Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Clear dividing line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

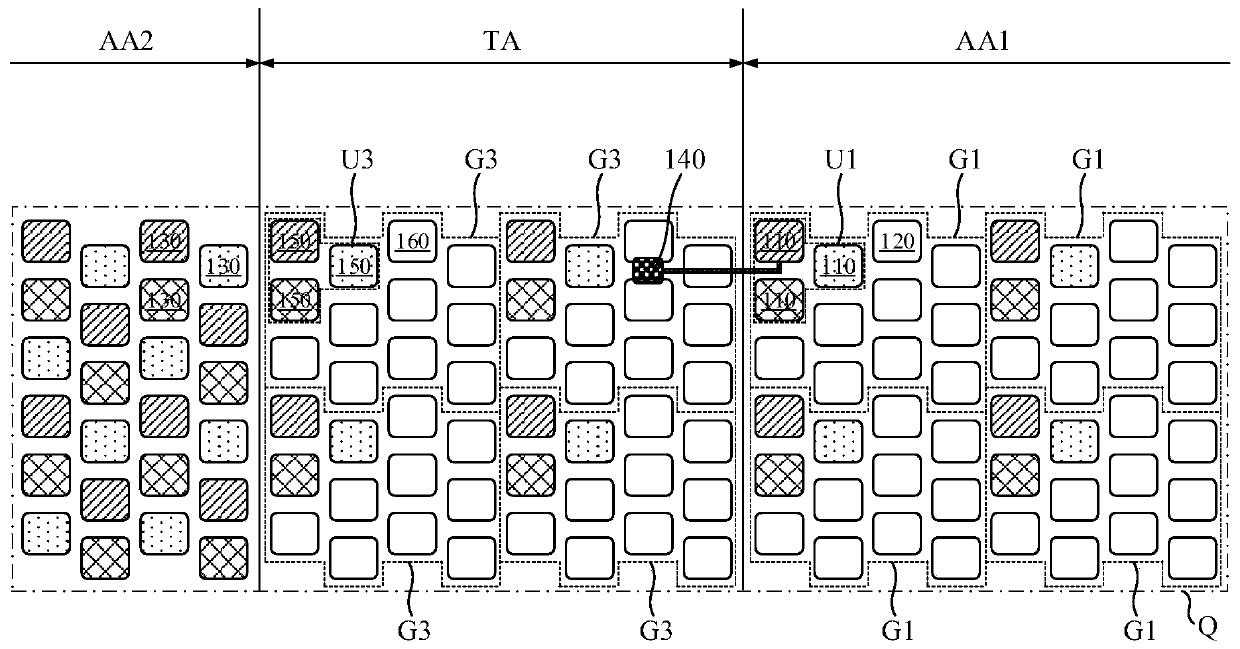

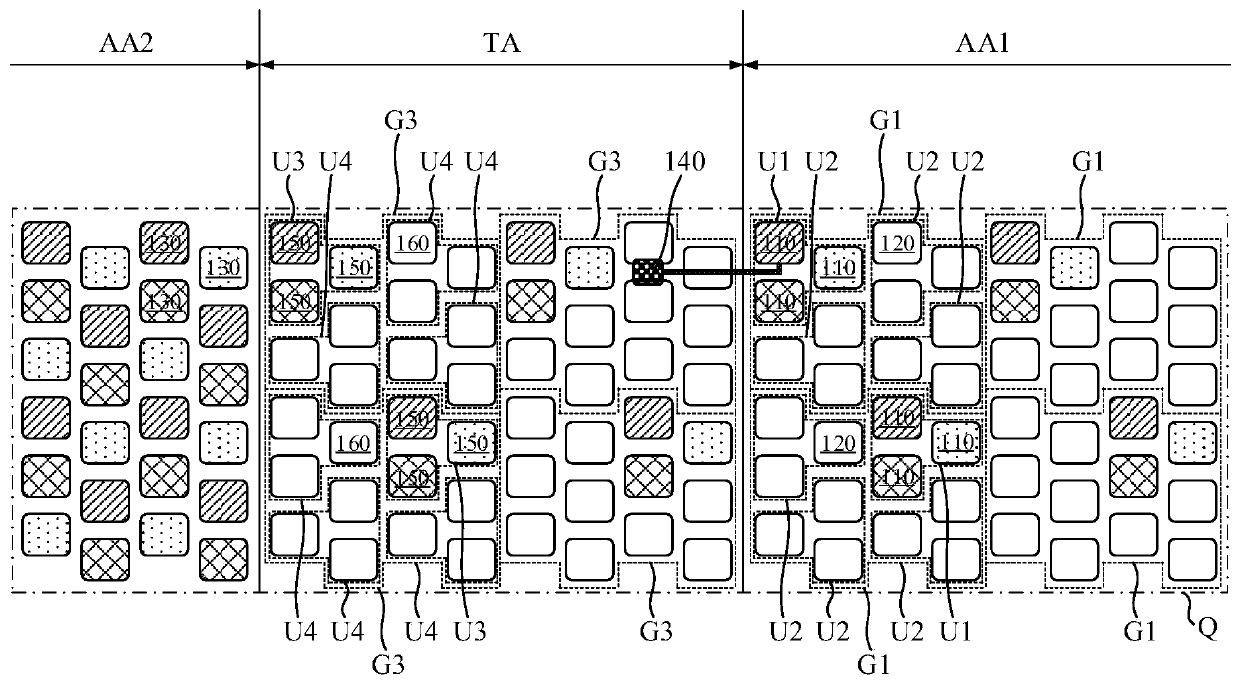

Display panel and display device

ActiveCN110783384AIncrease the display areaRealize full screen designSolid-state devicesSemiconductor devicesComputer hardwareComputer graphics (images)

The invention discloses a display panel and a display device. The display panel comprises a first display area and a second display area, and the light transmittance of the first display area is larger than that of the second display area. The display panel comprises first pixel groups located in the first display area and second sub-pixels located in the second display area, wherein each first pixel group comprises a first light-emitting pixel unit and a first non-light-emitting sub-pixel, and the first light-emitting pixel unit comprises first light-emitting sub-pixels; and the first pixel arrangement structure formed by the first light-emitting sub-pixels and the first non-light-emitting sub-pixels is the same as the second pixel arrangement structure formed by the second sub-pixels. According to the display panel provided by the embodiment of the invention, the boundary between the second display area with the higher PPI and the transition display area with the lower PPI in the display picture of the display panel is fuzzified, so that an obvious boundary between the two display areas is avoided, and the display effect is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

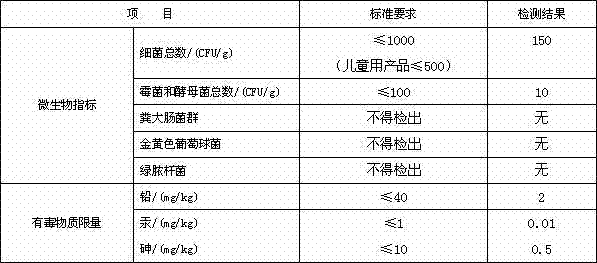

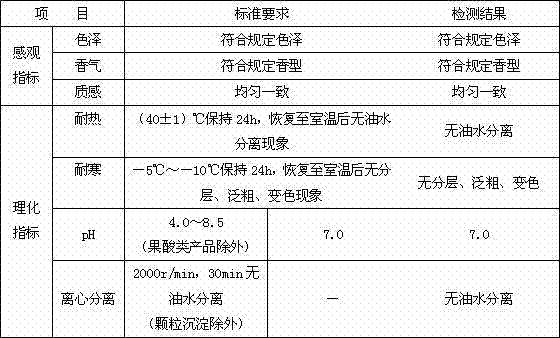

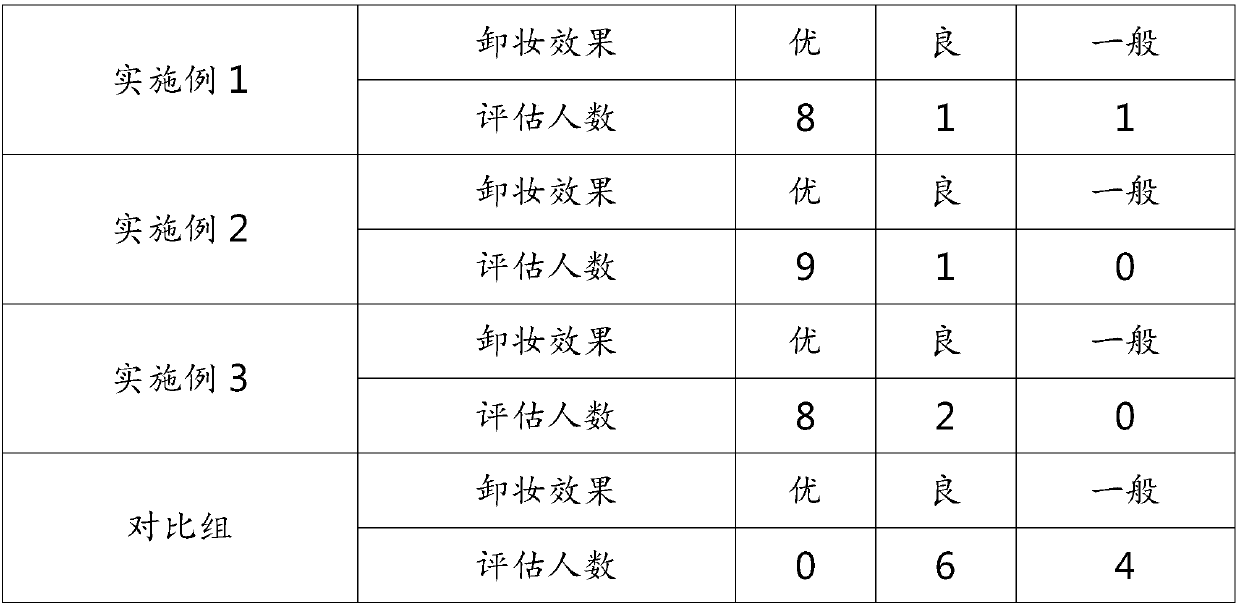

Double-layer cleansing lotion and preparation method thereof

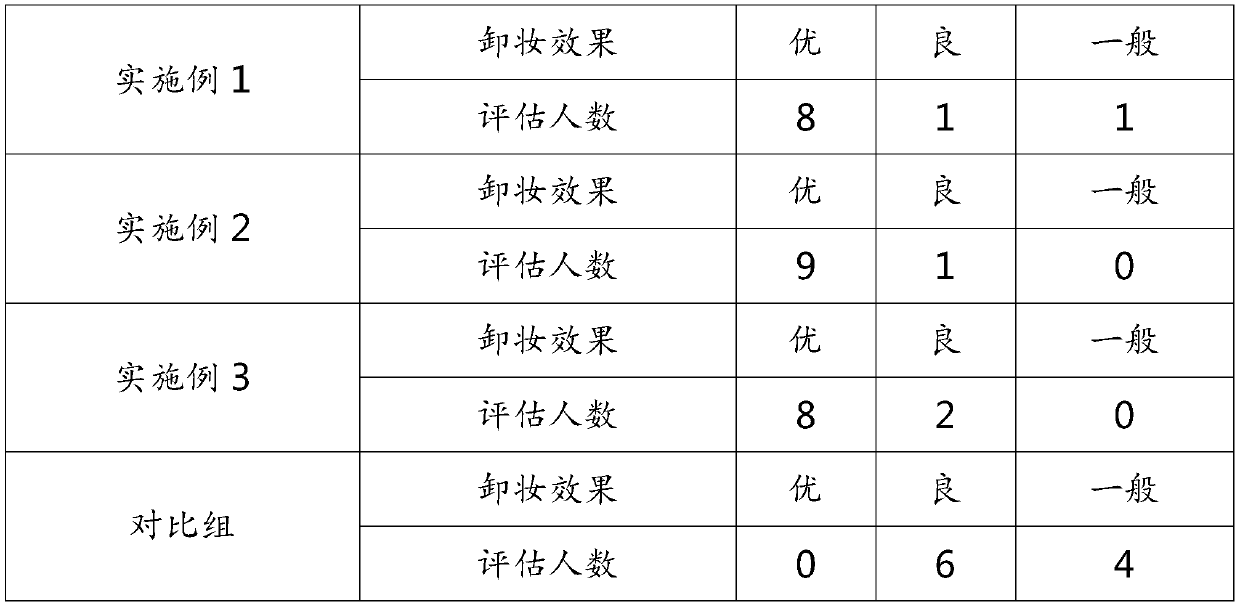

ActiveCN103202775AEasy to cleanGood removal effectCosmetic preparationsMake-upInorganic saltsEmulsion

The invention discloses a double-layer cleansing lotion and a preparation method thereof. The double-layer cleansing lotion comprises a water-phase layer and an oil-phase layer. The water-phase layer comprises water soluble preservatives, water soluble grease, inorganic salt electrolyte, moisturizing agent and water. The oil-phase layer comprises water-insoluble grease, oil soluble preservatives and oil soluble pigment. The preparation method includes: sequentially adding water soluble preservatives, water soluble grease, inorganic salt electrolyte and moisturizing agent into water, well mixing to obtain water-phase layer components, sequentially adding oil soluble preservatives and oil soluble pigment in water-insoluble grease, well mixing to obtain oil-phase layer components, and mixing the water-phase layer components and the oil-phase layer components to obtain the double-layer cleansing lotion. During use, the double-layer cleansing lotion can be emulsified by shaking to form emulsion, and instant deemulsification occurs to form double-layer structure with clearly-separated oil and water when the double-layer cleansing lotion stands still. The double-layer cleansing lotion is mild in cleansing, instant in emulsification, fast in deemulsification, clear in boundary and the like.

Owner:FOSHAN WIN COSMETIC

Electronic product shell and surface treatment process thereof

ActiveCN105323988AAchieve Textured LooksProcess color is not limitedVacuum evaporation coatingSputtering coatingLacquerVacuum coating

The invention relates to an electronic product shell and a surface treatment process thereof, in particular to an electronic product shell enabling two kinds of glosses on the same shell body or a single component and a surface treatment process of the electronic product shell. The process includes the following steps that: bottom paint is sprayed on a shell; a coating film coats on the bottom paint through vacuum coating; middle paint is sprayed on the coating film; matte surface paint is sprayed on the middle paint; and masking treatment is performed on a local region of the matte surface paint, and bright light surface paint is sprayed on the matte surface paint which has been subjected to the masking treatment, a region coated with the bright light surface paint is a bright region, and a masked region is a matte region. The surface treatment process is applied to the shell. With the electronic product shell provided by the invention adopted, the same shell can have the bright light region and the matte region, and therefore, the shell can have two kinds of glosses.

