Die special for lower bell jar

A lower bell jar and mold technology, which is applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unreasonable curvature of the edge of the lower bell jar and poor glazing effect, and achieve the effect of good glazing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

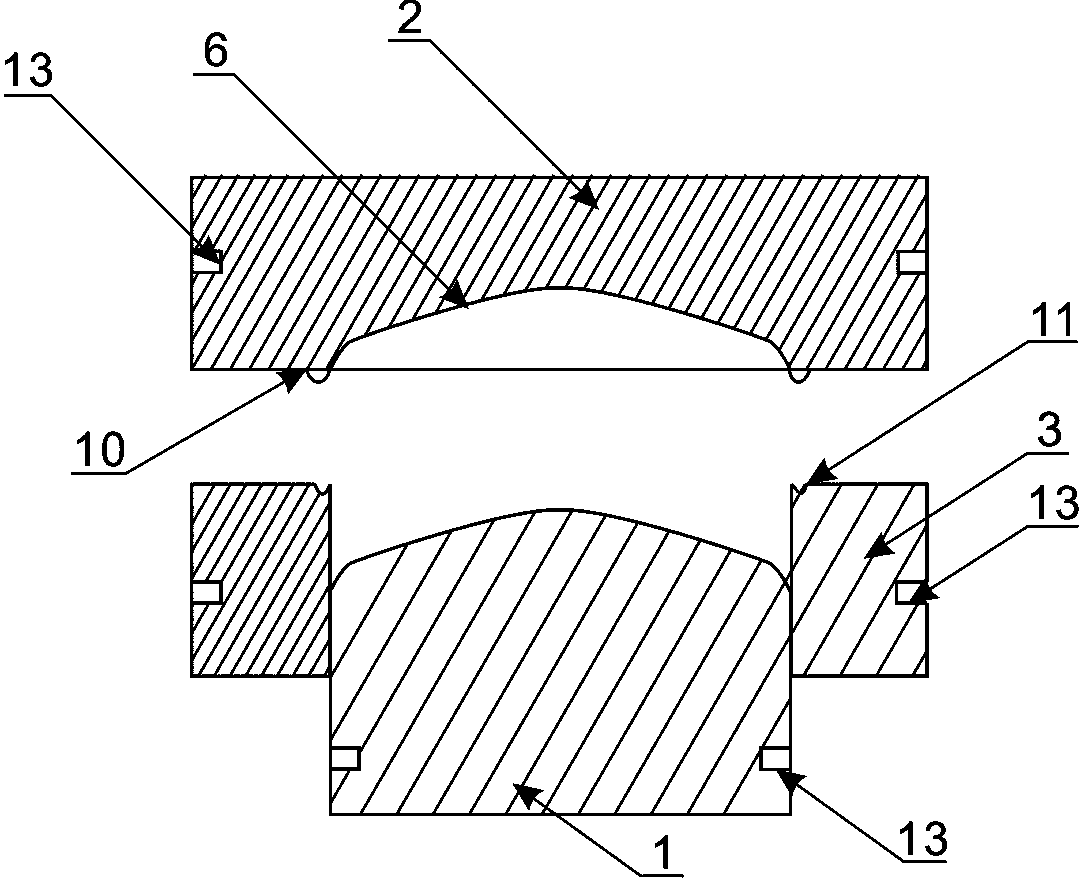

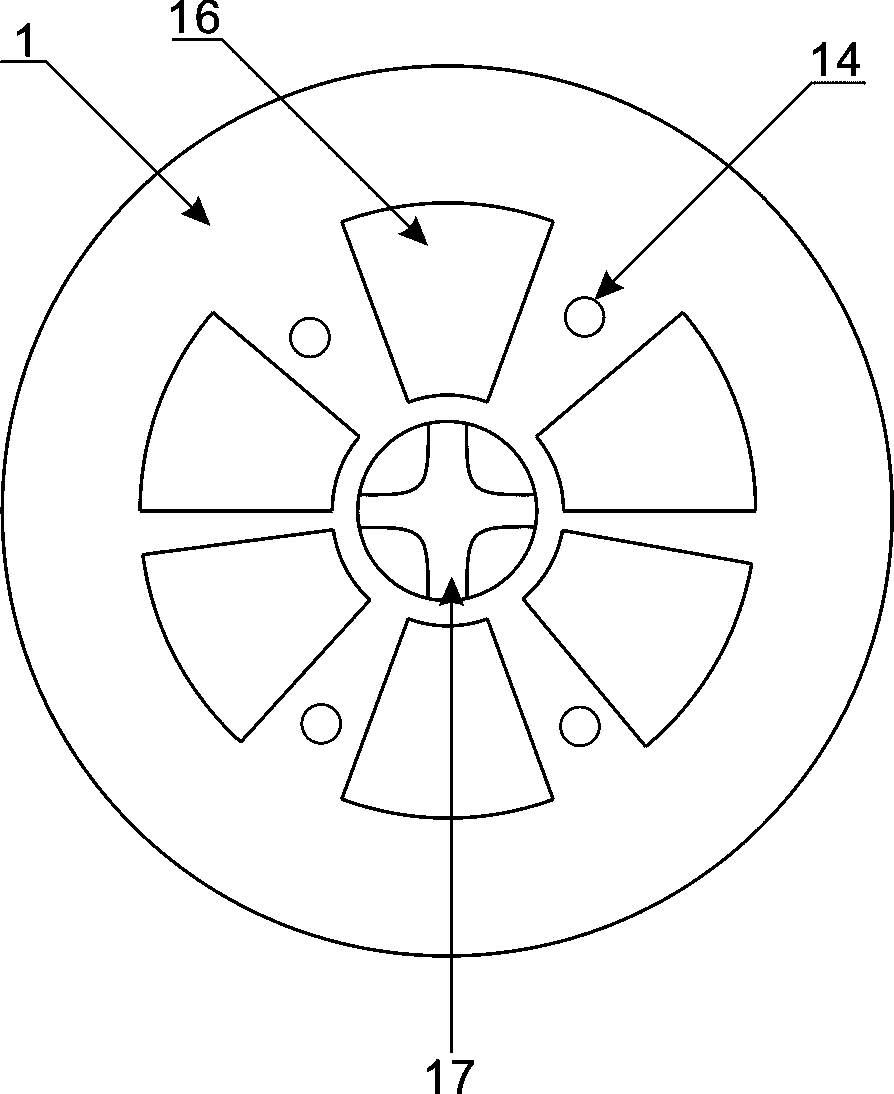

[0026] like Figure 1 to Figure 7 As shown, the present invention provides a special mold for the lower bell jar, comprising a punch 1, a die 2 and a blank holder 3, and the outer shape of the punch 1, the die 2 and the blank holder 3 is a cylinder. The punch 1 and the die 2 are used to press the steel into shape, and the blank holder 3 is used to place the steel, and at the same time, the punch 1 is embedded and moved inside to guide the punch 1 .

