Scroll compressor

A technology of scroll compressors and compression chambers, applied in the field of scroll compressors, can solve problems such as unstable operation of circular scrolls, increased vibration or noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

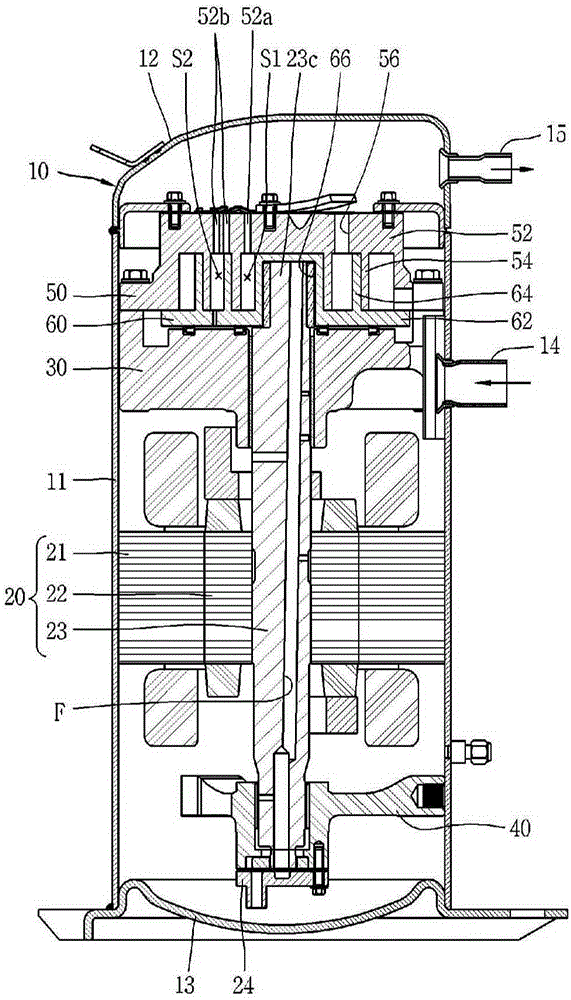

[0031] Hereinafter, a through-shaft scroll compressor according to the present disclosure will be described in detail based on an embodiment shown in the drawings.