Owner:VIVO MOBILE COMM CO LTD

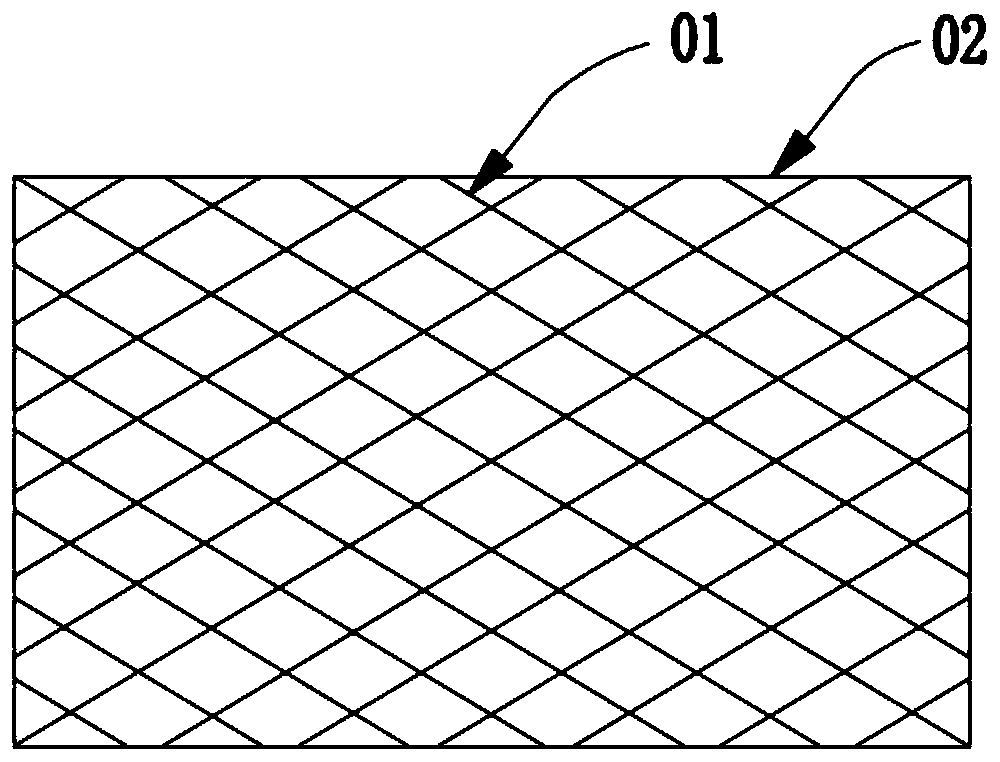

Preparation process for imitation full-body tile and grid provided with square lattices and used for preparation process

ActiveCN107520950AAvoid cross mixingAvoid out of shapeFeeding arrangmentsAuxillary shaping apparatusSurface layerBrick

The invention provides a preparation process for an imitation full-body tile and a grid provided with square lattices and used for the preparation process. The preparation process comprises the following steps that firstly, the grid with the square lattices is arranged on a material distribution platform; secondly, material distribution is conducted, and a preset textured pattern is formed; thirdly, a secondary color mist spray material is applied into the lattices not applied with a main color mist spray material in the grid; fourthly, press forming is conducted after a layer of fabric is applied; and fifthly, the processes such as marking are conducted on green bricks according to the corresponding codes of the bottom material textures distributed by a press, and the imitation full-body tile with the consistent decoration textures in the fabric layer and the bottom material layer are obtained. According to the preparation process for the imitation full-body tile and the grid with the square lattices, even slotting of the imitation full-body tile is conducted, the textures in a slot of the imitation full-body tile can be perfectly in joint with infiltrating textures of the surface layer, and no segmented offset or breakage phenomenon exists. The invention further provides the grid provided with the square lattices and used in the preparation process for the imitation full-body tile, and deformation of the textures in the powder crossed mixing and material push processes after material distribution can be avoided.

Owner:FOSHAN DONGPENG CERAMIC +2

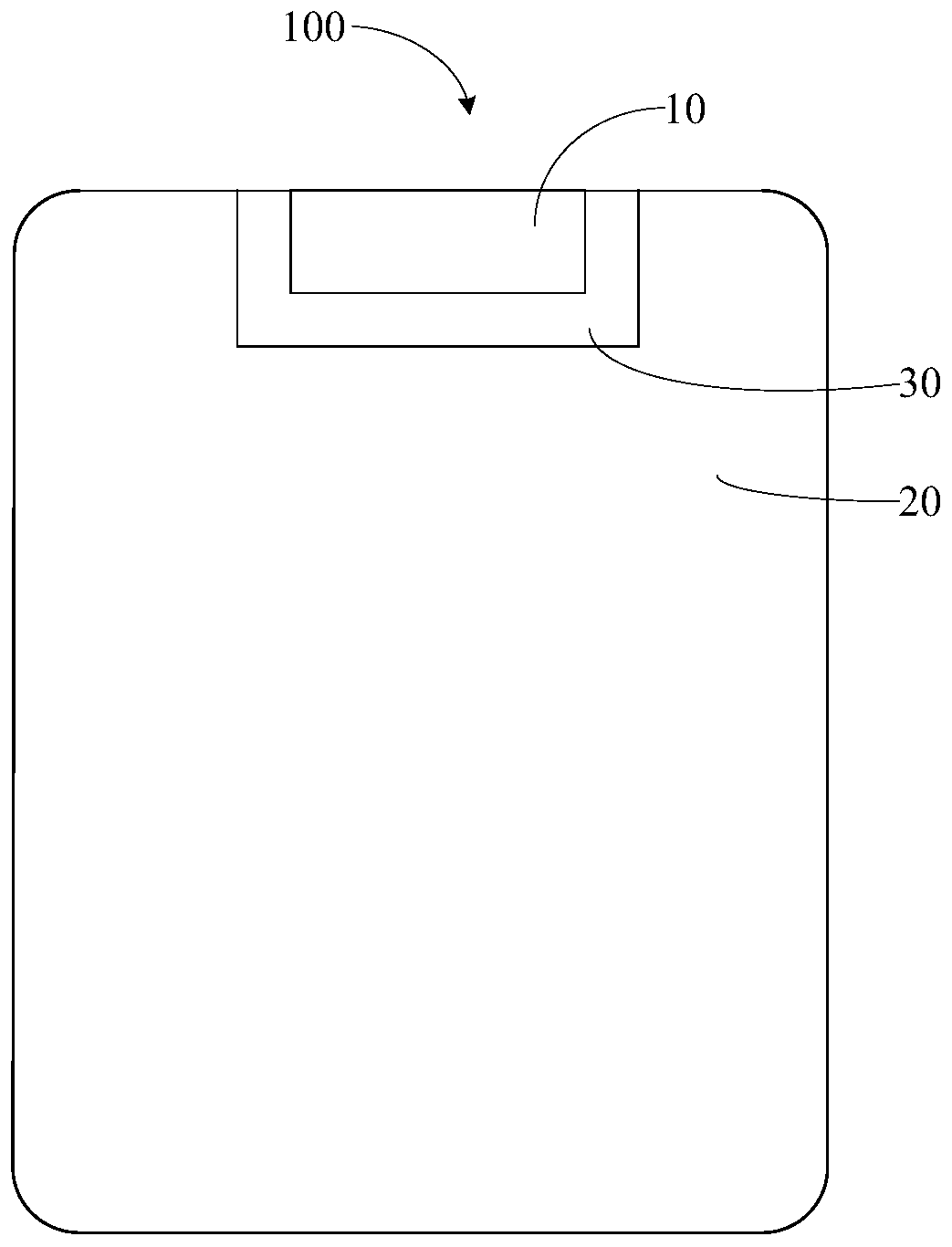

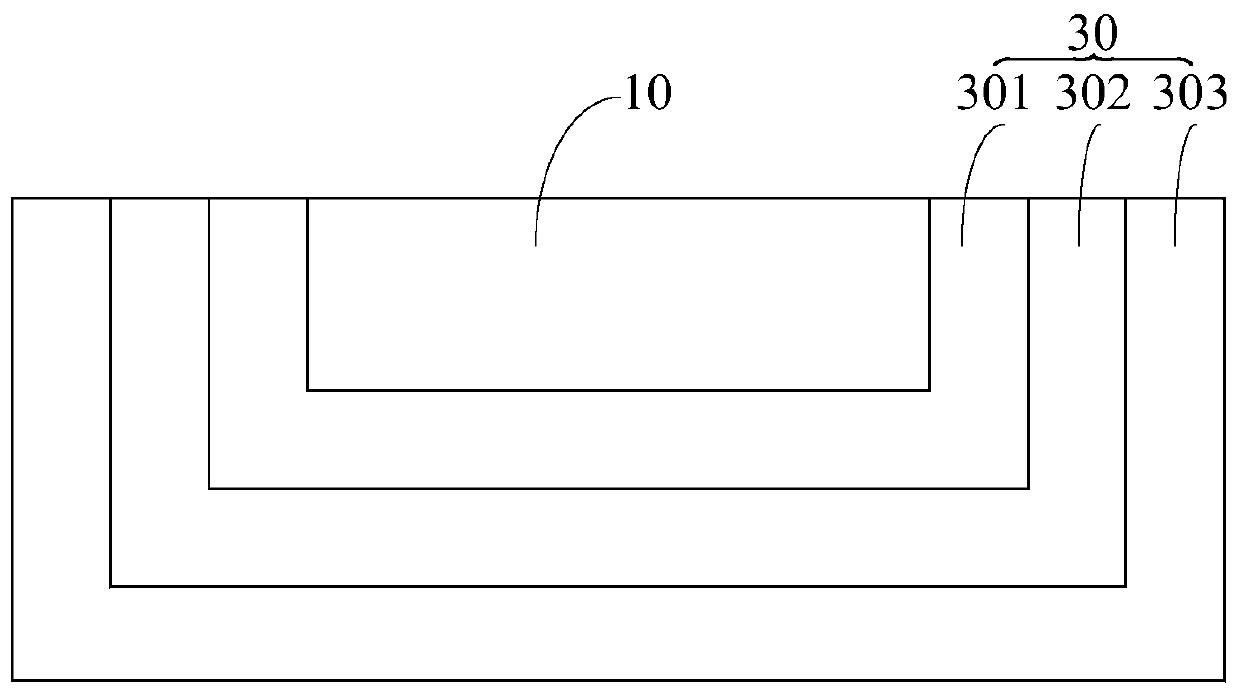

Display substrate, display panel, and display device

ActiveCN110767710AClear dividing lineImprove user experienceStatic indicating devicesSolid-state devicesDisplay deviceEngineering

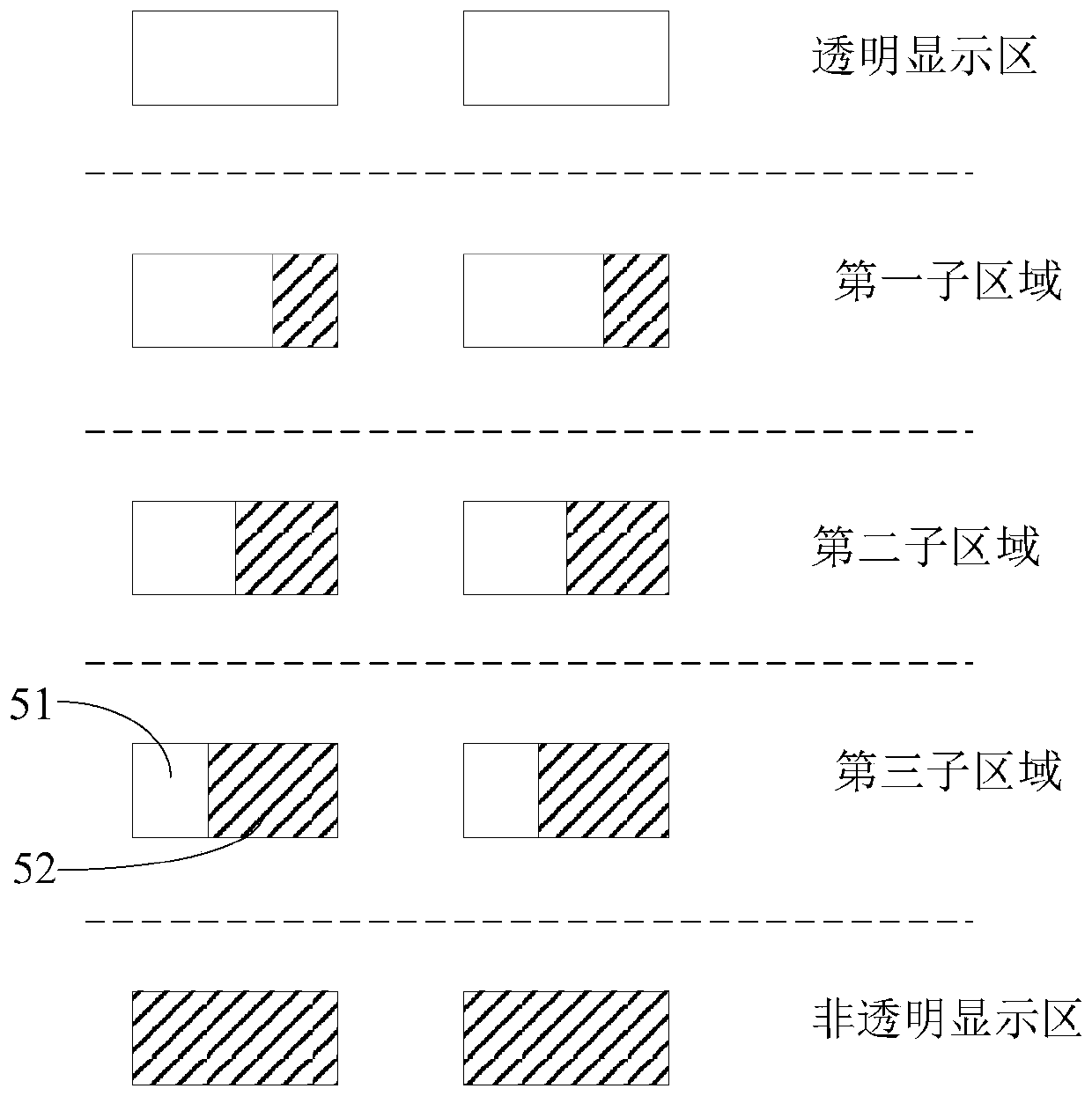

The invention provides a display substrate, a display panel, and a display device. The display substrate comprises a transparent display area, a non-transparent display area, and a transitional display area adjacent to the transparent display area and the non-transparent display area; and along the direction in which the non-transparent display area points to the transparent display area, the light transmittance of the transitional display area gradually increases, and the minimum light transmittance of the transitional display area is greater than the light transmittance of the non-transparent display area, and the maximum light transmittance of the transitional display area is less than the light transmittance of the transparent display area.

