Method for depositing metal or hard ornament film on plastic substrate

A technology for depositing metal and decorative films, applied in metal material coating technology, ion implantation plating, coating, etc., can solve problems such as complicated procedures and unfavorable industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

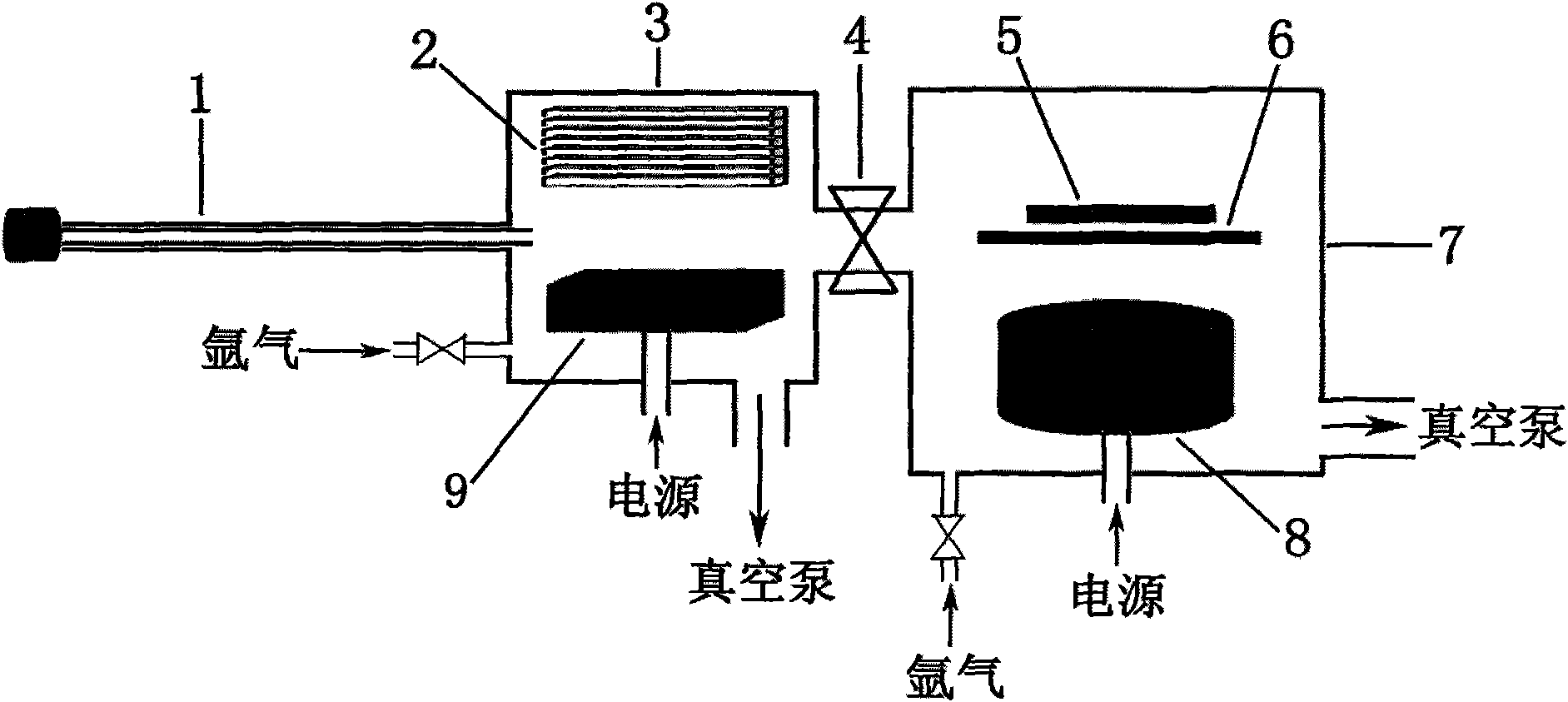

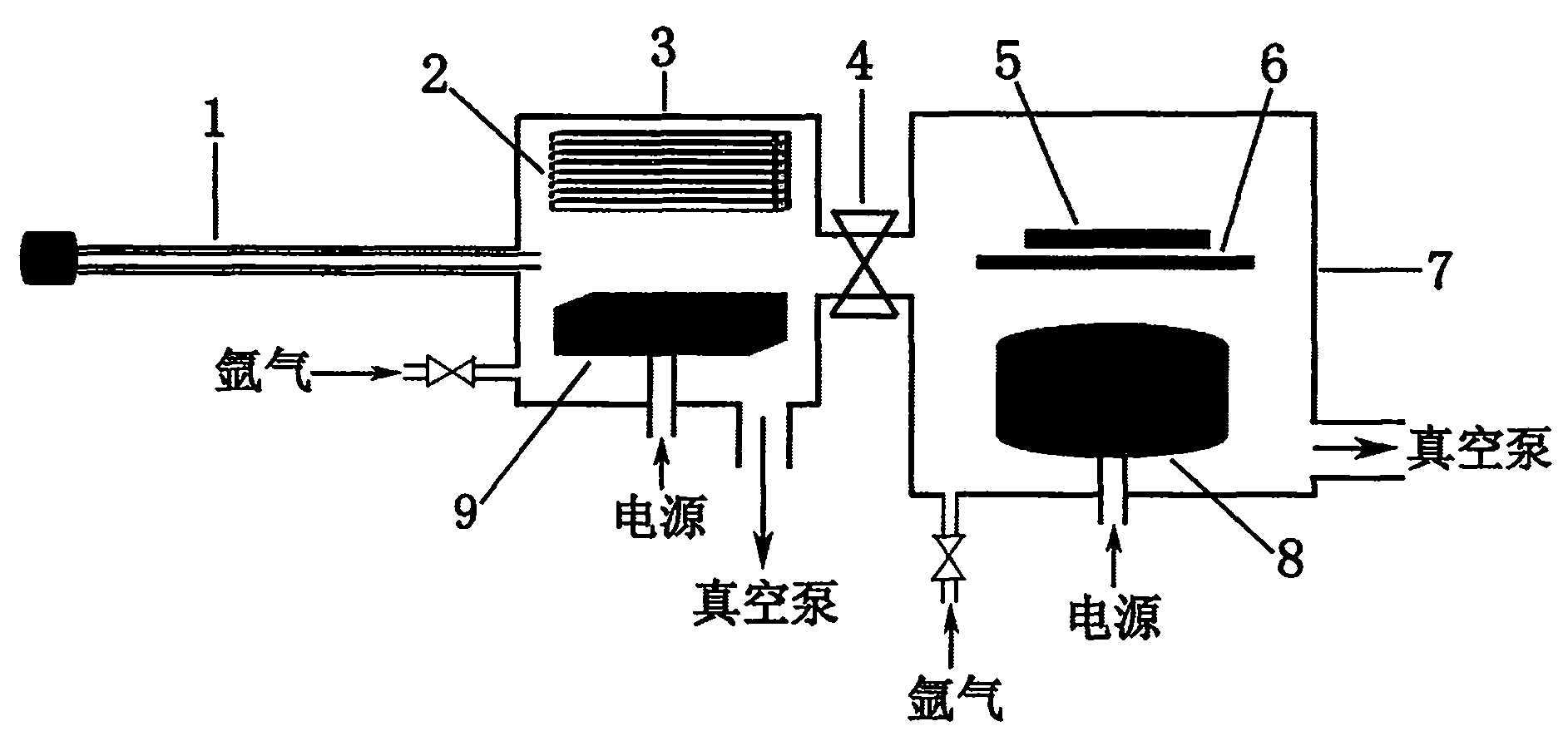

[0013] Embodiment 1: plastic substrate cleaning and plasma treatment method

[0014] Plastic substrates such as ABS, PMMA, PE, and PP are placed in deionized water or absolute ethanol for ultrasonic cleaning, and the cleaned plastic substrates are dried and placed on the sample library in the plasma processing chamber, and then Vacuum the chamber to a degree higher than 6×10 -3 Pa, take out the plastic substrate on the sample library with a magnetic force transfer rod and place it on the plasma processor, then feed high-purity argon, nitrogen or a mixture thereof with a flow rate of 20-100 sccm into the cavity to adjust the pressure in the cavity 3 ~ 10Pa, the power applied to the plasma generator is 10W / cm 2 The RF power supply is used, and the processing time is controlled at 3 to 10 minutes. The processed plastic substrate is directly transferred to the sputtering chamber through the sample transfer device for deposition of metal or hard film.

Embodiment 2

[0015] Embodiment 2: Preparation of metal decorative film by radio frequency magnetron sputtering on PMMA plastic substrate

