Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Reduce the number of generated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for propagating sulzer braconid flies

ActiveCN101664017AAvoid the formation of winged aphidsAvoid multiple generationsHorticultureAnimal husbandryNicotiana tabacumMulti generation

The invention discloses a method for propagating sulzer braconid flies. The method comprises the following steps: firstly, culturing a host plant of tobaccos, then propagating sulzers and afterwards propagating the sulzer braconid flies by the sulzers. By propagating the flies in batches, the multi-generation repeated propagation of the sulzer braconid flies is avoided, the generation quantity ofthe hyperparasite flies of the sulzer braconid flies is reduced, and the survival capability of the sulzer braconid flies in the field is enhanced. The propagation time and quantity of the sulzer braconid flies can be flexibly regulated and controlled according to the actual condition of the field, and different requirements on the sulzer braconid flies under different situations are met. The emergence rate of the stiff aphids of the sulzer braconid flies propagated by the invention is more than 90%, the male-female ratio is 0.8-1.0:1, and the utilization rate of the stiff aphids or the adultflies is more than 80%.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Synthesis method of semaglutide

ActiveCN106749613ALow costReduce the number of generatedPeptide preparation methodsBulk chemical productionSynthesis methodsPeptide sequence

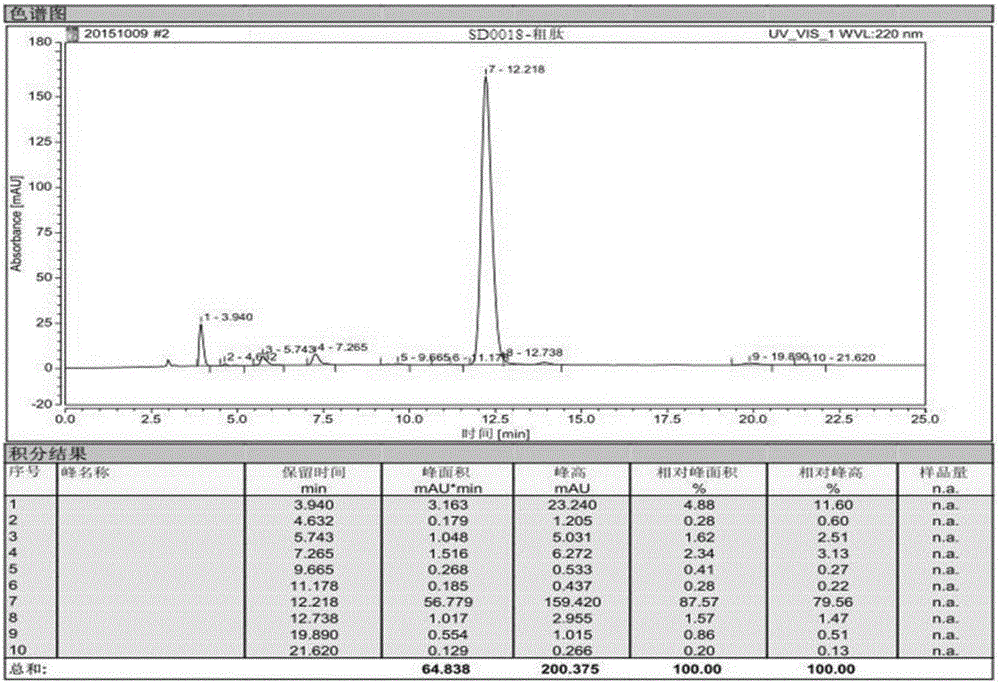

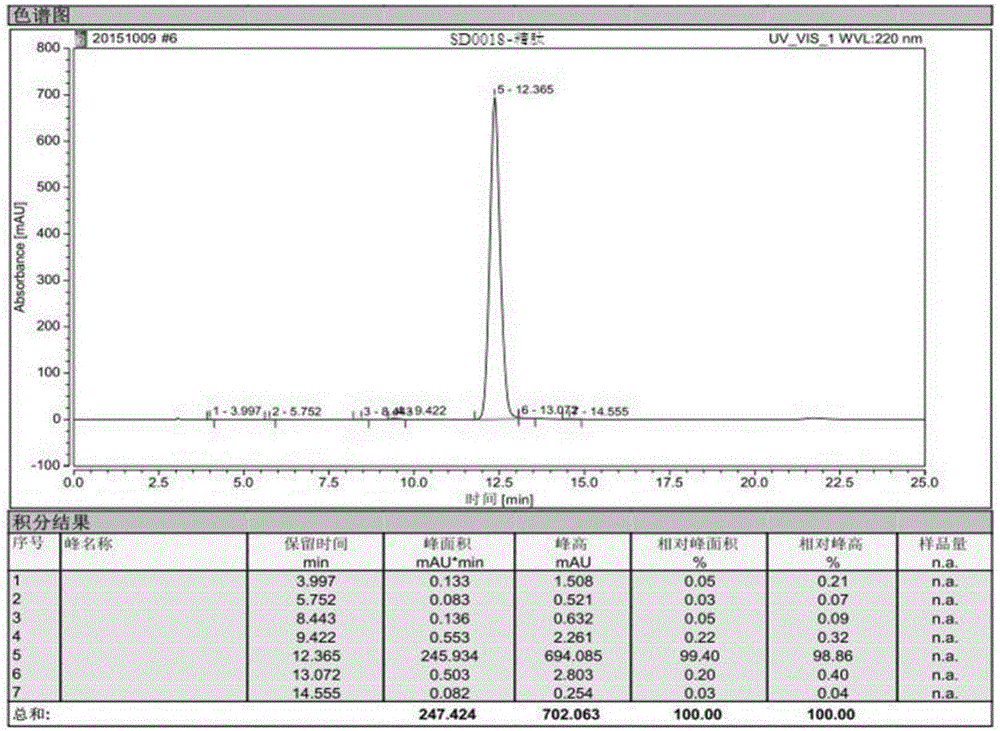

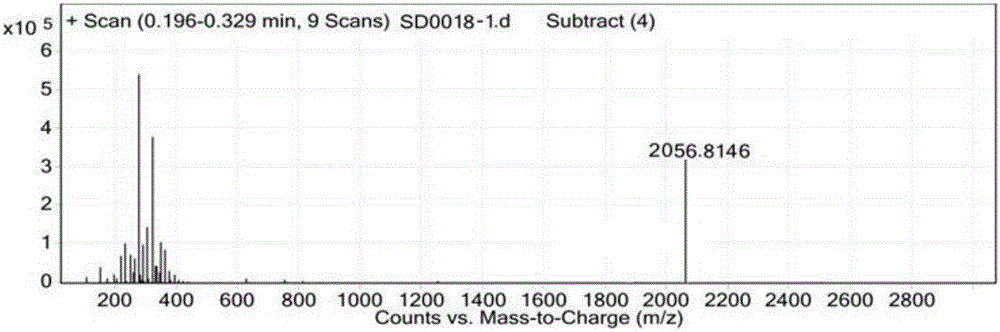

The invention relates to a synthesis method of semaglutide. According to the method, a semaglutide product is synthesized by adopting a solid-liquid phase combination method, and three fragments are simultaneously synthesized in a synthesis manner of 16+6+9 fragments, and therefore, the synthesis time of the product is greatly shortened; moreover, by step-by-step analysis on synthesis factors of His-Ala-Glu-Gly-Thr-Phe-Thr-Ser-Asp-Val-Ser-Ser-Tyr-Leu-Glu-Gly, Gln-Ala-Ala-N6-[N-(17-carboxy-1-oxoheptadecyl-L-gama-glutamyl [2-(2-aminoethoxy) ethoxy] acetyl [2-(2-aminoethoxy) ethoxy] acetyl]-Lys-Glu-Phe, Ile-Ala-Trp-Leu-Val-Arg-Gly-Arg-Gly-OH and the like, the difficulty in synthesis of a peptide sequence in solid-phase synthesis is reduced, the problem of batch amplification in the solid-phase synthesis is solved, and the synthesis efficiency is improved; and as liquid-phase fragment synthesis is adopted, the purification difficulty is effectively reduced, and the production cost is greatly lowered. The synthesis method disclosed by the invention has the advantages that the synthesis time can be shortened by 40%, the cost of materials is lowered, the generation quantities of deletion peptide and hybrid peptide are decreased, and the synthesis method is suitable for industrial large-scale production.

