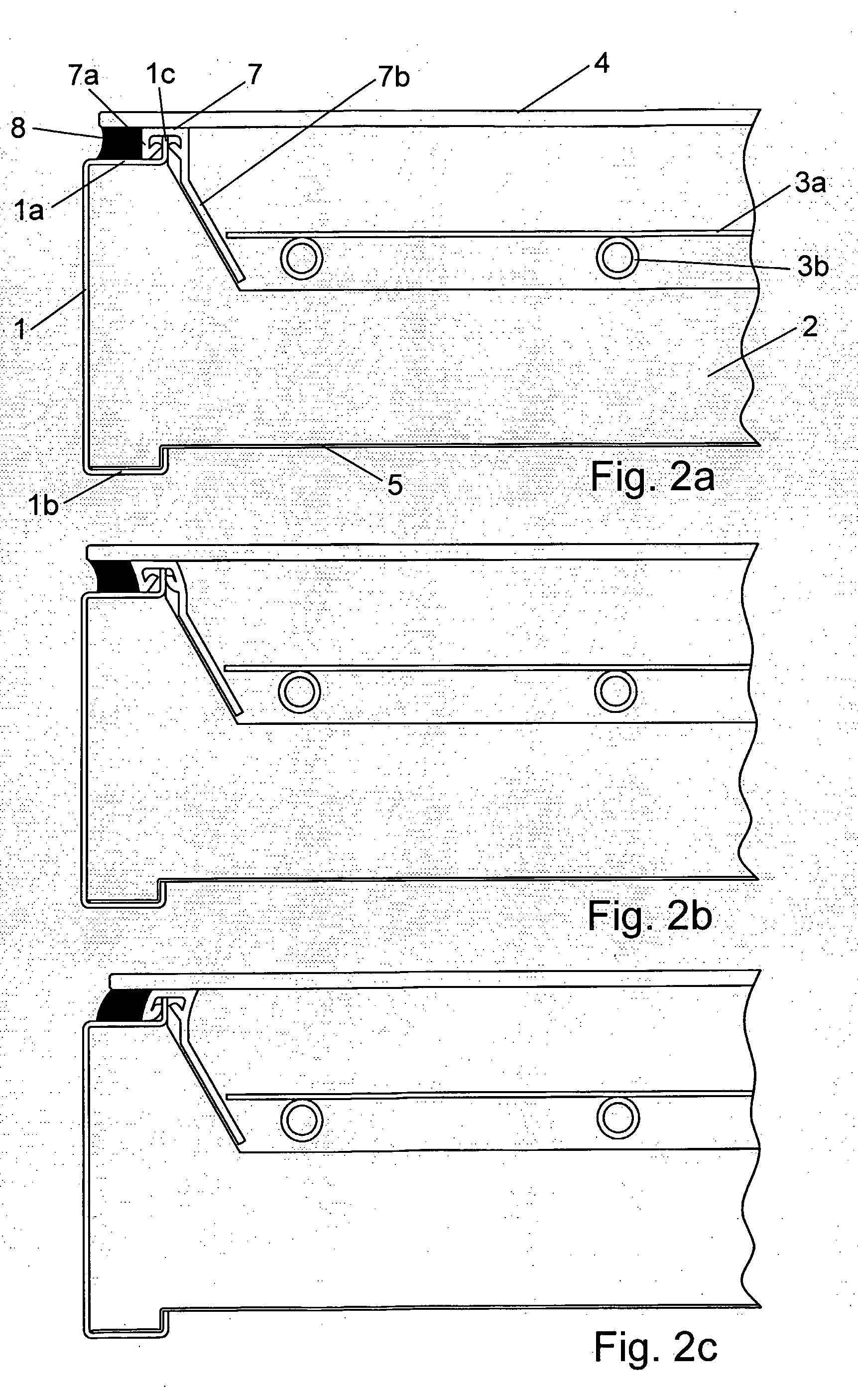

Solar Collector and Mounting Bracket

InactiveUS20090114209A1Reliable and flexibleEliminate riskSolar heating energyPipe supportsThermal expansionEngineering

A solar collector with a rectangular frame (1), preferably made of extruded or rollformed metal, containing an absorber plate (3), an insulating layer (2) beneath the absorber plate (3), and a cover pane (4) spaced above the absorber (3). Absorber tubing (3b.3c) is attached to the rear side of the absorber plate. The absorber (3) is secured to the frame (1) by mounting brackets (11a,11b) that engage the absorber tubing (3b,3c) and allow for substantially unhindered thermal expansion and contraction of the absorber. The collector can be integrated or roof mounted on a pitched roof, or may be installed on a flat roof by means of a mounting frame.

Owner:VKR HLDG AS

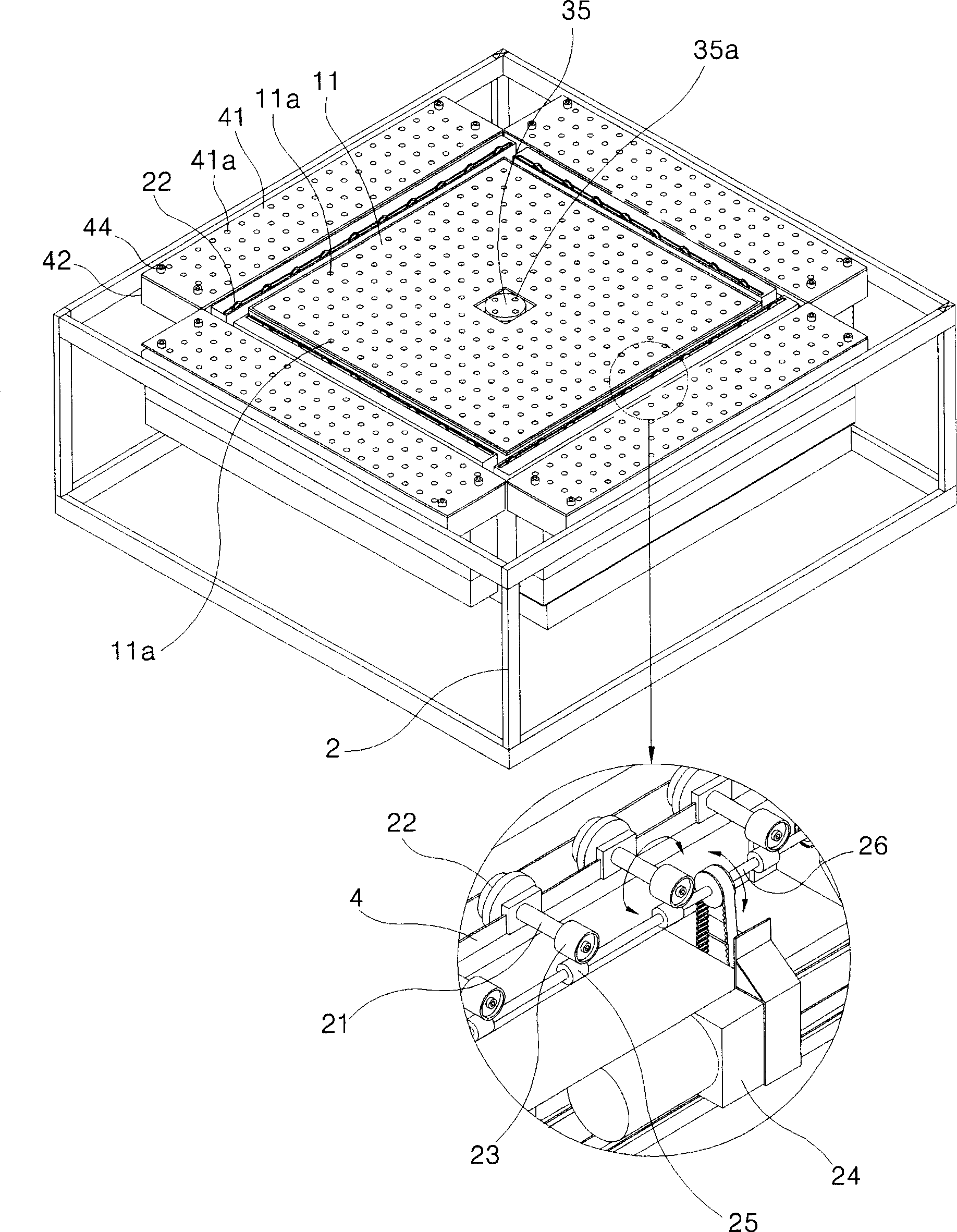

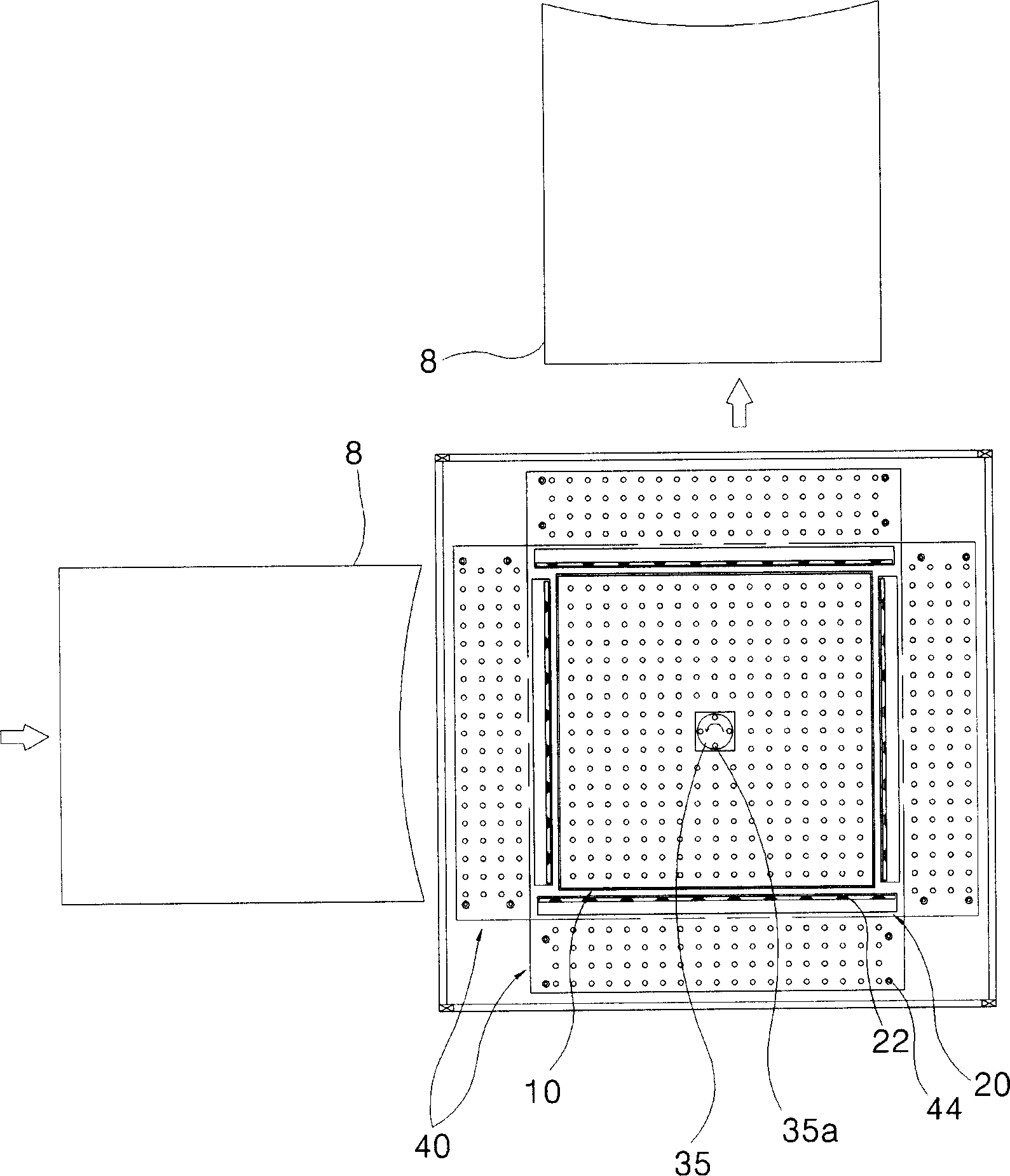

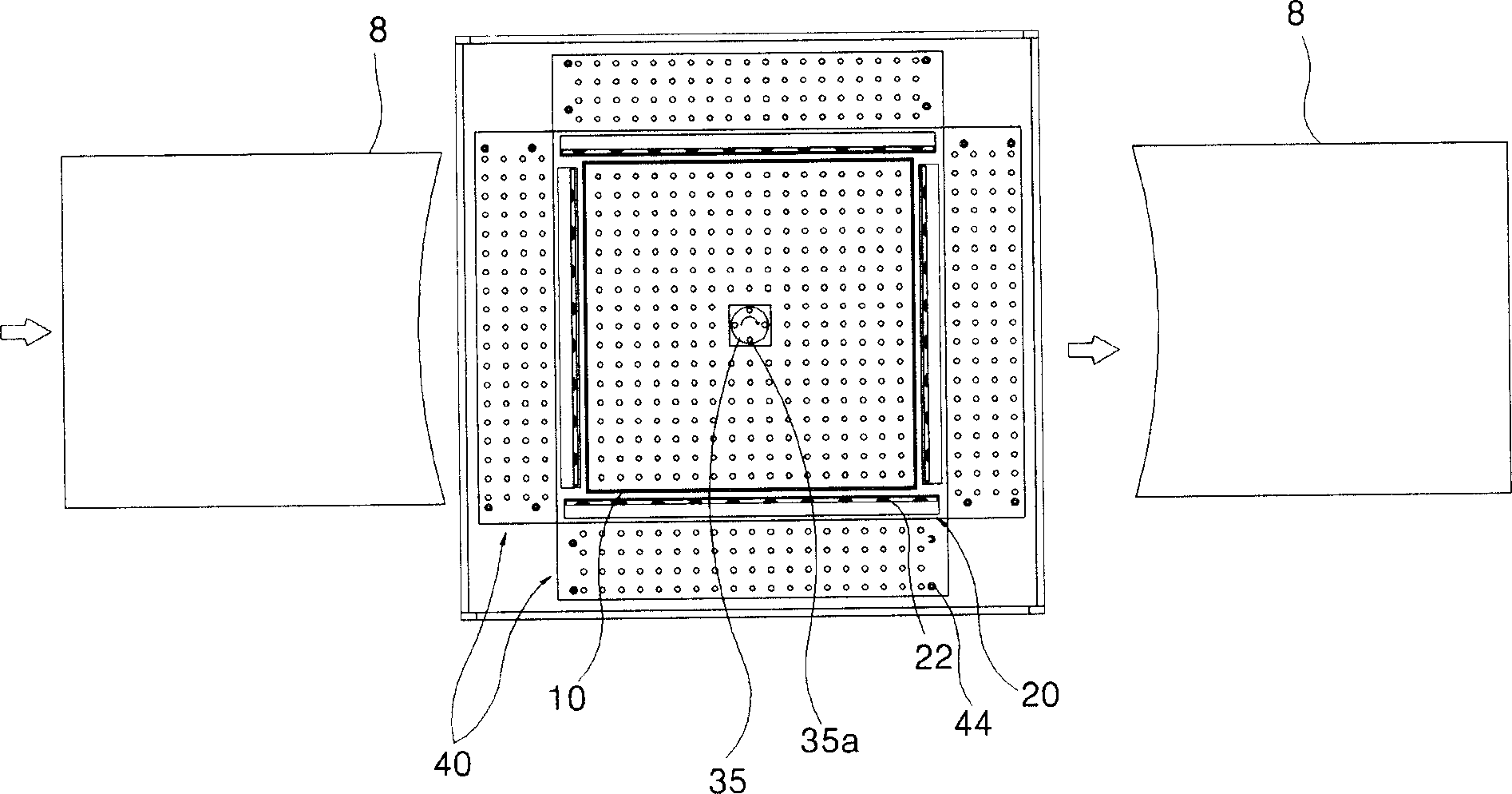

Plate glass direction conversion device

InactiveCN1891648AReduce surface damageSimple structureGlass transportation apparatusBulk conveyorsFlat glassMiniaturization

A direction changing device for flat glass minimizes the load on the flat glass by floating in the air, so that the flat glass is rotated in place and transferred in a specified direction. The flat glass direction changing device of the present invention comprises: an air ejector, comprising an air chamber and a fan box, the air chamber has an ejection plate for the air to float the flat glass, and the fan box is provided with an air jet fan for supplying air to the air chamber The roller transfer machine is arranged on the adjacent part of the outer peripheral surface of the air ejector, and has a plurality of rollers for transferring the flat glass in a prescribed direction; the rotary machine is arranged in the central part of the air ejector, so that the The flat glass is rotated in place. In the state of the flat glass floating in the air, the shaft rotates and transfers the flat glass, which not only minimizes the contact area between the flat glass and the roller and reduces the surface damage of the flat glass, but also simplifies the structure of the direction changing device regardless of the size of the flat glass , thereby miniaturizing the power and structure of the rotating equipment.