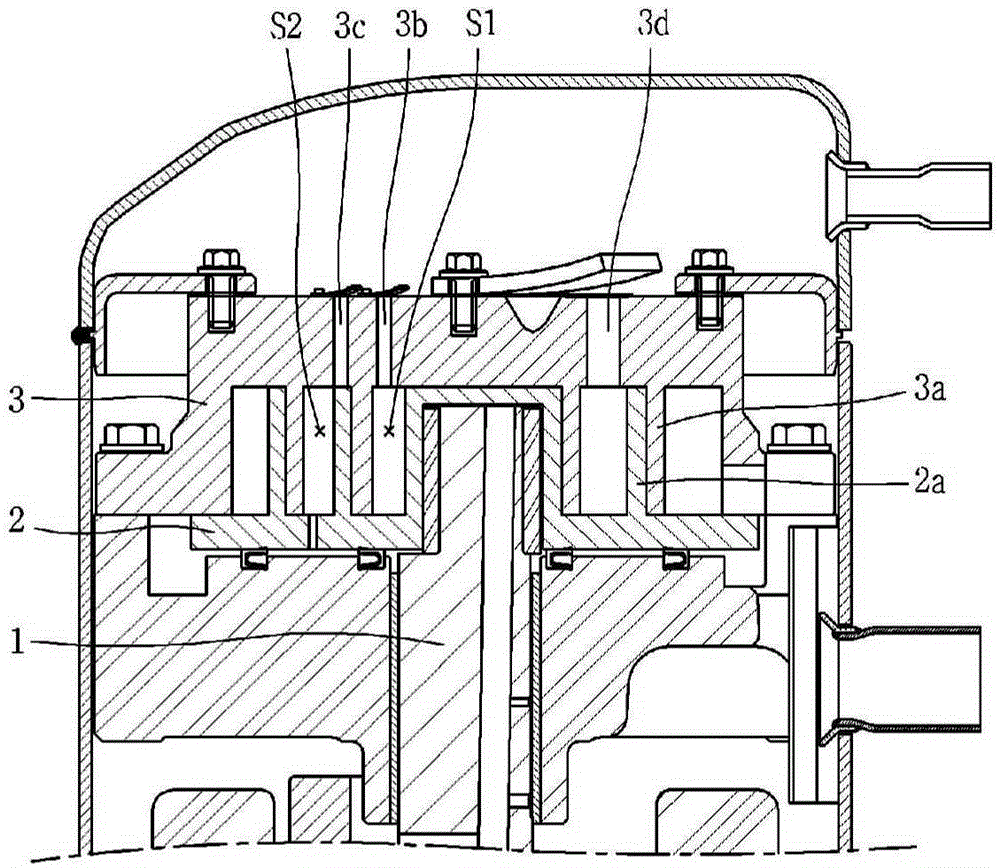

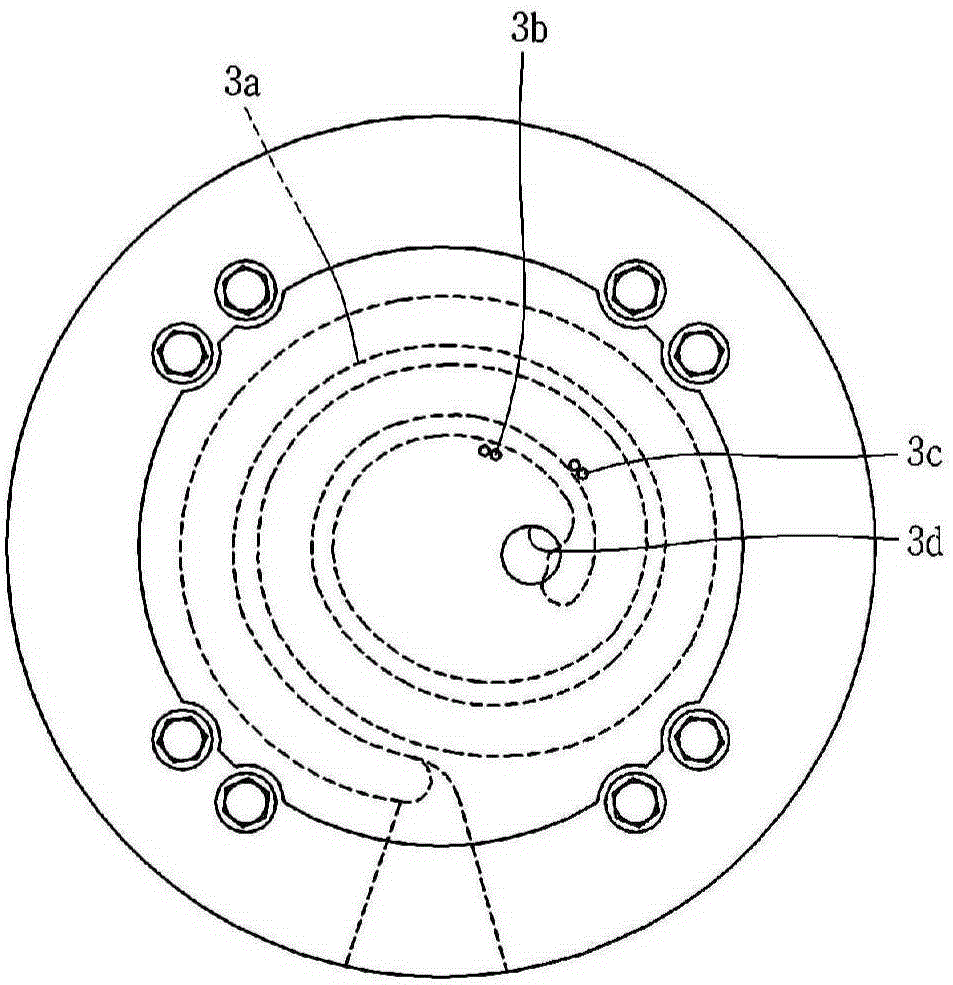

[0032] image 3 To show a longitudinal sectional view of a shaft through scroll compressor according to the present disclosure, Figure 4 to show the basis image 3 The axis of the shaft runs through the plan view of the compression unit in the scroll compressor, and Figure 5 to show and to image 3 The plan view of the split hole communicated with each compression chamber in the scroll compressor by the axis of the shaft.

[0033] As shown in the figure, in the shaft through scroll compressor according to the present embodiment, the driving motor 20 may be installed in the sealed container 10, and the main frame 30 and the subframe 40 may be installed on the upper side and the lower side of the driving motor 20. , the fixed scroll 50 may be fixed and installed on the upper side of the main frame 30 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com