Silicon slice positioning and loading device of chemical mechanical polishing equipment

A technology of chemical machinery and silicon wafers, applied in the direction of grinding/polishing equipment, grinding equipment, metal processing equipment, etc., to achieve the effect of improving processing quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

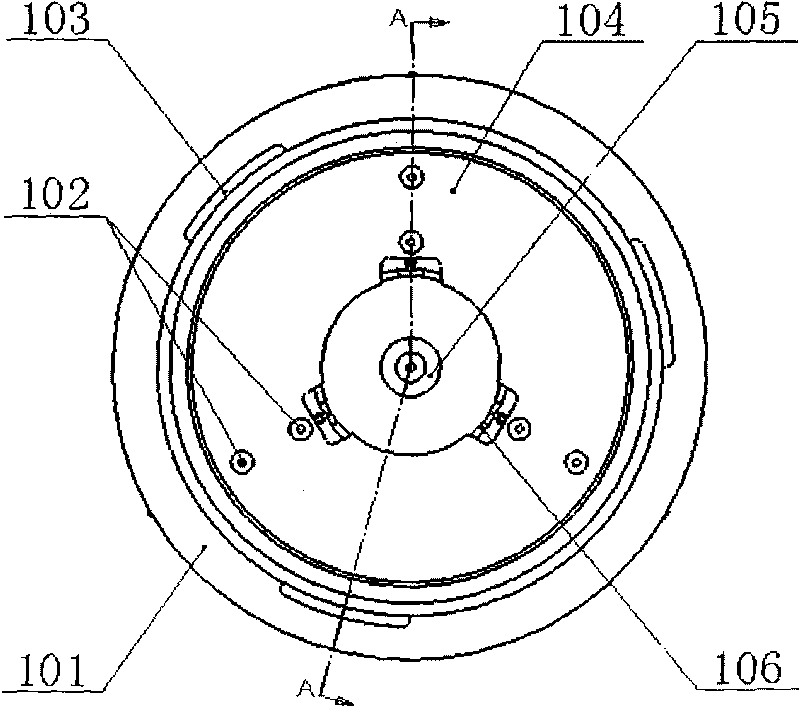

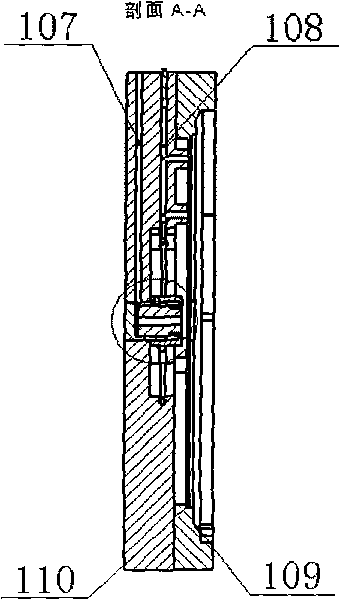

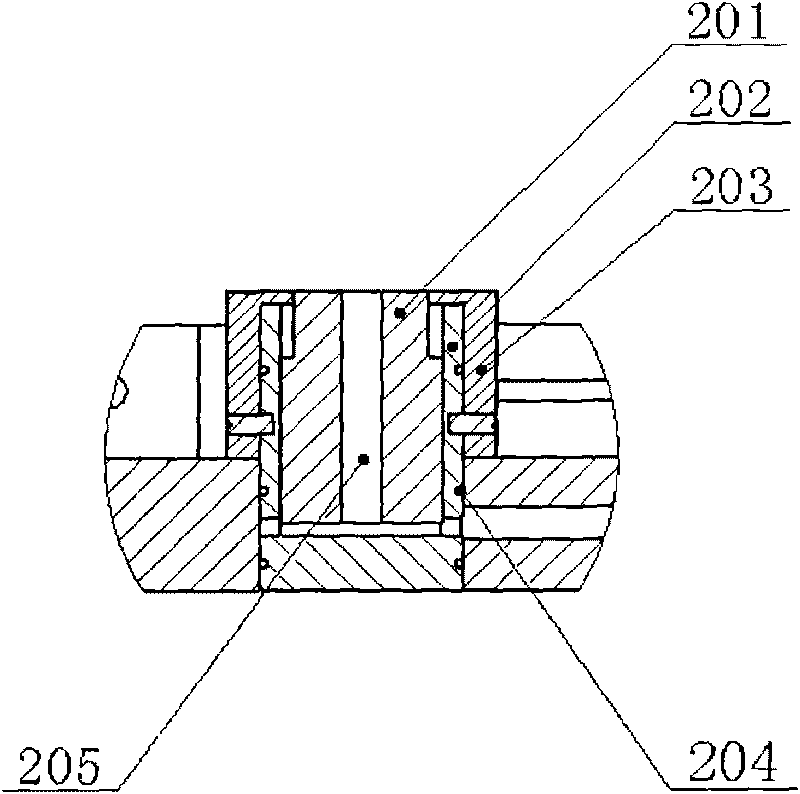

[0019] see Figure 1 ~ Figure 4 , the silicon wafer chemical mechanical polishing equipment positioning chip loading device has a loading chassis 104, a loading guide ring 101 is fixed on the loading chassis 104, and a first beveled chamfer 109 and a second beveled chamfer 110 are arranged in the loading guide ring 101; The loading chassis 104 is also provided with a water pressure nozzle, and there is a gap between the water pressure nozzle and the silicon chip 301 that can be mounted on the first chamfer 109. The water pressure nozzle has a central nozzle 105 and a peripheral nozzle 102. The structure of the central nozzle 105 It is: a central water pipe shaft 201 is provided, the outer surface of the central water pipe shaft 201 cooperates with the sealing sleeve 202, the sealing sleeve 202 is fixed on the loading chassis 104, the central through hole 205 of the central water pipe shaft 201 passes through the bottom gap and the first water pipe channel 107 connected, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com