Owner:YUNGU GUAN TECH CO LTD

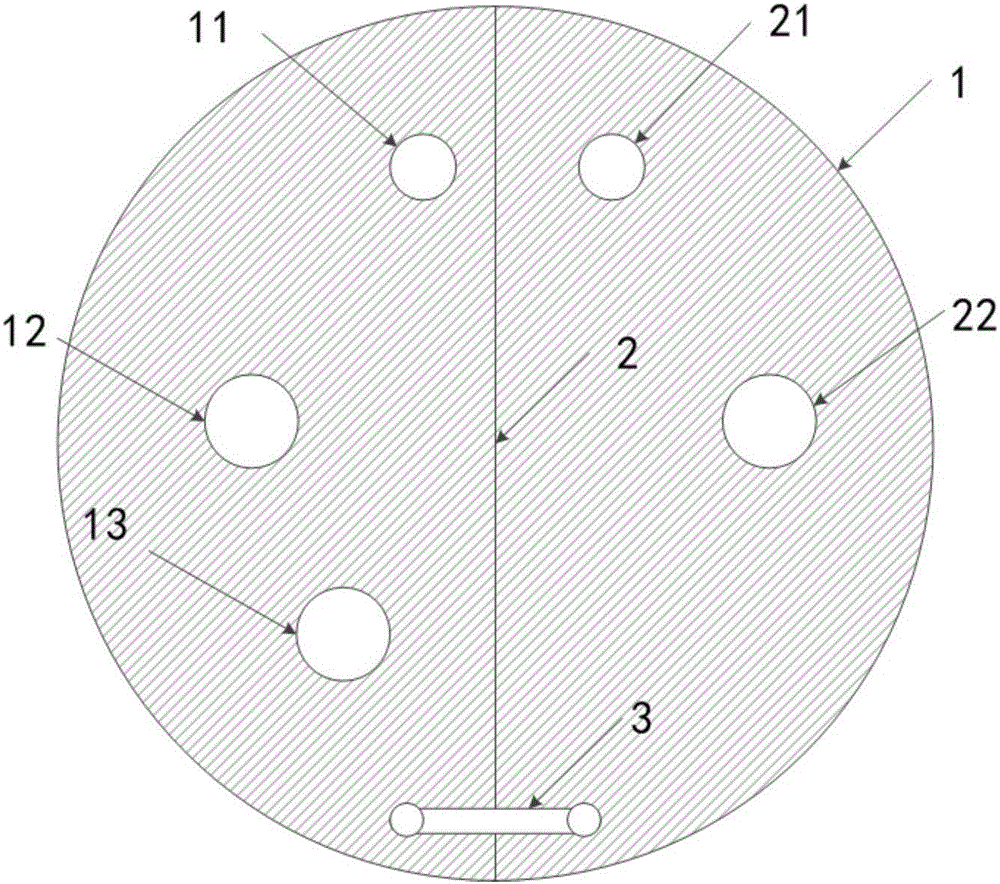

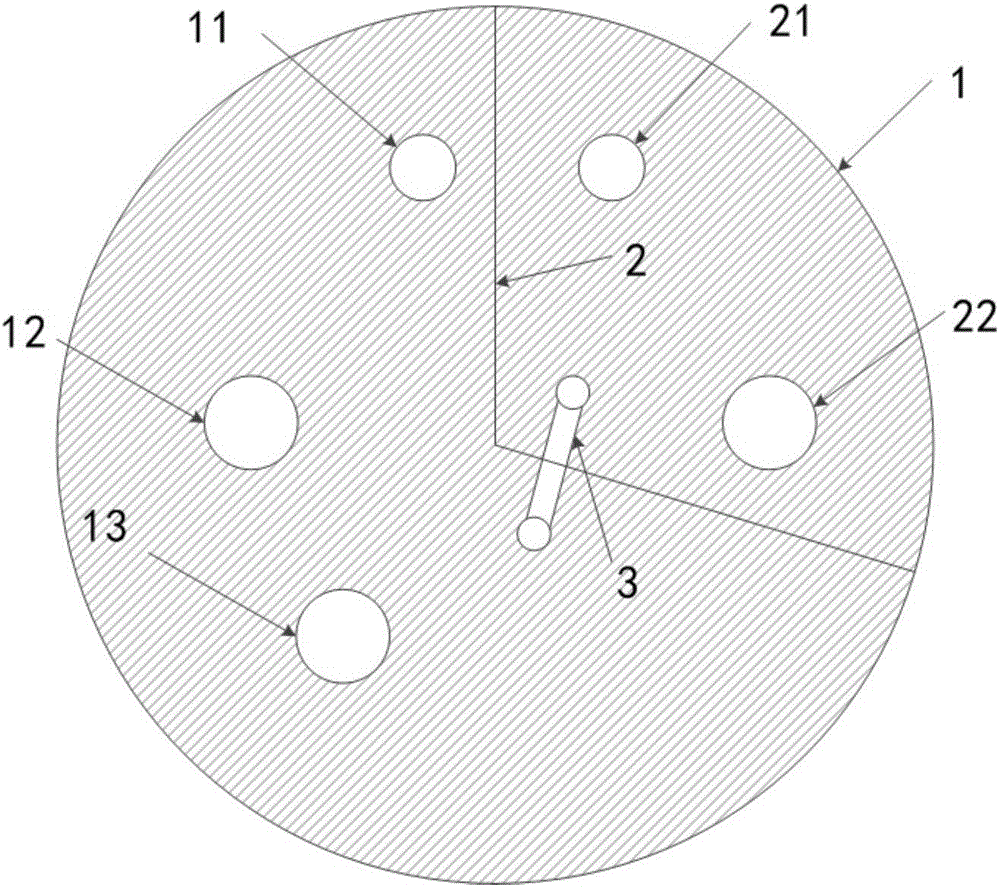

Touch display device and method, and washing machine

InactiveCN104423747ACooperate with usage habitsClear dividing lineOther washing machinesTextiles and paperComputer hardwareLaundry washing machine

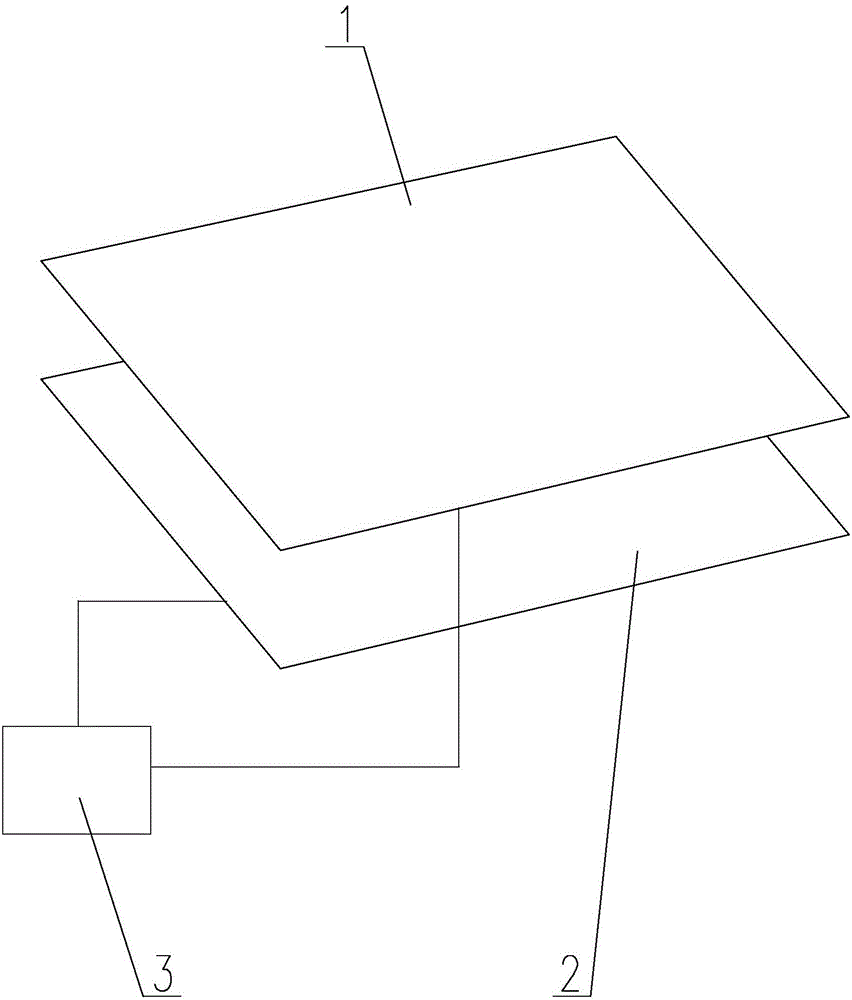

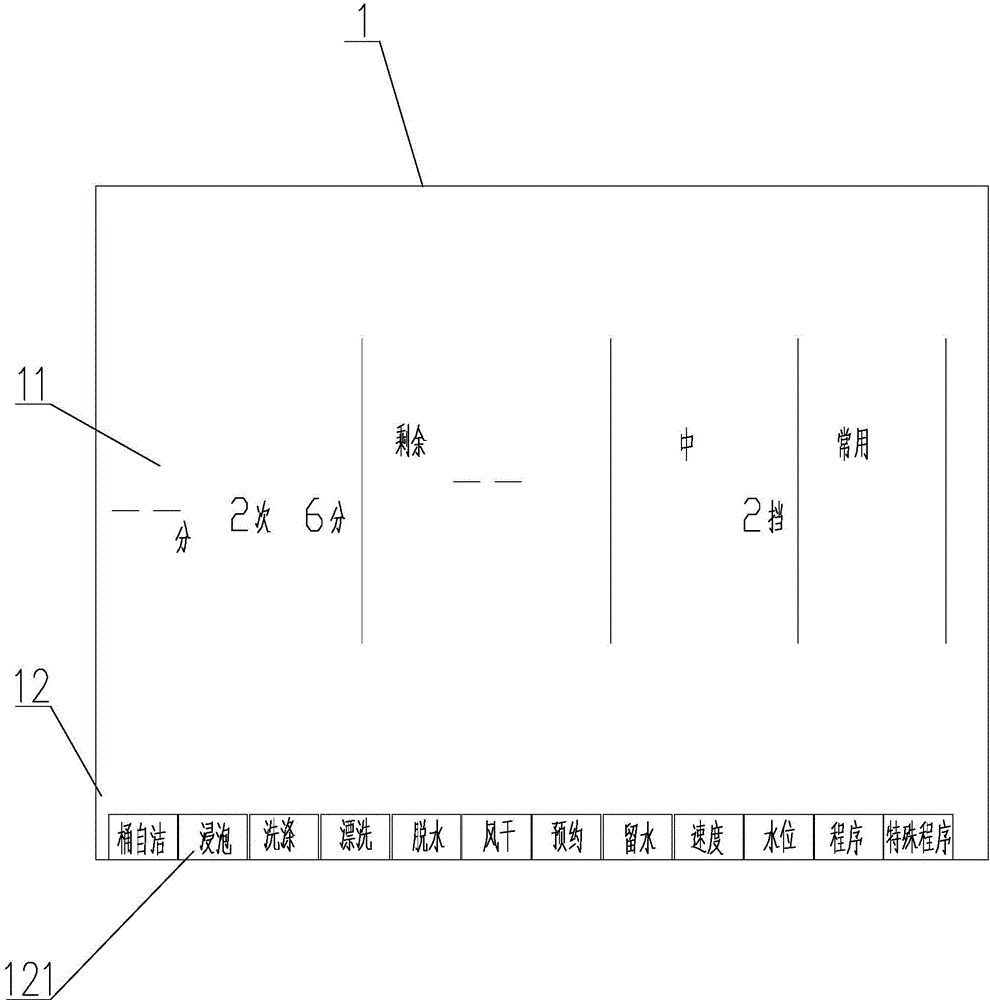

The invention discloses touch display device and method, and a washing machine. The touch display device comprises a display screen, and a touch screen arranged on the display screen; the touch screen and the display screen are both connected with a controller, wherein the touch screen is divided into a display area and a key area; a key is arranged on the key area, and the key area is used for sensing an input signal and transmitting the input signal to the controller; the display screen is used for receiving a control signal and displaying the operation result through the display area; the display area and the key area are different in background color and font color; the display screen is a VA type LCD. The touch display device has the advantages that the mode in combination of the touch key and the display screen replaces the traditional mode in combination of the mechanical key and the display screen, so as to adapt to the habits of users in use; the display time of the display screen under electrifying can be greatly reduced, and the view angle is expanded; the contrast ratio of the display screen is up to more than 100: 1, which realizes high definition display; the view angle of the display screen is up to 180 degrees, which means full view angle and is convenient to user to view.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

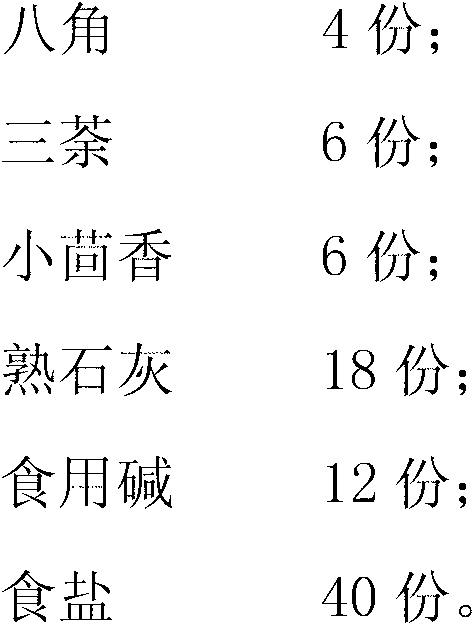

Preparation method for marinated egg

The invention relates to the field of foods and particularly to a method for preparing the marinated egg. The method comprises the following steps of: preparing a hyperosmotic hydrated lime mixed solution; adding spice seasoning in the hyperosmotic hydrated lime mixed solution; adjusting the pH value to 7.8-8.8 to obtain a curing liquid, wherein the hyperosmotic hydrated lime mixed solution contains edible salt hyperosmotic solution; soaking a fresh egg in the curing liquid for 6-10 days to obtain a marinated egg as a semi-finished product; and continuously curing the marinated egg as the semi-finished product for 1-3 days to obtain a raw marinated egg, wherein the curing process is carried out in an environment where the air pressure is higher than the atmospheric pressure and an egg shell is prevented from being mechanically damaged. According to the marinated egg prepared by the preparation method disclosed by the invention, an egg white part is glittering and translucent like a preserved egg; a yolk part is delicious like crab roe and is colorful in luster; the boundary of the egg white and the yolk is remarkable; the marinated egg is fragrant in mouthfeel and can be eaten in a cold or hot state; the flavors of the marinated egg in the cold and hot state are different; and the marinated egg has the advantages of favorable elasticity, large yolk particle and abundant nutrient value.

Owner:CHONGQING CITY LIANGPING COUNTY PANGPO FUDEJI CATERING

Three-layer cleansing lotion and preparation method thereof

ActiveCN107550743AEffective dissolutionDissolve easilyCosmetic preparationsMake-upAnti-Allergic AgentsPreservative

The invention provides a three-layer cleansing lotion and a preparation method thereof. The three-layer cleansing lotion is prepared from an upper-layer oil phase, a middle-layer oil phase and a lower-layer water phase, wherein the upper-layer oil phase is prepared from 10 to 25 percent of cyclopentasiloxane, 5 to 15 percent of isohexadecane and 0.5 to 2 percent of grape seed oil; the middle-layeroil phase is prepared from 25 to 35 percent of diethoxyethyl succinate and 0.1 to 0.5 percent of gromwell oil; the lower-layer water phase is prepared from 0.1 to 2 percent of surfactant, 15 to 25 percent of moisturizer, 0.01 to 0.2 percent of anti-allergic agent, 0.0001 to 0.5 percent of water-soluble pigment, 0.02 to 2 percent of preservative and the balance of deionized water; the components of all layers are mixed and prepared to obtain the three-layer cleansing lotion. According to the three-layer cleansing lotion, the different fats are matched with the surfactant, so that the cleansingeffect is optimal, and remarkable cleaning effects on water-soluble dirt and fat soluble dirt are achieved.