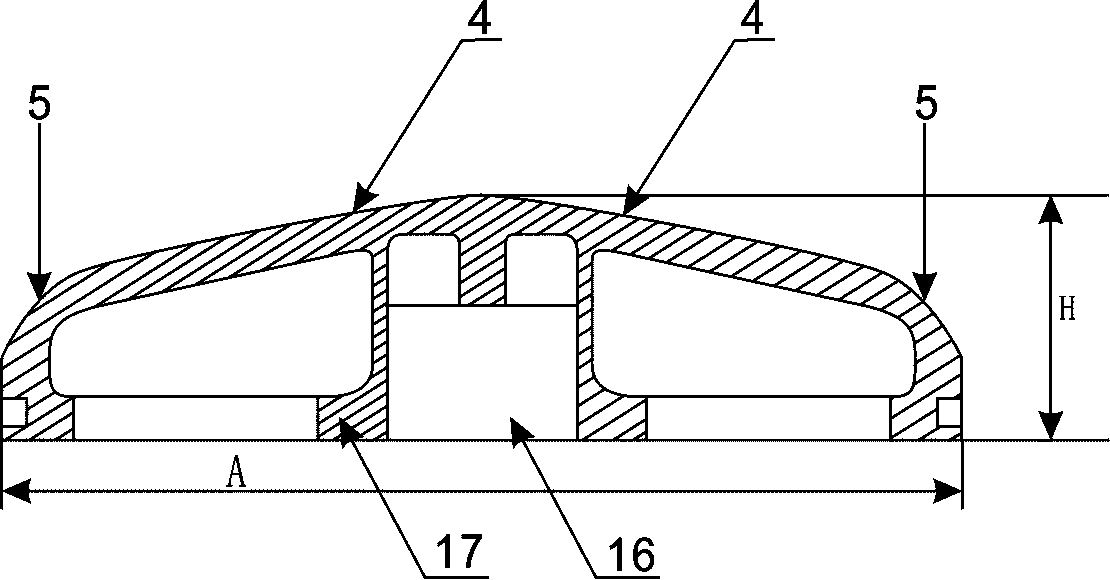

[0027] like figure 2 , image 3 As shown, the top of the punch 1 has a punch arc portion, and the punch arc portion includes a punch large arc portion 4 and a punch small arc portion 5 connected to both sides of the punch large arc portion 4 . One end of the die 2 has a die arc portion inside, and the die arc portion includes a die large arc portion 6 and a die small arc portion 7 connected to both sides of the die large arc portion 6 . The radius of the small arc portion 7 of the punch is 50 mm to 200 mm, and when the radius ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com