Double-spliced wood-plastic floor

A technology for wood-plastic floor and plastic floor, which is applied in the direction of floor, building, building structure, etc., can solve the problems of reducing the speed of double-split wood-plastic floor paving, increasing the difficulty of paving, and increasing labor costs. The effect of paving process, beautiful appearance and labor cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be clearly and completely described below through specific embodiments in conjunction with the accompanying drawings.

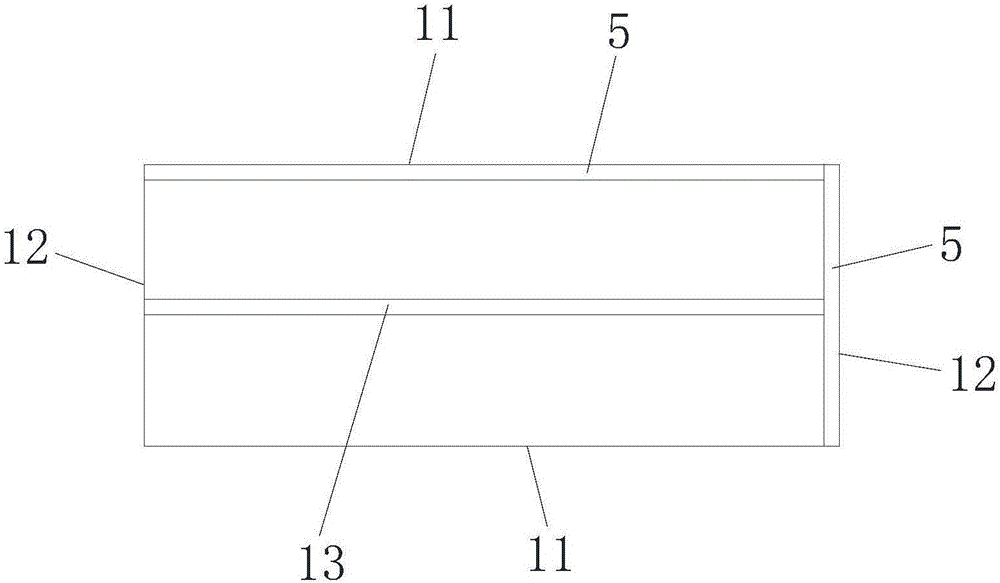

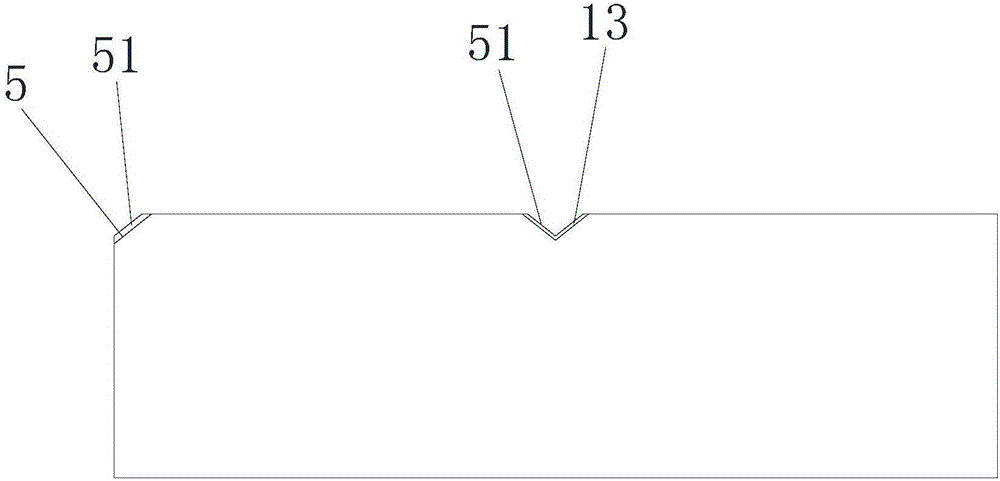

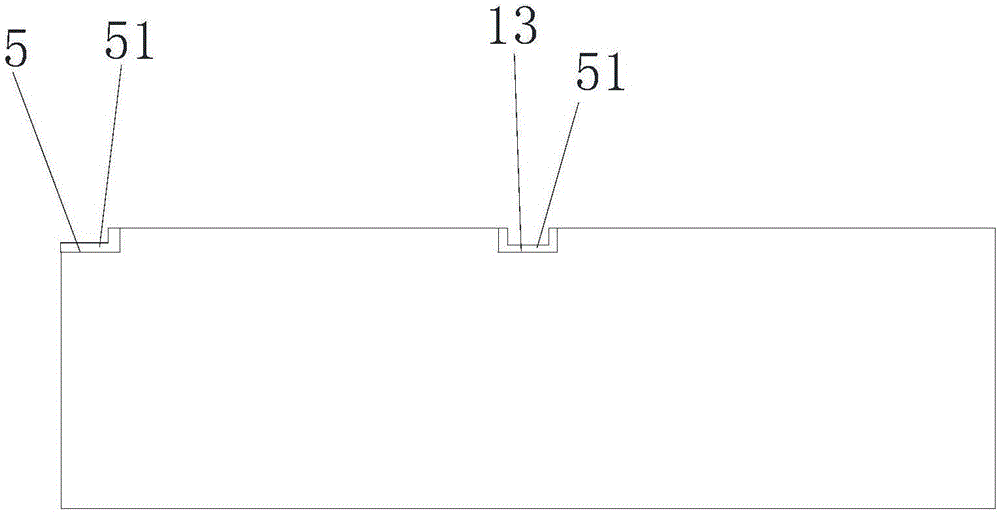

[0023] Please refer to Figure 1-5 As shown, the present invention provides a double-joint wood-plastic floor, including a WPC (Wood Plastic Composite, Wood Plastic Composite) layer 1, a middle material layer 2, a color film layer 3 and a wear-resistant layer 4 arranged sequentially from bottom to top. . The upper surface of the double wood-plastic floor has a pair of opposite first sides 11 and a pair of opposite second sides 12 . A boundary 13 is provided on the upper surface of the double wood-plastic floor, and the boundary 13 is roughly parallel to the first side 11 or the second side 12 . Due to the setting of the boundary 13, a single floor looks like two floors. When paving, only one floor needs to be paved to achieve the effect of paving two traditional floors, which greatly improves the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com