Owner:SINOPEP ALLSINO BIOPHARMACEUTICAL CO LTD

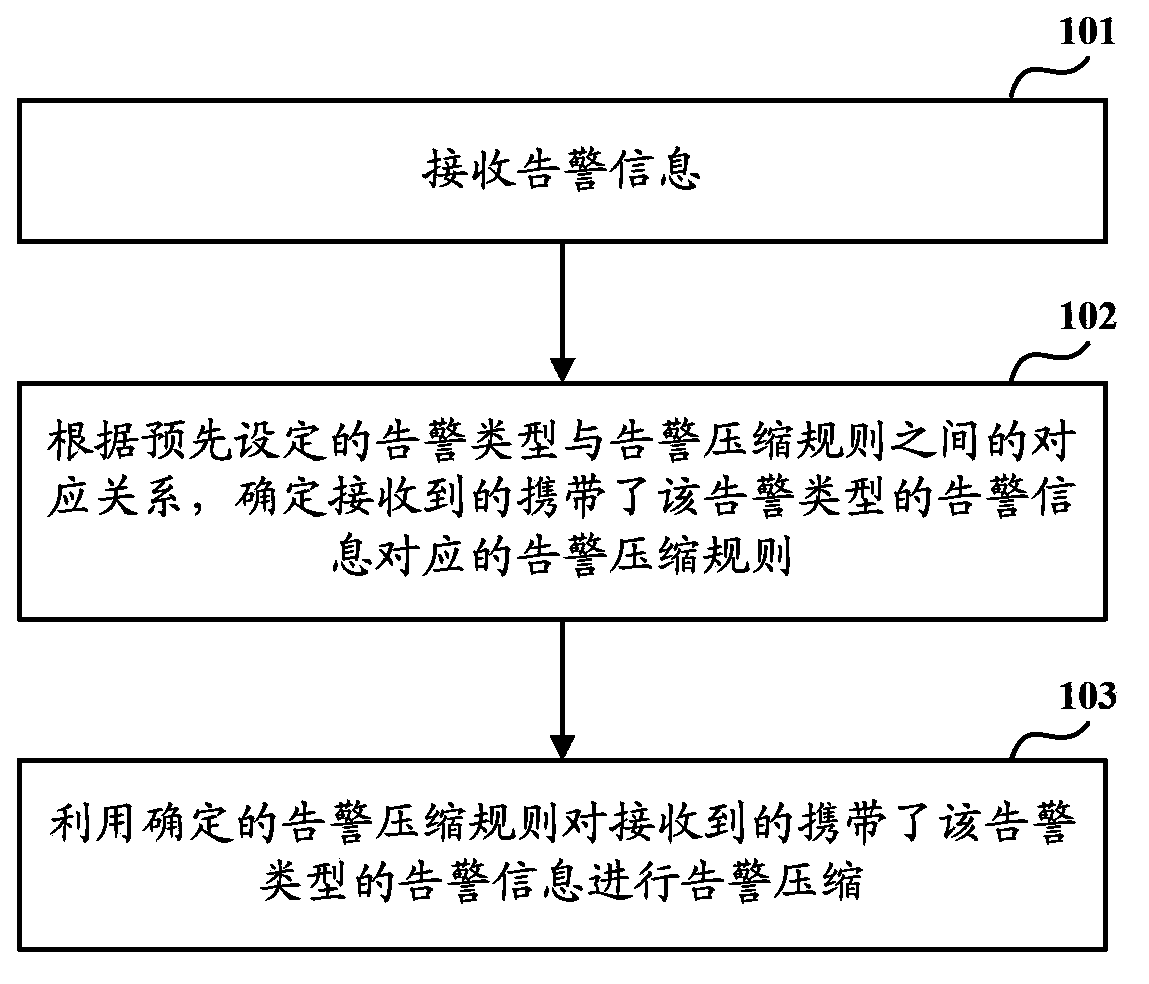

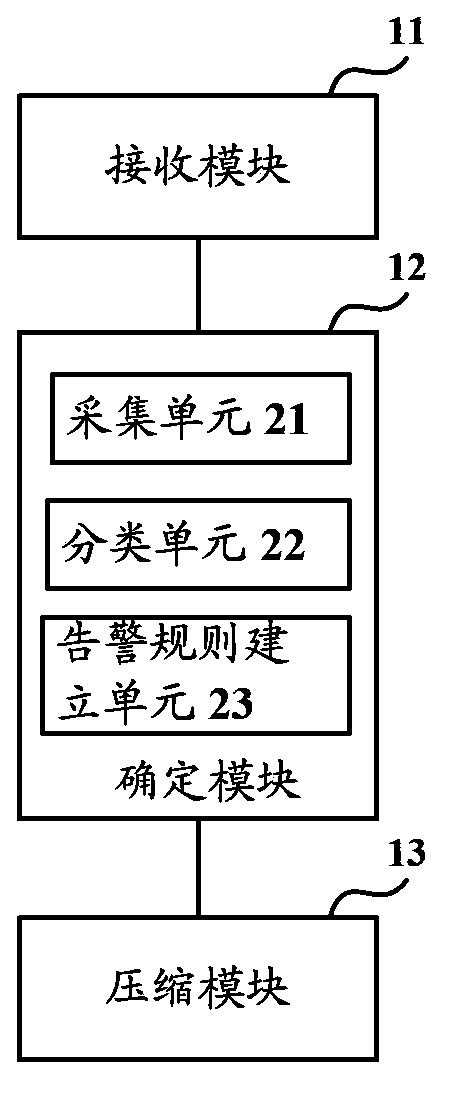

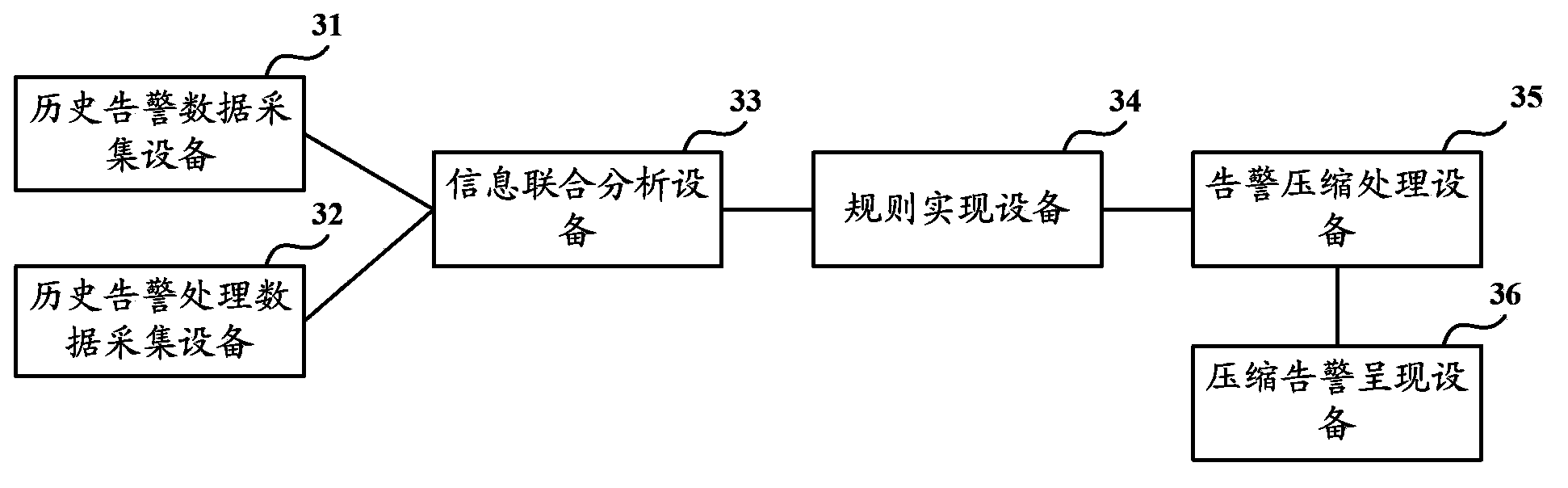

Method and device for compressing alarm information

ActiveCN103856339AEfficient and fast compression processingReduce the number of generatedData switching networksProcess efficiencyReal-time computing

The embodiment of the invention discloses a method and device for compressing alarm information. The method includes the following steps that after alarm information carrying an alarm type is received, an alarm compression rule corresponding to the received alarm information carrying the alarm type is determined according to the corresponding relation between a preset alarm type and the alarm compression rule, and alarm compression is carried out on the received alarm information carrying the alarm type by means of the determined alarm compression rule. By the adoption of the method and device for compressing the alarm information, the received alarm information can be effectively and quickly compressed, the amount of the generated alarm information and the number of sent alarm information text messages can be lowered, the amount of invalid information generated in the monitoring process can be lowered, and processing efficiency of the alarm information is improved.