Owner:TAE SUNG ENG

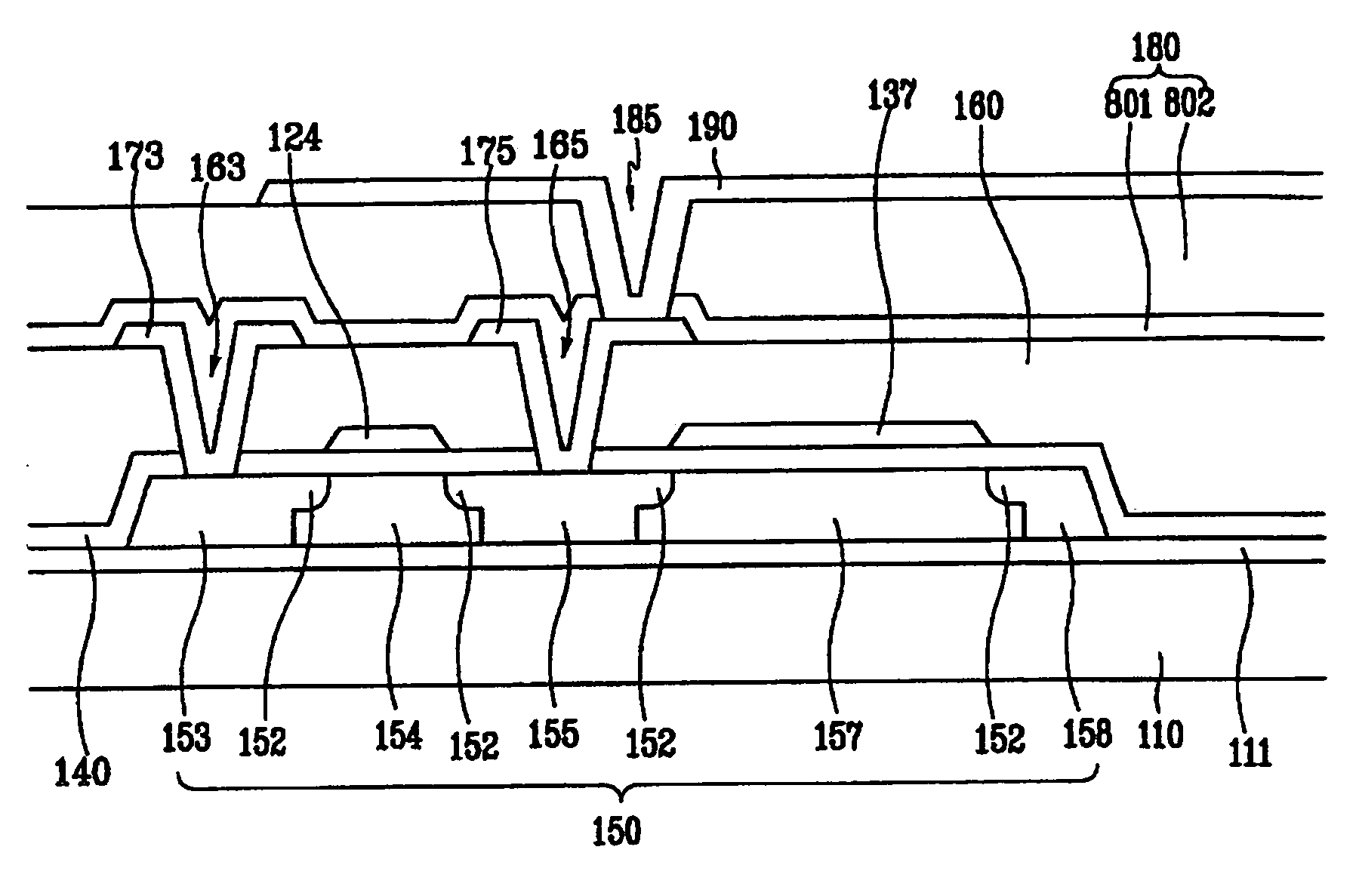

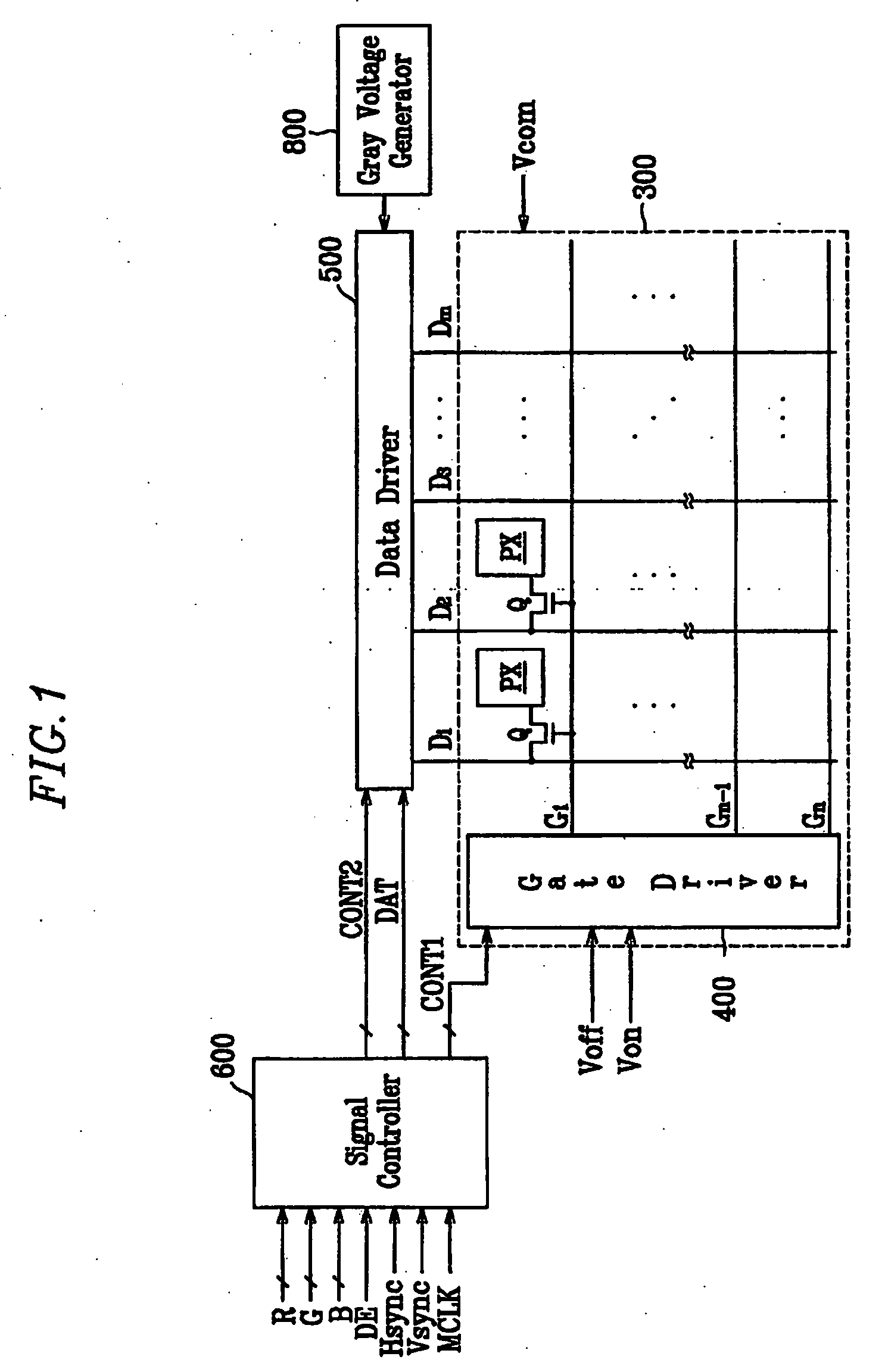

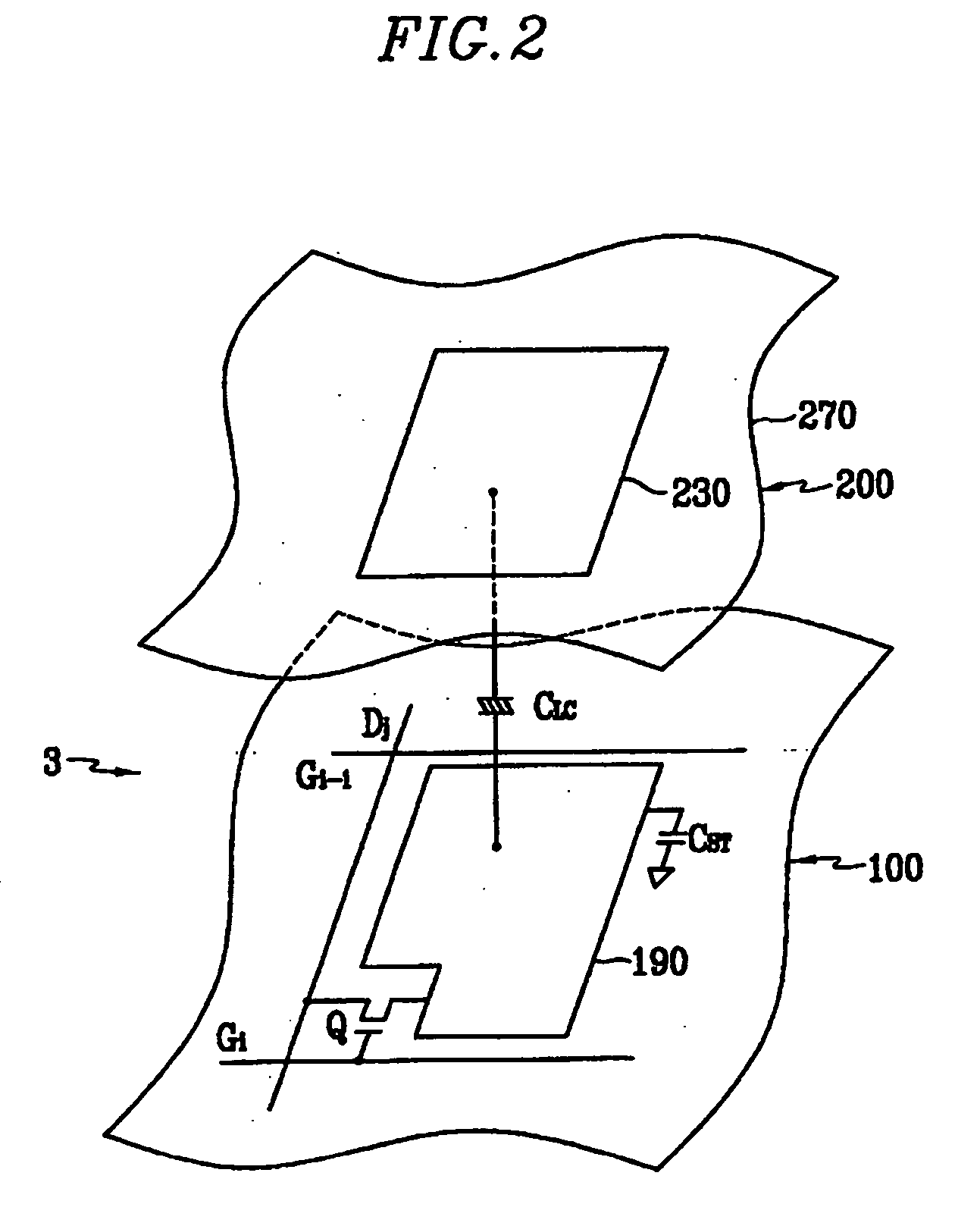

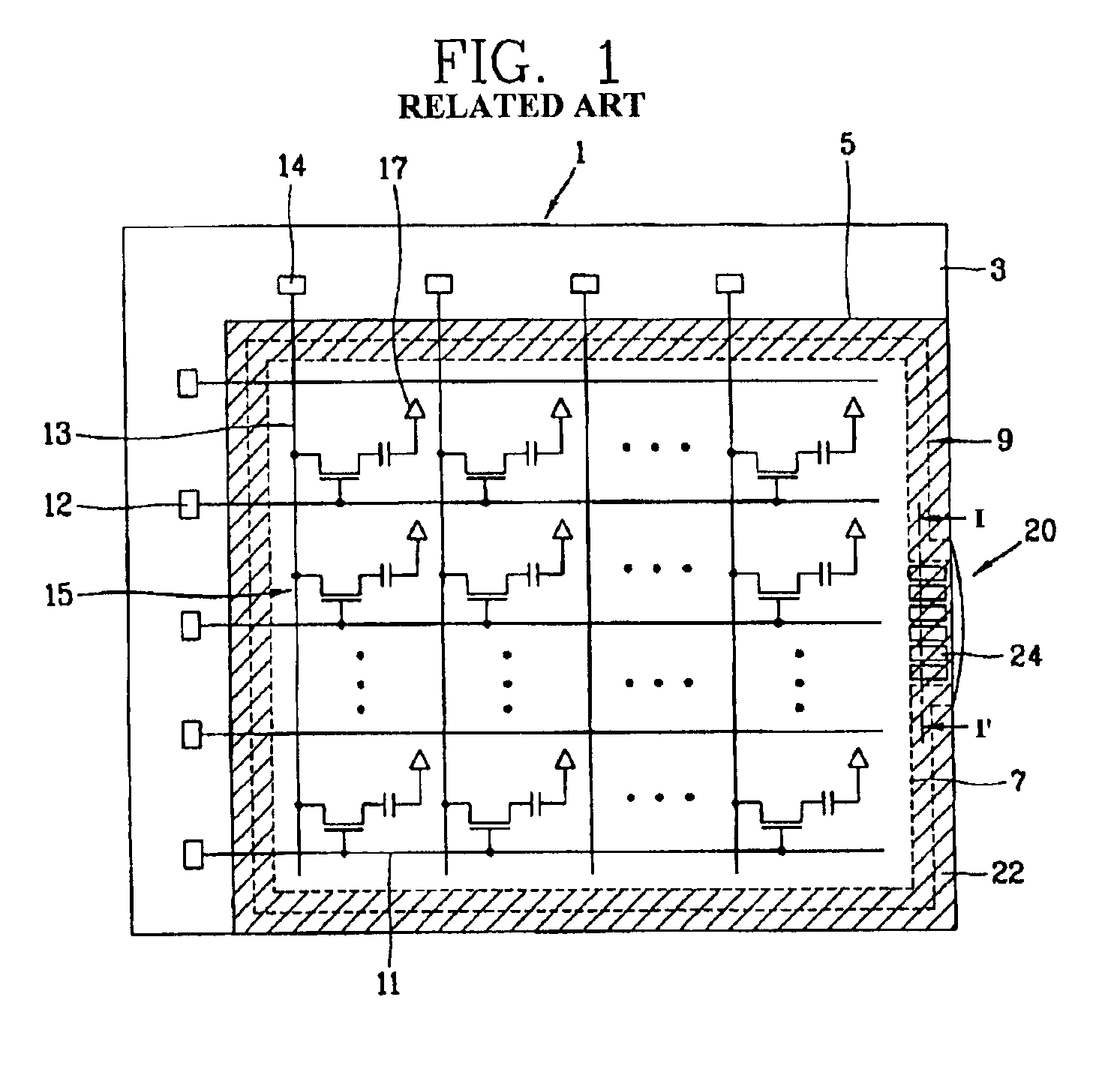

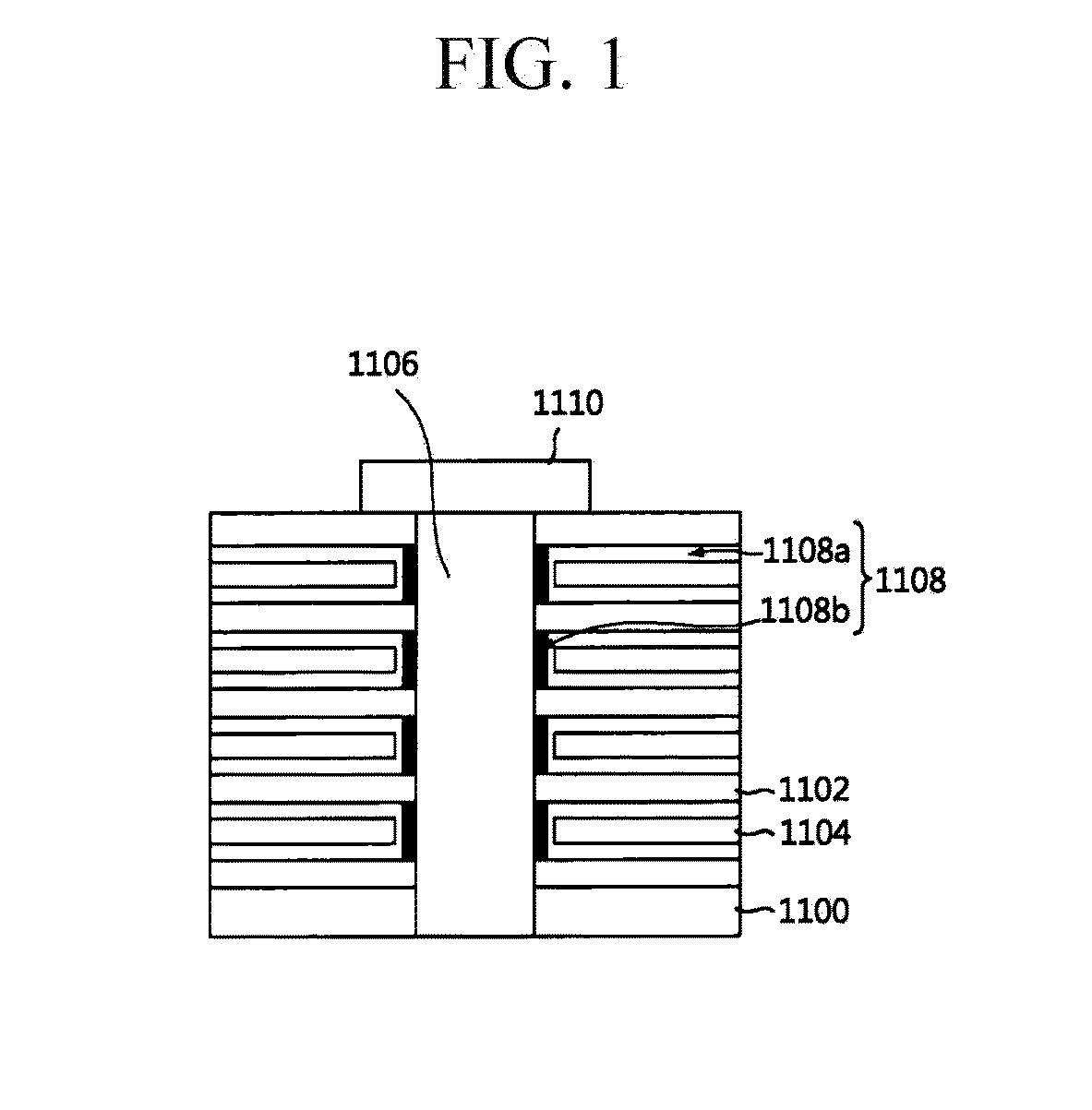

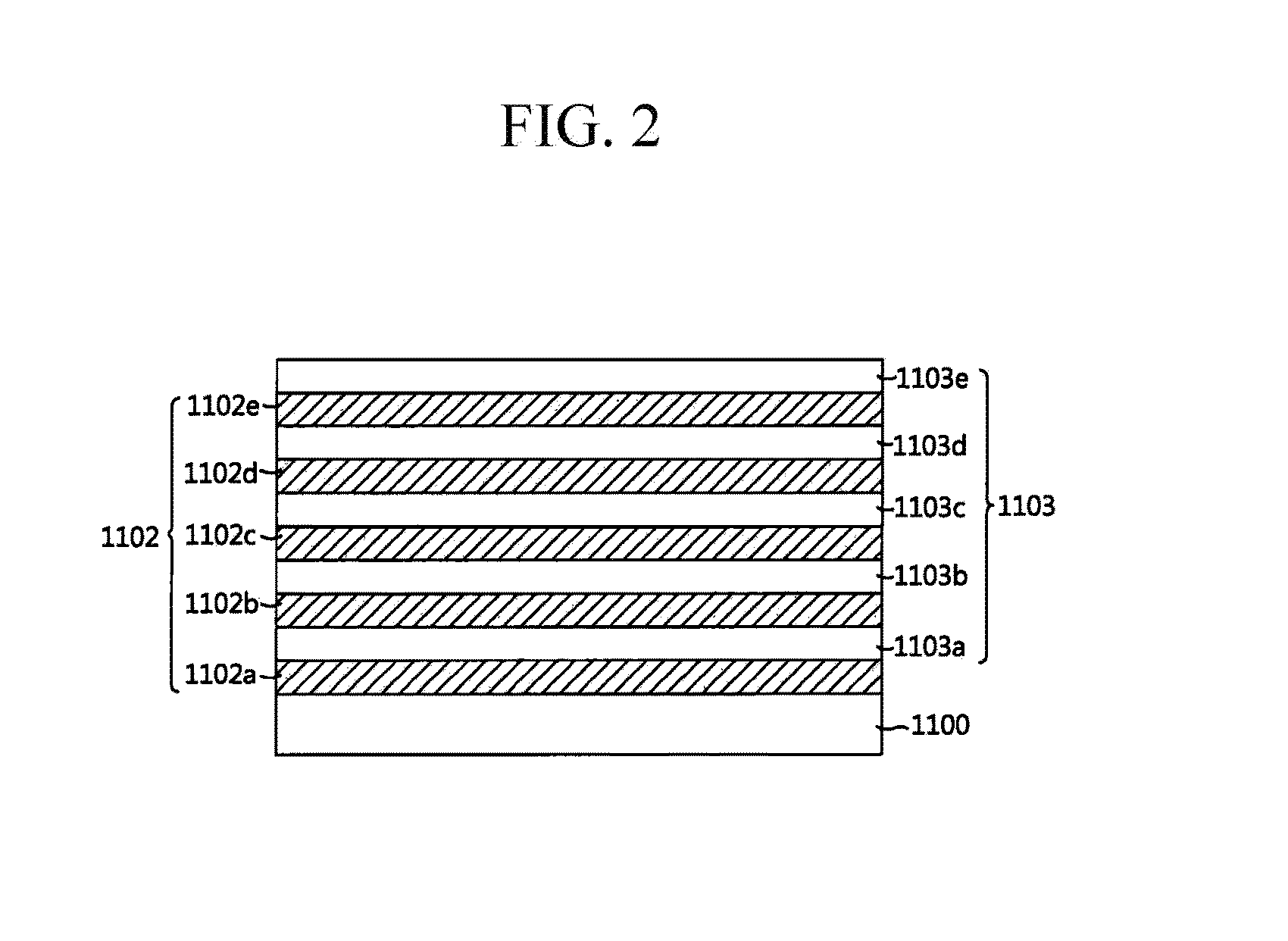

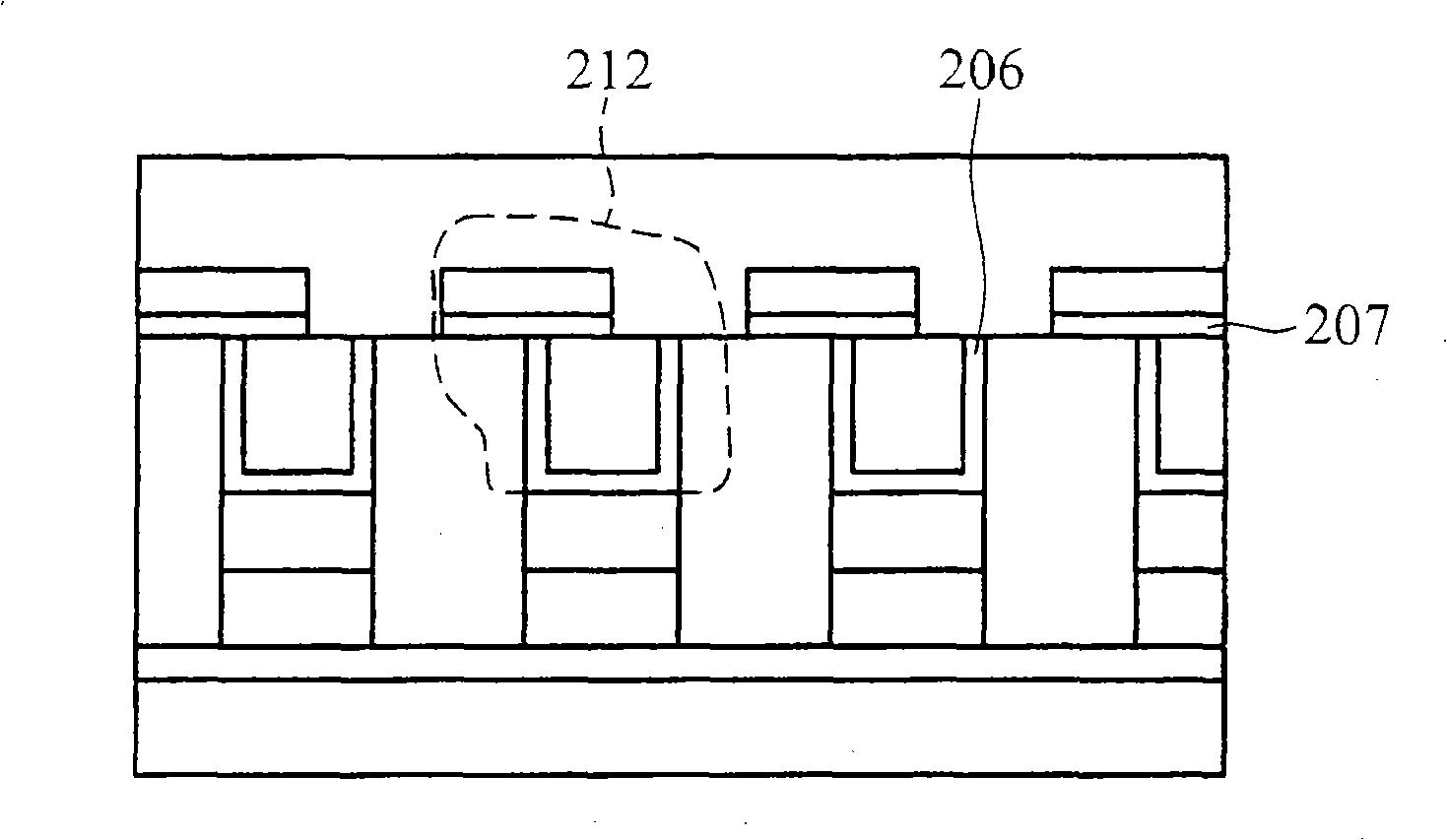

Thin film transistor array panel

ActiveUS20060049407A1Low resistivityAvoid signal delaySolid-state devicesNon-linear opticsTransistorElectrical and Electronics engineering

Improved thin film transistor array panels are provided. In one embodiment, a panel includes a plurality of gate lines, data lines, and a plurality of switching elements connected to the gate lines and the data lines. An interlayer insulating layer is formed between the gate lines and the data lines. A passivation layer covering the gate lines, the data lines, and the switching elements is also provided having a plurality of first contact holes exposing portions of the data lines, wherein the switching elements and the pixel electrodes are connected through the first contact holes. A plurality of contact assistants are formed on the passivation layer and are connected to the data lines through a plurality of second contact holes in the passivation layer. A plurality of auxiliary lines are connected to the data lines through a plurality of third contact holes in the interlayer insulating layer.