Owner:TIANJIN YU MEI JING GRP

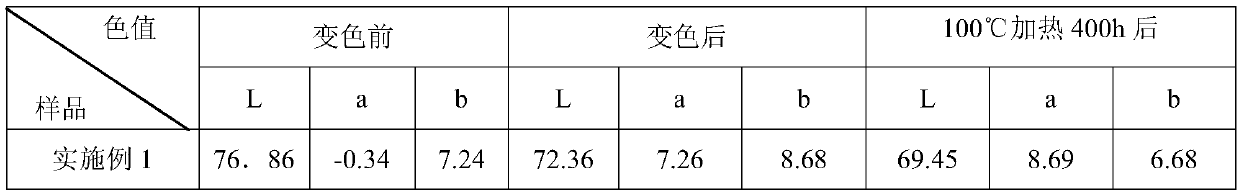

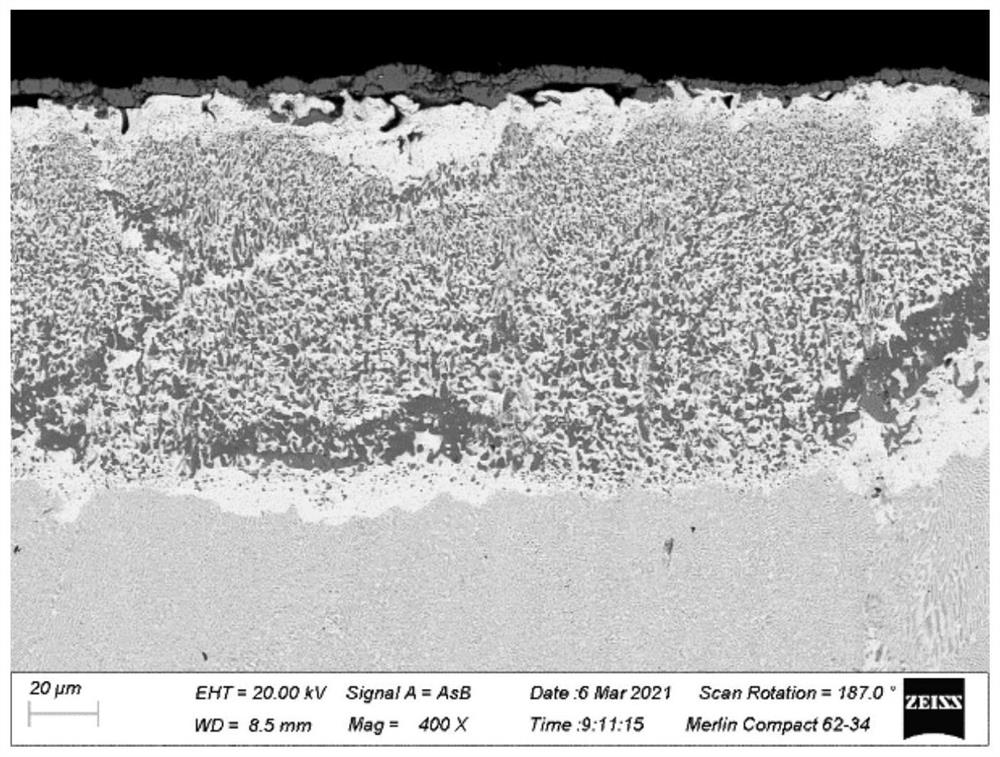

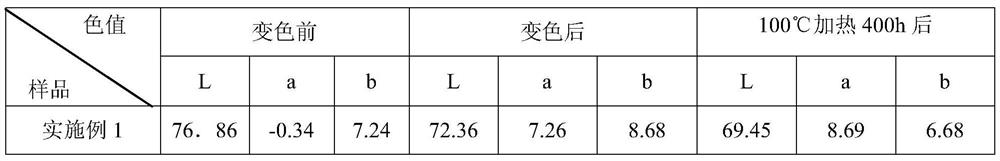

Thermochromic low-melting-point polyester film and preparation method thereof

ActiveCN111098577AExtended use timePrevent loss of functionSynthetic resin layered productsPolymer scienceCopolyester

The invention discloses a thermochromic low-melting-point polyester film and a preparation method thereof, and belongs to the field of polyester. The method comprises the following steps: taking terephthalic acid, 1, 4-butanediol or ethylene glycol as raw materials, adding aliphatic dibasic acid, polyester diol and a monohydroxy end-capping reagent by adopting a direct esterification method, and carrying out esterification and polymerization reactions to prepare the PBT or PET modified copolyester, crushing PET or PBT slices, uniformly mixing the crushed PET or PBT slices with a thermochromicmaterial, a heat stabilizer and an antioxidant in a high-speed mixer, and carrying out melt blending and pelletizing by using a double-screw extruder to obtain thermochromic low-melting-point polyester master batch; and using the prepared thermochromic low-melting-point polyester master batch as an intermediate layer and low-melting-point polyester as an outer layer to prepare three layers of thethermochromic low-melting-point polyester film. The prepared thermochromic polyester film is low in modulus, good in hand feeling, low in crystallinity, good in thermal adhesiveness and good in colorchanging performance, and can be widely applied to the fields of automobiles, buildings, heat-seal packaging films and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

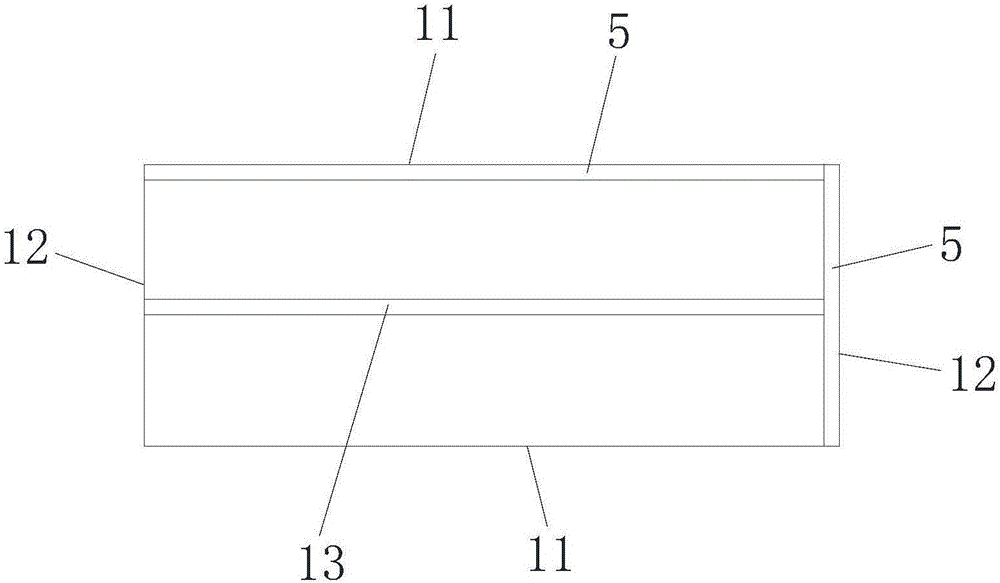

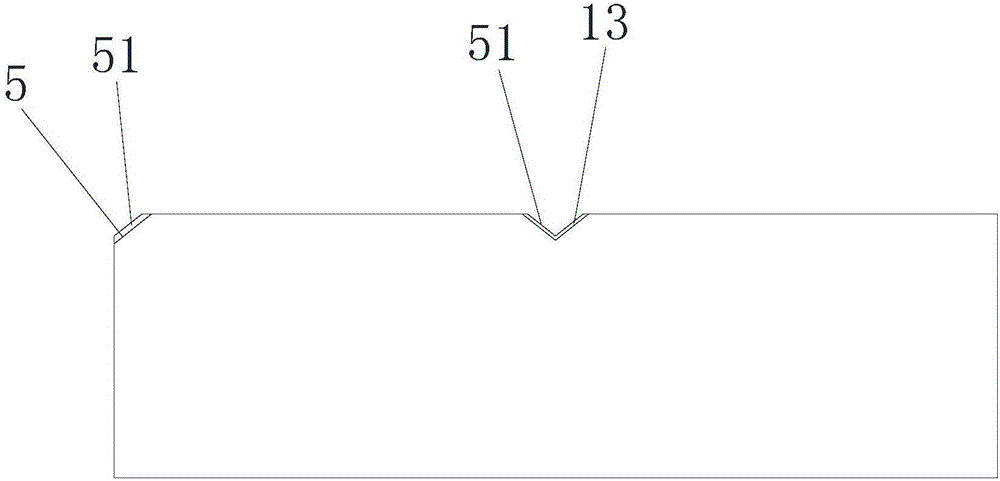

Double-spliced wood-plastic floor

The invention provides a double-spliced wood-plastic floor comprising a wood-plastic composite (WPC) layer, a middle material layer, a color film layer and a wearable layer which are arranged sequentially from bottom to top, wherein the upper surface of the double-spliced wood-plastic floor is provided with a pair of opposite first edges and a pair of opposite second edges; the upper surface of the double-spliced wood-plastic floor is provided with a boundary edge; the boundary edge is basically parallel with the first edges or the second edges; at least one first edge and / or second edge is provided with a boundary region; and the boundary region is arranged in the form of extending along the first edge and / or the second edge. The upper surface of the double-spliced wood-plastic floor is provided with the boundary edge, so that the single floor looks like two floors. During flooring, the effect of flooring the traditional two floors can be achieved only by flooring one floor, so the flooring efficiency is greatly increased and the labor cost is reduced. In addition, the boundary region, namely a boundary for differentiating different floors, is formed on the upper surface of each floor, and parting strips are not needed, so that flooring processes are reduced and the flooring difficulty is reduced.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