Owner:中国移动通信集团广西有限公司

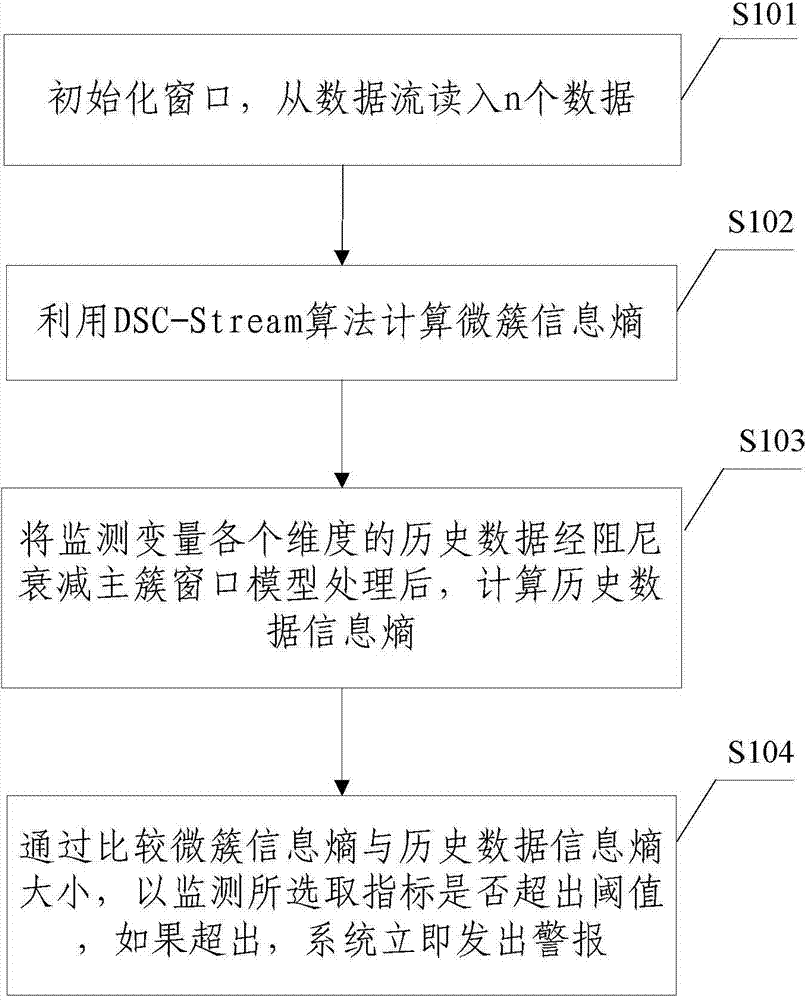

Maximum information entropy-based chemical data stream real-time abnormity detection method

ActiveCN104517041AReduce the number of generatedSolving Adaptive ProblemsTesting/monitoring control systemsSpecial data processing applicationsStreaming dataRobustification

The invention discloses a maximum information entropy-based chemical data stream real-time abnormity detection method. According to the method, a real-time clustering algorithm DSC-Stream (The Dimension Space Cluster-Stream) is used; a data dimension space is used as a starting point to divide the data dimension space into a plurality of dimension clusters according to the maximum entropy principle; the data in the same dimension cluster forms a micro cluster so as to realize the real-time clustering of the data streams; the algorithm can be used for effectively decreasing the quantity of the invalid grids generated in the traditional density grid algorithm so as to greatly improve the operational efficiency; meanwhile, through a method for setting dimension cluster similarity, the algorithm can be used for effectively solving the problem that the traditional density algorithm is sensitive to the scanning radius and the density threshold to cause poor robustness and can be better adapted to the stream data.

