Surface laser quenching process of car panel die

A technology of laser quenching for automobile panels, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of difficult quenching quality assurance, low laser energy utilization rate, and easy initiation of fatigue cracks, etc., to achieve hardness improvement and energy utilization The effect of improving the efficiency and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

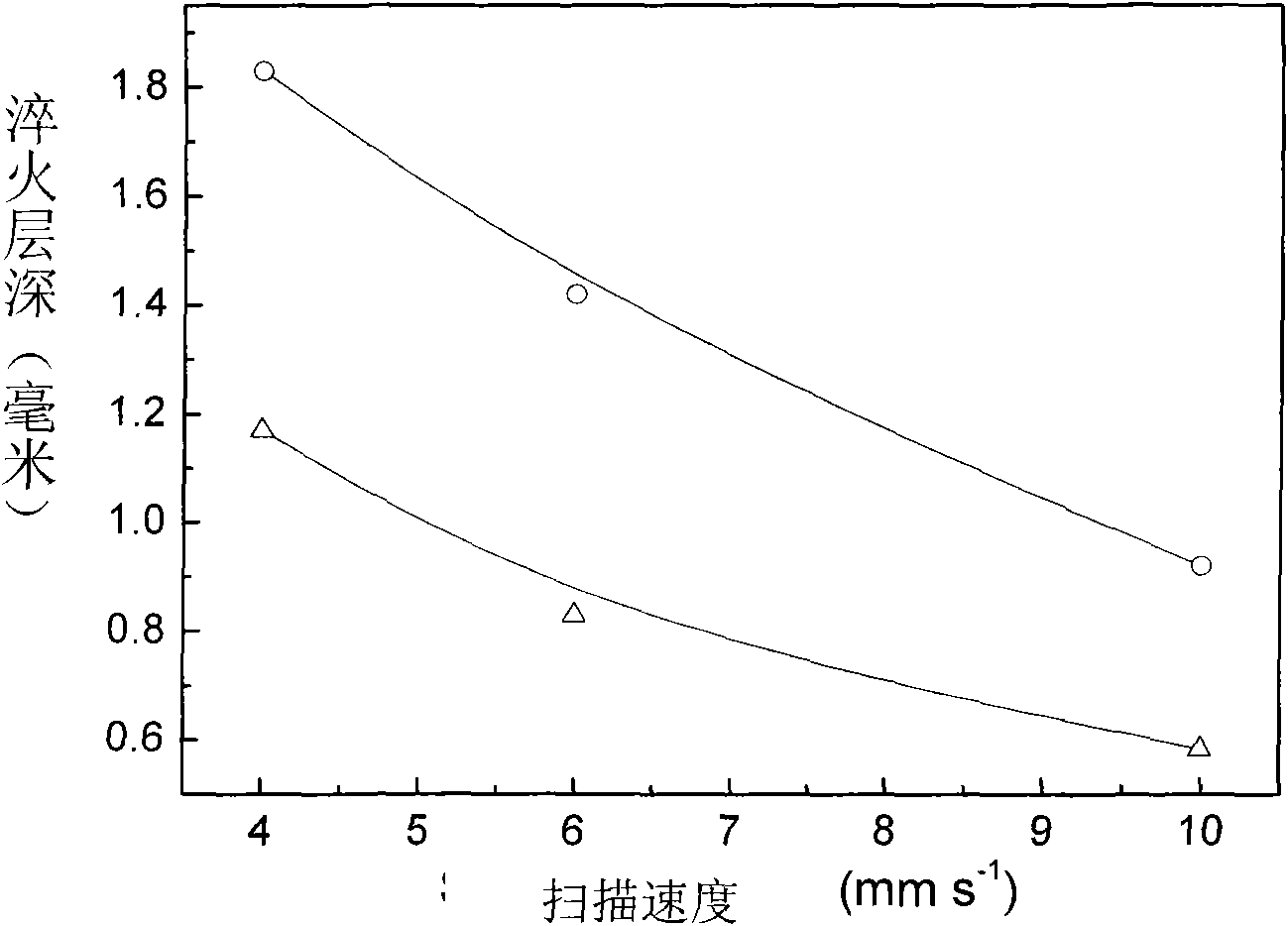

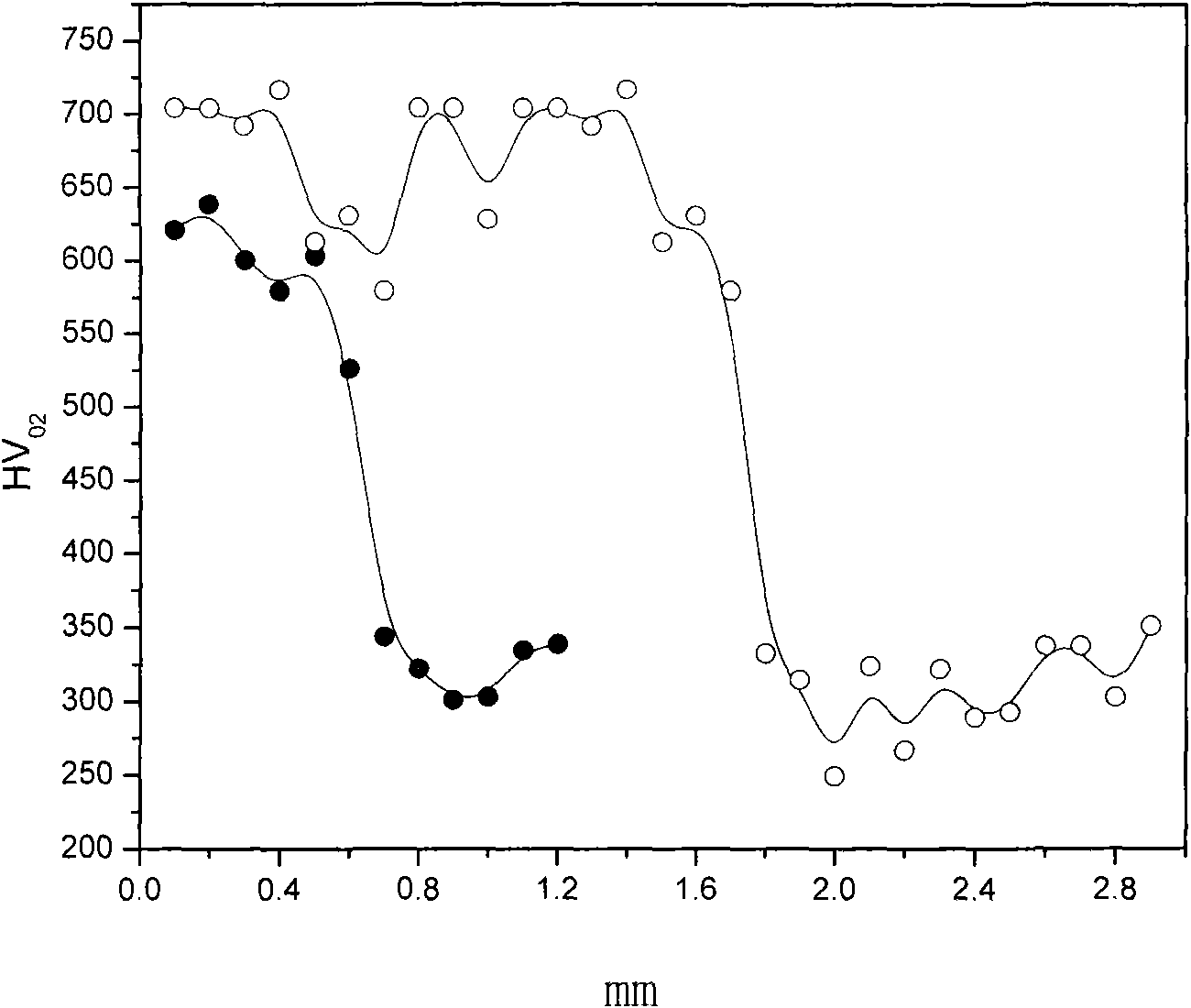

[0019] Example 1: Using 45# medium carbon steel as the substrate, a laser quenching test was performed.

[0020] In this embodiment, a layer of 0.01mm thick coating is first applied to the surface of the substrate; then CO with a power of 1800W is used 2 The laser emitted by the laser scans the coated mold surface with a spot size of 1×15MM and a scanning speed of 4MM / S; finally, the coating on the substrate surface is removed. The depth of the quenched layer is 1.8mm, and the hardness of the quenched layer is HRC56.

[0021] The paint of the above coating uses 60 parts by weight AL 2 O 3 Granules, 20 parts by weight of ZrO 2 Granules and 20 parts by weight of SiO 2 The particles are evenly dispersed with 20-50% of the weight of the above-mentioned paint and sprayed on the surface of the substrate. The Al 2 O 3 Particles, ZrO 2 Particles and SiO 2 The particle size of the particles is not greater than 1μM.

