High-heat-conductivity composite material and preparation method thereof

A technology of composite materials and high thermal conductivity fillers, applied in the field of thermally conductive composite materials, can solve the problems that limit the wide application of thermally conductive composite materials, the thermal conductivity of composite materials is not high, and the comprehensive mechanical properties of materials are reduced, and achieve convenient preparation and comprehensive mechanical properties. , the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 2g of graphene (xGnP) and 0.02g of carbon fiber (CF) were added to 500mL of isopropanol and dispersed by ultrasonic for 20 hours to obtain a graphene suspension; then 18.18g of low-density polyethylene (LDPE) powder was added to the suspension After stirring at high speed for 10 hours, the isopropanol was evaporated under reduced pressure to obtain a mixed powder; the prepared mixed powder was added to a mold, and hot-pressed at 170°C and 10MPa to obtain a high thermal conductivity composite material (LDPE- xGnP-10), wherein the mass content of the high thermal conductivity filler in the composite material is 10%. Cut the test sample according to the test sample size.

[0022] Wherein, the preparation method of graphene is according to literature (J.Mater.Chem.2010,20,8496-8505; Carbon 2010,48,2361-2380), 10g nano-graphite is added to 270mL concentrated sulfuric acid and fuming nitric acid under stirring (volume ratio is 2: 1) in the mixed solution, obtain uniform susp...

Embodiment 2

[0026] After premixing 12g of graphene and 2g of carbon nanotubes with 26g of polypropylene (PP) with a high-speed mixer, the resulting mixture was pelletized with a twin-screw extruder to form a high thermal conductivity composite material (referred to as PP-xGnP(6)- CNT(1)-35) Wherein, the mass content of the high thermal conductivity filler in the composite material is 35%. The prepared pellets were put into a mold and hot-pressed at 190°C and 18MPa, and the test samples were cut according to the size of the test samples.

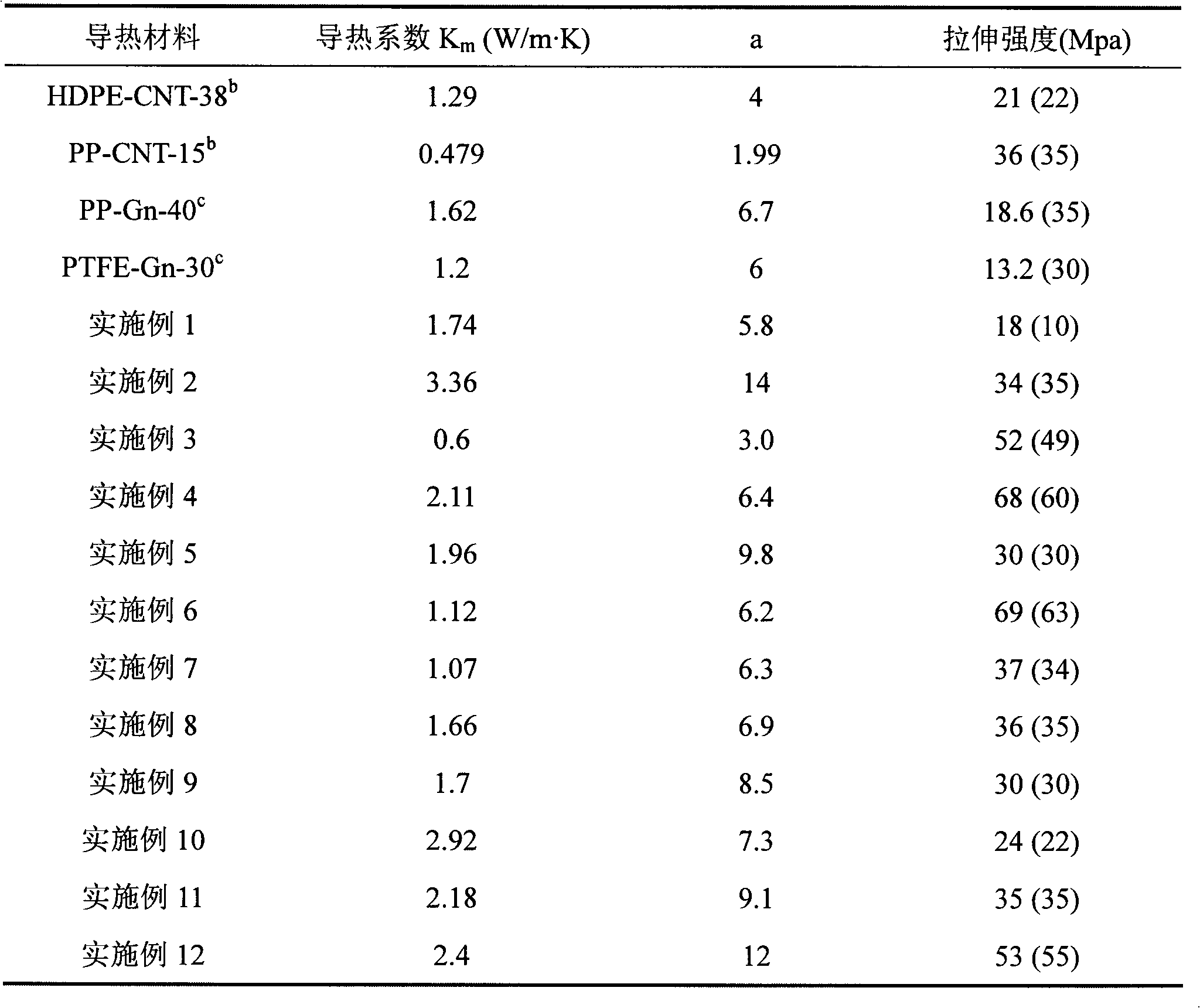

[0027] The thermal conductivity and tensile strength results of PP-xGnP(6)-CNT(1)-35 are shown in Table 1. In addition, as a comparative example, the thermal conductivity and tensile strength of PP-Gn-40 were tested by the same method. PP-Gn-40 is a thermally conductive composite material (preparation method such as document J. Chemical Production and Technology, 2001, 8 (2): 17-19) with graphite as the thermally conductive filler and polypropylene as t...

Embodiment 3

[0030] Add 500mg of graphene, 500mg of pitch-based carbon fiber (CF) and 19g of polyvinylidene fluoride (PVDF) into a ball mill and perform ball milling for 0.5 hours to obtain a mixed powder. The high thermal conductivity composite material (PVDF-xGnP(1)-CF(1)-5 for short) can be obtained by compression molding, wherein the total mass content of the high thermal conductivity filler in the composite material is 5%. Cut the test sample according to the test sample size.

[0031] The thermal conductivity and tensile strength results of PVDF-xGnP(1)-CF(1)-5 are shown in Table 1. In addition, as a comparative example, the thermal conductivity and tensile strength of PP-CNT-15 were tested by the same method. PP-CNT-15 is a thermally conductive composite material with carbon nanotubes as thermally conductive fillers and polypropylene as the base material. The mass content of carbon nanotubes is 15%.

[0032] The results show that the thermal conductivity of PVDF-xGnP(1)-CF(1)-5 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com