Owner:BEIJING UNIV OF CHEM TECH

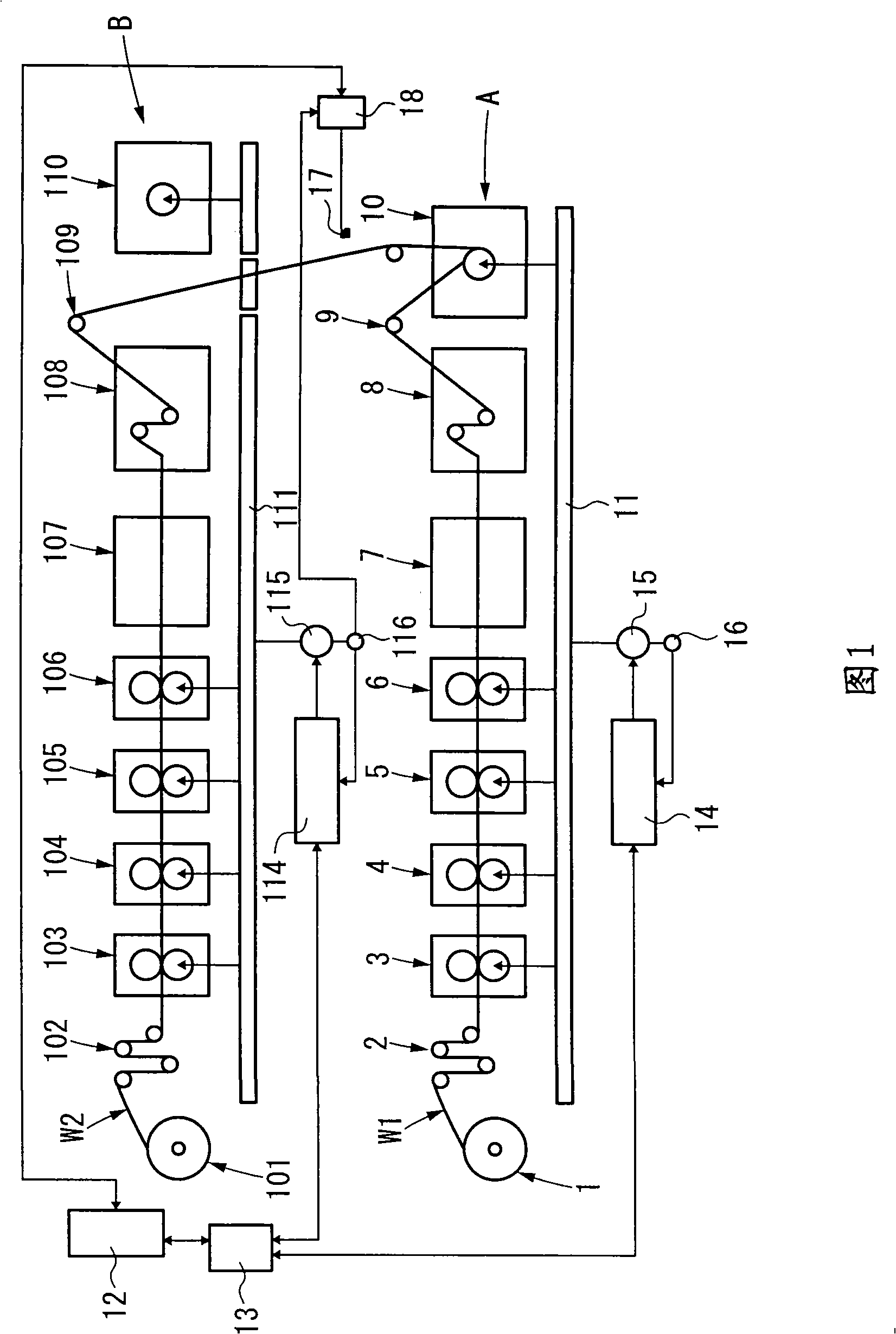

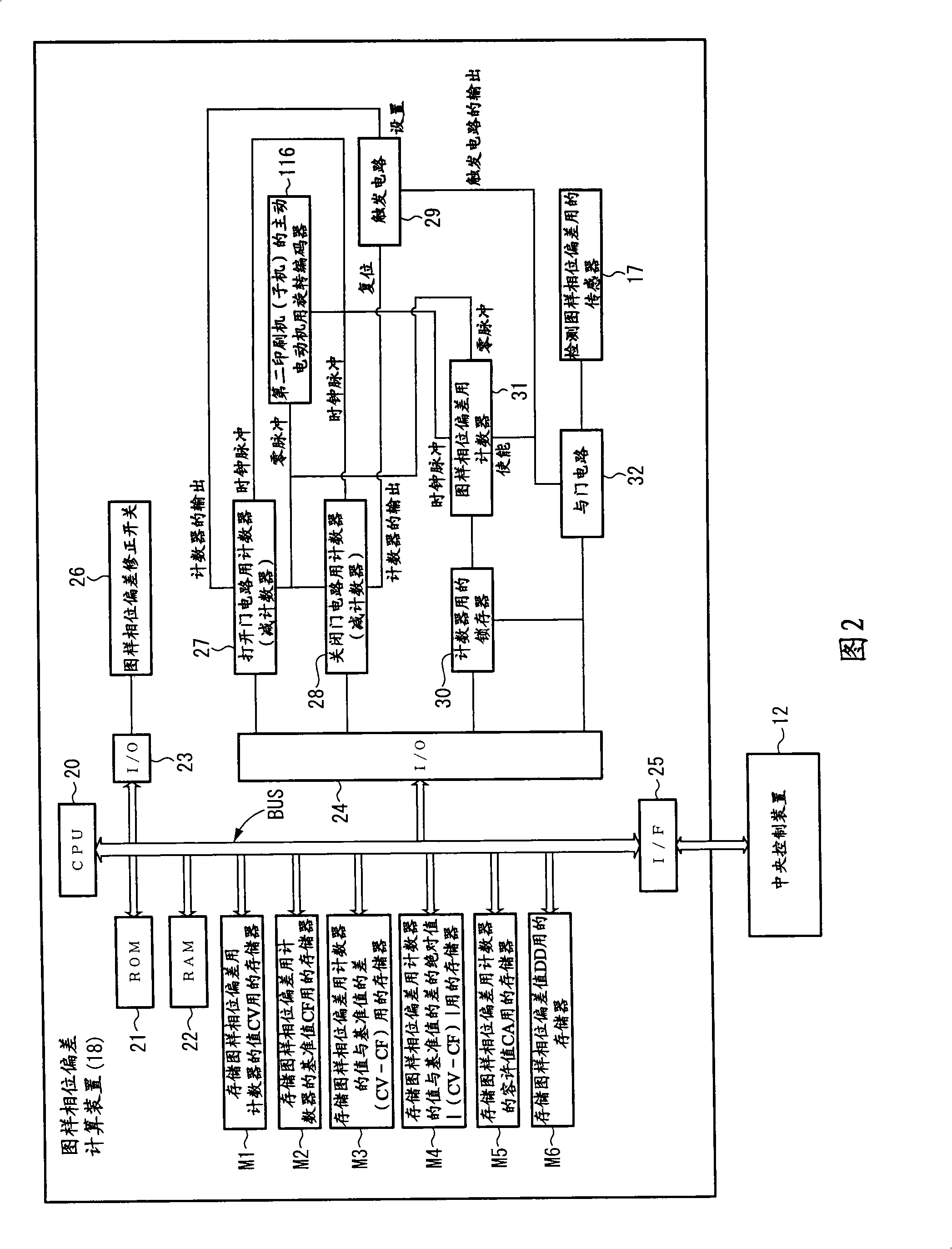

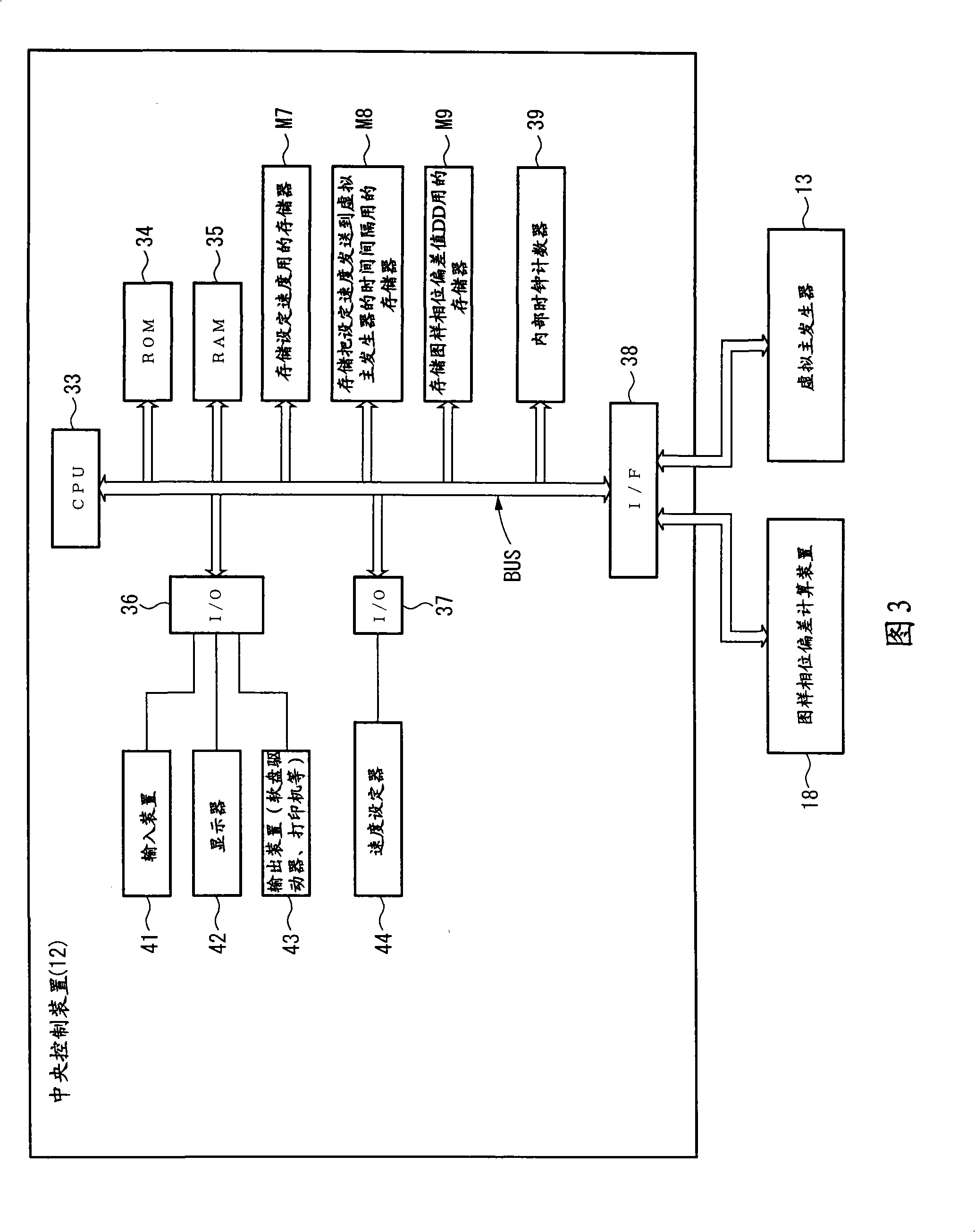

Synchronous control method and apparatus for web rotary printing press

InactiveCN101348034AReduce the burden onReduce the number of generatedFunction indicatorsFolding thin materialsSynchronous controlDrive motor

A synchronous control method and apparatus are disclosed for a web rotary printing press which comprises a first printing press, a second printing press, a drive motor for driving the second printing press, and a folder provided in the first printing press, and enables a web printed by the first printing press and a web printed by the second printing press to be superposed and folded by the folder. The synchronous control apparatus comprises a pattern phase deviation detecting sensor provided halfway through a transport path, on which the web printed by the second printing press is transferred so that the web is superposed on a web printed by the first printing press, and adapted to measure the position of a pattern printed by the second printing press, and a pattern phase deviation computing device and a central control device for controlling the rotation phase of the drive motor based on the position of the pattern printed by the second printing press, the position having been measured by the sensor.

Owner:KOMORI CORP

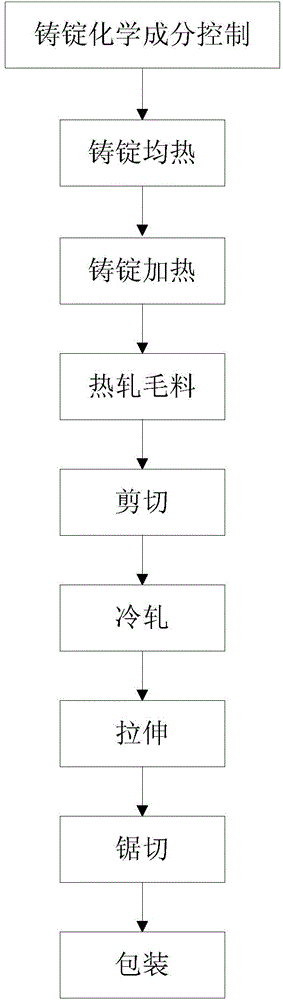

Production process of aluminum alloy plate for notebook computer

The invention discloses a production process of an aluminum alloy plate for a notebook computer. The production process comprises the following steps: controlling the chemical components of a cast ingot; uniformly heating the cast ingot, heating the cast ingot to 470-500 DEG C, and keeping the temperature for 10-50 hours; heating the cast ingot; hotly rolling raw materials; cutting; coldly rolling; straightening; sawing; and packing. The control of the chemical components of the cast ingot comprises the steps of controlling the Mg content in aluminum alloy to be 2.2-2.4%, the Cr content to be 0.15-0.20% and the use amount of a waste material in the aluminum alloy to be less than 35%, and adding a grain refiner in a casting process of the cast ingot. Compared with an existing production process, the production process has the advantages that the internal organization macro-segregation of the cast ingot is reduced, the content of impurities is effectively controlled, the production amount and size of a difficultly soluble interphase of the casting process are reduced, and the good effects in refining grains and controlling coarse compounds are achieved. The production process realizes the uniform control of large-scale cast ingot components and solves the problem that the internal organization of the aluminum alloy plate is non-uniform.