Owner:SAMSUNG DISPLAY CO LTD

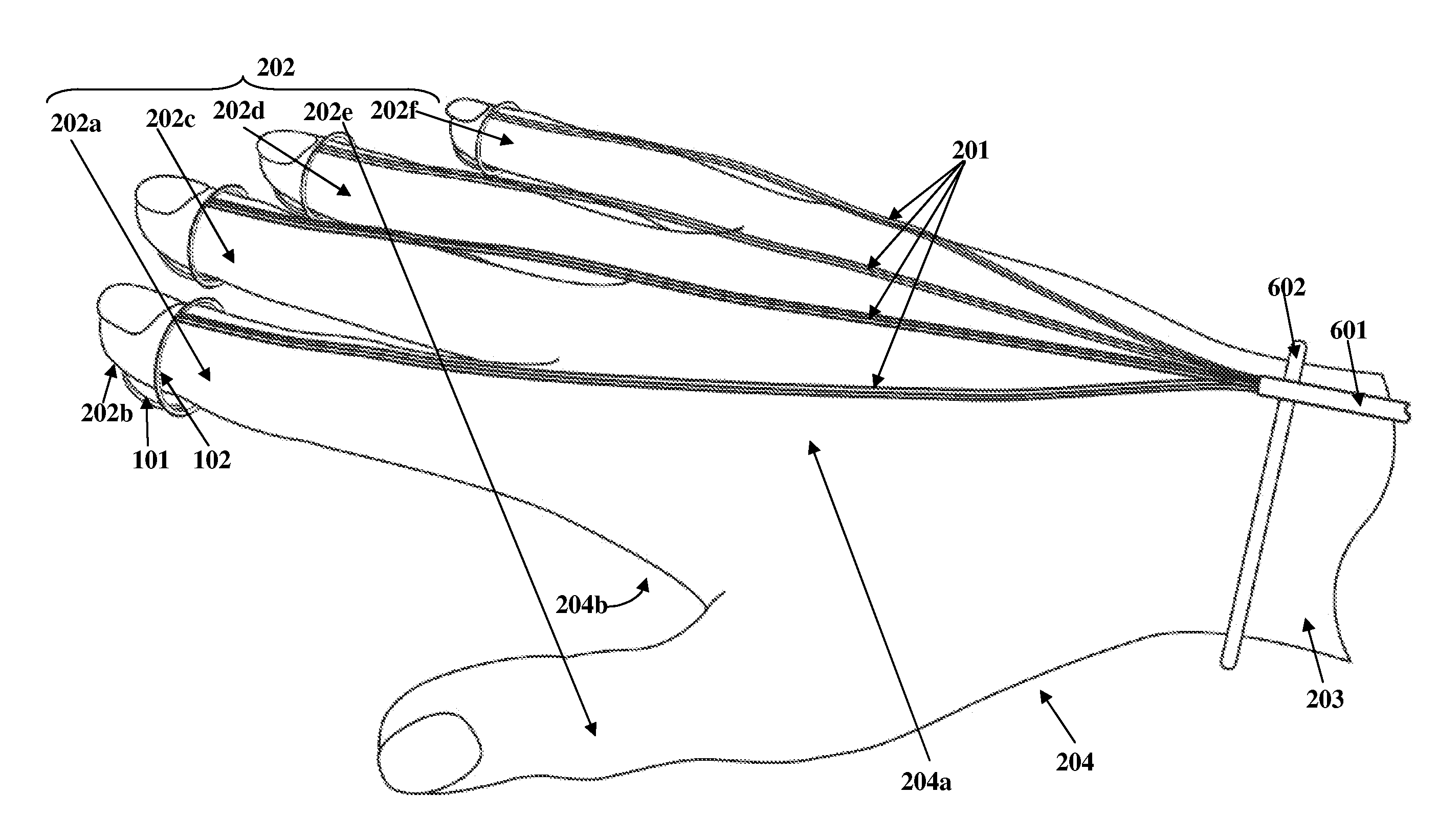

Apparatus and methods for optimizing anchoring force

ActiveUS8206417B2Prevent overcompressionMinimized contact areaSuture equipmentsDiagnosticsConstant forceStrain gauge

Apparatus and methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

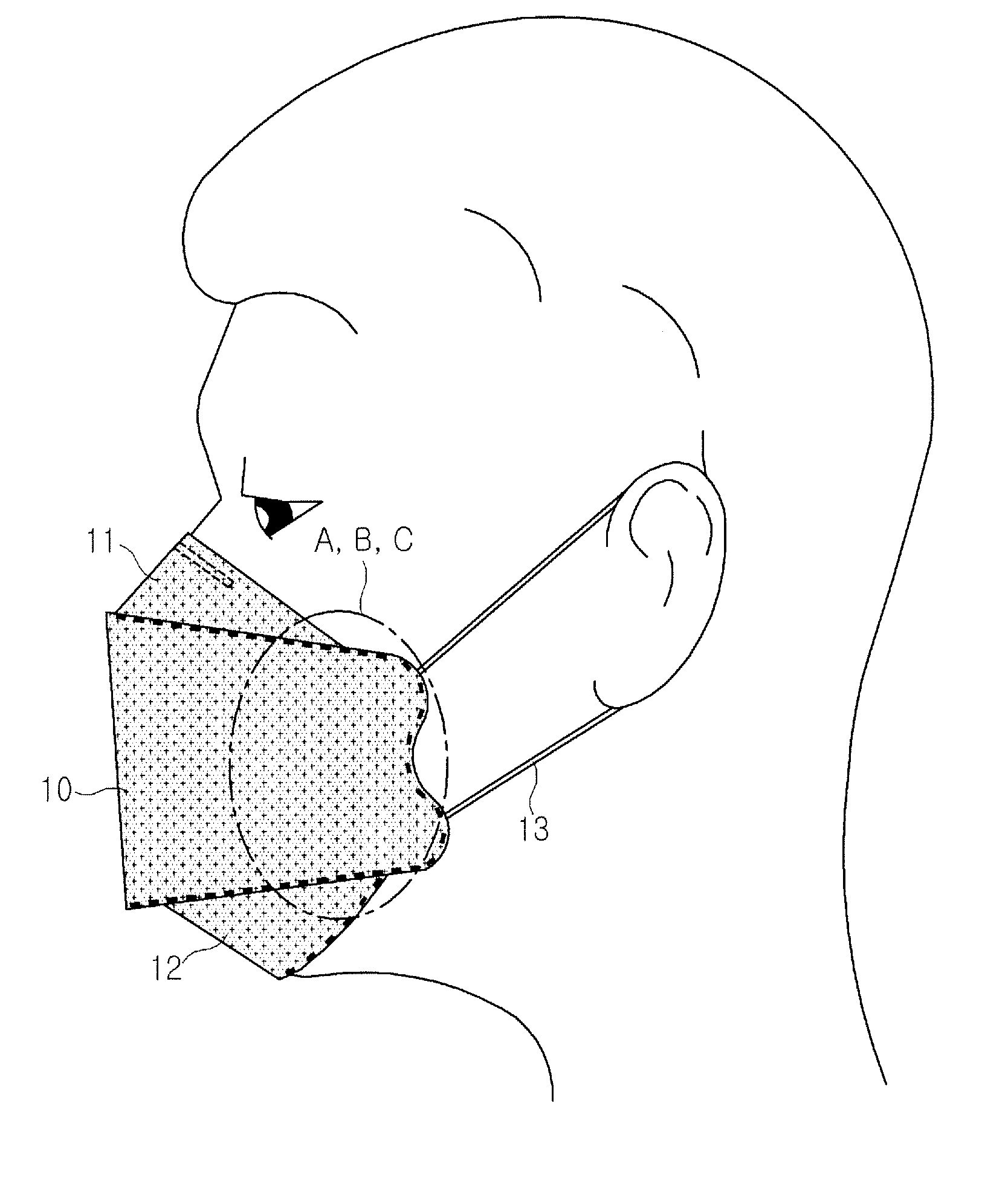

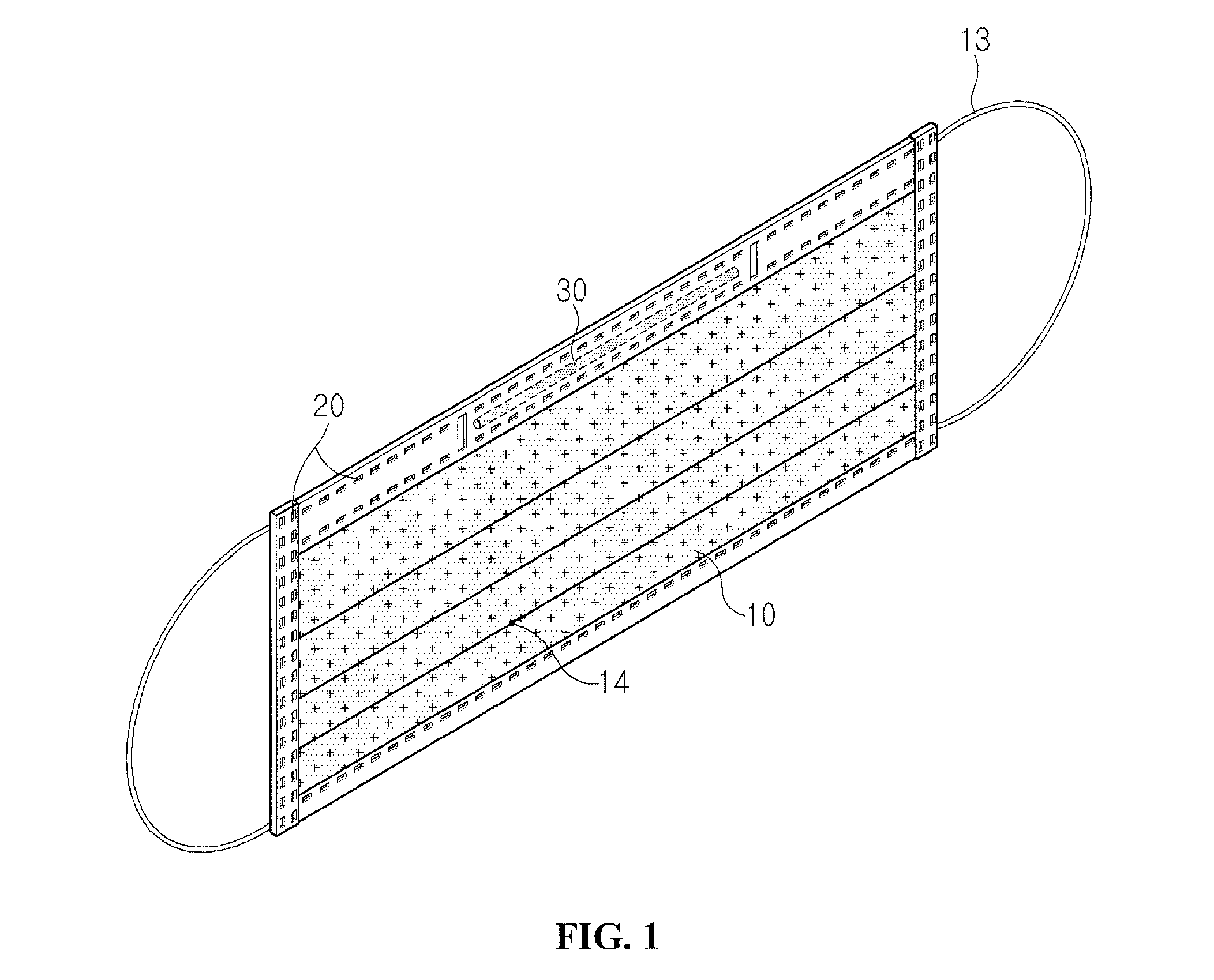

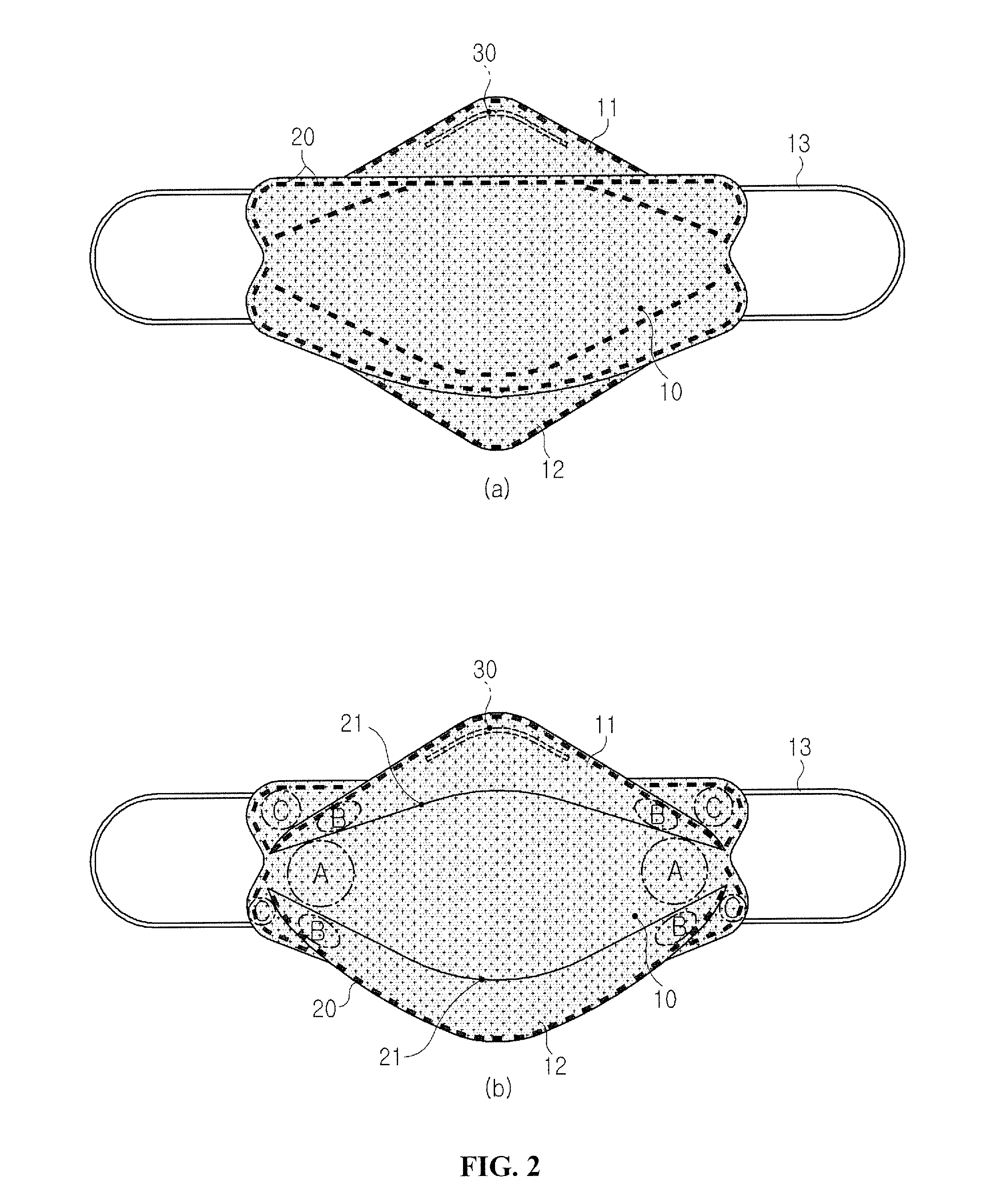

Four-sided dustproof mask

InactiveUS8251065B2Minimized contact areaIncreasing dust-filtering area of filterBreathing filtersBreathing masksChinLow-pass filter

The present invention relates to a four-sided dustproof mask including: an upper filter adapted to surround a wearer's nose area; a lower filter adapted to surround the wearer's chin area; and a protruded center filter adapted to attach the upper filter and the lower filter thereto in such a manner as to make the both ends of the upper filter and the lower filter correspond to center points formed at the both ends of a curved folding line dividing the protruded center filter into two sides, the curved folding line having a straight line portion having a predetermined length protrudedly extended from the center points thereof, whereby while the upper filter and the lower filter are being developed, the protruded center filter is protruded to a dome-like shape.

