Composite modification method used for multiplying thickness and hardness of steel nitriding layers or rapid heating quenching hardened layers

A quenching hardening and rapid heating technology, applied in the field of steel modification, can solve the problem of not being able to prepare high hardness and thick hardened layer at the same time, so as to improve the metallographic structure and mechanical properties, prolong the service life and shorten the processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

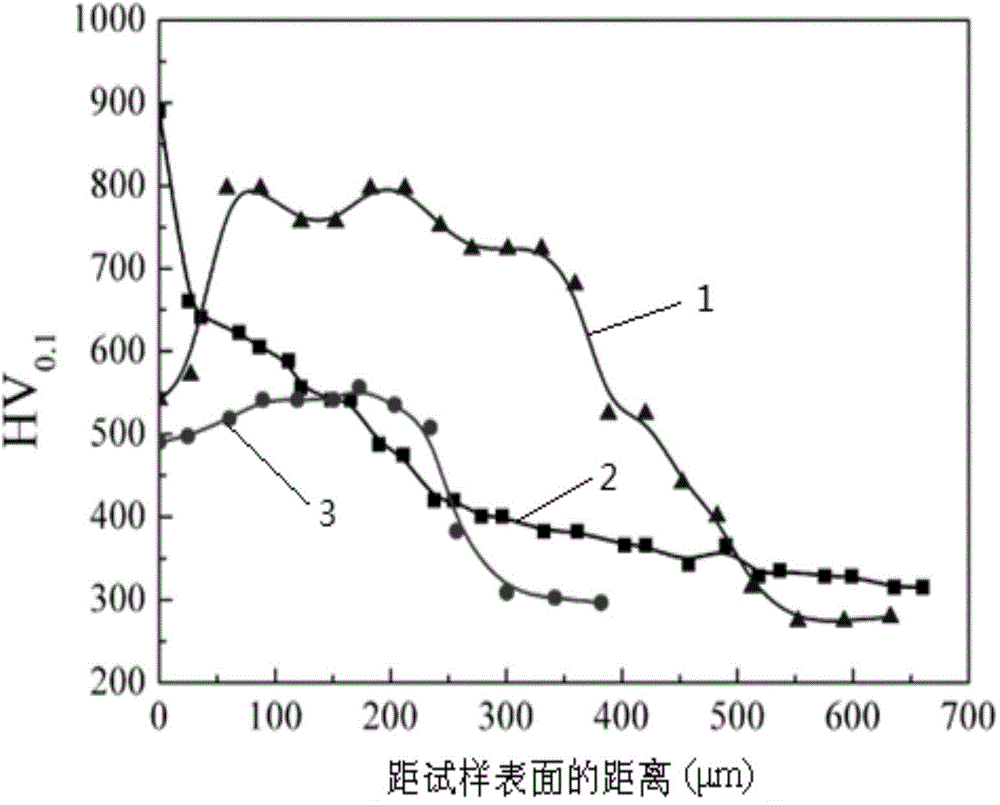

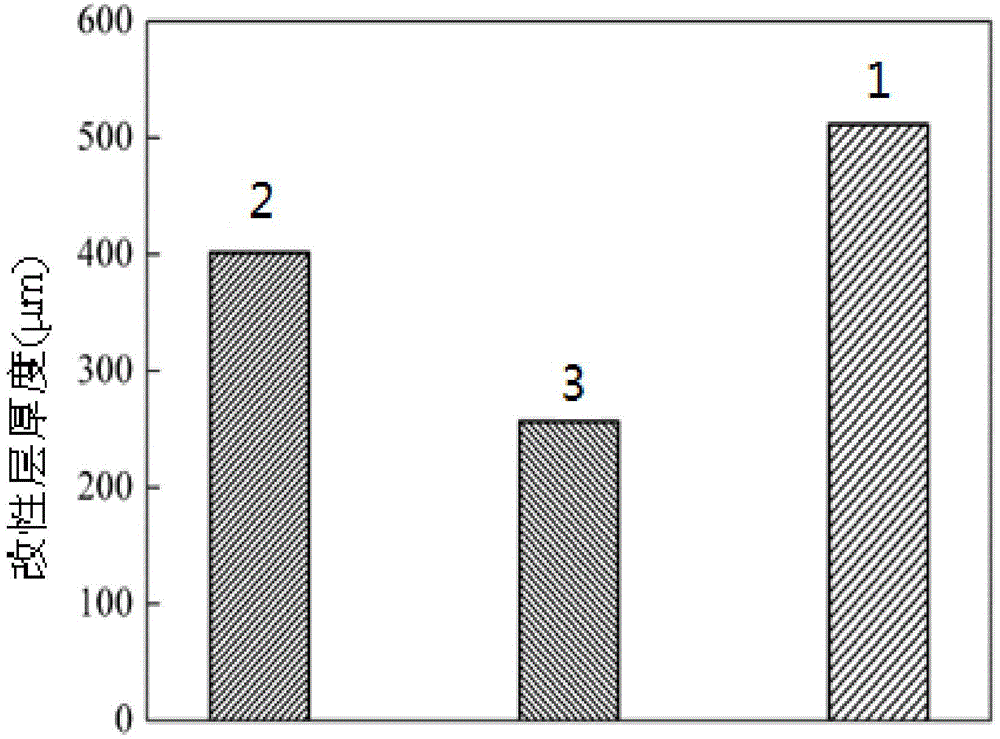

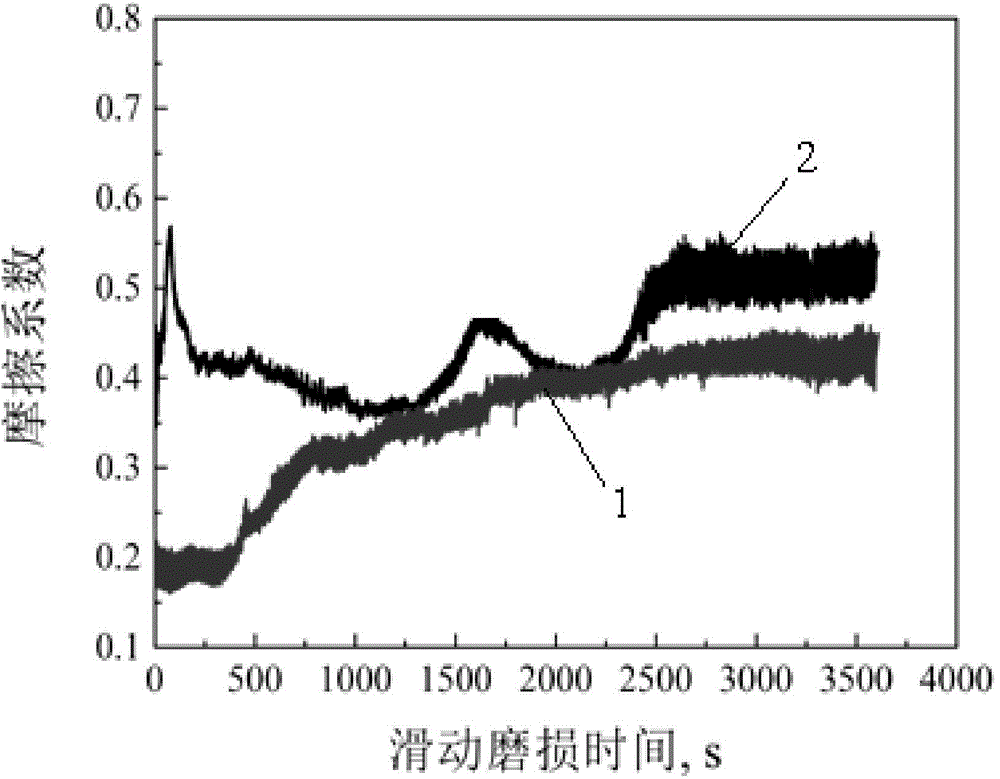

[0018] Specific embodiment one: a kind of composite modification method that makes the thickness and hardness of the nitriding or rapid heating and quenching hardened layer of steel described in this embodiment is doubled, specifically according to the following steps:

[0019] 1. Pretreatment: Use 240-mesh and 800-mesh water sandpaper to polish the steel surface in turn, and then place the polished steel in ethanol and acetone for ultrasonic cleaning to obtain the pretreated steel;

[0020] 2. Nitriding: Nitriding the pretreated steel, and then cooling the steel to room temperature with the furnace in a nitrogen or ammonia atmosphere to obtain nitriding steel; the nitriding temperature is 400 ° C ~ 620°C, the nitriding time is 2h~16h;

[0021] 3. Laser quenching: In an argon or nitrogen atmosphere, blacken the steel after nitriding, and then perform laser quenching on the steel surface after blackening. The laser power is 1kW to 5kW, and the scanning speed is It is 10mm / s~30...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that the nitriding described in step 2 is ion nitriding, gas nitriding or salt bath nitriding. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the ion nitriding is specifically carried out according to the following steps: the pretreated steel is placed in a pulse plasma multi-component co-infiltration furnace In the process, the infiltration agent is passed, and the temperature of the pulse plasma multi-component co-infiltration furnace is raised to 400 ° C ~ 620 ° C, and then kept at a temperature of 400 ° C ~ 620 ° C, a furnace pressure of 150 Pa ~ 400 Pa, and an infiltration agent plasma bombardment atmosphere for 2 hours ~ 8h, the ion nitriding is completed; the permeating agent is N 2 and H 2 mixed gas or nitrogen-containing atmosphere. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com