Owner:SOUTHWEST ALUMINUM GRP

Crosslinked fluorocopolymer moldings

A cross-linked fluorine-containing copolymer moldings applicable to a plasma irradiation step, which is molded as a peroxide cross-linking product of a fluorine-containing copolymer blend comprising a fluorine-containing elastomer copolymer and a fluorine-containing resin copolymer, which is a vinylidene fluoride-tetrafluoroethylene copolymer, both of the copolymers having reaction sites capable of reacting with a common peroxide-based cross-linking agent, respectively, has desired normal state physical properties and compression set value, even if applied to a plasma irradiation step, while reducing particle generation quantity of the fluorine-containing copolymers themselves.Crosslinked fluorocopolymer moldings which are obtained by subjecting a fluorocopolymer blend comprising both a fluoro- elastomer copolymer and a fluororesin copolymer consisting of a vinylidene fluoride / tetrafluoroethylene copolymer which each have reaction sites reactive with a common peroxide-type crosslinking agent to molding and crosslinking and which are subjectable to plasma irradiation. The moldings are reduced in the quantity of particles generated from the fluorocopolymer itself when subjected to plasma irradiation, and exhibit normal-state physical properties and compression set favorable to sealing material.

Owner:UNIMATEC CO LTD

Method for producing porcelain basal body composite plate

The invention involves a production method for ceramic matrix composite boards. The method including the following specific steps: (1) The required raw materials are treated by press forming after ball milling; (2) Green bricks are treated by biscuit firing at 1150 DEG C plus or minus 5 DEG C; (3) The green bricks treated by biscuit firing are treated by 600 mesh sand blasting to get a smooth surface and a required surface area; (4) The green bricks are cleaned up, and then sprayed with coating; (5) the coating is solidified for 15 minutes at 380 DEG C; (6) The solidified products are treated by aging and then packaged in classification for warehousing. This method can reduce the secondary firing process ceramic products with a surface coating curing temperature at just 380 DEG C, which significantly optimizes the secondary high energy-consuming firing process in the common glazed tile production by saving 70% energy consumption in the process and meanwhile significantly reduces the produced gases as CO2 and SO2.

Owner:冼金源 +2

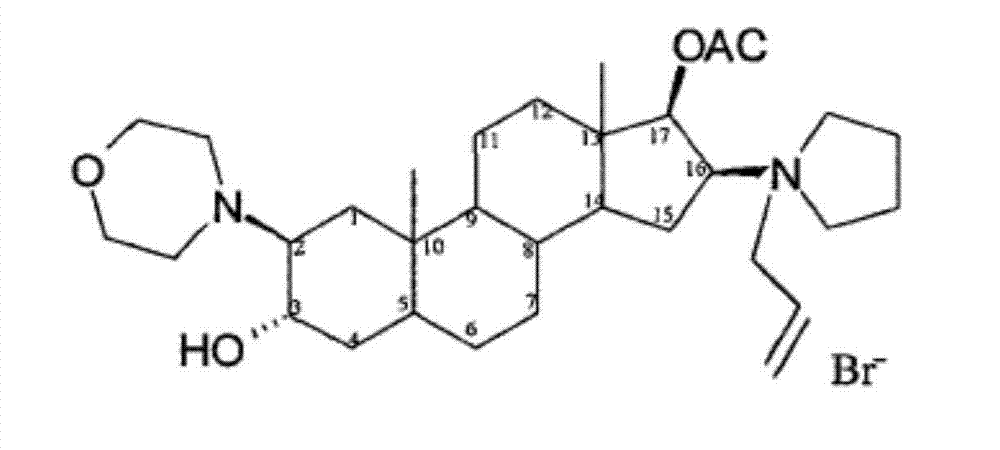

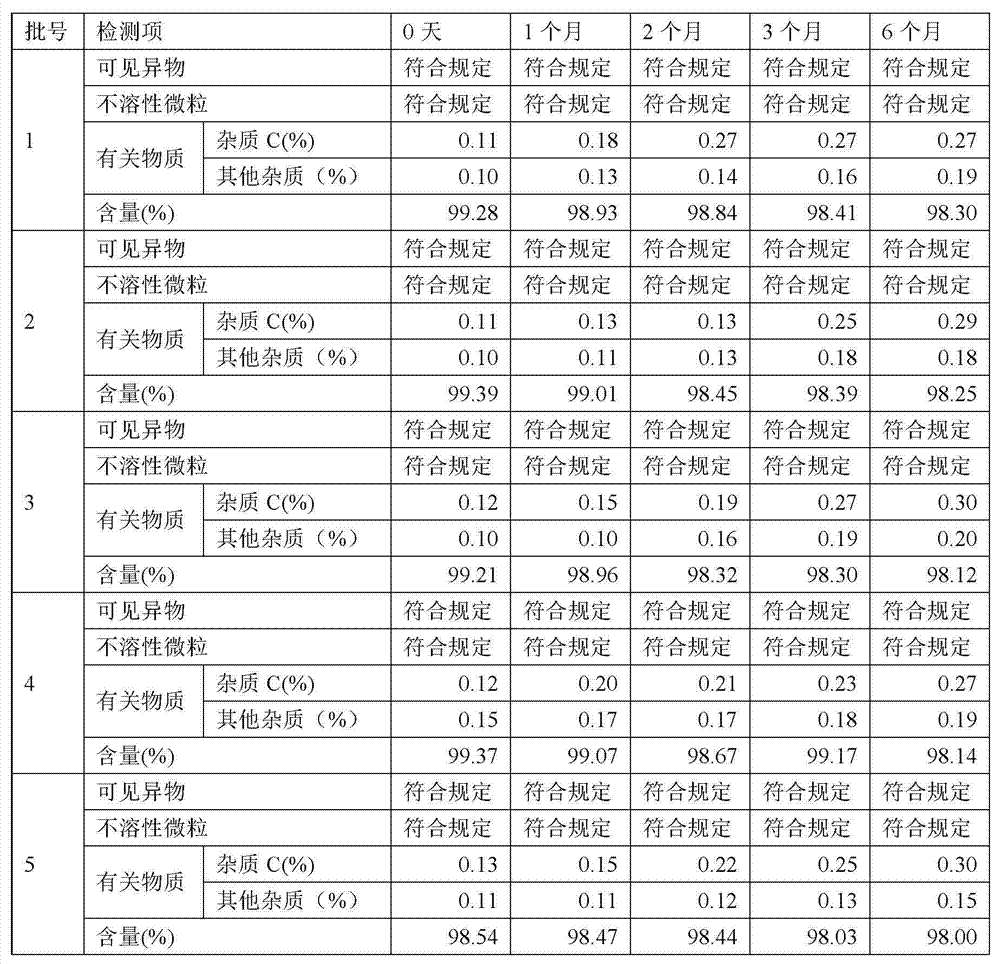

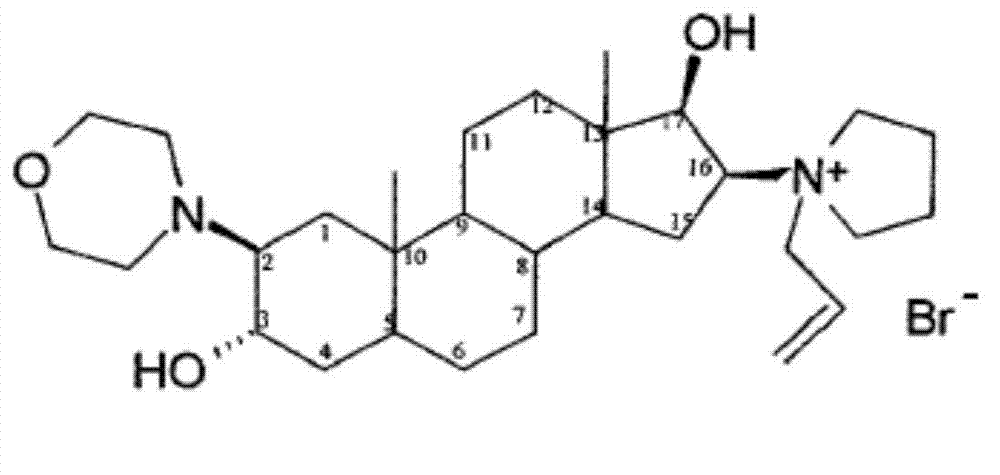

Rocuronium bromide-containing injection

ActiveCN102949339AReduce hydrolysisReduce hydrolysis reactionOrganic active ingredientsMuscular disorderBULK ACTIVE INGREDIENTActive ingredient

The invention relates to a rocuronium bromide-containing injection. The injection is prepared from rocuronium bromide serving as an active ingredient and a pharmaceutically-acceptable carrier as accessories. The pH value of a system is maintained by adding a 1-5 percent acetate buffer solution, so that the stability of the solution is enhanced, the pH value of a system is maintained at the same time, degradation of main medicaments in a preparation process is suppressed, the stability of the main medicaments is enhanced, and the quantity of rocuronium bromide impurities C in an autoclave sterilizing process is reduced. Finally, a rocuronium bromide injection which has high stability and stable quality and is suitable for storing for a long time is obtained.