[0016] The purity of the chromium, nickel or titanium metal target for sputtering is 99%, and the relative density is ~0.98. The chromium, nickel or titanium target is correctly installed in the target gun, and the vacuum is pumped until the background vacuum of the sputtering chamber is higher than 2.0× 10 -4 Pa, take the PMMA plastic after the processing of embodiment 1 as the substrate, the substrate is not heated (water cooling is controlled at room temperature), and a certain amount of argon gas is passed into the sputtering chamber, and the pressure in the sputtering chamber is adjusted to be 0.2~5Pa, The RF sputtering power is adjusted to 20W / cm 2 , the deposition time is controlled to be 10-60 minutes, and the prepared metal film has a bright silver-white metallic luster.

Embodiment 3

[0017] Embodiment 3: Preparation of hard decorative film by radio frequency magnetron sputtering on ABS plastic substrate

[0018] The purity of titanium, titanium nitride, titanium carbide or titanium carbonitride targets for sputtering is 99%, and the relative density is ~0.96. The target is correctly installed in the target gun, and the vacuum is pumped until the background vacuum of the sputtering chamber is high. at 2.0×10 -4 Pa, with the ABS plastic substrate treated in Example 1 as the substrate, the substrate is not heated (water cooling is controlled at room temperature), and a certain amount of argon, helium, nitrogen, acetylene, methane is passed into the sputtering chamber or its mixed gas, adjust the pressure in the sputtering chamber to 0.5-8Pa, and adjust the RF sputtering power to 15W / cm 2 , the deposition time is controlled at 5-80 minutes, and the prepared hard film is golden yellow, black, blue or silver gray.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com