Metal laser deep-layer quenching process

A laser and metal technology, applied in the field of metal laser deep quenching process, can solve the problems of shallow depth of laser quenching and hardening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

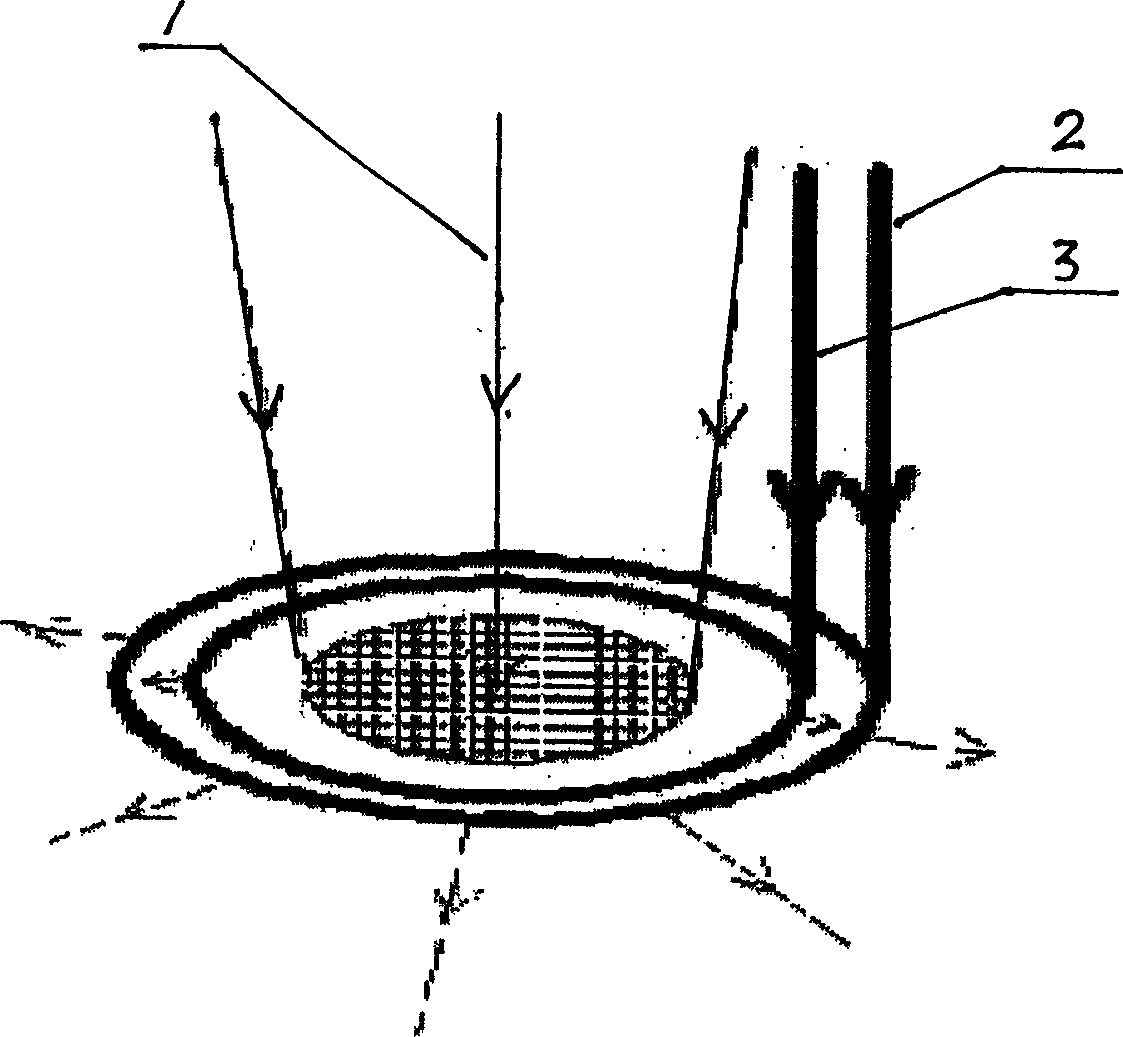

[0013] Combine below figure 1 , figure 2 and image 3 A detailed description of the embodiment of the present invention, the laser spot can be a rectangular laser spot, or a circular spot such as figure 1 , 1 is the laser beam, the size of the spot can be adjusted, the flow and direction of the coolant 2 are fixed, the injection direction of the coolant 2 is 5-15° to the outside, and the distance from the spot can be adjusted, during the process of the coolant 2, The gas 3 and the laser beam 1 move synchronously. The gas 3 is argon, which not only has a cooling effect, but also has a protective effect on the laser active area. Take woodworking knives as an example, such as figure 2 , image 3 As shown, the knife is made up of a knife body 5 and a blade 4. Originally, the blade 4 was manufactured by brazing and inserting high-speed steel or hard alloy. The main problem is that the process is complicated. For the hard alloy edge, due to the brittleness of the material its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com