Owner:TIANJIN CHASE SUN PHARM CO LTD

Emulsifiable natural oil coating agent applied to granulated compound feed

InactiveCN109965089APassivated adhesion spreading retardationAdhesion spreading delay time optimizationAnimal feeding stuffAccessory food factorsVegetable oilAntioxidant

The invention discloses an emulsifiable natural oil coating agent applied to a granulated compound feed. The emulsifiable natural oil coating agent comprises natural animal and vegetable oil, concentrated soybean lecithin oil, an emulsifying agent, an antioxidant, an anti-mildew preservative, a polar solvent, vitamins, amino acid chelated trace elements, probiotics and Chinese herbal medicine superfine powder. After mixing, the raw materials are stirred, dispersed and homogenized to obtain sticky paste; 5-10 times of clear water is added into the coating agent to form slurry in appropriate glutinousness, the coating agent and auxiliary agents thereof can be adopted for preparing the slurry, and the slurry can be mixed with water to be diluted for livestock and poultry breeding objects to drink and can also be mixed with the granulated compound feed to be used for feeding the breeding objects; when the mixed granulated compound feed is used for feeding aquaculture objects, dust is evidently reduced, and by hydrophilic and lipophilic characteristics of liposome and a phospholipid complex dissolved in aquaculture water, surface tension of water in a feeding area can be reduced, so that feeding stress response of the aquaculture objects is relieved, and implementation effects of a healthcare prevention and treatment scheme in aquaculture production are improved.

Owner:江苏欧克动物药业有限公司

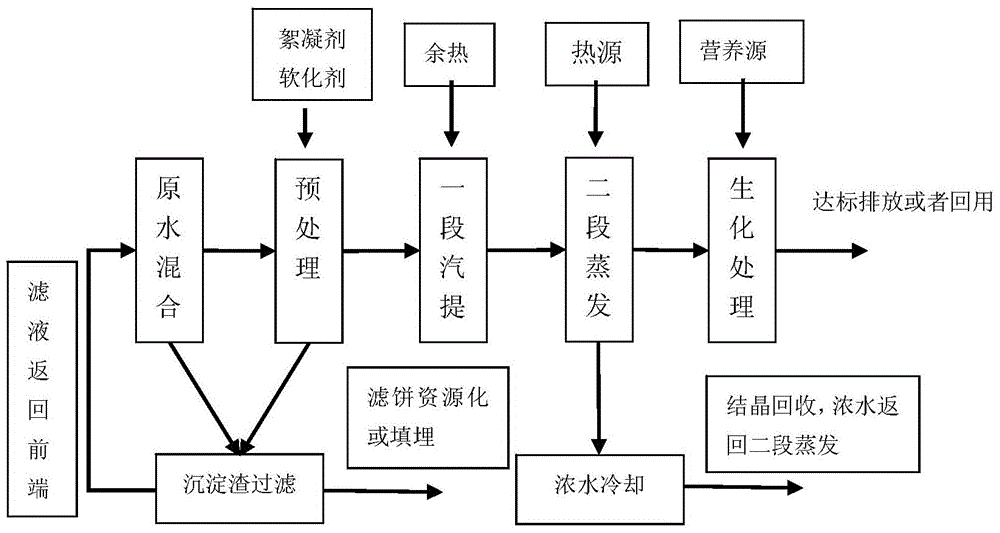

Treatment method of gold smelting plant high-salt wastewater hard to treat and containing ammonia and nitrogen

ActiveCN104445799AEasy to handleImplement bid processingWaste water treatment from metallurgical processMultistage water/sewage treatmentAmmoniacal nitrogenWater quality

The invention discloses a treatment method of gold smelting plant high-salt wastewater hard to biodegrade and containing ammonia and nitrogen. According to the method, technological procedures such as desalting pretreatment, two-stage separated evaporation and biochemical treatment are mainly adopted. By adopting mature and reliable technologies, the technological process is safe, efficient, free of secondary pollution, capable of recycling valuable materials and comprehensively utilizing resources, and controllable in cost; the quality of treated water reaches the first-class emission standard and the water recycle standard. By combining a plurality of treatment technologies, the treatment method disclosed by the invention has the advantages of achieving a remarkable benefit increment effect, breaking through the technical bottlenecks of the original treatment process and the existing treatment method, effectively solving the problem of hard degradation of high-salt complex wastewater and creating good environmental protection and economic benefits.

Owner:厦门紫金矿冶技术有限公司

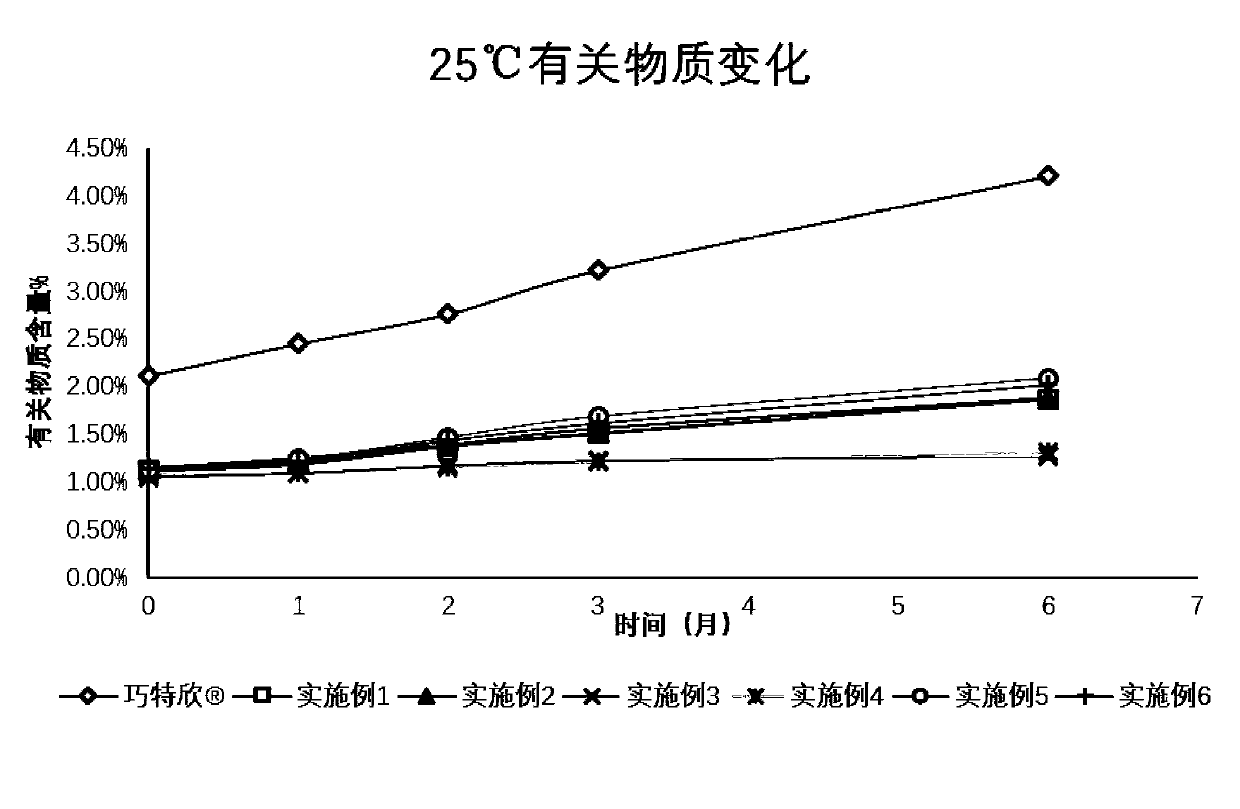

Injection containing carbetocin and stabilizer and storable at normal temperature

PendingCN111012739AReduce the number of generatedImprove stabilityPeptide/protein ingredientsInorganic non-active ingredientsPostpartum haemorrhageEngineering

The invention relates to an injection containing carbetocin and a stabilizer and storable at a normal temperature. The injection can be stored at normal temperature and comprises carbetocin, the stabilizer, a pH regulator and water for injection, wherein the stabilizer is composed of compound amino acid, so the stability of the injection can be improved. The injection is used for preventing uterine tension insufficiency and postpartum hemorrhage.

Owner:CHANGCHUN SHENGJINNUO BIOLOGICAL PHARMA

Physical control method for mosquito and fly pests of edible mushrooms

InactiveCN106172359AReduce the number of habitatsReduce the number of eggs spawnedAnimal repellantsCultivating equipmentsGreenhousePlastic mulch

The invention discloses a physical control method for mosquito and fly pests of edible mushrooms. The method comprises the procedures of carrying out site selecting, carrying out mulching film laying, carrying out bagging, carrying out inoculating, carrying out inoculated culture, carrying out mushroom emergence management and carrying out harvesting, wherein woven mulching films are laid to the ground of a mushroom hothouse or mushroom greenhouse, a medium substance is loaded to mushroom bags, sterilizing and inoculating are carried out, the mushroom bags are placed in an appropriate environment for culture and mushroom emergence, harvesting is carried out after mushroom caps are flat and smooth, and the color of the woven mulching films and the color of the mushroom bags are specific gray. According to the method, an environment, which plays a role in repelling the mosquito and fly pests of the edible mushrooms, is created in a culture place by using plastic products, for edible-mushroom culture, with the specific gray, so that the habitation and the quantity of propagation of the mosquito and fly pests in the culture place are reduced, and then, the aims of protecting the growth of the edible mushrooms and improving the yield and quality of the edible mushrooms are achieved.

