High-purity Ti2AlC powder material and preparing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation of the above-mentioned high-purity Ti provided by the present invention 2 The method for AlC powder material, concrete steps comprise:

[0018] (1) weighing: take Ti powder, TiC powder, Al powder and active carbon powder, the mol ratio of four kinds of raw materials is n(Ti):n(TiC):n(Al):n(C)=(1.15 ~1.95):(0.5~0.95):1:(0.15~0.95);

[0019] (2) mix the raw material powder that takes by weighing;

[0020] (3) Sintering: After pressing the uniformly mixed raw material powder into tablets, place it in the cavity of a microwave sintering device, and sinter in an argon-protected environment, and cool naturally after sintering.

Embodiment 1

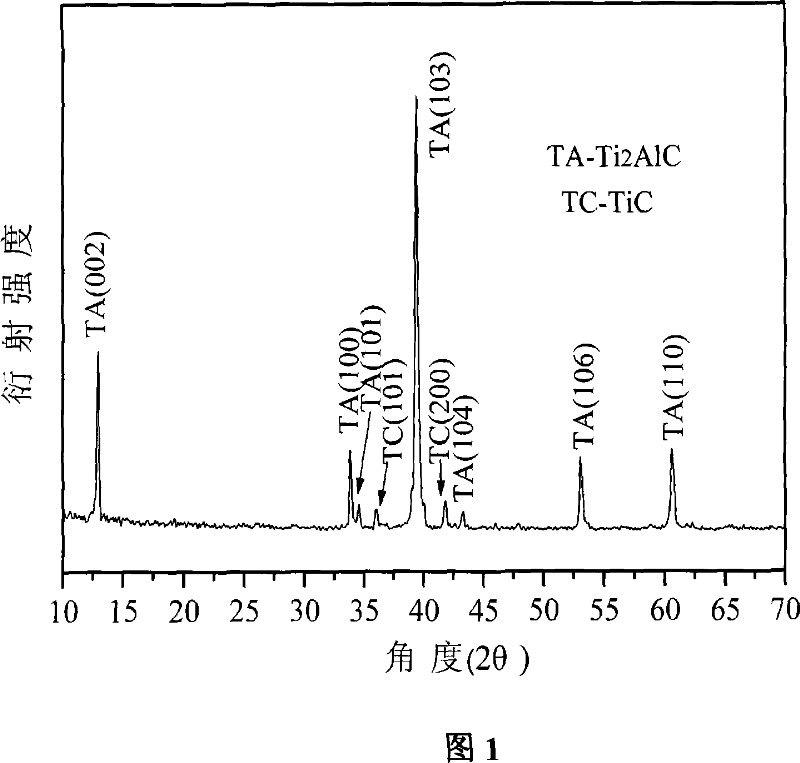

[0022] Embodiment 1: Raw material powder is mixed with n(Ti):n(TiC):n(Al):n(C)=1.25:0.85:1:0.2 in molar ratio; mix evenly, put into microwave sintering system after tableting , and sintered under the protection of argon. The frequency used is 2.45GHz, the power is controlled at 0.8KW, the temperature is 850°C, and the temperature is kept for 5 minutes. After the grinding of the obtained material, measure its phase composition, the result shows: the product only has Ti 2 Two components of AlC and TiC, Ti 2 The AlC content is 93.5%.

Embodiment 2

[0023] Embodiment 2: The molar ratio of raw material powder is n(Ti):n(TiC):n(Al):n(C)=1.15:0.95:1:0.15 ingredients; mix evenly, put into microwave sintering system after tabletting , and sintered under the protection of argon. The frequency used is 2.45GHz, the power is controlled at 0.5KW, the temperature is 800°C, and the temperature is kept for 10 minutes. After the grinding of the obtained material, measure its phase composition, the result shows: the product only has Ti 2 Two components of AlC and TiC, Ti 2 The AlC content is 93.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com