Preparation method for patterned graphene membrane

A graphene film, graphene technology, applied in the direction of graphene, patterned surface photoengraving process, opto-mechanical equipment, etc., can solve the problems of complex template manufacturing process and high cost, and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Such as Figure 4 Shown, the preparation method of patterned graphene film of the present invention comprises the following steps:

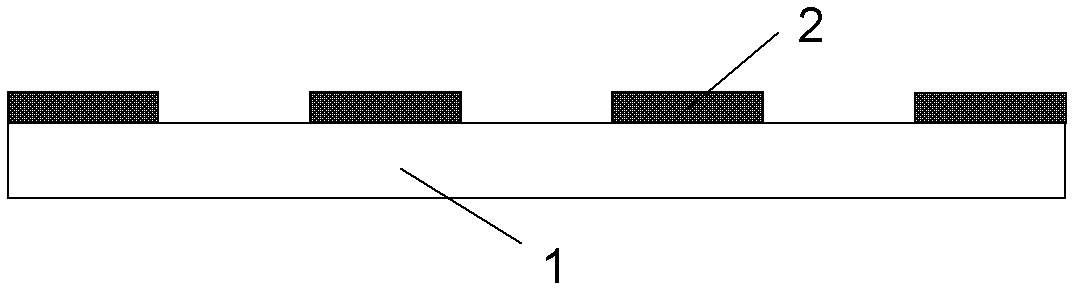

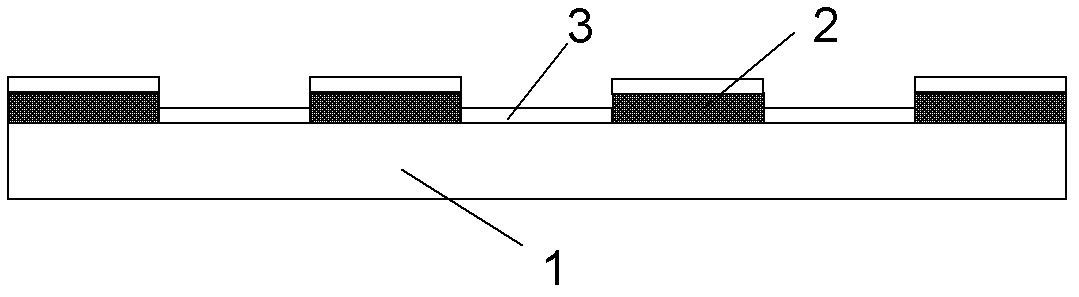

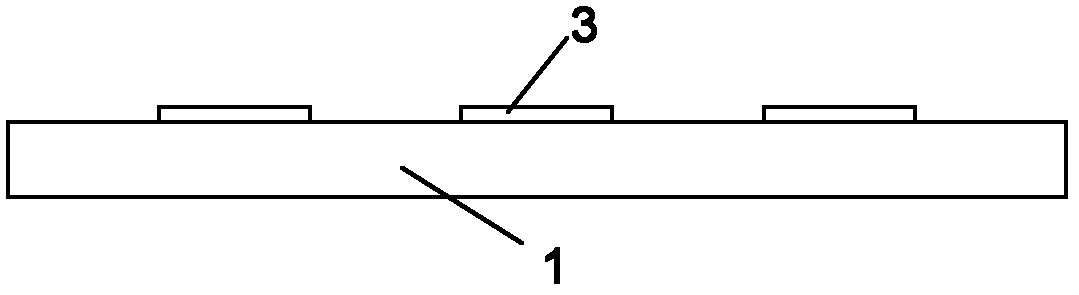

[0041] 1) First coat the photoresist or PMMMA2 on the substrate 1 by spin coating or scraping coating, and pattern the photoresist by ultraviolet lithography or electron beam etching process, in which the region where the graphene pattern needs to be formed The photoresist or PMMMA is removed by exposure and development process. Wherein, the substrate may be glass, metal, quartz, or an organic film, and the organic film may be a PET film, a PS film, a PE film, a PAN film, or the like. The thickness of photoresist or PMMMA is 1-10μm, such as figure 1 shown.

[0042] 2) Prepare graphene oxide solution: add graphite, sodium nitrate and concentrated sulfuric acid under the condition of ice-water bath, stir well and slowly add potassium permanganate, then stir at 25-40°C until the solution becomes paste; after that Add deionized water, cont...

Embodiment 1

[0047] Such as Figure 4As shown, the preparation method of the patterned graphene film of the present embodiment comprises the following steps:

[0048] 1) PMMA2 is first spin-coated on the glass substrate 1, the thickness of the PMMA is 5 μm, and the PMMA is patterned by an electron beam etching process, wherein the PMMA in the area where the graphene pattern needs to be formed is removed. Such as figure 1 shown.

[0049] 2) Preparation of graphene oxide solution: under ice-water bath conditions, add 1g graphite, 0.25g sodium nitrate, 11.75ml concentrated sulfuric acid (98%) in a 200ml beaker, slowly add 1.5g potassium permanganate after stirring well, and then add 1.5g potassium permanganate at 35 °C and stir until the solution turns into a paste. Then quickly add 46ml of deionized water, continue to stir for 15min, then add 140ml of deionized water and 1.5ml of hydrogen peroxide, and stir for 10min. The resulting suspension was filtered and washed with dilute hydrochlo...

Embodiment 2

[0054] Such as Figure 4 As shown, the preparation method of the patterned graphene film of the present embodiment comprises the following steps:

[0055] 1) Spin-coat the positive photoresist 2 on the PET film substrate 1 first, the thickness of the photoresist is 10 μm, and pattern the photoresist through the ultraviolet lithography process, wherein the photoresist in the region where the graphene pattern needs to be formed The resist is removed through an exposure process. Such as figure 1 shown.

[0056] 2) Prepare graphene oxide solution:

[0057] Under the condition of ice-water bath, add 1.5g of graphite, 0.35g of sodium nitrate, 11.75ml of concentrated sulfuric acid (98%) into a 200ml beaker, stir well and slowly add 2.0g of potassium permanganate, then stir at 40°C until the solution becomes Mushy. Then quickly add 46ml of deionized water, continue to stir for 15min, then add 140ml of deionized water and 1.5ml of hydrogen peroxide, and stir for 10min. The result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com