Pure-nickel metallographic etchant and corroding method using same

A technology of corrosive liquid and pure nickel, which is applied in the chemical industry, can solve the problems of no corrosion of grain boundaries, no observation of grain boundaries and grain size, no observation of phase and phase contrast, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

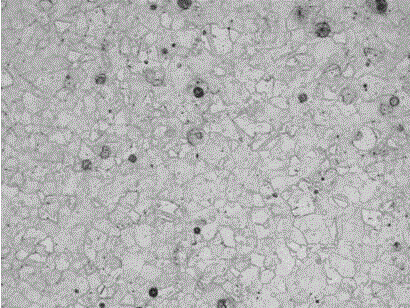

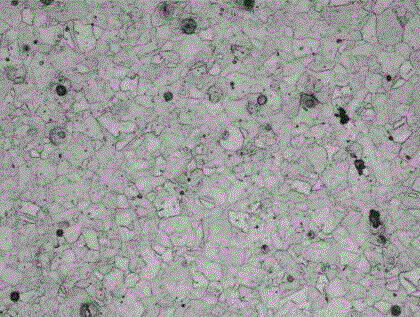

Image

Examples

Embodiment Construction

[0017] The pure nickel N6 wire rod with a diameter of 8mm produced by the horizontal continuous casting method is used for metallographic sample sampling by wire cutting to make a metallographic sample with a height of 15mm, and then the sample is mounted by a mounting machine, and an appropriate amount of mounting powder is added. Set a sample with a height of 25mm, and then use water sandpaper of different thicknesses for grinding, such as successively use 400 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh, 1500 mesh, and 2000 mesh water sandpaper to grind the sample. When using 400 mesh to 1200 mesh water sandpaper for grinding and polishing, the speed of the polishing machine is set at 550 rpm, and when using 1500 and 2000 mesh metallographic sandpaper for grinding and polishing, the surface of the metallographic sample is relatively smooth at this time. When the fast speed is selected, it is easy to form new scratches, so the speed of the polishing machine is set to 500 rp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com