Gel pad and UV-curving production method thereof

A gel and ultraviolet technology, used in mattresses, spring mattresses, liquid-filled cushions, etc., can solve problems such as low efficiency, not long enough cooling time, and affecting appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

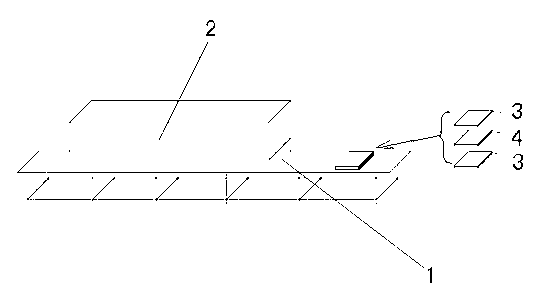

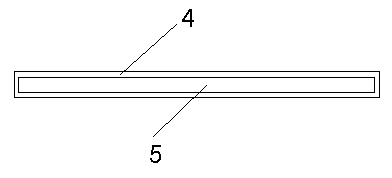

[0018] Get 5 kilograms of monomers, 0.01 kilograms of cross-linking agents, 0.001 kilograms of photoinitiators, and 94.989 kilograms of water to form 100 kilograms of gel materials. , methacrylamide, AMPS (2-acrylamide-2-methylpropanesulfonic acid) in the composition of two or more, such as a mixture of sodium acrylate and AMPS at a ratio of 3:1. The crosslinking agent used is a compound with non-conjugated multiple double bonds, which is polyol (glycerol), N, N'-methylenebisacrylamide, such as glycerol, and the photoinitiator used is BP (Benzophenone, benzophenone, Jiangyin Moore Chemical, called photoinitiator BP), the water is pure water, the prepared gel material is poured into the prepared gel bag, and after exhausting, it is blanched and sealed. Two pieces of tempered glass or quartz glass flatten the gel bag cover, and transport the semi-finished product of the gel bag cover pressed with glass to the ultraviolet light machine for curing through the conveyor belt. The ir...

Embodiment 2

[0020] Take 22 kilograms of monomers, 1 kilogram of crosslinking agent, 1 kilogram of photoinitiator, and 76 kilograms of water to form 100 kilograms of gel raw materials. , methacrylamide, AMPS (2-acrylamide-2-methylpropanesulfonic acid) in the combination of two or more, such as sodium acrylate, acrylamide and AMPS in a ratio of 3:1:1 Prepared mixture. The crosslinking agent used is a compound with non-conjugated multiple double bonds, such as polyol (glycerol), N, N'-methylenebisacrylamide, such as N, N'-methylenebisacrylamide , the photoinitiator used is commercially available photoinitiator 184 (Methanone, 1-hydroxycyclohexyl phenyl ketone, Jiangyin Moore Chemical Industry), the water is pure water, and the prepared gel material is poured into the prepared gel In the plastic bag cover, heat the seal after exhausting, flatten the gel bag cover with two pieces of tempered glass or quartz glass, and transport the semi-finished product of the gel bag cover pressed with glass...

Embodiment 3

[0022] Get 30 kilograms of monomers, 2 kilograms of cross-linking agents, 2 kilograms of photoinitiators, and 66 kilograms of water to form 100 kilograms of gel raw materials. , methacrylamide, AMPS (2-acrylamide-2-methylpropanesulfonic acid) in the combination of two or more, such as acrylamide: AMPS: sodium acrylate: methacrylamide is 5:1 :2:1 mixture. The crosslinking agent used is a compound with non-conjugated multiple double bonds, which is polyhydric alcohol (glycerol), N, N'-methylenebisacrylamide, such as using glycerol and N, N'-methylene The mixture of methacrylamide, the photoinitiator used is commonly used commercially available diaryliodonium salt (GE company in the United States). The water is pure water, and the prepared gel material is poured into the prepared gel bag Inside the cover, heat the seal after exhausting, flatten the gel bag cover with two pieces of tempered glass or quartz glass, and transport the semi-finished product of the gel bag cover presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com