Owner:JANGJUNG CO LTD

Cutting, profiling, and edge-preparing apparatus

InactiveUS7320268B2Formed in shape with easeImprove accuracyPortable latheMetal working apparatusEngineeringKnife holder

An apparatus for cutting and / or profile machining an edge of a pipe is provided. The apparatus includes a housing, a rotatable faceplate mounted on a front surface of the housing, and a tool holder mounted on the faceplate and holding a cutting tool. In a first embodiment, a cutting apparatus includes gearing that permits the tool holder to be moved relative to a surface of a pipe in a rapid-feed mode, a slow-feed mode and a rapid-return mode. In second and third embodiments, a profile machining apparatus includes a carriage having a profiling roller or shaft that advances (or retracts) relative to a pipe along a path defined by a template. The carriage to which the cutting tool is mounted is pivoted about a support shaft permitting the carriage and tool to change its angle and orientation relative to the pipe while advancing or retracting.

Owner:MORI KENICHI

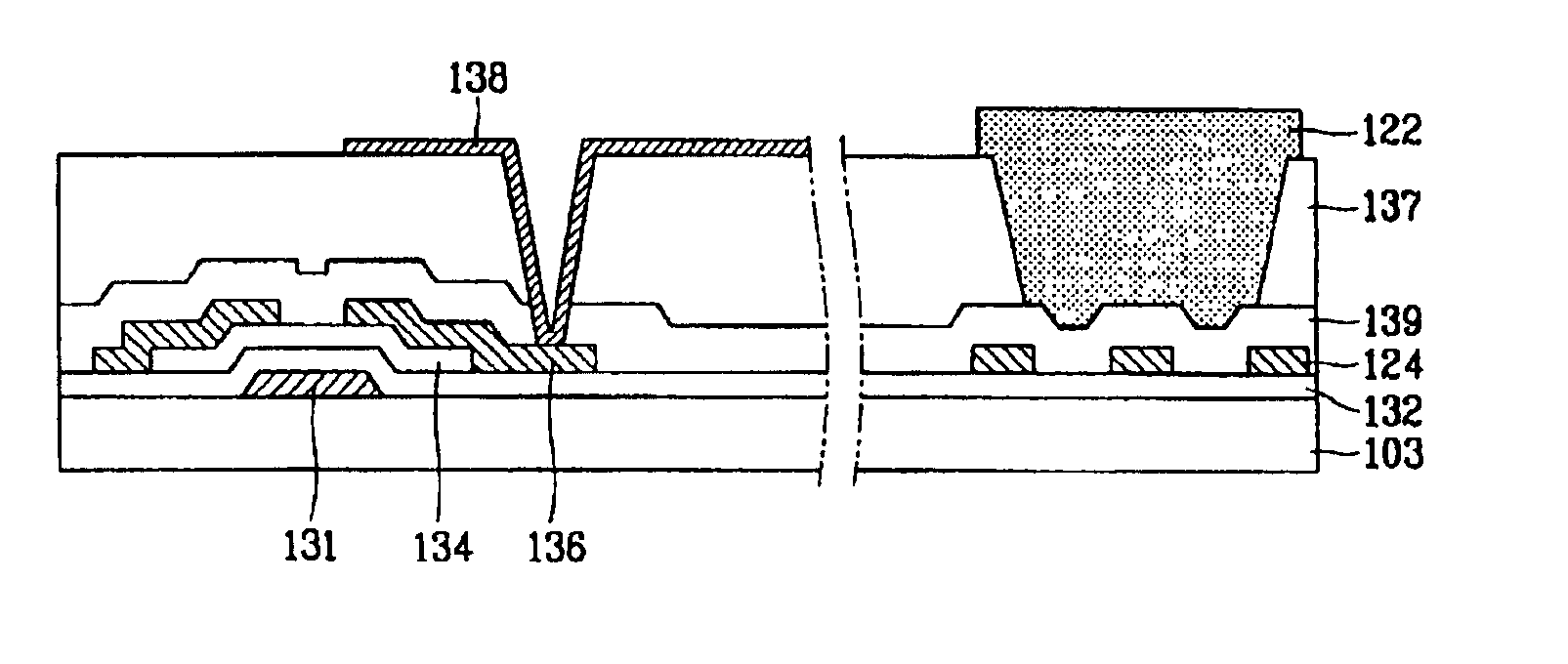

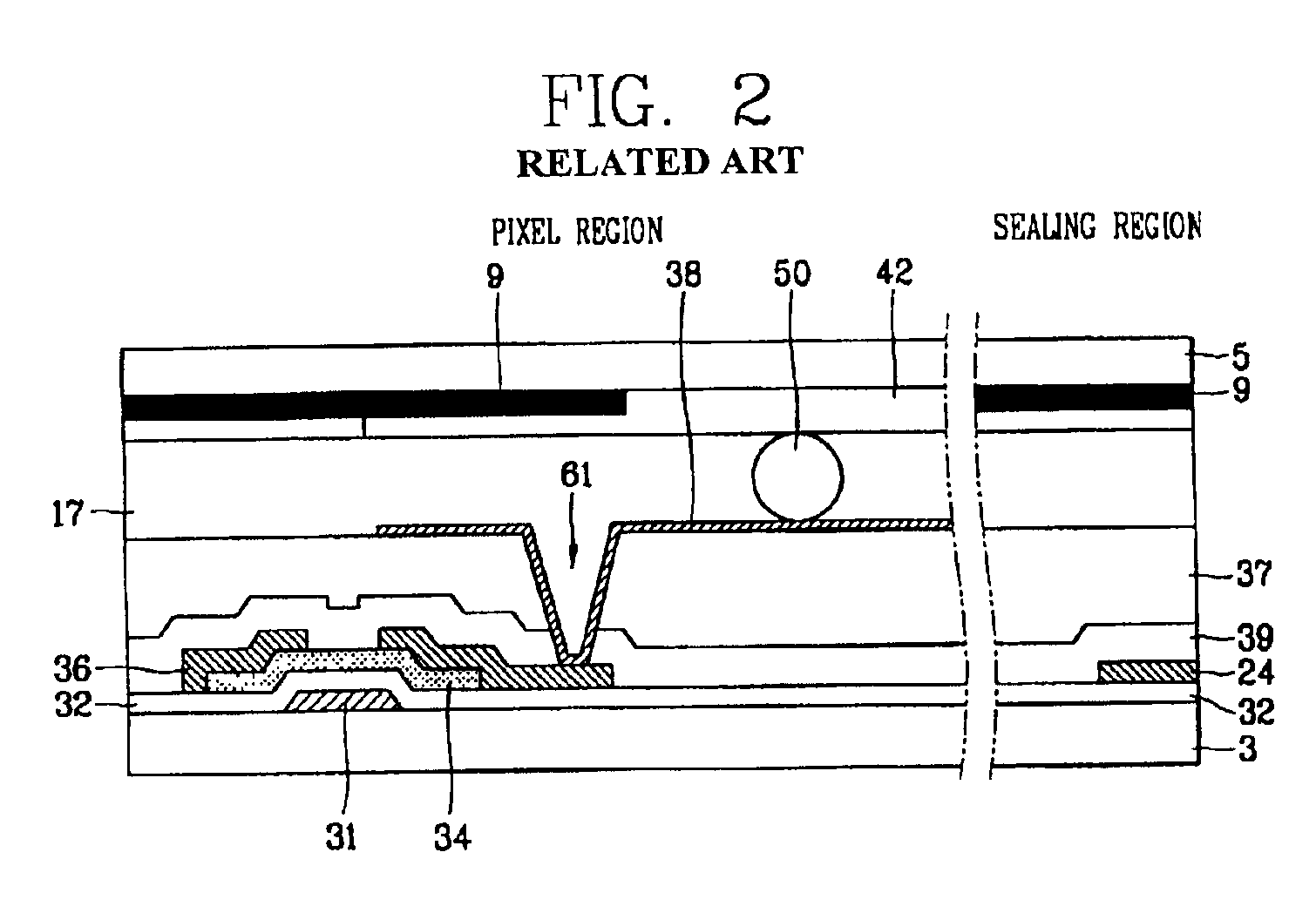

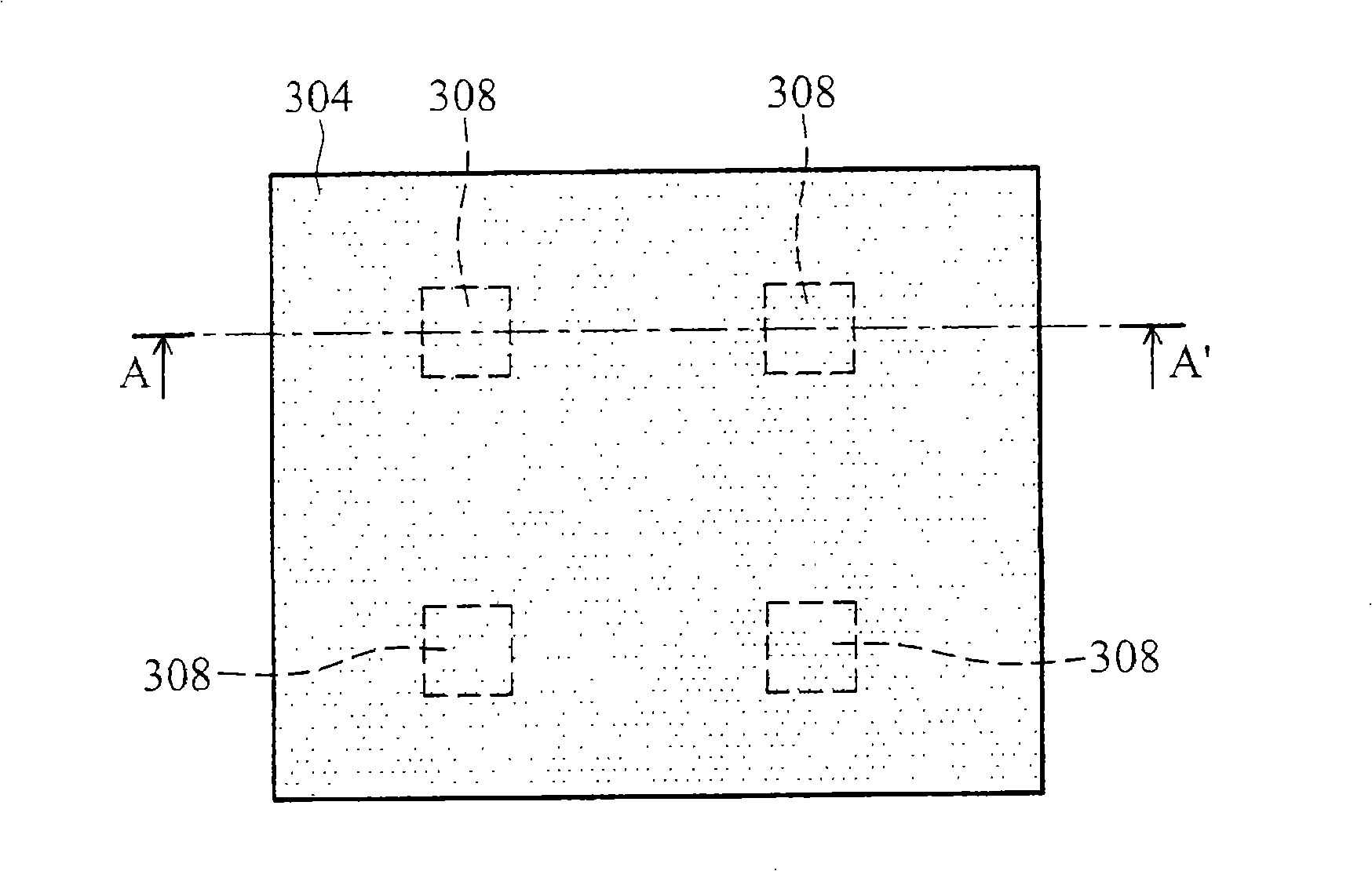

Liquid crystal display device and method for fabricating the same

InactiveUS6859254B2Improve adhesionMinimized contact areaNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display device includes a first substrate having a plurality of thin film transistors and a plurality of metal lines, a first insulation material layer formed on the metal lines, a second insulation material layer formed on the first insulation material layer on the metal lines, a first hole formed in the second insulation material layer over at least two of the metal lines, a second contact hole formed in the first and second insulation layers exposing a drain electrode of the thin film transistors, a pixel electrode connected to the drain electrode through the second contact hole, a sealing material formed within the first hole, a second substrate bonded to the first substrate via the sealing material, and a liquid crystal material disposed between the first and second substrates.