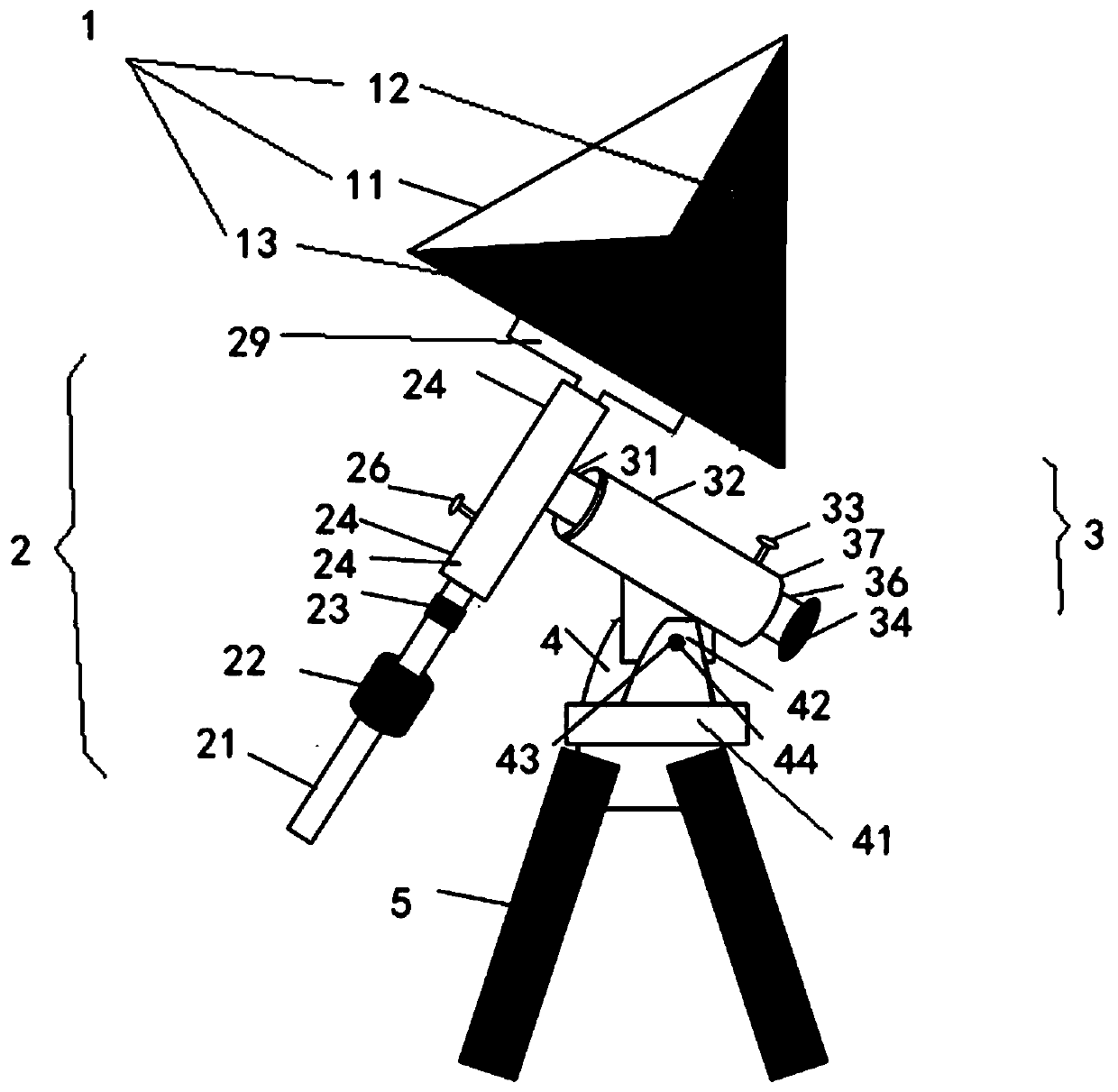

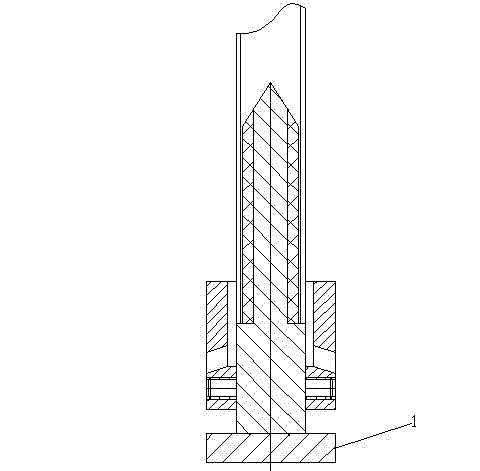

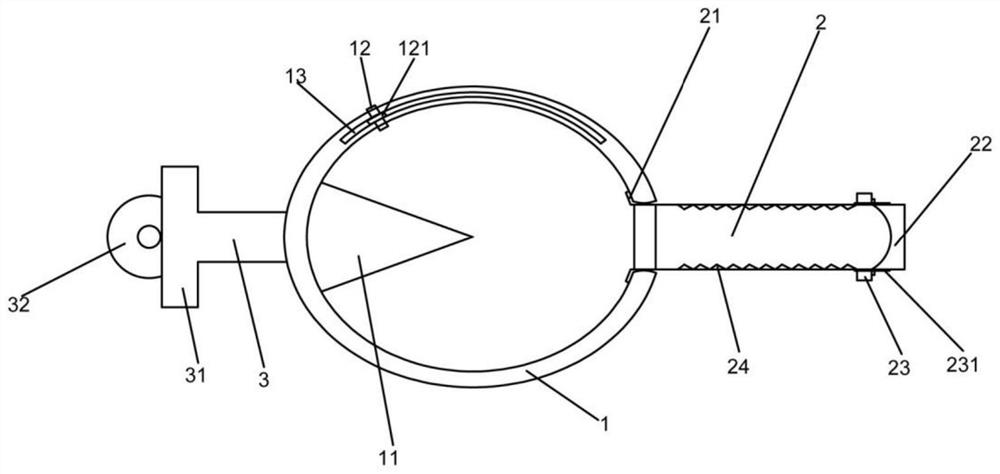

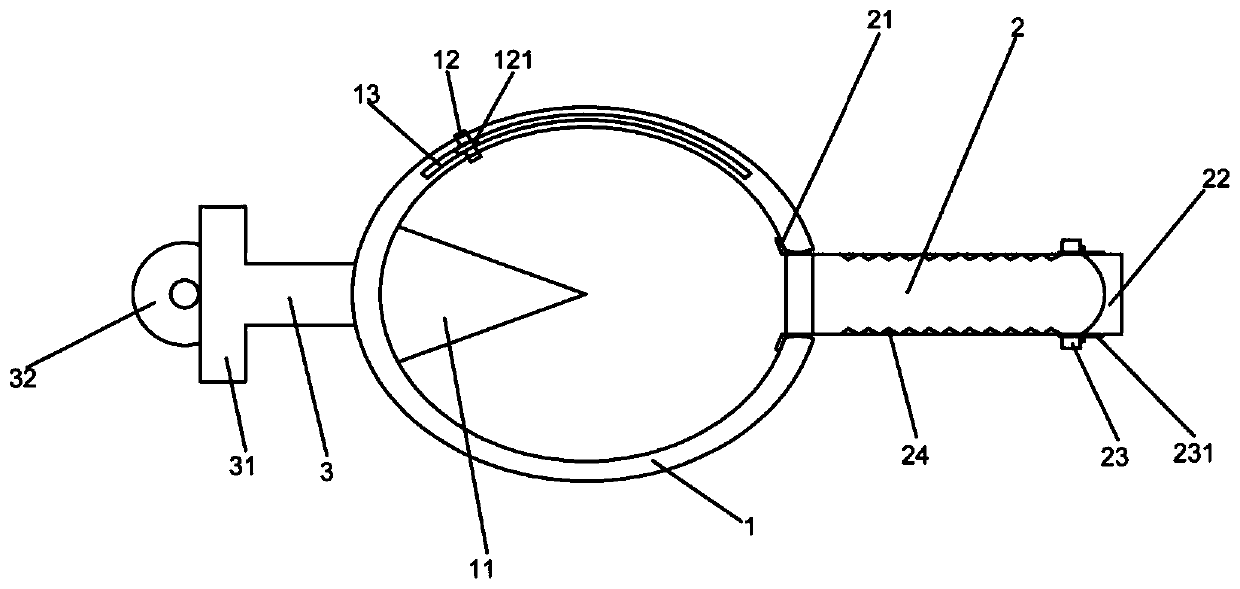

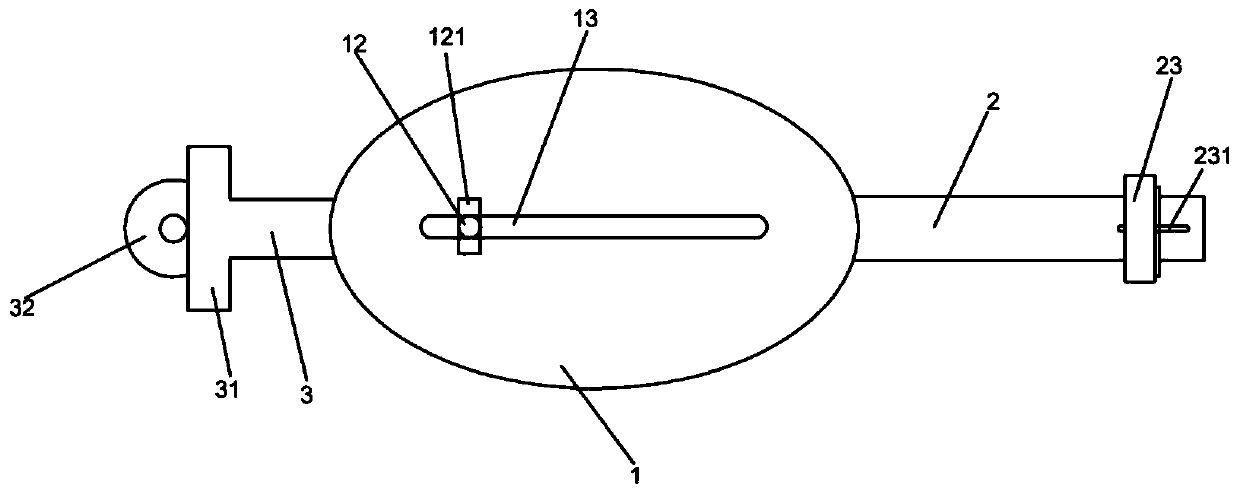

Artificial corner reflector for SAR (synthetic aperture radar) interferometry calibration

ActiveCN109901118AHigh precisionEasy to adjustWave based measurement systemsGround subsidenceSynthetic aperture sonar

The invention relates to an artificial corner reflector for SAR (synthetic aperture radar) interferometry calibration. The artificial corner reflector comprises a corner reflector and a base adjustingdevice. The base adjusting device is connected with the corner reflector, and is used for carrying out multi-directional adjustment on the corner reflector. The corner reflector is a triangular pyramid structure having a folding hinge device; and after observation, the whole corner reflector is folded into a triangle plane through the hinge device. The base adjusting device comprises a longitudinal angle adjusting device, a latitudinal angle adjusting device, a pitch angle adjusting device and a tripod. The tripod is a steel tripod, and serves as a part connecting to the ground. The artificial corner reflector is suitable for calibration for surface deformation monitoring of ground subsidence and ground fracture in a plain area, has the advantages of being detachable, waterproof, high inprecision, easy to adjust and high in reliability and the like, and lays the foundation for the follow-up calibration and surface micro-deformation monitoring work.

Owner:张磊

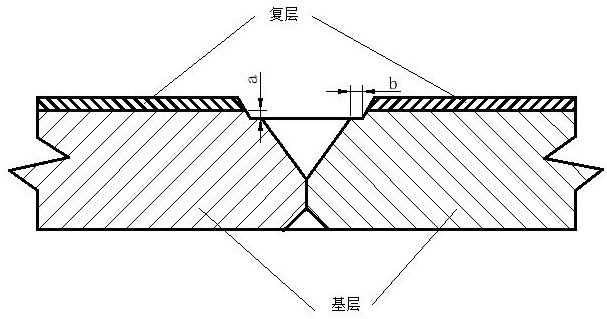

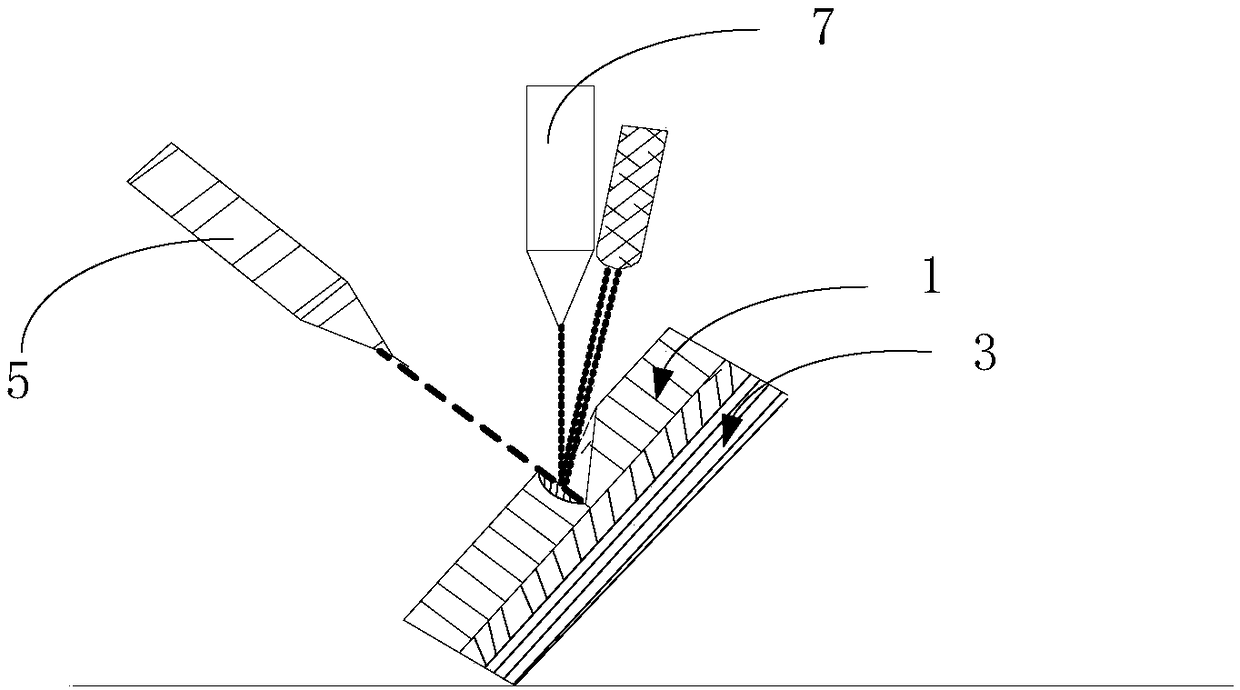

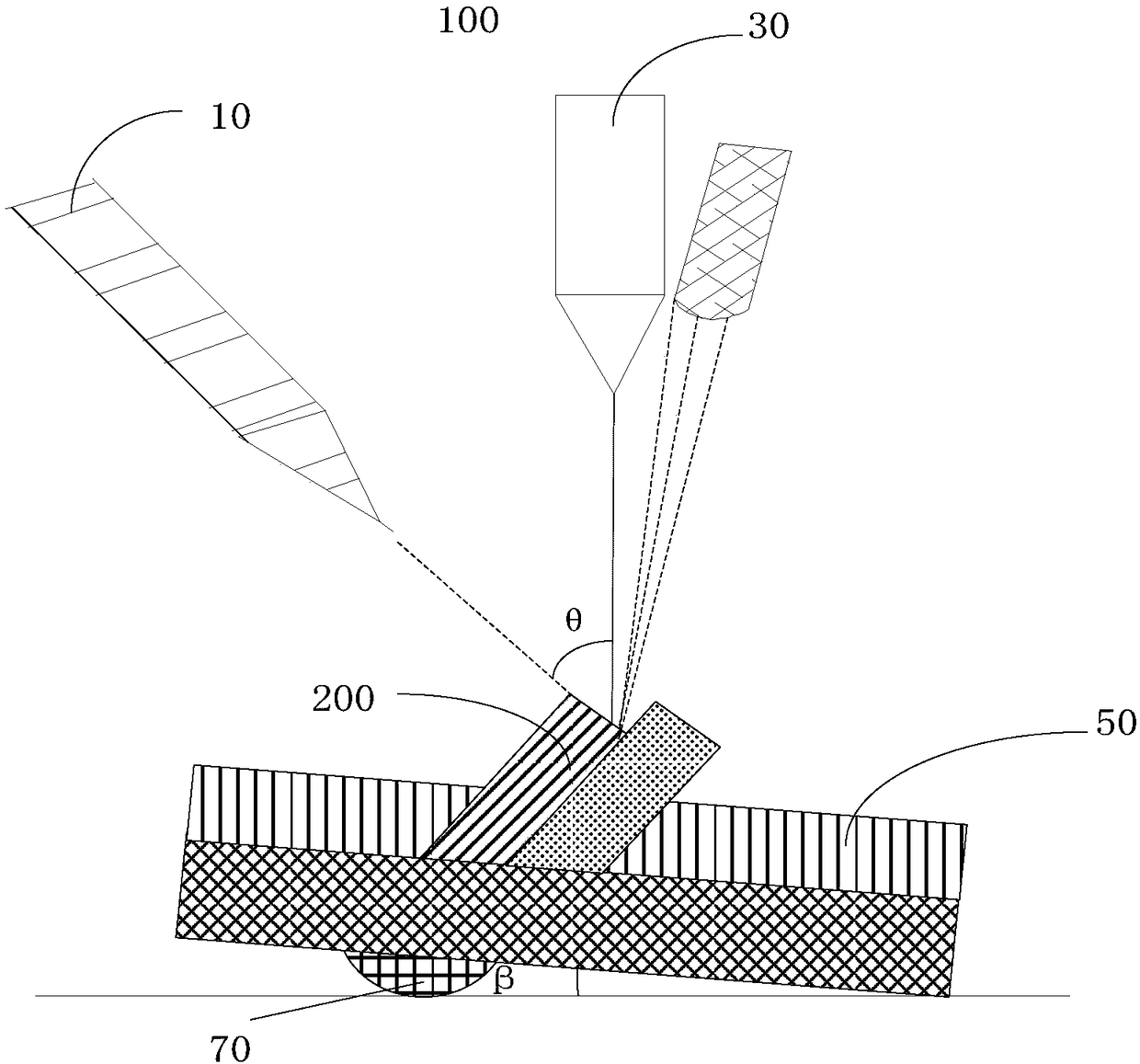

Welding method of stainless steel composite plate

PendingCN113878204AInhibited DiffusionReduce dilutionArc welding apparatusButt jointSS - Stainless steel

The invention relates to a welding method of a stainless steel composite plate and belongs to welding methods. The welding method is realized by the following steps that a groove is machined, and a composite layer side is downwards machined by taking a boundary between a composite layer and a base layer as a reference to form a concave table; when a welding joint of the composite plate is assembled, the unfitness of butt joint is controlled to 0.5-1.5 mm; the base layer is welded through automatic submerged arc welding, and a welding bead is 1 mm lower than the boundary between the composite layer and the base layer; and a transition layer and the composite layer are both welded through stainless steel flux-cored wire CO2 gas shielded welding. According to the welding method, assembly deviation is strictly controlled, when the base layer and the transition layer are welded, the height of a welding seam can be well controlled, the fusion ratio can be controlled, carbon diffusion is effectively restrained, dilution of base layer base metal to the composite layer is reduced, embrittlement and cracks of a fusion area are avoided, and the quality of the welding joint is improved; and when the transition layer and the composite layer are welded, stainless steel flux-cored wire CO2 gas shielded welding is adopted, semi-automatic and full-automatic welding is achieved, and the welding efficiency is improved by 3-4 times.

