Gantry swing arm type automatic vehicle cleaning mechanism

An automatic car washing and swing arm technology, which is applied in vehicle maintenance, vehicle cleaning, vehicle cleaning equipment, etc., can solve the problems of high labor intensity, low local pressure, and large demand for car washing, and improve the degree of cleaning and car washing efficiency, solve local unevenness, and the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

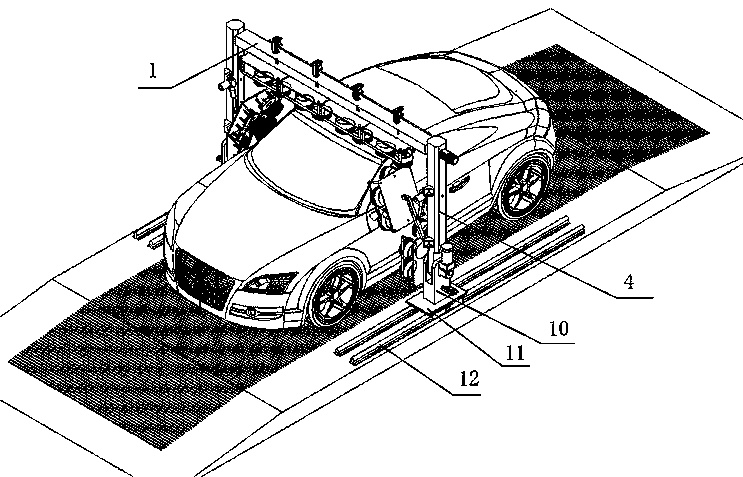

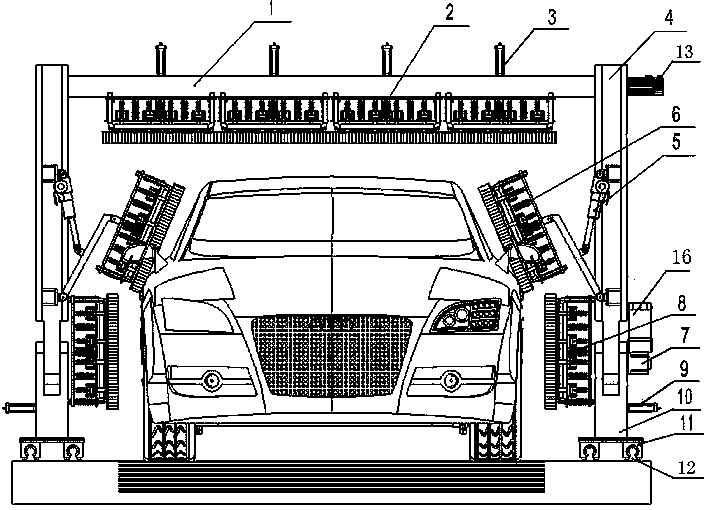

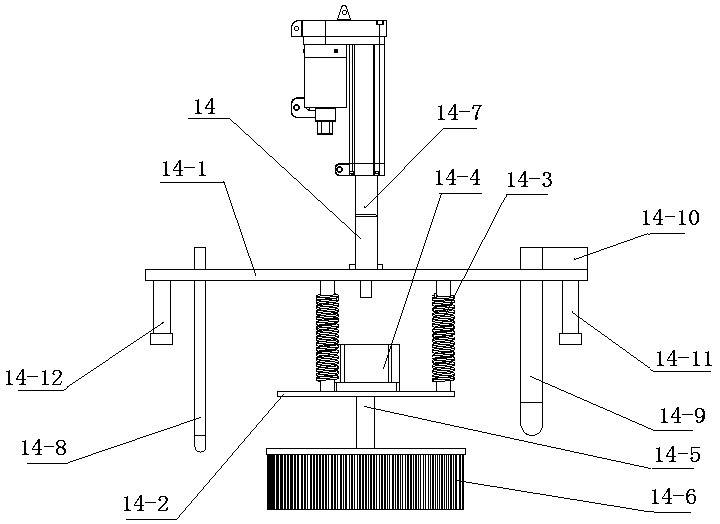

[0027] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 1-Figure 4 As shown, a gantry swing arm type automatic car washing mechanism includes: a guide device 12 arranged on the ground, a movable slider 11 that can slide back and forth on the guide device 12, two movable sliders 11 that can be fixed on the movable slider 11 The swing arm support 10 moving back and forth, the two gantry swing arms 4 connected by connecting shafts arranged on the swing arm support 10 and the gantry crossbeam 1 arranged on the two gantry swing arms 4 connected by shafts.

[0029] In this embodiment, the guide device 12 is two parallel fixed guide rails, which can make the entire gantry move longitudinally along the vehicle (of course, other guide mechanisms can be used as required). The movement of the swing arm support 10 can be realized by telescopic devices such as slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com