Fine-grain forging method for large-size GH690 nickel-based alloy bar billet

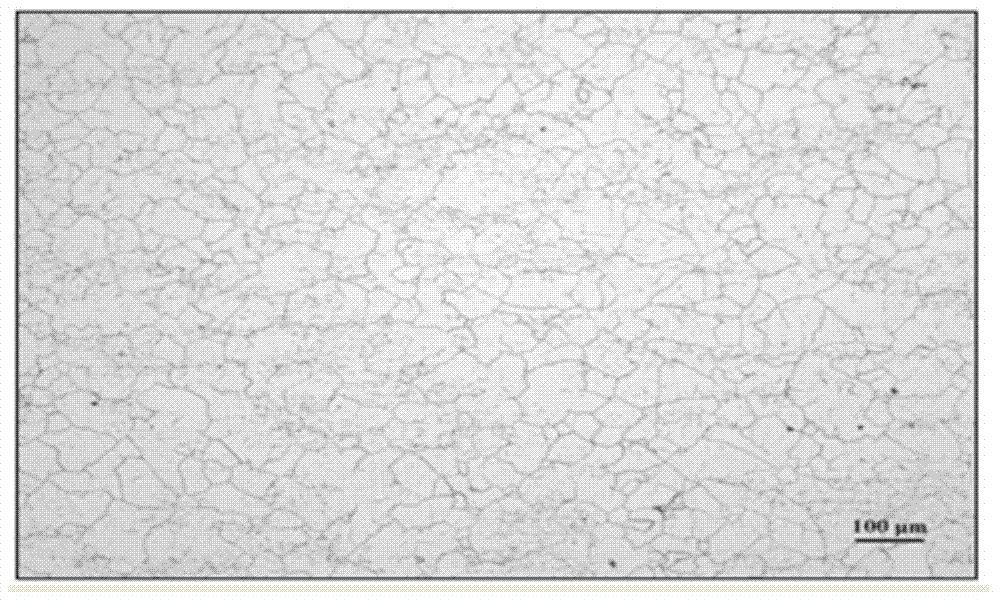

A GH690, nickel-based alloy technology, applied in the field of forging, can solve problems such as hindering the application of alloys, coarse grain structure, and poor control of fire deformation, so as to improve the yield and stability of the structure, and the grains are uniform and fine Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

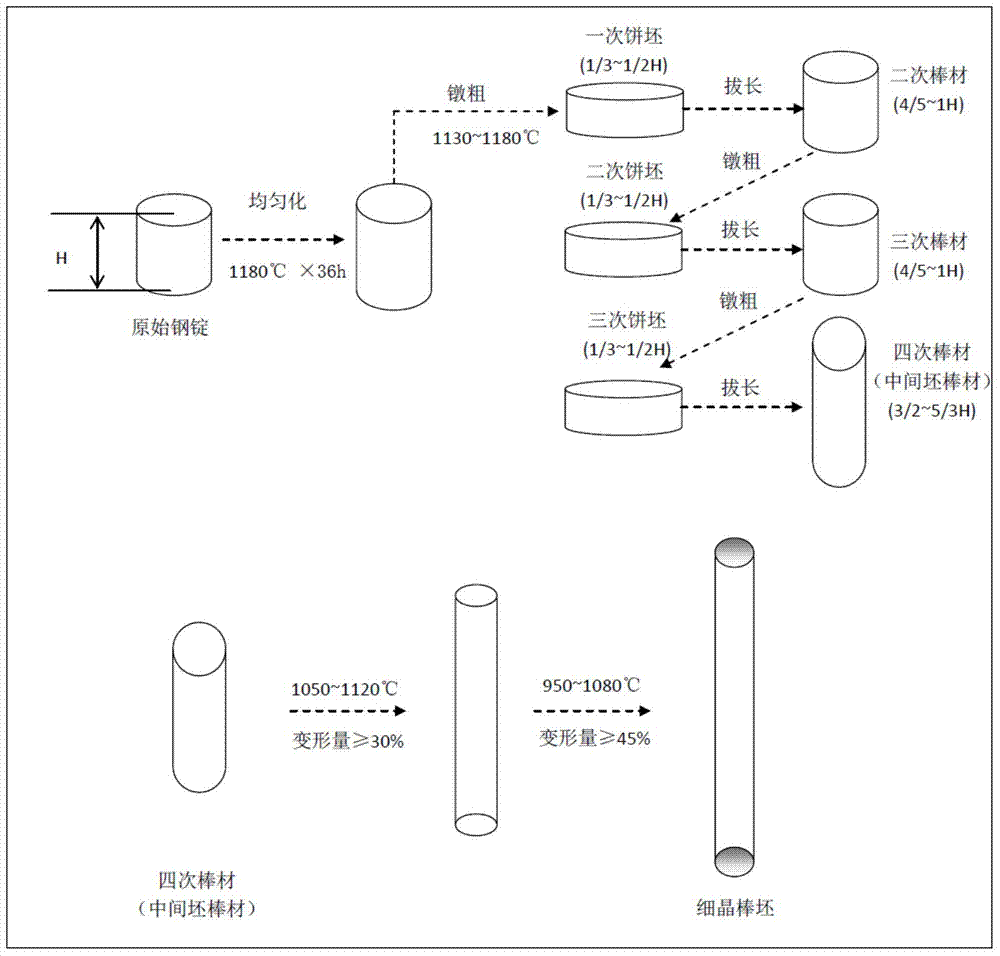

[0027] The steps of a method for fine-grain forging a large-size GH690 nickel-based alloy billet are as follows:

[0028] Step 1: Homogenization. The GH690 nickel-based alloy steel ingot was heated to 1180° C. in a heat treatment furnace and held for 36 hours.

[0029] Step 2: Upsetting. The homogenized GH690 nickel-based alloy steel ingot is heated to 1180° C. in a heating furnace, and then the steel ingot is upset to 1 / 2 times the height of the original steel ingot on a forging press to obtain a primary cake. The primary cake base is stretched on a forging press to return to the height of the original steel ingot to obtain a secondary bar.

[0030] Step 3: Heating the secondary bar described in step 2 to 1180°C in a heating furnace, then upsetting the secondary bar on the forging press to 1 / 2 times the height of the steel ingot to obtain a secondary cake Blank. The secondary cake is stretched on the forging press to return to the height of the original steel ingot to obt...

Embodiment 2

[0037] The steps of a method for fine-grain forging a large-size GH690 nickel-based alloy billet are as follows:

[0038] Step 1: Heat the GH690 nickel-based alloy steel ingot to 1180°C in a heat treatment furnace and keep it warm for 36 hours.

[0039] Step 2: Heating the homogenized GH690 nickel-based alloy steel ingot to 1160° C. in a heating furnace, and then upsetting the steel ingot to 2 / 5 times the height of the original steel ingot on a forging press to obtain a primary cake. Then, the primary cake base is stretched on a forging press and changed back to 9 / 10 times the height of the original steel ingot to obtain a secondary bar.

[0040] Step 3: Heating the secondary bar to 1160° C. in a heating furnace, then upsetting the secondary bar on a forging press to 2 / 5 times the height of the steel ingot to obtain a secondary cake. The secondary cake is stretched on a forging press to return to 9 / 10 times the height of the original steel ingot to obtain a tertiary bar.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com