Owner:唐禹明

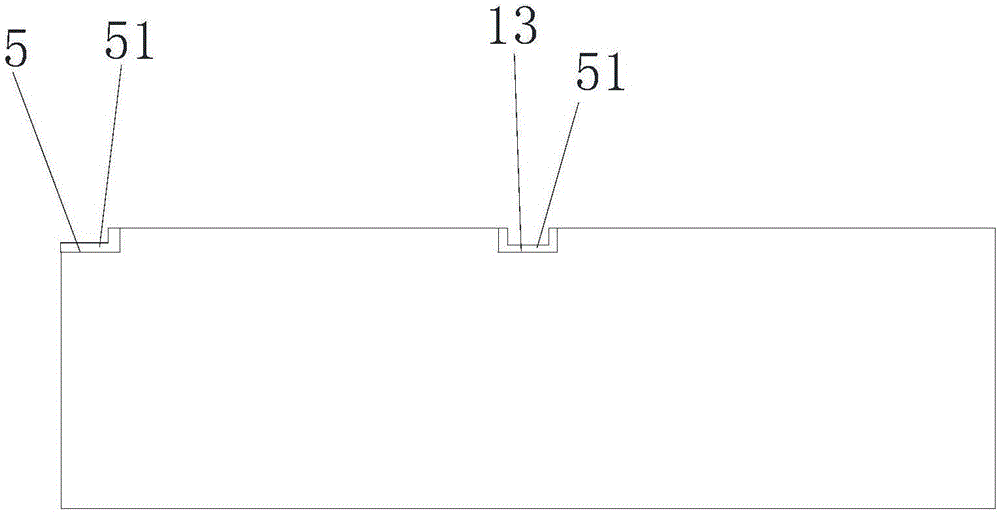

Preparation method of bonding mark, wafer bonding method, bonding mark and semiconductor device

PendingCN110854053AEasy to identifyReduce riskSemiconductor/solid-state device detailsSolid-state devicesDevice materialStructural engineering

The invention provides a preparation method of a bonding mark. The method comprises steps of S1, forming a groove on a bearing wafer through etching; S2, filling metal in the groove; and S3, removingthe metal on a surface of the bearing wafer to retain the metal filled in the groove so as to form a bonding mark on the bearing wafer. The preparation method is advantaged in that after the groove isformed by etching, identification of the surface of the mark is improved by depositing metal in the groove, the risk of a bonding gap caused by the groove is reduced, and the bonding quality is improved. Furthermore, the invention further provides a bonding mark prepared based on the method, and the bonding mark has a clear boundary and is easy to identify, the identification failure rate is reduced, the wafer rejection rate can be reduced, and productivity is improved. Furthermore, the invention further provides a wafer bonding method and a semiconductor device prepared based on the wafer bonding method.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Double-layer cleansing lotion and preparation method thereof

ActiveCN103202775BEasy to cleanGood removal effectCosmetic preparationsMake-upInorganic saltsEmulsion

The invention discloses a double-layer cleansing lotion and a preparation method thereof. The double-layer cleansing lotion comprises a water-phase layer and an oil-phase layer. The water-phase layer comprises water soluble preservatives, water soluble grease, inorganic salt electrolyte, moisturizing agent and water. The oil-phase layer comprises water-insoluble grease, oil soluble preservatives and oil soluble pigment. The preparation method includes: sequentially adding water soluble preservatives, water soluble grease, inorganic salt electrolyte and moisturizing agent into water, well mixing to obtain water-phase layer components, sequentially adding oil soluble preservatives and oil soluble pigment in water-insoluble grease, well mixing to obtain oil-phase layer components, and mixing the water-phase layer components and the oil-phase layer components to obtain the double-layer cleansing lotion. During use, the double-layer cleansing lotion can be emulsified by shaking to form emulsion, and instant deemulsification occurs to form double-layer structure with clearly-separated oil and water when the double-layer cleansing lotion stands still. The double-layer cleansing lotion is mild in cleansing, instant in emulsification, fast in deemulsification, clear in boundary and the like.

Owner:FOSHAN WIN COSMETIC

A kind of preparation technology of imitation whole body brick

ActiveCN107520950BAvoid cross mixingAvoid out of shapeFeeding arrangmentsAuxillary shaping apparatusBrickMechanical engineering

A preparation process for imitating whole-body bricks. The preparation process includes the following steps: Step 1: Place a grid with a square grid on a cloth table; Step 2: Spread the cloth to form a preset texture pattern; Step 3: Spray the auxiliary color The material is distributed in the grid without the main color spray material in the grid; step 4: apply another layer of fabric and then punch it; step 5: mark the brick adobe according to the code of the texture of the bottom material clothed by the press, and obtain Decorate the imitation whole body brick with the same texture in the fabric layer and the bottom material layer. Even if the imitation whole-body brick prepared by the present invention is grooved, the texture in the groove can be perfectly connected to the seepage texture of the surface layer, and there is no segmental offset or fracture phenomenon. In addition, a kind of above-mentioned imitation whole-body brick is proposed The grid used in the preparation process is a square grid, which can avoid the cross-mixing of the powder after the cloth and the deformation of the texture during the pushing process.

Owner:FOSHAN DONGPENG CERAMIC +2

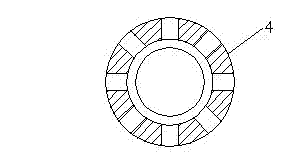

Sandblasting position controlling device

InactiveCN102240981AGuaranteed not to be sandblastedEasy to controlAbrasive machine appurtenancesSand blastingEngineering

The invention relates to a sandblasting machine, especially to a sandblasting position controlling device in the sandblasting machine. The sandblasting position controlling device comprises a rotating mandrel which forms a bolt connection with a rotating disc of the sandblasting machine, inclusive of an outer protection sleeve which is a circular hollow body, wherein a plurality of sand-guiding holes are disposed on the wall of the hollow body and the outer protection sleeve is arranged at the bottom of the rotating mandrel. With the combination of the sandblasting position controlling device and the sandblasting machine, when tubular workpieces are sandblasted, the workpieces inside the outer protection sleeve can be guaranteed not to be sandblasted, and sandblasting areas can be easily controlled, thus creating a clear boundary between the sandblasted part and the part which is not sandblasted.

Owner:TIANJIN ZHONGHUAN TIANJIA ELECTRONICS

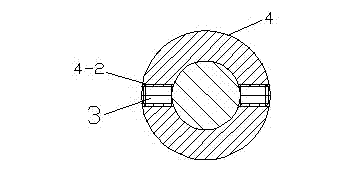

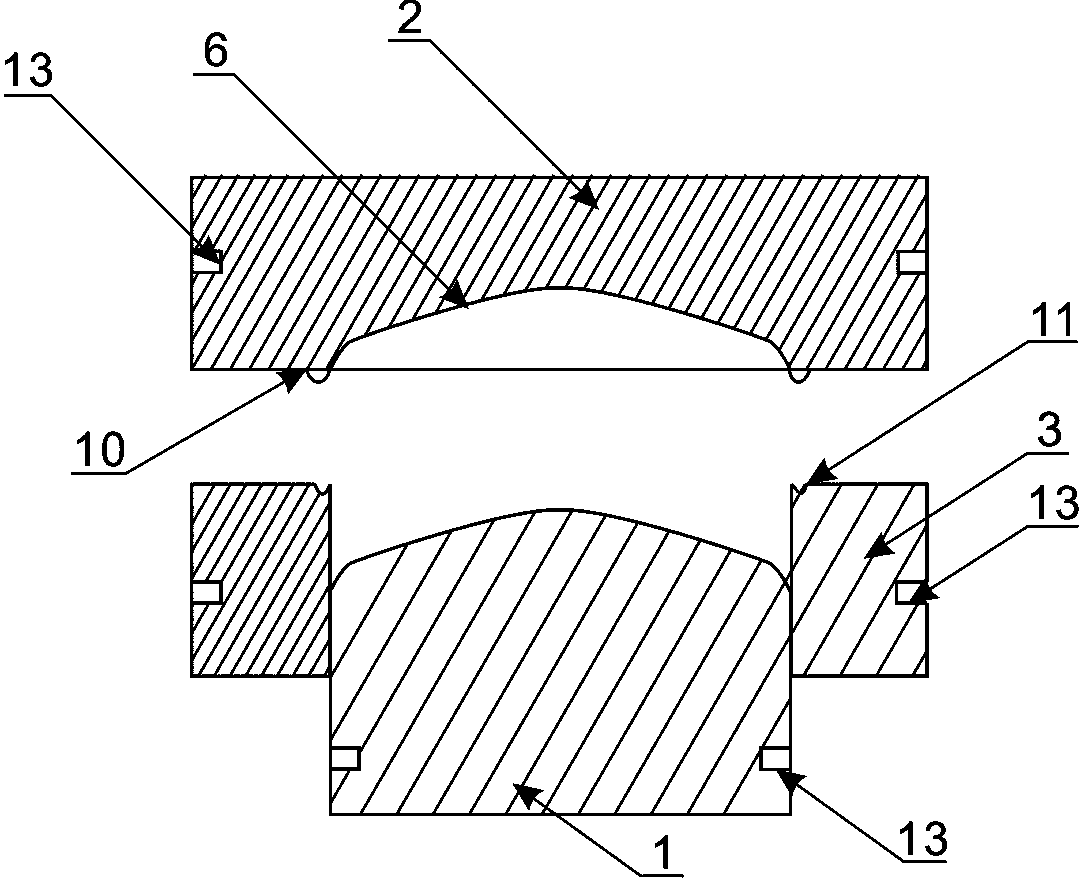

Centrifugation bottle for PRP multistage parallel extraction, and use method thereof

ActiveCN106076442AImprove efficiencyWill not be pollutedLaboratory glasswaresBlood plasmaEngineering

Owner:南宁腾科宝迪生物科技有限公司

A kind of oil-water double-layer makeup remover and preparation method thereof

ActiveCN108175733BQuick clearEasy to cleanCosmetic preparationsMake-upOil and greaseAnti-Allergic Agents

The invention discloses an oil and water double-layer makeup remover and a preparation method thereof. The oil and water double-layer makeup remover is prepared from 3-18% of a humectant, a pH regulator, 0-0.05% of plant extract essence, 30-50% of emollient oil, 0.01-1.0% of a relaxing anti-allergic agent, 0.1-0.5%of a preservative, 0.1-5% of an emulsifier, 0-0.2% of a metal ion chelating agent, 0.5-5% of salt, and the balance of deionized water, and the sum of the percentages of all above components is 100%. The makeup remover has the advantages of strong makeup removing ability, fast layering speed, mildness and non-irritation.

Owner:SHANGHAI ZHONGYI DAILY CHEM CO LTD

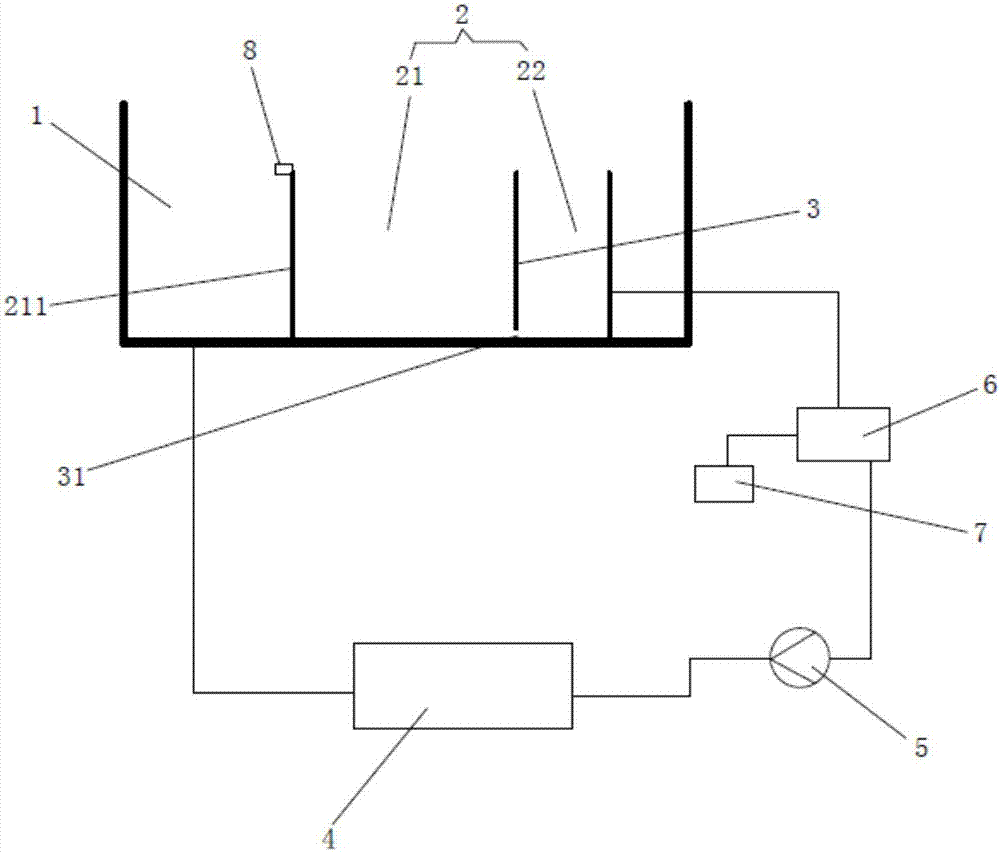

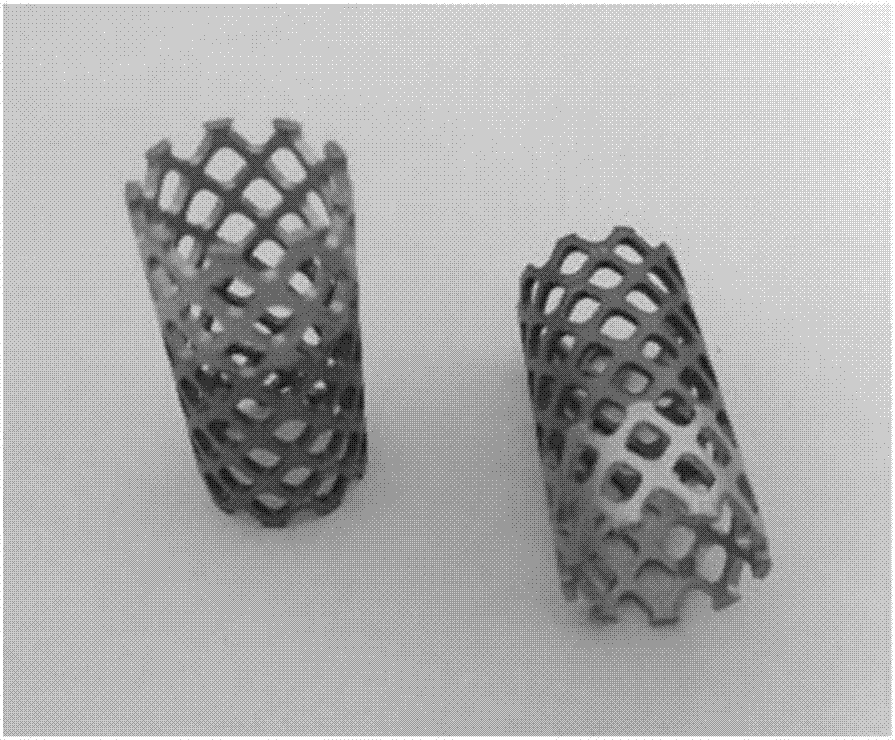

Corrosion device and method for preparing two-color film layer on metal surface

The invention discloses a corrosion device for preparing a two-color film layer on a metal surface. The corrosion device comprises a tank mechanism, a liquid drewing mechanism and a control mechanism,a first tank body for containing metal products communicates with the bottom of a second tank body which is pumped with corrosive liquid, an overflow sensor is arranged at the edge of the first tankbody, and the partial surface of the metal products is subjected to corrosion treatment based on a connectivity principle and an overflow control method. The invention further provides a method basedon the corrosion device; the method comprises the steps that the metal products coated with a first color film layer is placed in the first tank body, and the corrosive liquid is entered the first tank body through buffering of the second tank body; a liquid level of the first tank body rises steadily and a rising speed is controllable so as to form a flat and uniform corrosion interface; and thensecond coloring treatment is performed on the corrosion part. The obtained products have a clear color boundary and an attractive appearance, and the method based on the corrosion device is particularly suitable for the production of the two-color film layer on the surface of irregular products or mesh structure products.