Owner:GUANGXI UNIV

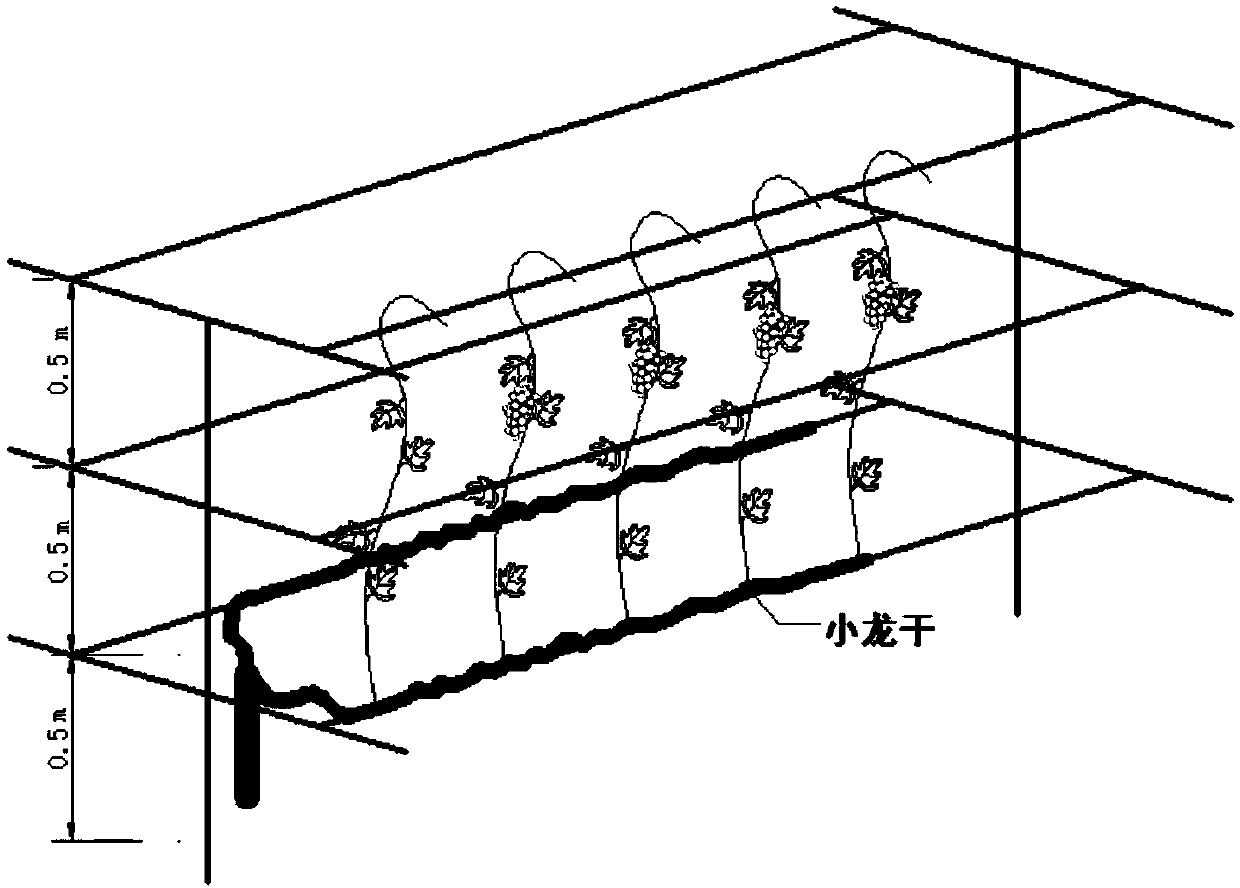

Cultivation method for enlarging fruit grains of facility grapes

ActiveCN109548554AWeakened vegetative growthSlow growth rateSaving energy measuresCultivating equipmentsGrain weightShoot

The invention discloses a cultivation method for enlarging fruit grains of facility grapes. According to the cultivation method, the growth of grape shoots is controlled by changing environmental conditions (mainly for supplementing the ultraviolet rays), removing winter bud shoots and inhibiting the growth of winter bud shoots and simply shaping and trimming the shoots, compared with the traditional way for controlling the growth by manually pinching main and auxiliary shoots for multiple times, the cultivation method of the invention is simple in operation, the labor is saved by more than 25percent, and the management efficiency is improved; the planting cost is reduced, and the growth rate of the shoots is reduced by more than 36 percent compared to the traditional technology; the number of auxiliary shoots is reduced, and the occurrence rate of the auxiliary shoots is reduced by more than 58 percent compared with the traditional technology; the grape grains can be significantly enlarged, and the unit grain weight is increased by more than 35 percent compared with the traditional method; and the grape grain soluble solid content is increased by more than 11 percent, and the rate of high-quality fruits is more than 92 percent.

Owner:SHANDONG WEIFANG ACADEMY OF AGRICULTURAL SCIENCES +1

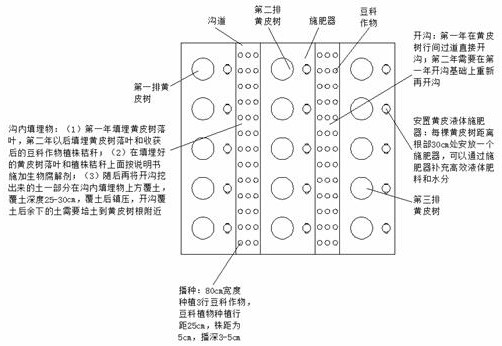

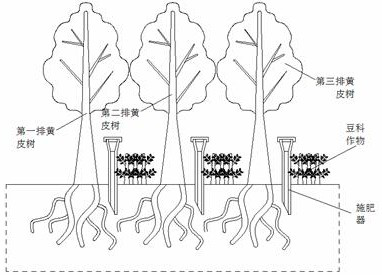

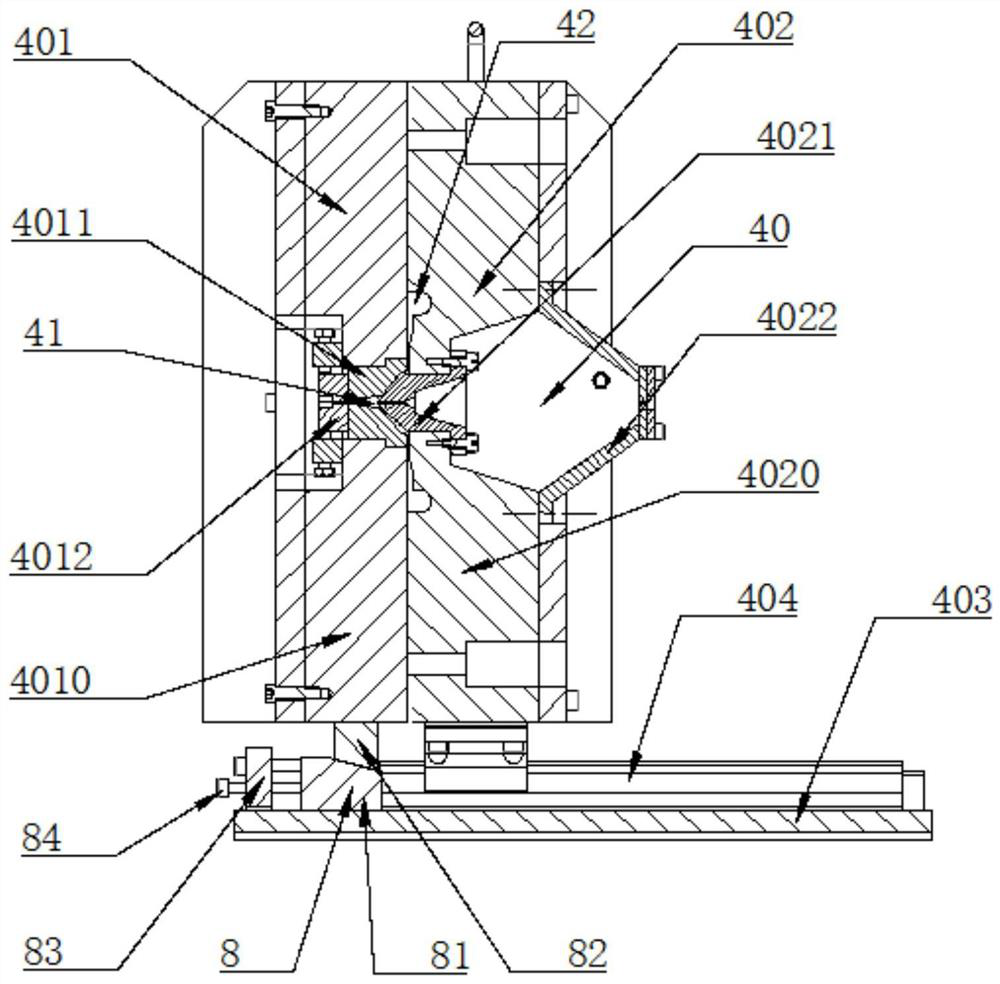

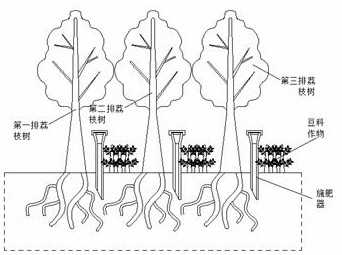

Technology for improving soil fertility and benefits of clausena lansium orchard

InactiveCN113099934APromote fruit settingIncreasing the thicknessFabaceae cultivationFertilising methodsFruit treeFruit set