Owner:LG DISPLAY CO LTD

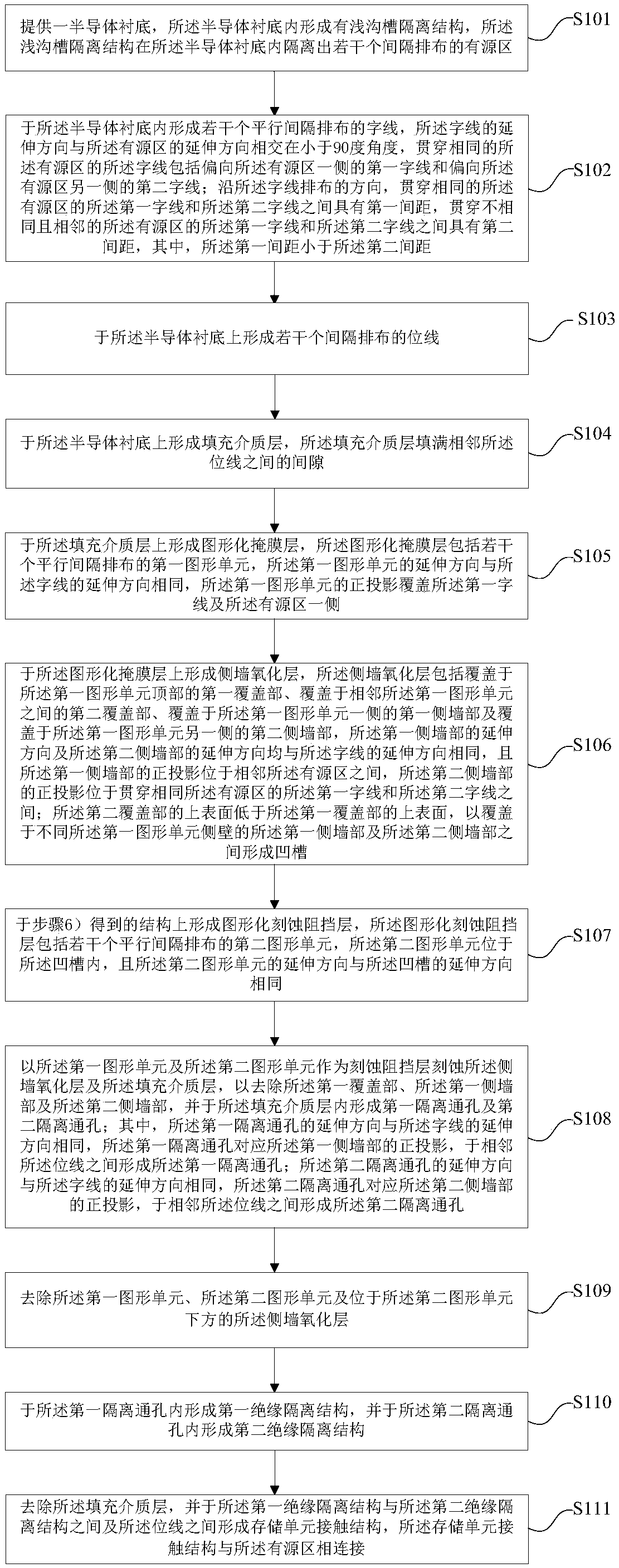

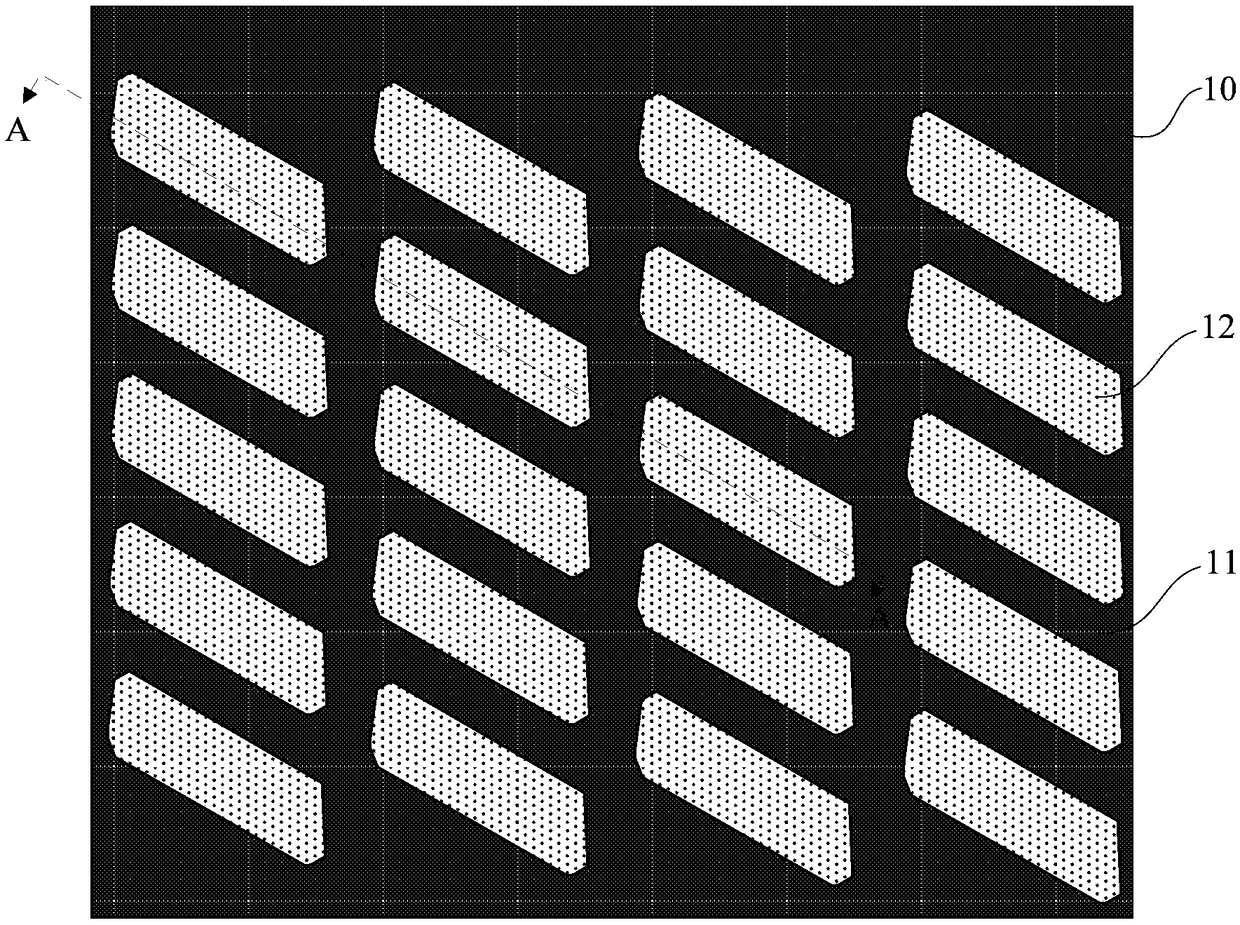

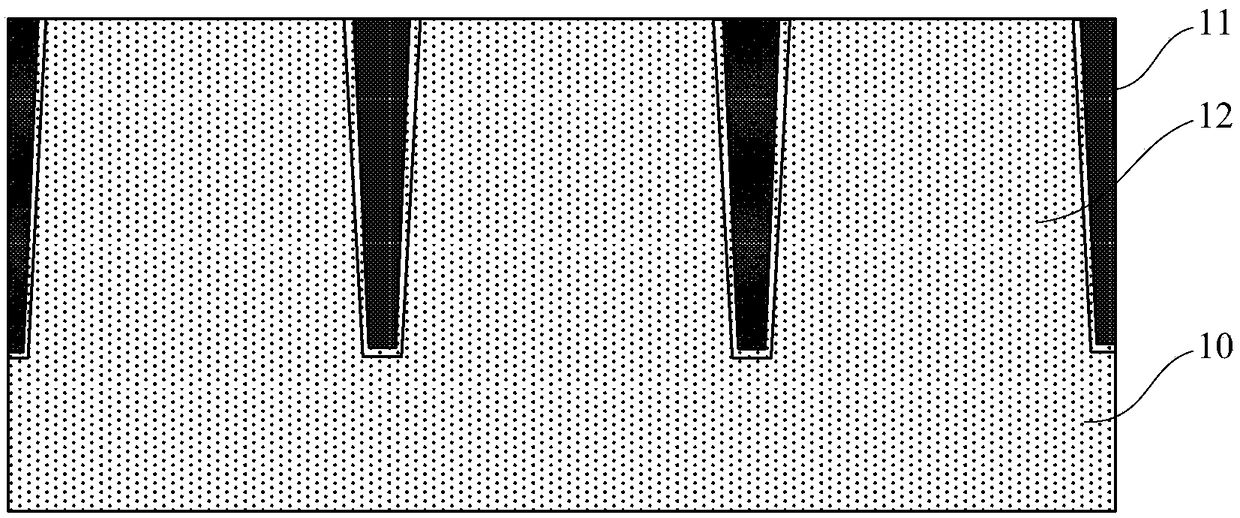

Semiconductor structure, memory structure and manufacturing method thereof

ActiveCN108933136AReduce contact resistanceMaximize contact areaTransistorSemiconductor/solid-state device manufacturingElectrical conductorSemiconductor structure

The invention provides a semiconductor structure, a memory structure and a manufacturing method thereof. The method comprises the following steps: 1) a semiconductor substrate is provided; 2) a word line is formed in the semiconductor substrate; 3) a bit line is formed on the semiconductor substrate; 4) a filling dielectric layer is formed on the semiconductor substrate; 5) a graphical mask layeris formed on the filling dielectric layer; 6) a side wall oxide layer is formed on the graphical mask layer; 7) a graphical etching barrier layer is formed on the structure obtained in the step 6); 8)a first isolation through hole and a second isolation through hole are formed in the filling dielectric layer; 9) a first graphical unit, a second graphical unit and a side wall oxide layer below thesecond graphical unit are removed; 10) a first insulation isolation structure is formed in the first isolation through hole, and a second insulation isolation structure is formed in the second isolation through hole; and 11) the filling dielectric layer is removed, and a conductive plug is formed. The conductive plug can realize reduction of contact resistance between the conductive plug and an active region.

Owner:CHANGXIN MEMORY TECH INC

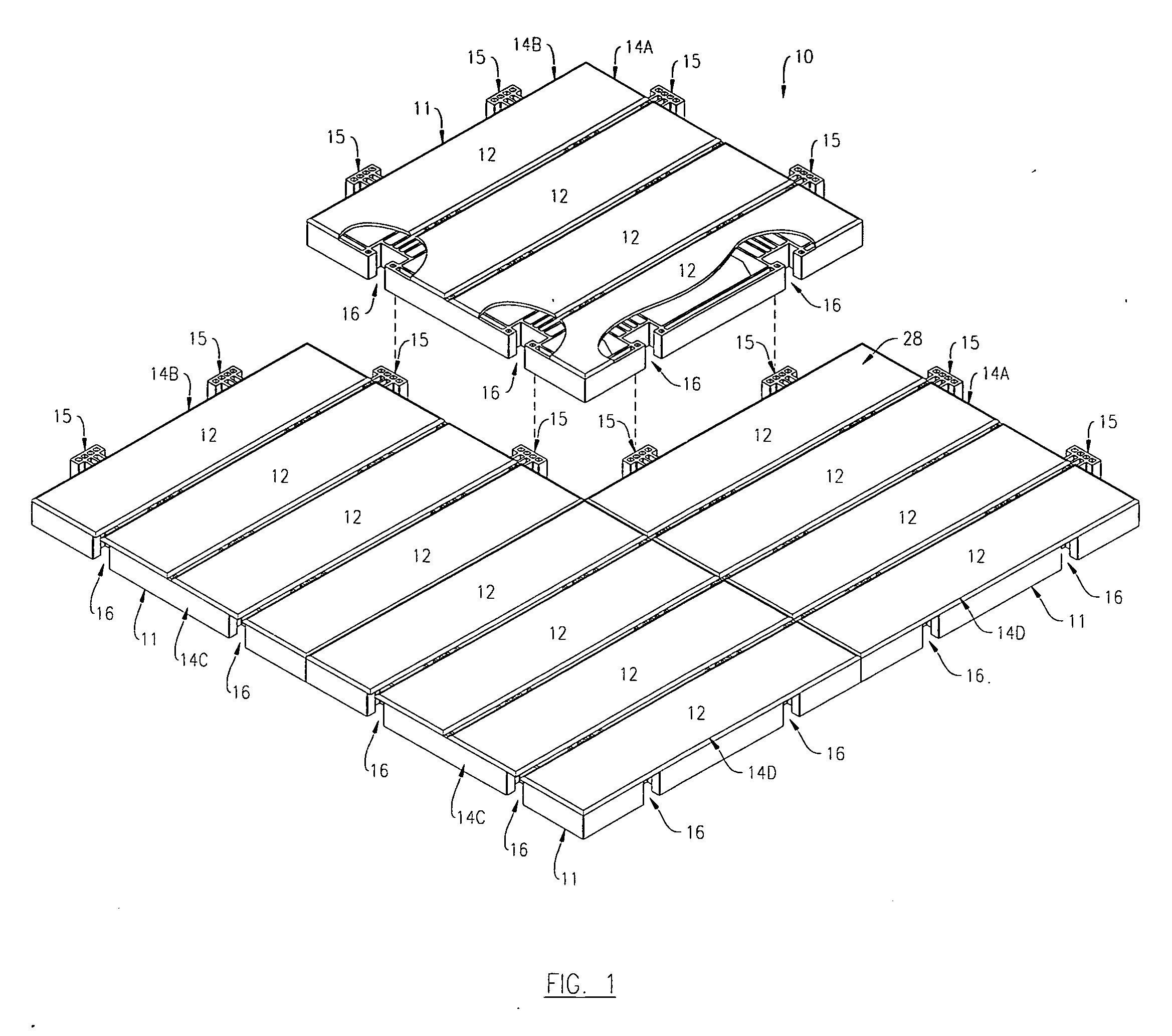

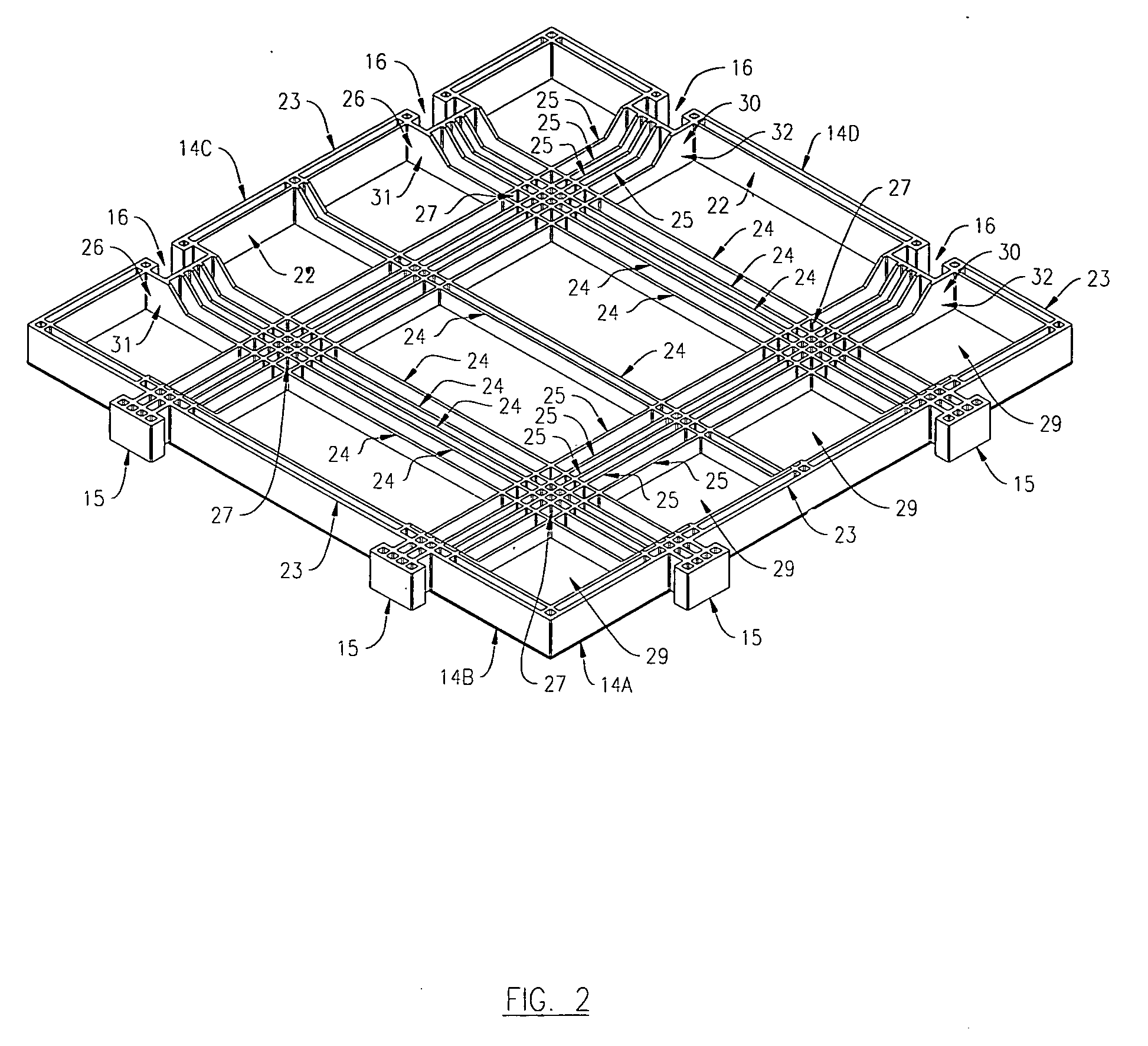

Portable deck

InactiveUS20060265987A1Easy to assembleImprove handlingCovering/liningsSingle unit pavingsEngineeringMechanical engineering

A portable floor made of interlocking modules and the process of assembling. Each module consists of rectangular panels, between each panel is a gap that provides for the drainage of liquids and small debris. Supporting the panels are four vertical sides of a base attached to the outer edges of the panels. The base also has a hollow structure with an interior wall that reinforces the module. Two consecutive sides have male connectors, the remaining two sides have female connectors. The male connectors are aligned directly opposite the female connectors. The connectors are used to connect adjoining modules. Connectors are uniformly spaced for alignment. The sides of the modules raise the panels above the ground. The bottom surfaces contain supports and support ends which provide rigidity and support.