Owner:DABO MEDICAL TECH CO LTD

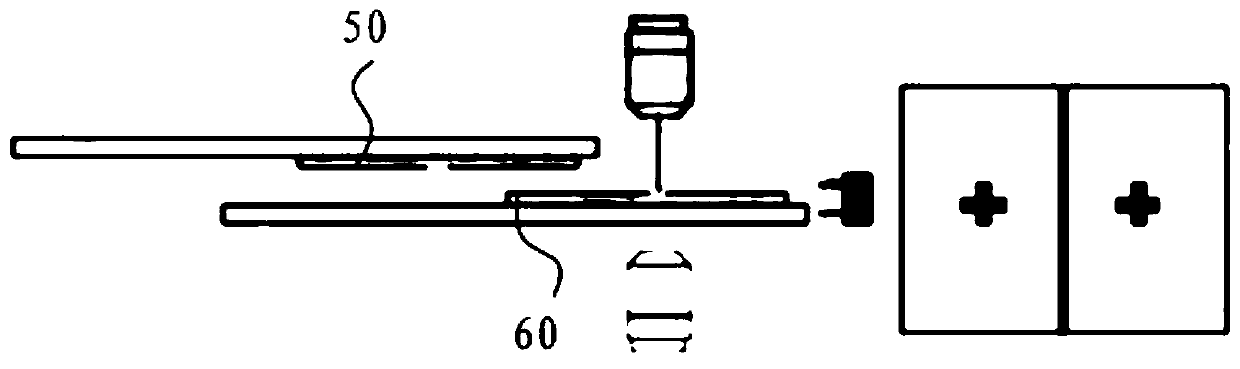

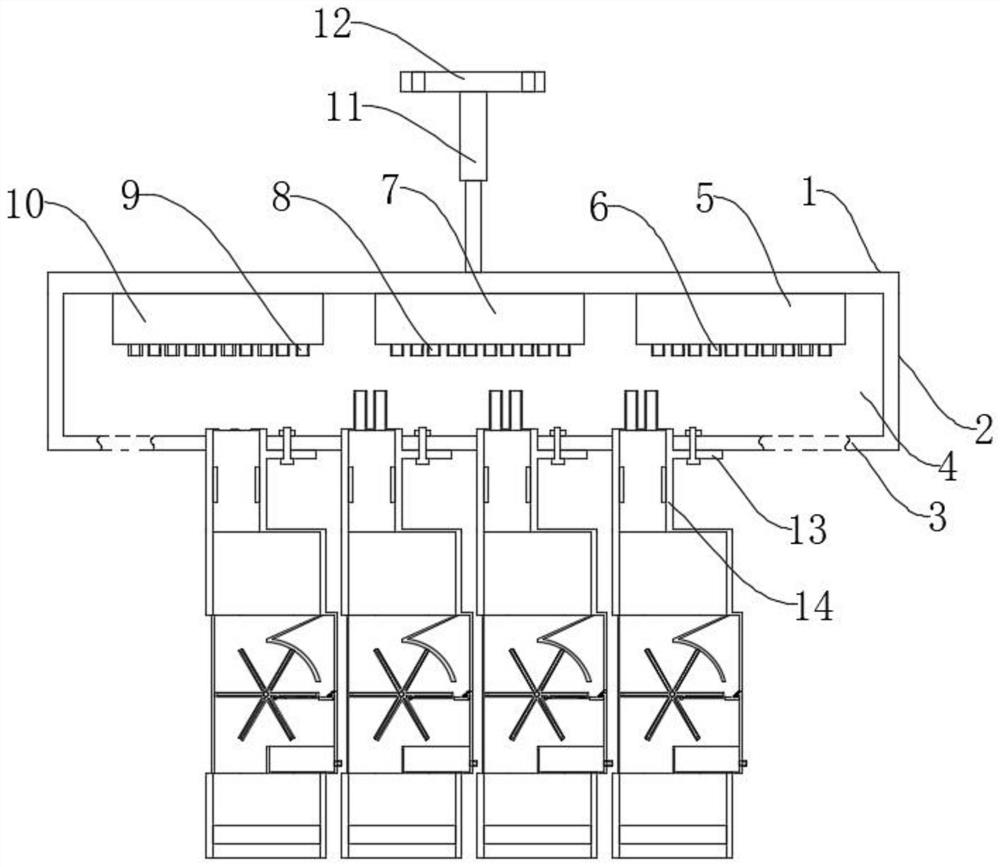

Spraying equipment for decorative picture production based on fixed-point spraying

PendingCN114308446AClear dividing lineThe phenomenon of not smudging each otherLiquid spraying apparatusSpray boothsStructural engineeringMechanical engineering

The invention discloses spraying equipment for decorative picture production based on fixed-point spraying, and relates to the field of spraying equipment.The spraying equipment comprises a spraying assembly arranged above a decorative picture, the spraying assembly comprises an upper fixing plate, a connecting frame is fixedly arranged at the edge of the lower surface of the upper fixing plate, and a lower fixing plate is fixedly arranged at the lower end of the connecting frame; an accumulation cylinder used for gathering coating is arranged below the feeding cylinder, a cleaning cylinder used for cleaning the coating is arranged below the accumulation cylinder, a spraying cylinder used for spraying the coating is arranged below the cleaning cylinder, and the feeding cylinder, the accumulation cylinder, the cleaning cylinder and the spraying cylinder are integrally arranged up and down and communicate with one another. According to the spraying device, the powdery coating can be fully and automatically mixed and sprayed on the surface of the decorative picture during spraying, and a high-pressure air area can be formed around the spraying position, so that the boundary of the spraying position is obvious, the phenomenon of mutual shading is avoided, the spraying processing of the decorative picture can be completed only by spraying a layer of coating on the decorative picture, and the coating is saved.

Owner:FUJIAN YINGHAO CULTURAL & CREATIVE CO LTD

A kind of three-layer makeup remover and preparation method thereof

ActiveCN107550743BEffective dissolutionDissolve easilyCosmetic preparationsMake-upHexadecaneActive agent

Owner:TIANJIN YU MEI JING GRP

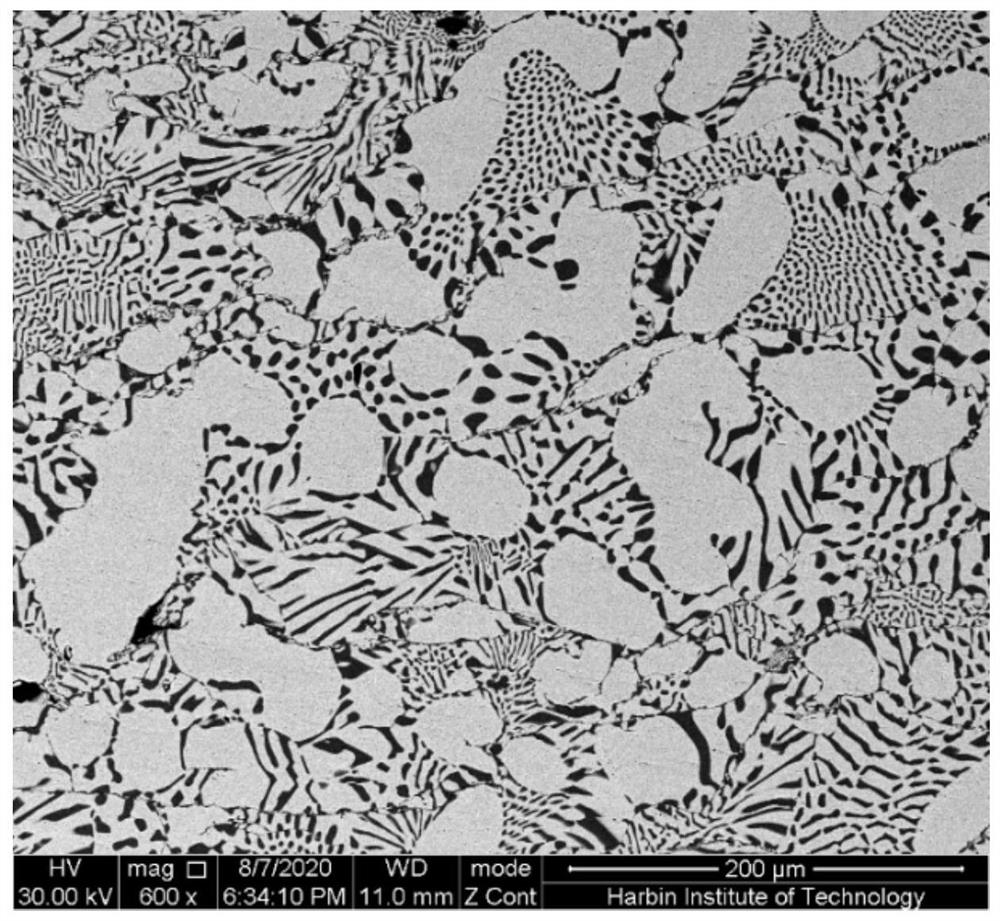

Method for improving high-temperature oxidation resistance of AgCu alloy by using three-dimensional network reinforced phase

The invention provides a method for improving the high-temperature oxidation resistance of AgCu alloy by using a three-dimensional network reinforced phase and relates to the method for improving the high-temperature oxidation resistance of the AgCu alloy. By means of the method for improving the high-temperature oxidation resistance of the AgCu alloy by using the three-dimensional network reinforced phase, the problem that existing silver-copper-based brazing filler metal is poor in high-temperature oxidation resistance is solved. The method comprises the steps that graphene sponge is prepared, AgCuTi soldering paste is prepared and formed to obtain flaky solid AgCuTi soldering paste, the graphene sponge is placed between two pieces of the solid AgCuTi soldering paste to obtain a to-be-infiltrated test piece, infiltration is performed under the vacuum condition to obtain the AgCu alloy enhanced by three-dimensional network TiC, and finally a Cu2Ti compound aggregation layer is removed through polishing. The three-dimensional network TiC nanosheet reinforced phase prepared by the method can form effective and continuous multiple obstructions on internal diffusion of oxygen in the AgCu alloy, and the problem that in a conventional method for preparing an anti-oxidation coating, the anti-oxidation function fails due to abrasion damage of a surface coating is solved. The method is suitable for preparing the AgCu alloy.

Owner:HARBIN INST OF TECH

A kind of temperature-sensitive discoloration low-melting point polyester film and preparation method thereof

ActiveCN111098577BExtended use timePrevent loss of functionSynthetic resin layered productsPolymer scienceButanediol

Owner:CHINA PETROLEUM & CHEM CORP +1

A long-distance photosensitive measurement and analysis device

ActiveCN110426374BSimple structureEasy to operateScattering properties measurementsLight sensingImage resolution

Owner:WUCHANG UNIV OF TECH

Method for bonding colored part and white part of phenolic resin billiard

InactiveCN103302782AEliminates the defect of poor bondingClear dividing lineWhole bodySurface roughness

The invention discloses a method for bonding a colored part and a white part of a phenolic resin billiard. The method comprises the following steps of: firstly, casting a colored material in a first die, so as to form the colored part of the billiard, secondly, performing curing process on the colored part of the billiard, with the curing temperature being 70 to 90 DEG C and the curing temperature being 1.5 to 2.5 hours, and then performing demolding, thirdly, increasing the surface roughness of the colored part of the billiard, fourthly, cleaning the surface of the colored part of the billiard, fifthly, putting the colored part of the billiard into a second die, and casting white material in the second die, so as to form the base body of the billiard, and sixthly, performing curing process on the base body of the billiard, with the curing temperature being 70 to 90 DEG C and the curing temperature being 3.5 to 4.5 hours, and then performing demolding, so as to obtain the billiard. The method can effectively bond the colored part and the white part of the billiard body to form a whole body, and can also ensure that a boundary line between the colored part and the white part of the billiard body is obvious.

Owner:SHANGHAI XINZHAN RUBBER CO LTD

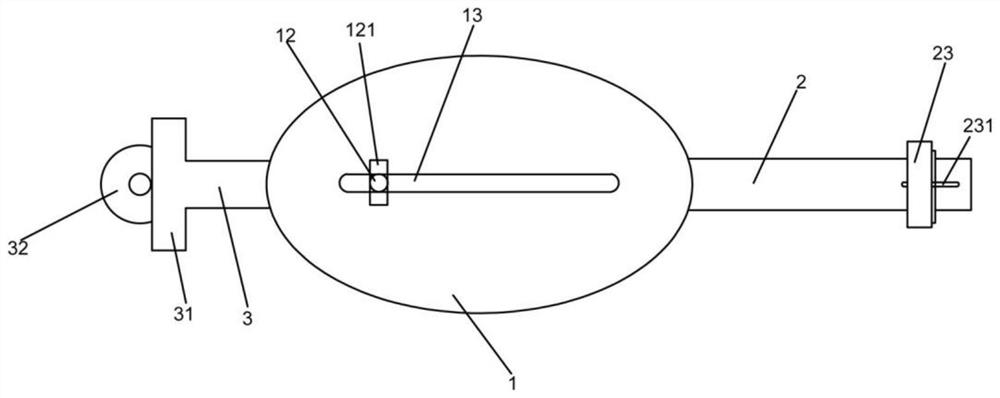

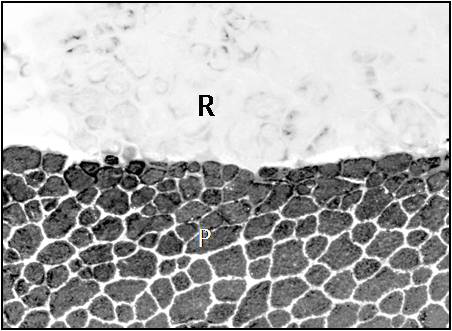

A Histological Method to Distinguish Three Kinds of Muscle Cells in Carp

ActiveCN107831112BReduce crystallizationIntegrity guaranteedWithdrawing sample devicesPreparing sample for investigationRed meatAmmonium sulphide

The invention discloses a histological method for distinguishing three kinds of carp muscle cells, wherein the method comprises the specific steps: freezing a treated sample with isoamyl and liquid nitrogen; freezing the sample at low temperature, slicing, and drying at room temperature; putting the slice into a constant-temperature pretreatment liquid, treating, and then cleaning with a cleaningliquid; adding a cleaning liquid into the slice, pouring out after the temperature is constant, adding an ATPase reaction liquid with the same temperature, carrying out a reaction, and cleaning and impregnating with distilled water; soaking the slice with a CaCl2 solution, a CoCl2 solution and an ammonium sulfide solution successively, and cleaning and impregnating with distilled water after the soaking is finished; absorbing excess moisture of the slice, covering with cover glass, sealing the slice, observing with an optical microscope, and thus distinguishing the three kinds of carp muscle cells. Boundary lines of red meat cells, pink meat cells and white meat cells in microscope images obtained by the distinguishing method are obvious, and the distribution of the three kinds of carp muscle cells can be clearly distinguished.

