Fermented alga liquid fertilizer synergist and production method and application thereof

A technology of fertilizer synergist and production method, which is applied in the direction of fertilizer mixture, application, fertilization device, etc., can solve the problem of large molecular weight of seaweed liquid or extract, achieve significant inhibition, complete extraction, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

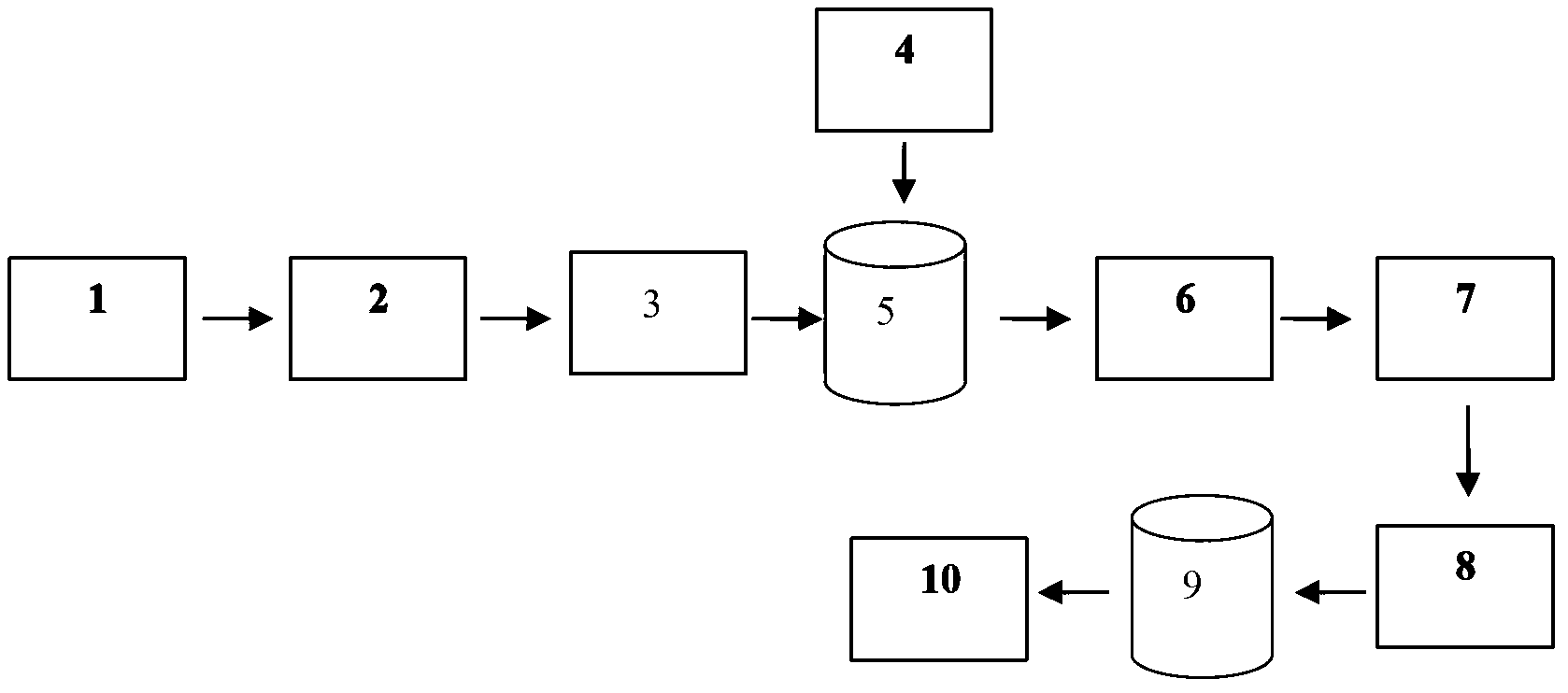

Method used

Image

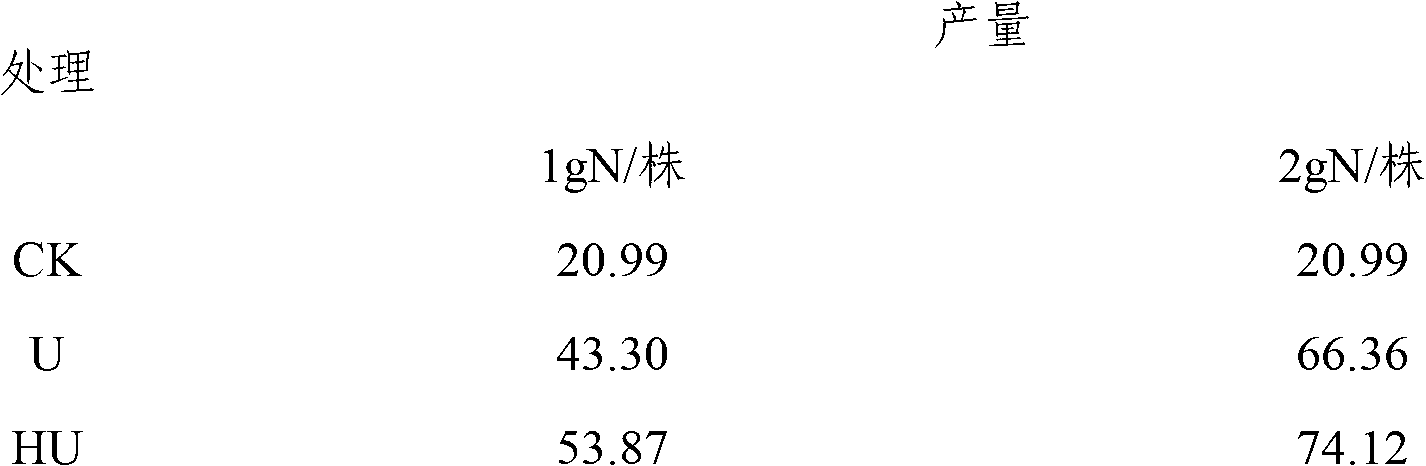

Examples

Embodiment 1

[0078] Embodiment 1: preparation fermented seaweed liquid fertilizer synergist of the present invention

[0079] The preparation steps are as follows:

[0080] A, natural sea-tangle raw material adopts pulverizing equipment to pulverize, gets 800 weight parts of natural sea-tangle powders and 100 weight parts of cornmeal, 30 weight parts of sugars and stirs and mixes to obtain a kind of mixture, adds water, makes its water content reach 30% by weight of said mixture, The pH value is adjusted to 6 with a 10% aqueous sodium hydroxide solution by weight to obtain a natural seaweed fermentation material;

[0081] B. Mix 0.1 part by weight of EM flora fermented liquid (produced by Jilin Great Wall Agricultural Machinery Biotechnology Co., Ltd.) with 0.1 part by weight of sucrose and 0.5 part by weight of water, and store it in an airtight container for 20 hours to obtain a kind of EM fermentation bacteria group stock solution;

[0082]C, dilute the EM fermented flora stock soluti...

Embodiment 2

[0087] Embodiment 2: preparation fermented seaweed liquid fertilizer synergist of the present invention

[0088] The preparation steps are as follows:

[0089] A, after the sea-tangle raw material is pulverized by crushing equipment, get 1100 parts by weight of sea-tangle powder and 110 parts by weight of cornmeal, 60 parts by weight of sugar and stir and mix to obtain a mixture, add water to make its water content reach 45% by weight of the mixture, and then Its pH value is adjusted to 7 with a concentration of 10% sodium hydroxide aqueous solution by weight to obtain a natural seaweed fermentation material;

[0090] B. Mix 1.5 parts by weight of EM flora fermented liquid (produced by Jilin Great Wall Agricultural Machinery Biotechnology Co., Ltd.) with 1.5 parts by weight of sucrose (glucose) and 15 parts by weight of water, and store it in an airtight container for 22 hours to obtain a EM fermentation flora stock solution;

[0091] C. Dilute the EM fermentation flora stoc...

Embodiment 3

[0096] Embodiment 3: preparation fermented seaweed liquid fertilizer synergist of the present invention

[0097] The preparation steps are as follows:

[0098] A, after wakame is crushed by crushing equipment, take 1000 parts by weight of undaria pinnatifida powder, mix with 140 parts by weight of cornmeal and 40 parts by weight of sugar, stir and mix to obtain a mixture, add water to make its water content reach the weight of the mixture 40%, then adjust its pH value to 7 with a concentration of 15% potassium hydroxide aqueous solution by weight to obtain a natural seaweed fermentation material;

[0099] B. Mix 1.0 parts by weight of EM flora fermented liquid (produced by Jilin Great Wall Agricultural Machinery Biotechnology Co., Ltd.) with 1.0 parts by weight of glucose and 10 parts by weight of water, put them in an airtight container and store them for 28 hours to obtain a kind of EM fermentation bacteria group stock solution;

[0100] C, the EM fermented flora stock sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com