Owner:IANNONE EDWARD J

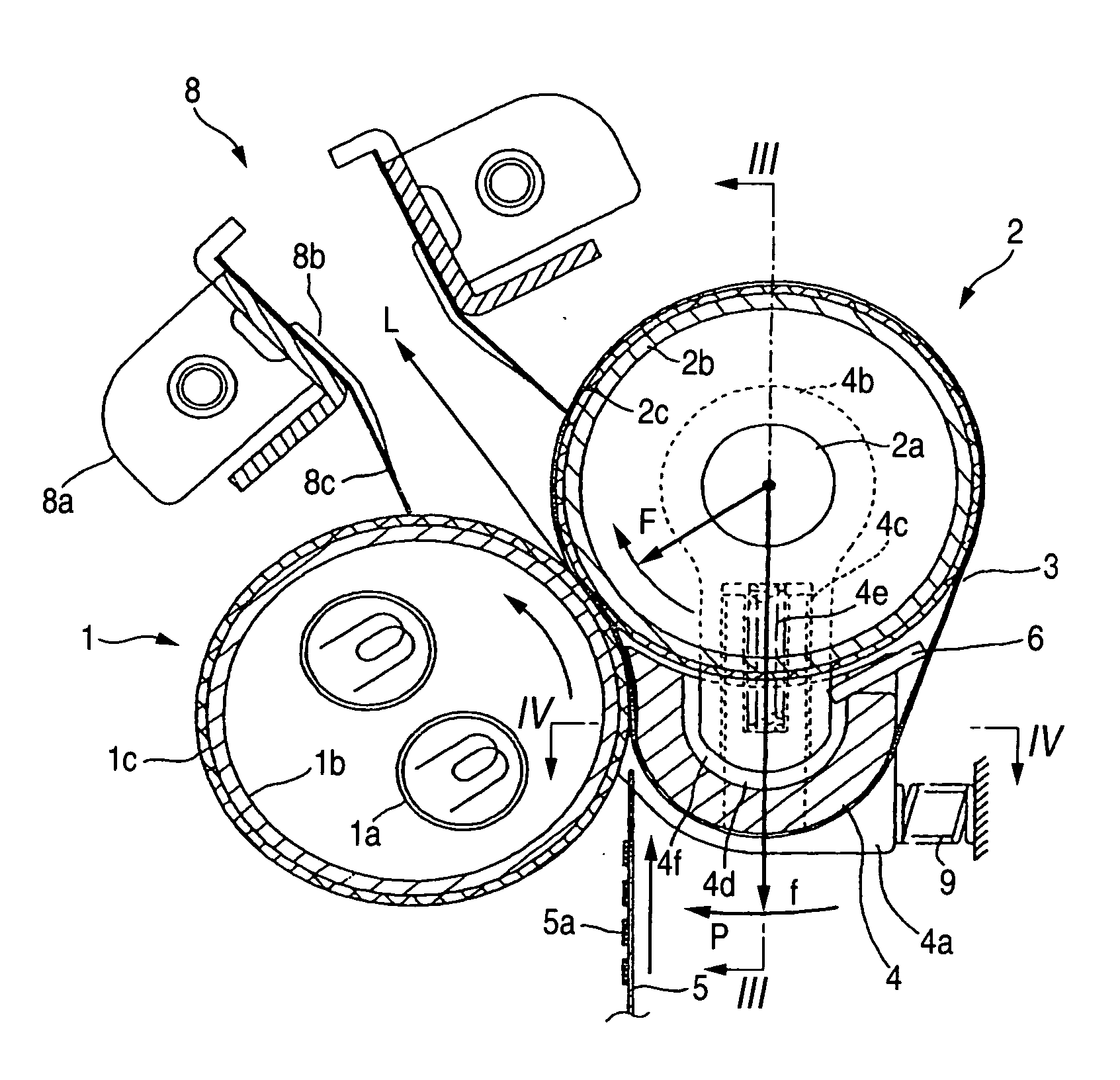

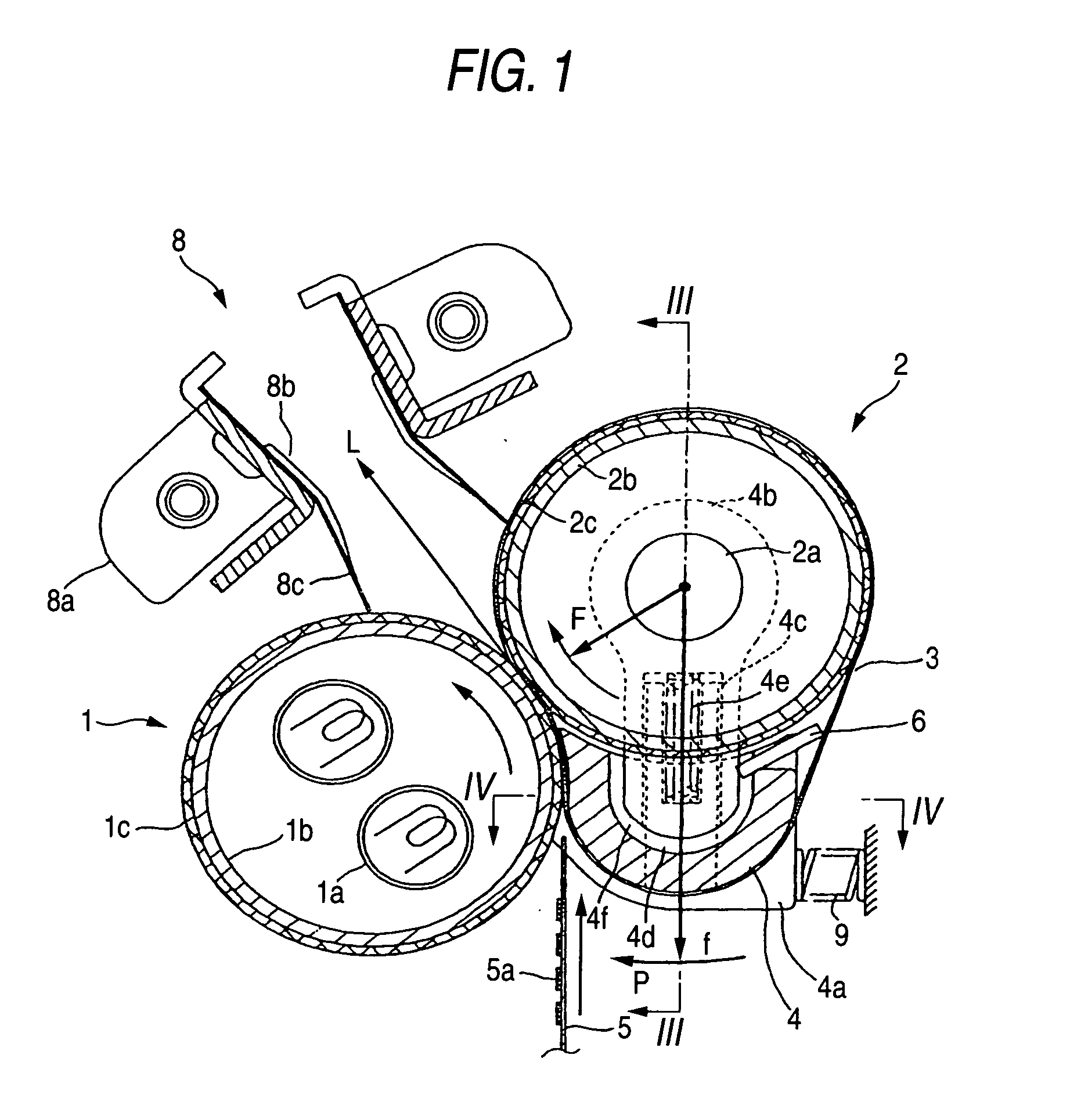

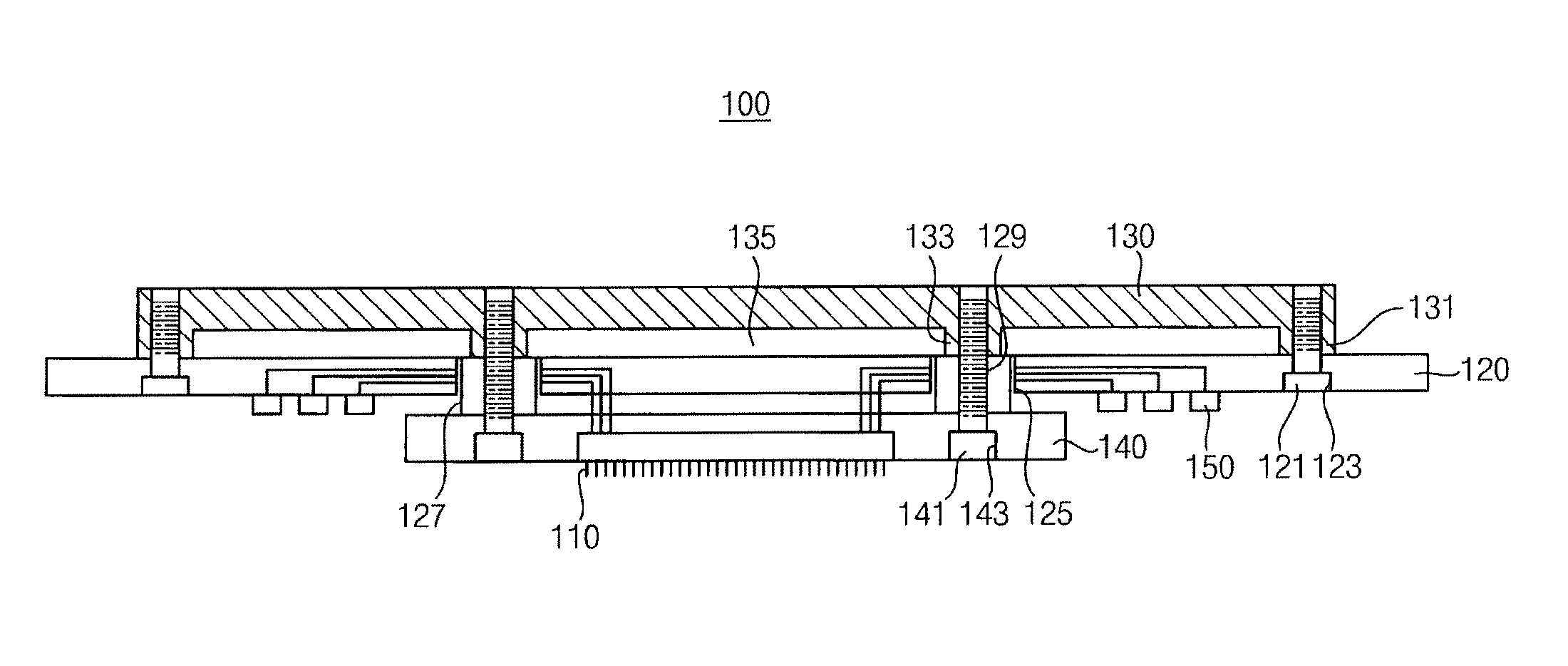

Fixing device and image forming apparatus incorporating the same

InactiveUS20050123328A1Prevent surfaceImage can be preventedOhmic-resistance heatingElectrographic process apparatusImage formationContact position

In a fixing device for fixing a toner image onto a recording medium, a healing roller is provided with an elastic layer formed on an outer periphery thereof. An endless belt is adapted to be circulated. A press member presses a part of the endless belt against the heating roller so as to deform the elastic layer, thereby forming a fixing nip portion through which the recording medium it passed. A guide member has a slope portion extended so as to close to a tangential line defined at a press contact position between the heating roller and the press member, as is being away from the exit of the fixing nip portion. A fixing pressure generated at the exit of the fixing nip portion is greater than a fixing pressure generated at an entrance of the fixing nip portion.

Owner:SEIKO EPSON CORP

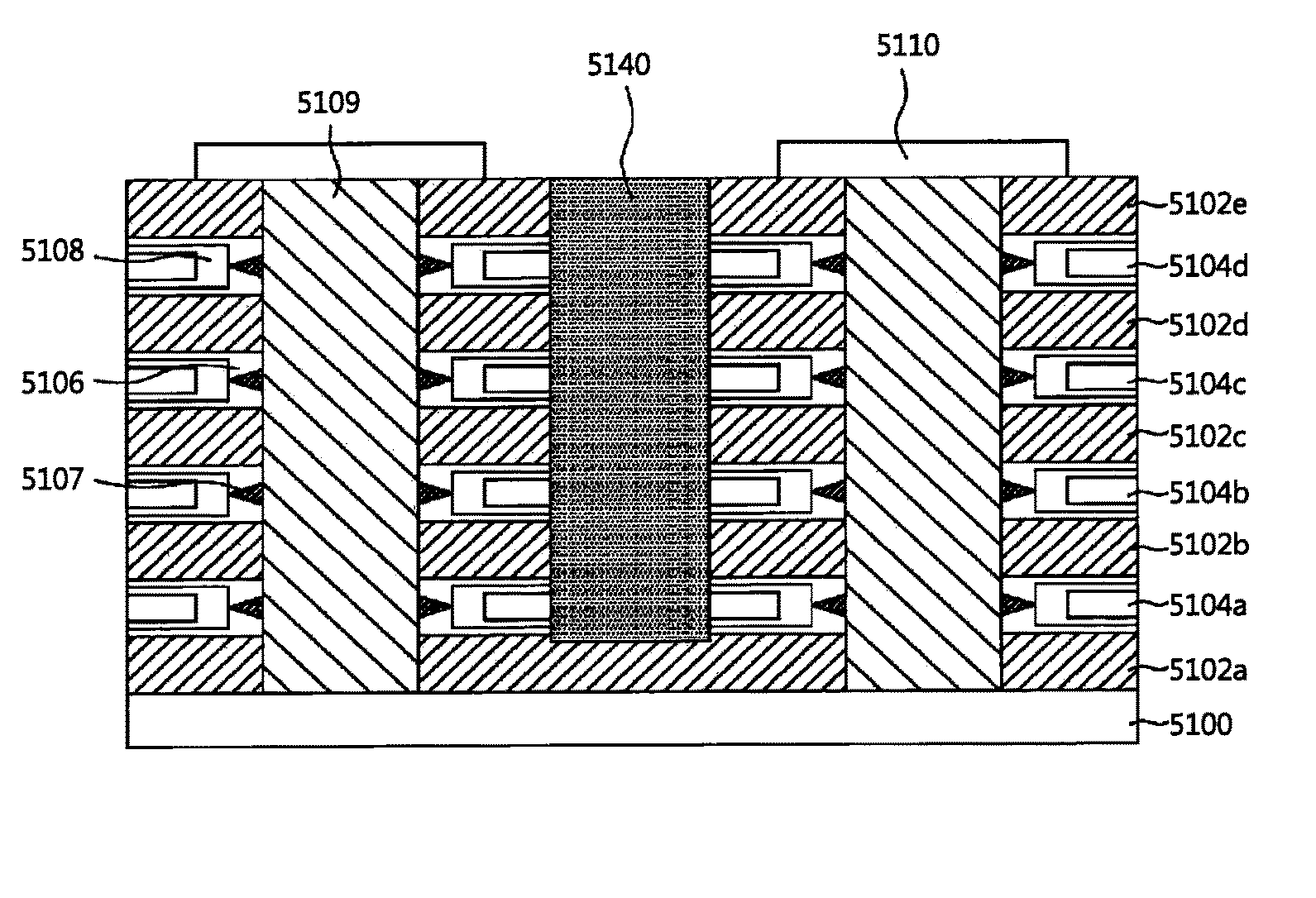

Vertical resistive random access memory device, and method for manufacturing same

InactiveUS20150162383A1Reduce manufacturing costHighly integratedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The present invention relates to a resistance change memory device and a method for manufacturing the same. According to an exemplary embodiment of the present invention, the resistance change memory device includes: a plurality of horizontal electrodes configured to be stacked at a predetermined interval from each other and extended in a horizontal direction; inter-layer insulating layers configured to each be formed between the plurality of horizontal electrodes; a plurality of vertical electrodes configured to have cross points with the horizontal electrodes by penetrating through the plurality of stacked horizontal electrodes and the inter-layer insulating layers in a vertical direction; and a metal oxide layer configured to have a U-shaped section in a form enclosing the horizontal electrode between the inter-layer insulating layer and the horizontal electrode and to make an oxygen composition ratio of a surface contacting the vertical electrode be higher than that of a surface contacting the horizontal electrode by performing oxygen treatment on the vertical electrode to have threshold switching characteristics and memory switching characteristics.