Owner:ZHEJIANG OCEAN UNIV

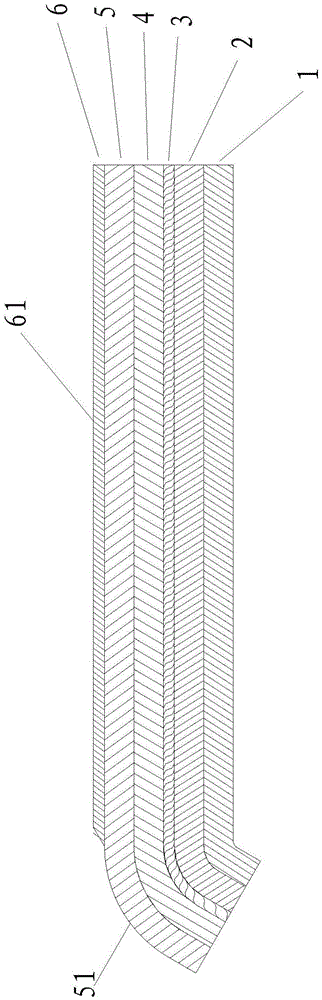

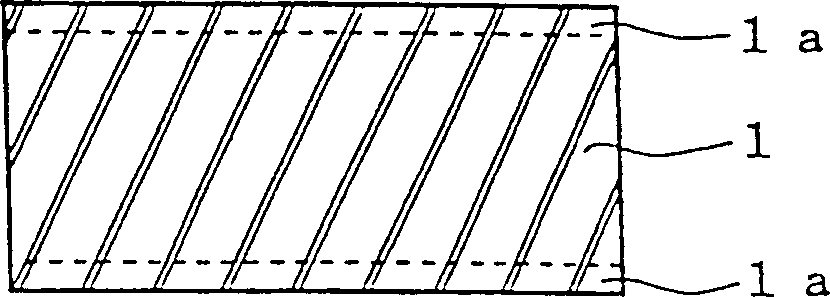

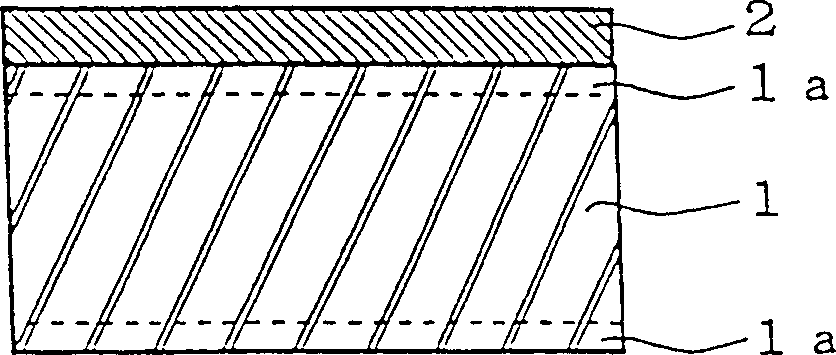

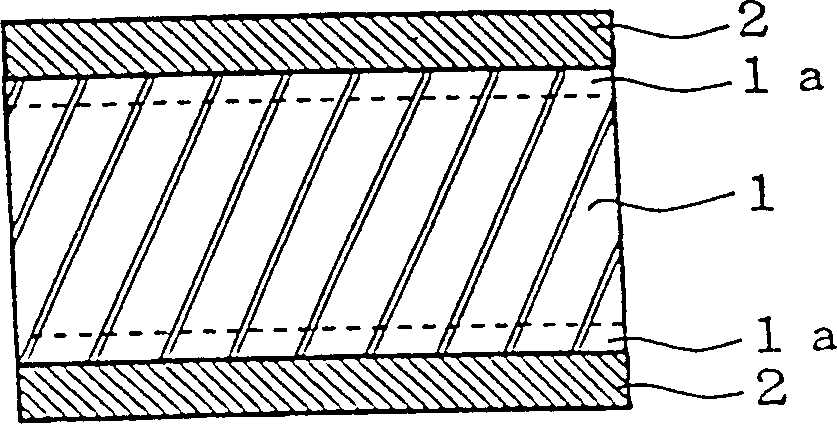

Base for masking tape for coating and masking tape for coating

InactiveCN1105761CGood followabilityClear dividing lineLiquid surface applicatorsLamination ancillary operationsPolypropyleneChemistry

A base (1) for a masking tape for coating, which is made of a polyolefin resin film having an elastic modulus of 15 to 55 kgf / mm<2>, both surfaces of the film being modified by irradiation with corona or the like; a base (2) as set forth above, wherein a layer of a modified resin such as a polyester-urethane resin or the like is formed on at least one surface thereof; and a masking tape (3) for coating, produced by forming a layer of a pressure-sensitive adhesive comprising a thermoplastic saturated block polymer, a thermoplastic unsaturated block polymer and a tackifier or a layer of a cross-linked acrylic pressure-sensitive adhesive on one surface of the base (1). The polyolefin resin of the base (1) is a polypropylene-polyethylene block copolymer or the like, while the acrylic pressure-sensitive adhesive of the tape (3) is one containing a chlorinated polypropylene resin or the like. The use of the above base enables the production of a masking tape which is excellent in follow-up properties, gives a clear parting line, and can be peeled off without leaving any residue.

Owner:DEXERIALS CORP

A sample carrying platform and a double-beam system electron microscope

The invention provides a dual-beam system electron microscope comprising an ion cutting machine, an electron camera, a sample bearing table and a driving mechanism. An inclined angle exists between the cutting direction of the ion cutting machine and the direction of the optical axis of the electron camera, and the cutting direction and the direction of the optical axis face the sample bearing table. The sample bearing table comprises a sample inserting slot. The sample inserting slot is provided with an oblique angle of a first preset angle and used for accommodating a sample having a fracture surface at the first preset angle. The ion cutting machine is used for processing the fracture surface of the sample in the direction of scraping the fracture surface of the sample. The driving mechanism is used for driving the sample bearing table to rotate at least after the fracture surface of the sample is processed so as to drive the sample to rotate to the optical axis which exactly faces the fracture surface of the sample and is perpendicular to the electron camera. The invention also provides the sample bearing table used for the dual-beam system electron microscope.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Long-distance light-sensing measurement and analysis device

ActiveCN110426374ASimple structureEasy to operateScattering properties measurementsCamera lensLight sensing

The invention, which relates to the technical field of medical appliances, provides a long-distance light-sensing measurement and analysis device comprising a functional ball, a lighting tube disposedon the functional ball, and a control rod disposed at one side, away from the lighting tube, of the functional ball. The lighting tube and the control rod are arranged coaxially and axes of the lighting tube and the control rod passes through the center of the functional ball. A reflective coating is arranged on the inner wall of the function ball; a refractor is arranged in the function ball; anobservation lens is arranged at the function ball; and a chute for observing the sliding of the lens is formed in the function ball. A driving machine for driving the control rod to rotate around theaxis of the control rod is arranged at the end portion of the control rod. The long-distance light-sensing measurement and analysis device having a simple structure is used conveniently. With light offset, a target is detected at multiple angles to obtain accurate target information; the resolution is high; the boundary line is obvious; and the long-distance light-sensing measurement and analysisdevice can be carried on a high-altitude detector to detect and analyze a long-distance ground target accurately.

Owner:WUCHANG UNIV OF TECH

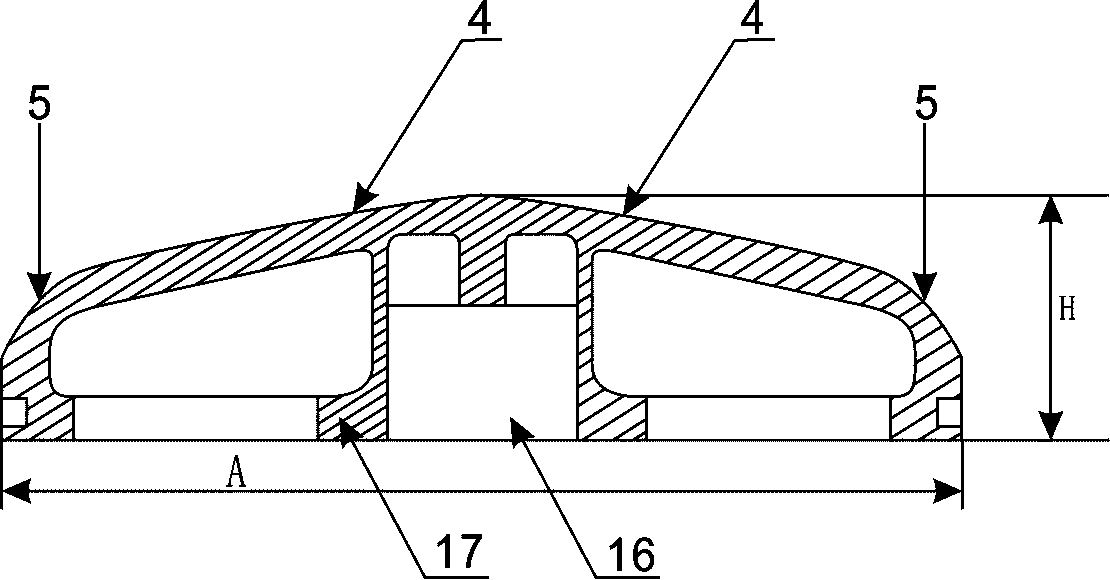

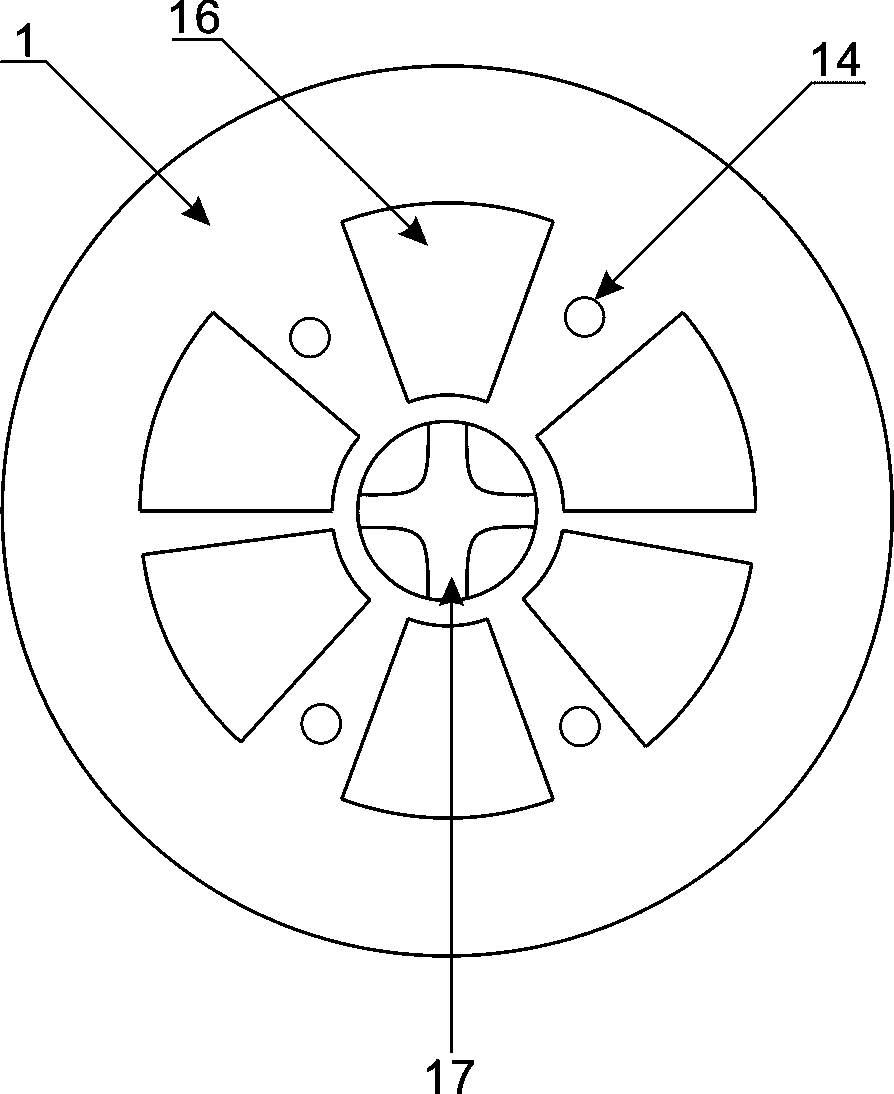

Die special for lower bell jar

The invention discloses a die special for a lower bell jar. The die comprises a male die, a female die and a blank holder. A male die arc-shaped part is arranged on the top of the male die, a female die arc-shaped part is arranged inside one end of the female die, the two outer sides of the female die arc-shaped part are outer inclined surfaces, and flanges are arranged between the two outer inclined surfaces and the female die arc-shaped part. A cavity is formed inside the blank holder, the radius of a small male die arc part ranges from 50 mm to 200 mm, and the radius of a small female die arc part is 0 mm-10 mm larger than the radius of the small male die arc part. The die comprises the male die, the female die and the blank holder, the male die arc-shaped part and the female die arc-shaped part are mutually embedded correspondingly, rolled steel can be punched into the lower bell jar, the radius of the small male die arc part and the radius of the small female die arc part play a key role in achieving the glaze pouring effect of the lower bell jar, the radius of the small male die arc part is arranged to be from 50 mm to 200 mm, and the good glazing effect can be acquired through a glaze pouring experiment.

Owner:四川汉莫尼机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com