A kind of preparation technology of imitation whole body brick

A preparation process and a technology for full-body bricks, which are applied in the production field of ceramic bricks, can solve the problems of stacking and packaging consumption and damage, and achieve the effects of improving production efficiency and saving temporary storage space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: a kind of preparation technology of imitation whole body brick, comprises the following steps:

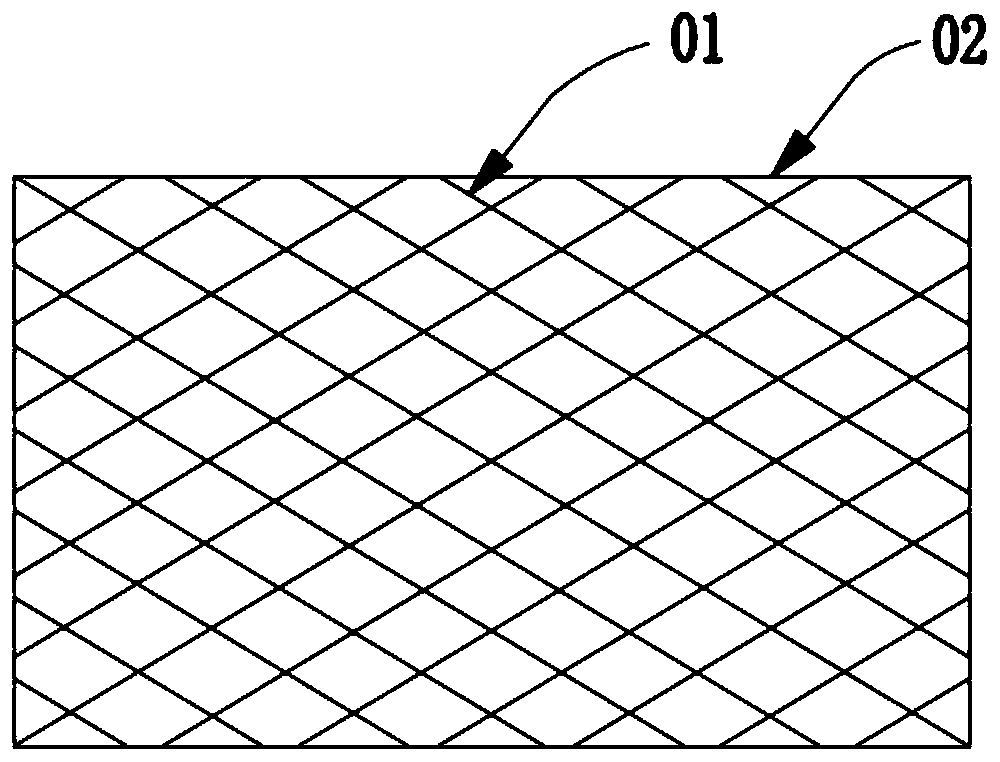

[0031] Step 1: Place the grid with a square grid on the distribution table, the angle between the bars of the grid and the frame is at right angles, and the side length of the small square in the grid is 10-50mm;

[0032] Step 2: Use the main color spray powder to spread in the grid according to the preset texture, so that the main color powder falls into the grid at the corresponding position to form a preset texture pattern;

[0033] Step 3: Distribute more than one auxiliary color spray powder on the grid where the main color powder is not applied to form a pattern, so as to obtain a complete primer layer. Transfer the laid base material to the mold frame through a grid composed of many regular small squares;

[0034] Step 4: After applying a thin layer of fabric powder, stamping and molding, thereby forming an adobe with a composite layer of fabric layer...

Embodiment 2

[0039] Embodiment two: a kind of preparation technology of imitation whole body brick, comprises the following steps:

[0040] Step 1: Place the grid with a square grid on the distribution table, the angle between the bars of the grid and the frame is at right angles, and the side length of the small square in the grid is 10-50mm;

[0041] Step 2: Use the main color spray powder to spread in the grid according to the preset texture, so that the main color powder falls into the grid at the corresponding position to form a preset texture pattern;

[0042] Step 3: Distribute more than one auxiliary color spray powder on the grid where the main color powder is not applied to form a pattern, so as to obtain a complete primer layer. Transfer the laid base material to the mold frame through a grid composed of many regular small squares;

[0043] Step 4: Stamping to form an adobe with a preset texture;

[0044] Step 5: Mark the adobe according to the code of the fabric texture of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com