Manufacturing method of low-emissivity coated laminated glass capable of removing film in peripheral area and being bent by drying

A low-radiation coating and surrounding area technology, applied in the field of coated laminated glass manufacturing, can solve the problems of difficult film removal and low removal efficiency of automotive coated glass, so as to avoid film corrosion, ensure film quality, and prevent secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

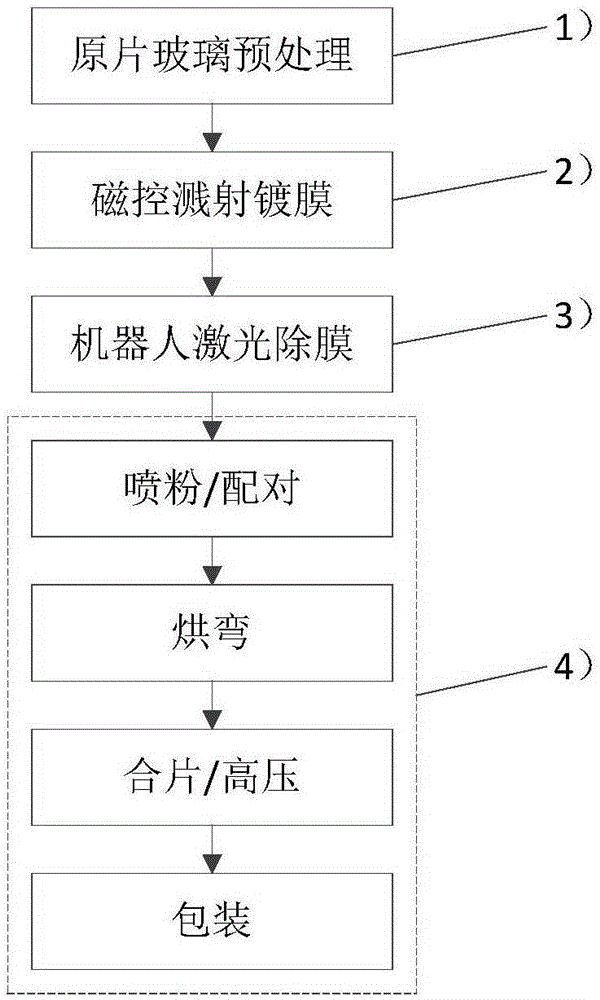

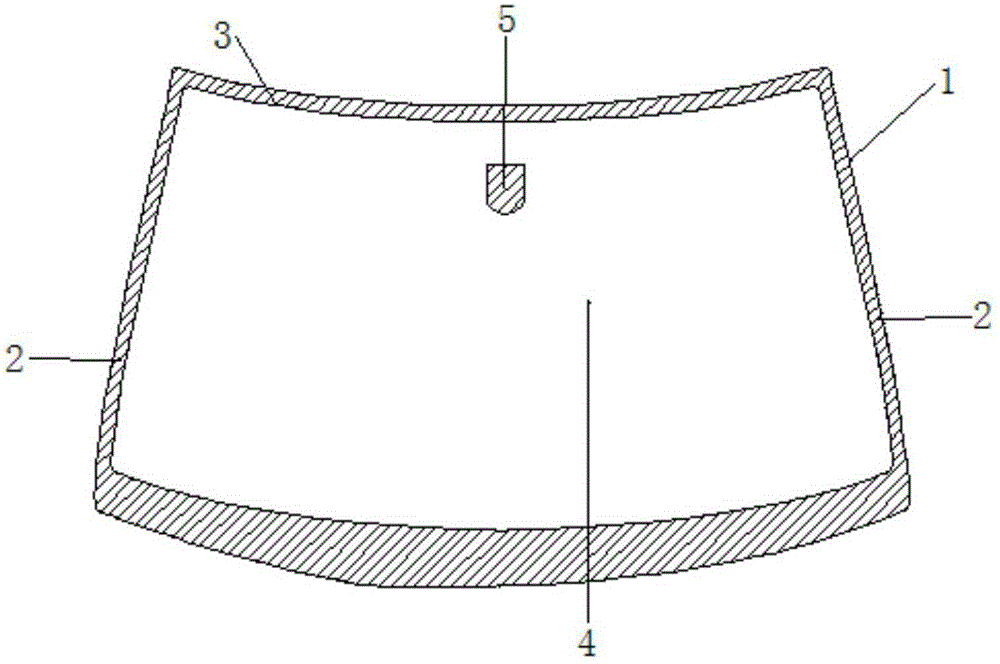

[0048] Such as figure 1 As shown, a method for manufacturing a bakeable and bendable low-emissivity coated laminated glass in which the film is removed in the peripheral area comprises the following steps:

[0049] 1) Pretreatment of the original glass: Slicing, loading, cutting, edging, washing and drying the original green float glass with a thickness of 1.8mm to obtain the original glass of automotive grade, which is "large sheet" glass;

[0050] 2) Coating: use the magnetron sputtering coating equipment to coat the surface of the automotive-grade original glass obtained in step 1) with a low-emissivity film layer, and the low-emissivity film layer adopts the film system configuration disclosed in Chinese patent 200810071891.4;

[0051] 3) Film removal: Input the CAD graphics of the peripheral film removal area 2 into the system control software of the CNC (ComputerNumericalControl) host computer, set the working power of the laser to 500W according to the thickness of the ...

Embodiment 2

[0058] A method for manufacturing a bakeable and bendable low-emissivity coated laminated glass in which the film is removed in the peripheral area, the method comprising the following steps:

[0059] 1) Pretreatment of the original glass: the original white float glass sheet with a thickness of 1.8mm is sliced, loaded, cut, edged, washed and dried to obtain the original glass of automotive grade, which is "large sheet" glass;

[0060] 2) Coating: use magnetron sputtering coating equipment to coat the surface of the original automotive-grade glass with a low-emissivity film, and the low-emission film adopts the film system configuration disclosed in Chinese patent 200810071891.4;

[0061] 3) Film removal: input the CAD graphics of the surrounding area 2 to be removed and the base area 5 to be removed into the system control software of the CNC (ComputerNumericalControl) host computer, set the working power of the laser to 800W according to the thickness of the film layer, and s...

Embodiment 3

[0064] A method for manufacturing a bakeable and bendable low-emissivity coated laminated glass in which the film is removed in the peripheral area, the method comprising the following steps:

[0065] 1) Pretreatment of raw glass: the raw transparent float glass with a thickness of 2.1 mm is sliced, loaded, cut, edged, washed and dried to obtain automotive-grade raw glass, which is called "large piece" glass;

[0066] 2) Coating: Use magnetron sputtering coating equipment to coat low-emissivity film on the surface of the original automotive-grade glass. The low-emission film adopts the double-silver Low-E film system configuration disclosed in Chinese patent 20092007779.4;

[0067] 3) Film removal: input the CAD graphics of the peripheral film removal area 2 into the system control software of the CNC (ComputerNumericalControl) host computer, set the working power of the laser to 1000W according to the thickness of the film layer, and set the spot diameter to 10mm. Start the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com