Water-based multi-layer membrane for lithium ion battery

A technology for lithium-ion batteries and diaphragms, applied in secondary batteries, battery pack components, separators/films/diaphragms/spacers, etc., can solve problems such as melting, peeling, and volume changes of diaphragms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0162] The preparation steps of water-based multilayer diaphragm are as follows:

[0163] 1) Select Enjie to produce ND9 series PE microporous base membrane;

[0164] 2) The PE microporous base film is passed through the MCD type coating machine (purchased from Fuji Machinery Industry Co., Ltd.), and the water-based inorganic particle slurry described in the following table 1 is coated on the PE microporous film through gravure printing, And finally after baking in an oven, a PE microporous membrane covered with an inorganic coating can be obtained;

[0165] 3) Pass the obtained PE microporous membrane covered with inorganic coating through the coating machine, and at the same time apply the water-based organic particle slurry shown in Table 1 on the intermediate product of the inorganic coating through gravure printing, and after drying After baking and shaping, the final water-based multilayer separator can be obtained.

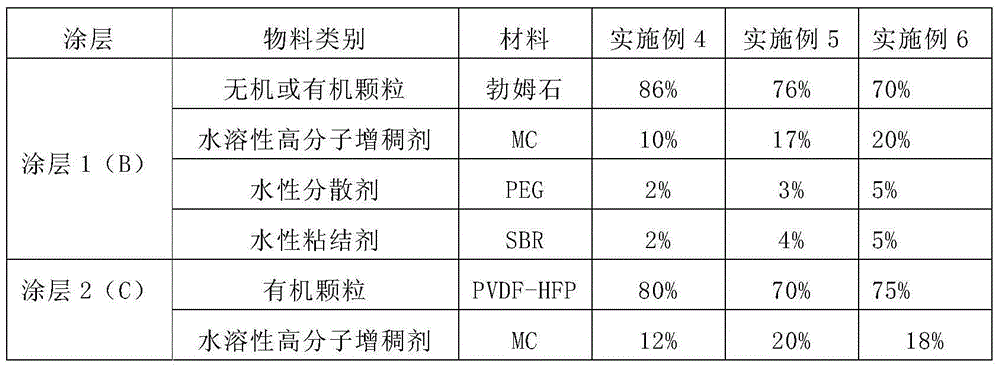

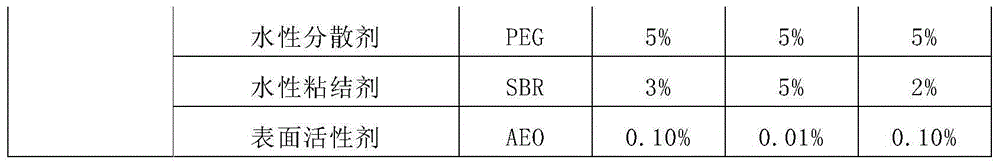

[0166] Table 1

[0167]

[0168]

[0169] ...

Embodiment 9

[0173] Embodiment 9: test result

[0174] Embodiment 1-8 and comparative example 1 are tested, and the results are as follows:

[0175]

[0176] where MD means longitudinal direction;

[0177] TD means landscape orientation.

[0178] It can be seen from the test results that when the two coating structures are used at the same time, it can not only meet the high temperature resistance of the separator, but also meet the bonding performance of the positive and negative electrodes and the separator, so that while meeting the performance of the battery separator, it can also meet the requirements of the battery. Consistent processing requirements.

Embodiment 10-13 and comparative example 2

[0179] Examples 10-13 and Comparative Example 2: Preparation of lithium-ion batteries

[0180] In this embodiment, the lithium-ion battery is composed of a positive electrode system, a negative electrode system, and an electrolyte system, wherein lithium manganate is used in the positive stage, graphite is used in the negative electrode, the electrolyte solution is an EC / EMC system, and the lithium salt concentration is (LiPF 6 ) is 1mol / L. Preparation process: the positive electrode is composed of lithium manganate and PVDF in a weight ratio of 100:3, and the negative electrode is composed of graphite, carboxymethyl cellulose (CMC), styrene-butadiene rubber emulsion in a weight ratio of 100:2:3 and PVDF shown in the table below -HFP composition. NMP is used as the solvent for the positive electrode, and water is used as the solvent for the negative electrode, and positive and negative electrode slurries are made respectively, and the separator shown in the table below is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com