Embodiment 2

[0022] Example 2: Using 40Cr medium carbon steel as the base material, a laser quenching test was performed.

[0023] The process flow and laser of this embodiment are the same as those of embodiment 1, except that the thickness of the coating on the surface of the substrate is 0.1MM; the laser scanning speed is 6MM / S; the coating of the coating uses 70 parts by weight of Al 2 O 3 Granules, 10 parts by weight of ZrO 2 Granules and 20 parts by weight of SiO 2 The particles are uniformly dispersed in water with 20-50% of the weight of the paint, and then sprayed on the surface of the substrate. The depth of the quenched layer is 1.4mm, and the hardness of the quenched layer is HRC58.

Embodiment 3

[0024] Example 3: Using Cr12MoV as the substrate, a laser quenching test was performed.

[0025] The process flow and laser of this embodiment are the same as those of embodiment 1, except that the thickness of the coating on the substrate surface is 0.02MM; the laser scanning speed is 10MM / S; the coating of the coating uses 70 parts by weight of Al 2 O 3 Granules, 18 parts by weight of ZrO 2 Granules and 12 parts by weight of SiO 2 The particles are uniformly dispersed in water with 20-50% of the weight of the paint, and then sprayed on the surface of the substrate. The depth of the quenched layer is 0.8mm, and the hardness of the quenched layer is HRC56.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com