Pressure responsive centralizer

a centralizer and pressure technology, applied in the direction of drilling casings, wellbore/well accessories, pipes, etc., can solve the problems of high induced pressure, pressure has been known to be a significant factor in the failure of subsea wells, and annular pressure buildup in wellbores, so as to reduce apb, enhance casing products, and increase casing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The numerous innovative teachings of the present application will be described with particular reference to the presently preferred embodiment (by way of example, and not of limitation).

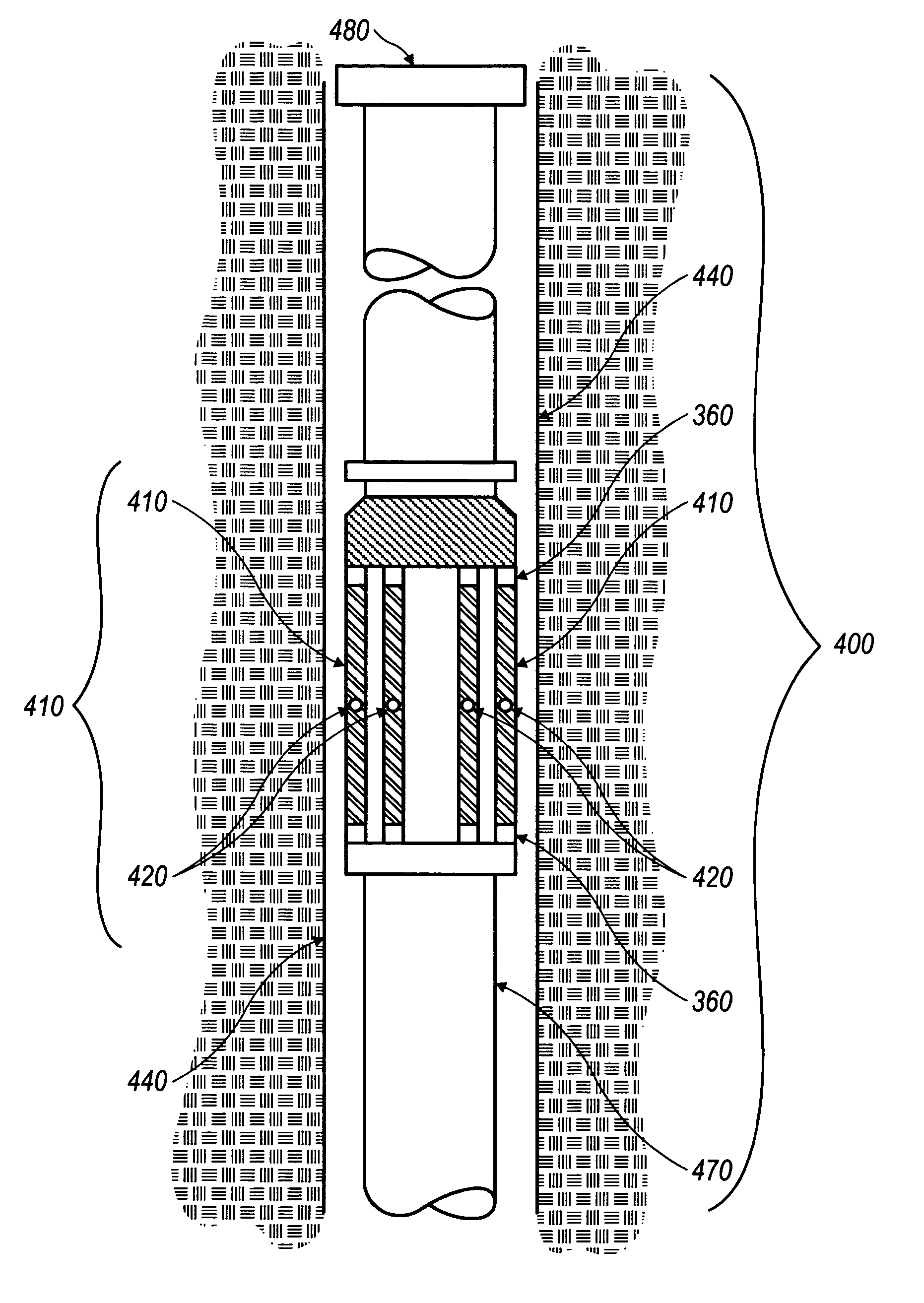

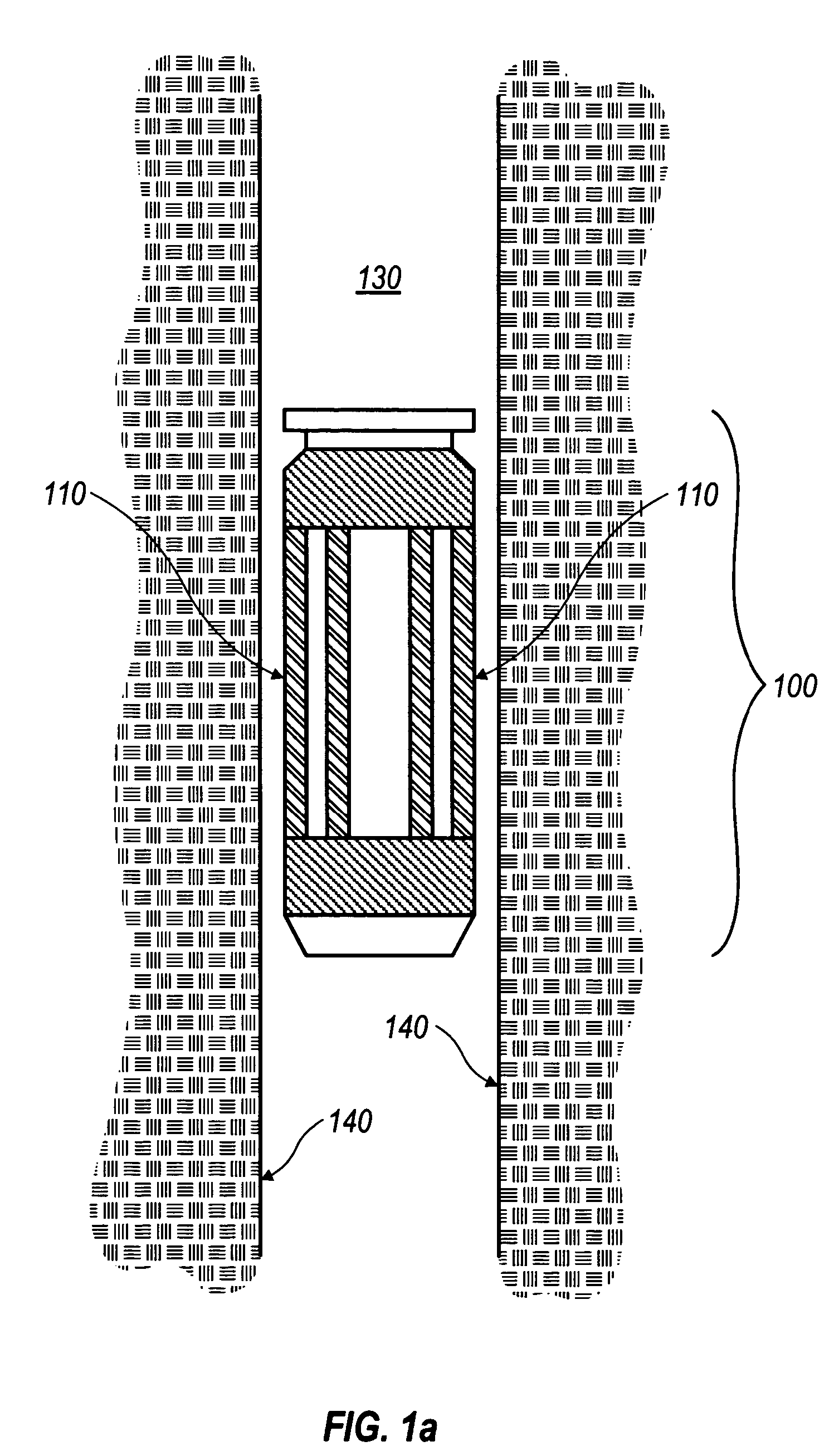

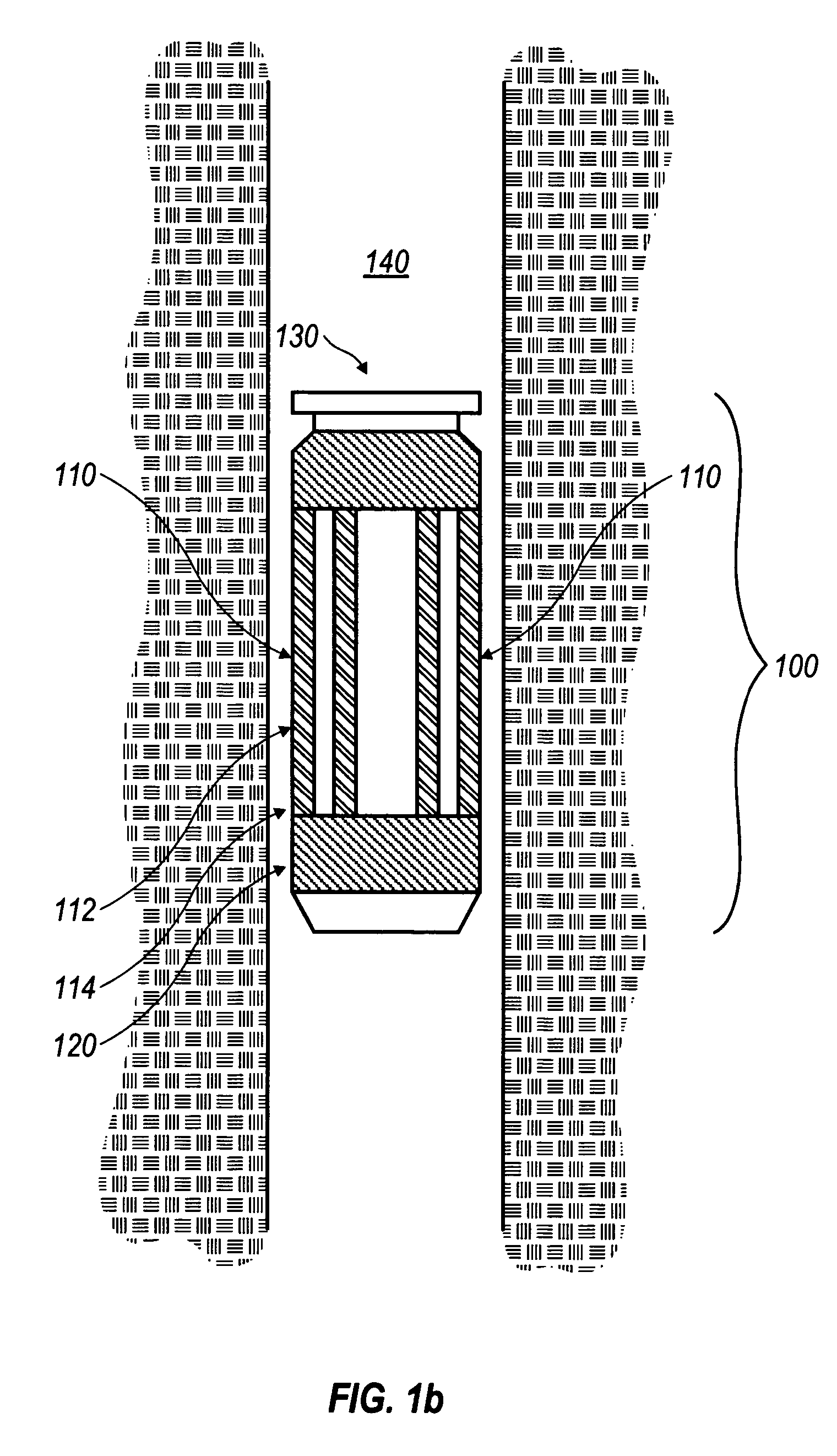

[0030] The disclosed inventions take advantage of a new way in which the pressure in boreholes can be controlled. In one embodiment, a centralizer is combined with a rupture disk to allow for the release of excess pressure from a wellbore. The hollow components in this embodiment contain a burst disk or rupture disk, which are selected to rupture at a predetermined pressure as required by well hydrostatic pressure and other factors. The inside and outside diameters of the centralizer preferably provide effective centering of the casing in the borehole or outer casing. The number of struts and rupture and burst disks may be adjusted in such a way as to meet the specific pressure and volume needs of a specific project. For instance, in one embodiment, there may be six struts with one rupture di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com