Owner:INTELLECTUAL DISCOVERY CO LTD

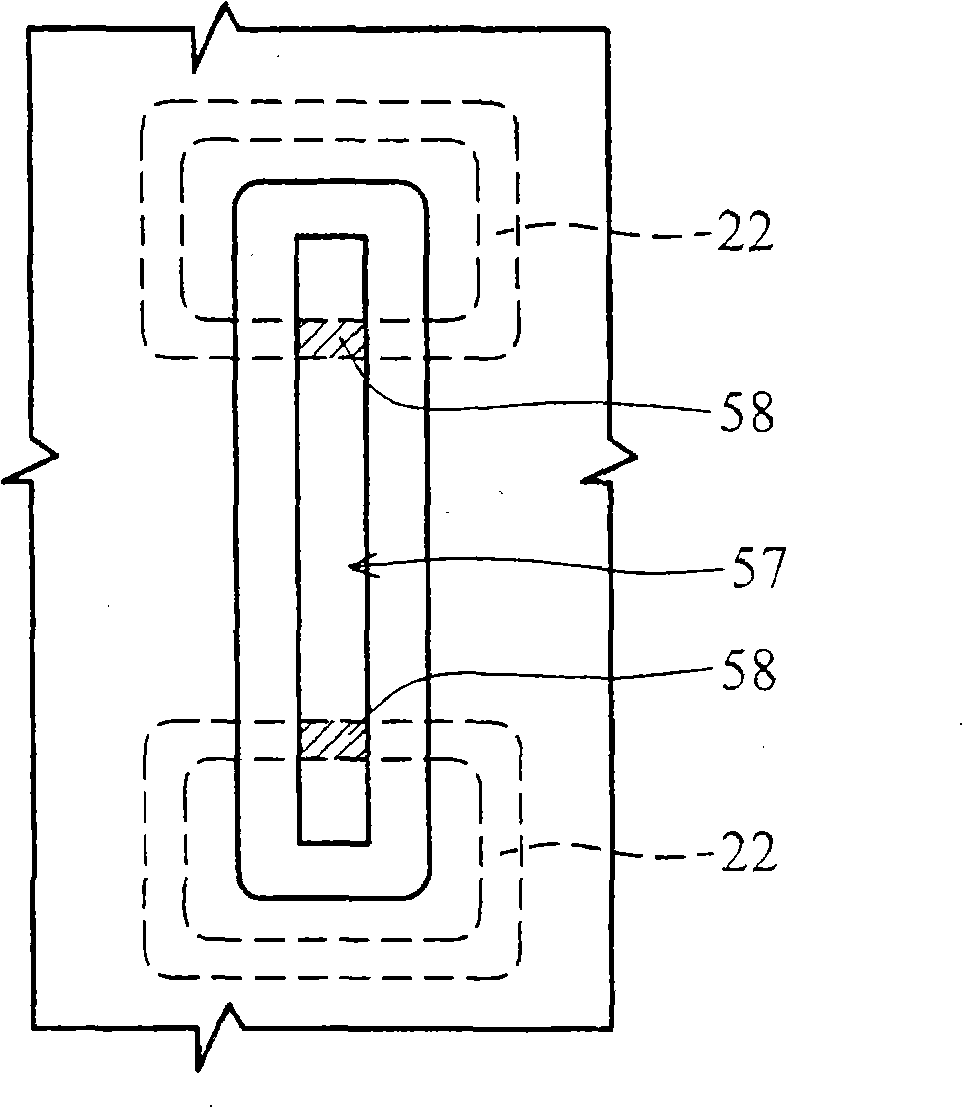

Phase-changing storage device and manufacture method thereof

ActiveCN101355137AImprove featuresNo damageSolid-state devicesDigital storagePhase transitionEngineering

The invention provides a phase transition storage device, comprising a substrate, an electrode layer, a phase transition storage structure. The electrode layer is formed on the substrate, the phase transition storage structure is formed on the electrode layer and is electrically connected to the electrode layer, wherein the phase transition storage structure comprises a cup-shaped heating electrode, an insulating layer, an electrode structure and a pair of double-layer clearance walls, wherein the cup-shaped heating electrode is arranged on the electrode layer; the insolating layer is arranged on the cup-shaped heating electrode along the first direction and partly covers on the cup-shaped heating electrode; the electrode structure is arranged on the cup-shaped heating electrode along the second direction, and partly covers on the insolating layer and the cup-shaped heating electrode; the pair of the double-layer clearance walls is arranged on a pair of side walls, and partly covers on the cup-shaped heating electrode; and the double-layer clearance walls comprise a clearance wall made of a phase transition material and a clearance wall made of an insolating material.

Owner:PROMOS TECH INC +1

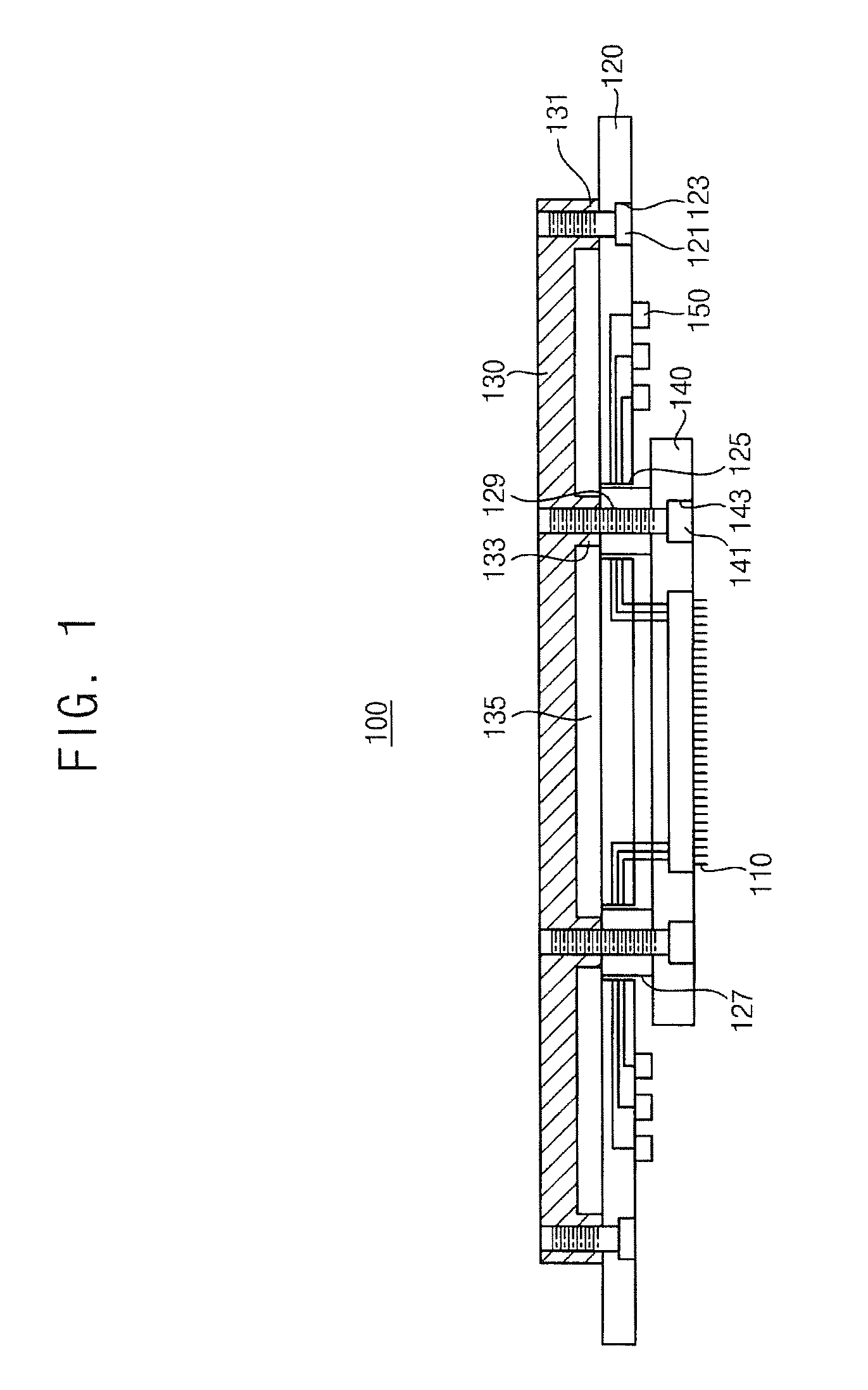

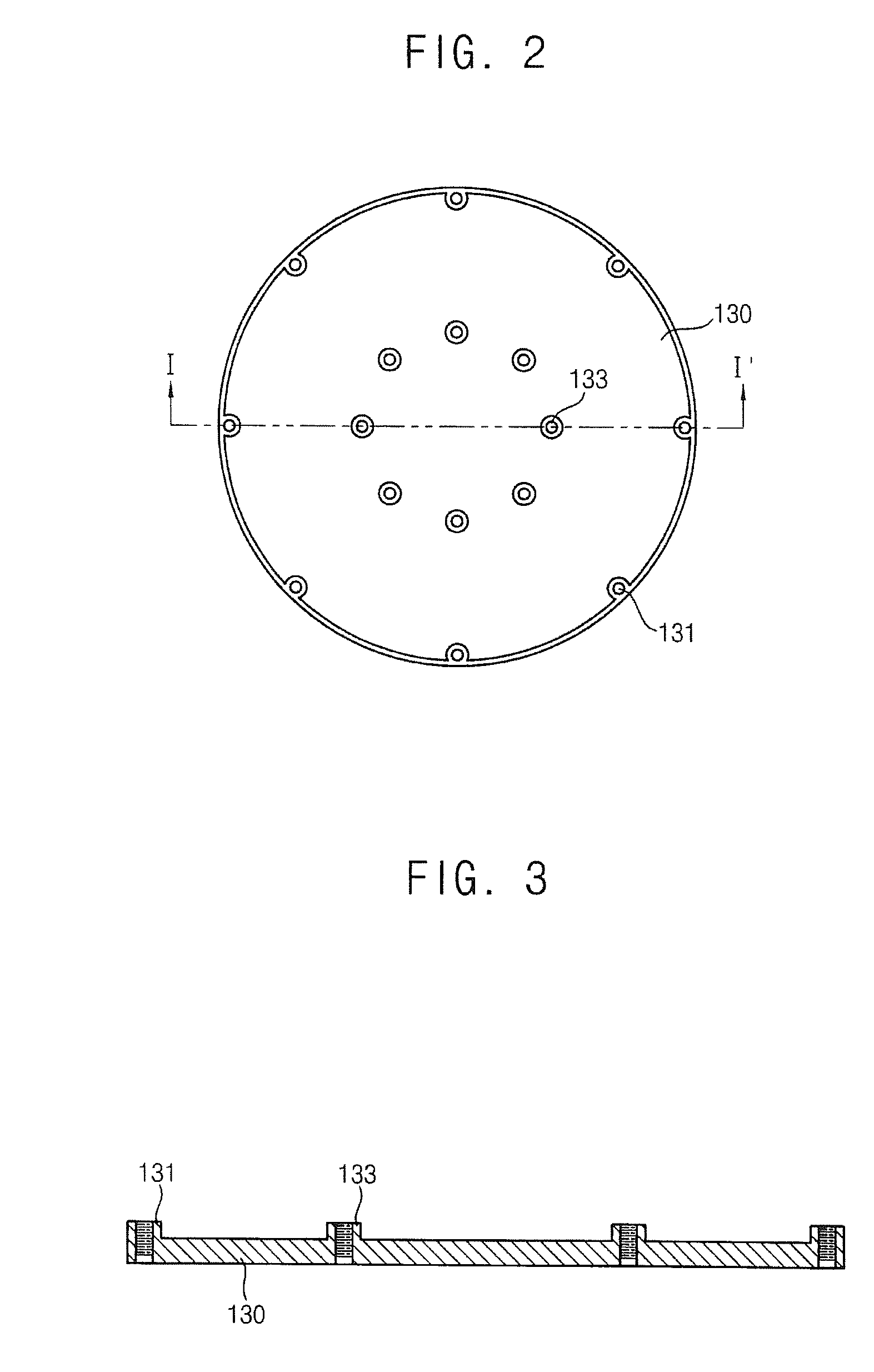

Probe card

ActiveUS7733103B2Excellent thermal deformation-resistant characteristicEasy alignmentSemiconductor/solid-state device testing/measurementElectrical testingProbe cardElectrical and Electronics engineering

A probe card includes a probe, a circuit board, a first reinforcing plate and a second reinforcing plate. The probe makes contact with an object. The circuit board is electrically connected to the probe. The first reinforcing plate has a first tap and a second tap for providing an adjustable gap between the first reinforcing plate and an upper surface of the circuit board. The second reinforcing plate is positioned under a lower surface of the circuit board. The second reinforcing plate combined with the second tap to form an adjustable gap between the second reinforcing plate and a lower surface of the circuit board.

Owner:M2N

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com