The invention discloses a technology for improving soil fertility and benefits of a clausena lansium orchard, which comprises the following steps: ditching passages between rows of clausena lansium trees, filling fallen leaves, applying liquid fertilizer, applying efficient calcium-boron fertilizer, spraying a biological decomposition agent and planting leguminous crops. The intercropping and interplanting mode of the clausena lansium trees and the leguminous crops mainly comprises a way of ditching in the passages between two rows of clausena lansium trees. According to the technology for improving the soil fertility and benefits of the clausena lansium orchard, the fertilizer utilization rate is increased by applying the efficient liquid fertilizer; the flower and fruit setting rate, the storage and transportation resistance and the stress resistance are improved through the efficient calcium-boron fertilizer, and decomposition of fallen leaves and straw is accelerated by spraying the biological decomposition agent; and soil is supplemented with biological nitrogen by planting land-cultivating leguminous crops, biological carbon of the soil is increased by returning fallen leaves and straw to the field, finally sustainable utilization of the cultivated land in the clausena lansium orchard is achieved, and economic benefits, social benefits and environmental benefits of clausena lansium planting are improved.

Owner:GUANGDONG OCEAN UNIVERSITY

Lubricating oil

The invention relates to a lubricating oil which mainly solves the problems of low stability, poor lubricating effect and short service life in the existing common lubricating oil. The invention is characterized in that the lubricating oil is prepared from the following components in parts by weight: 350-450 parts of lubricating oil base oil, 15-35 parts of polymethacrylate, 10-20 parts of high-base-number sulfurized calcium alkyl phenate, 11-15 parts of magnesium hydroxy silicate, 11-15 parts of molybdenum dibutyl dithiocarbamate, 12-17 parts of isooctyl oleate, 12-20 parts of polyisobutylene succimide, 5-8 parts of molybdenum dialkyl dithiocarbamate, 10-20 parts of dimethyl silicone oil, 5-10 parts of sorbitan monooleate and 2-5 parts of epoxyethane / epoxypropane block polymer ether. The lubricating oil has the advantages of excellent comprehensive properties, favorable stability, favorable lubricating property, favorable defoaming property, favorable oxidation resistance and favorable abrasion resistance, and has wide application prospects.

Owner:WENZHOU TUOYU TECH CO LTD

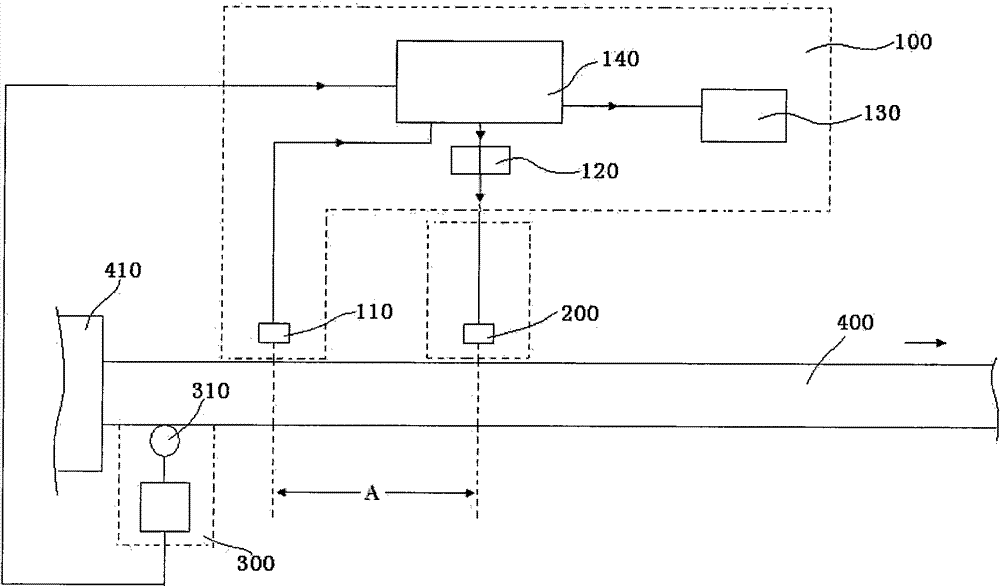

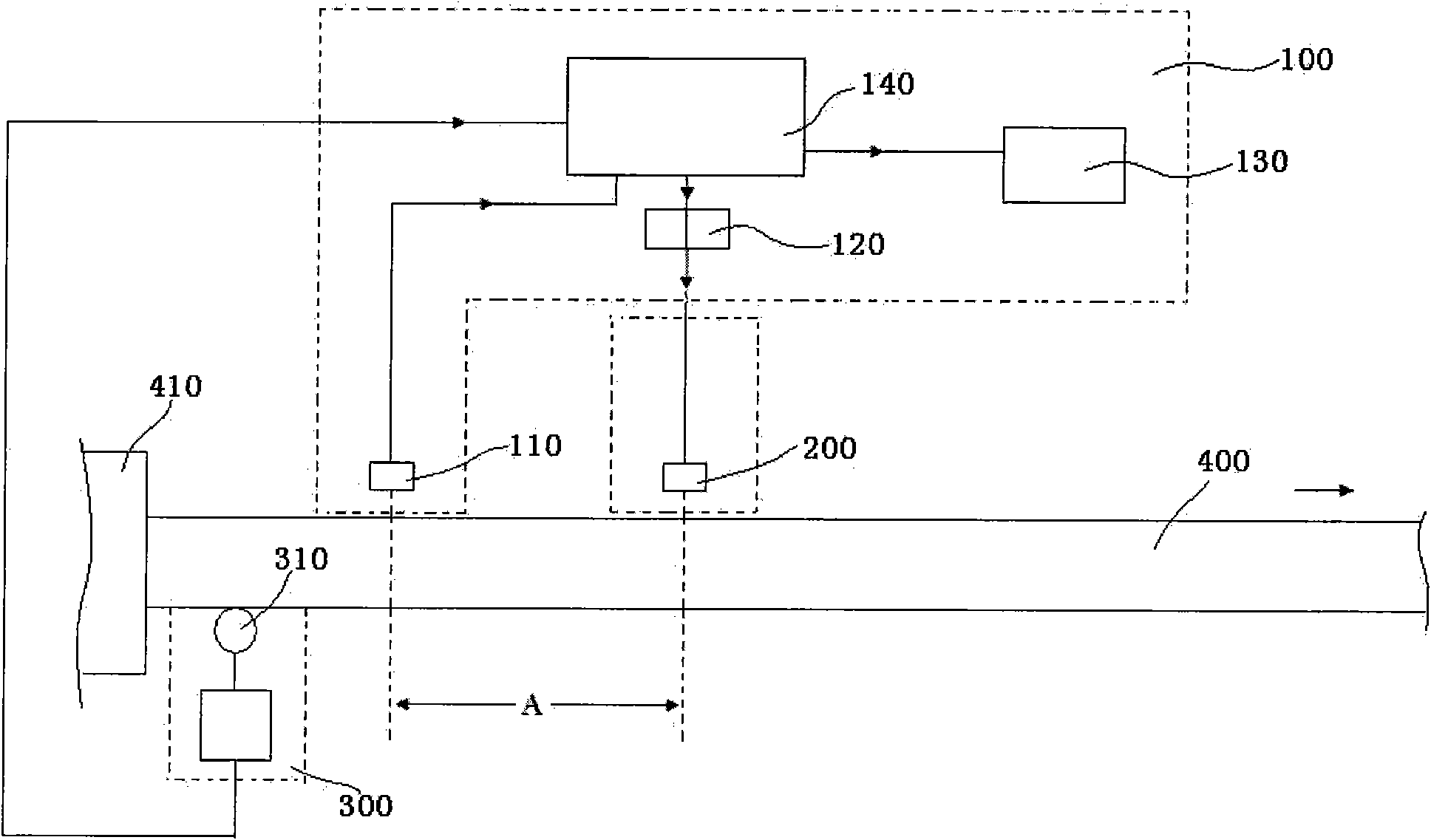

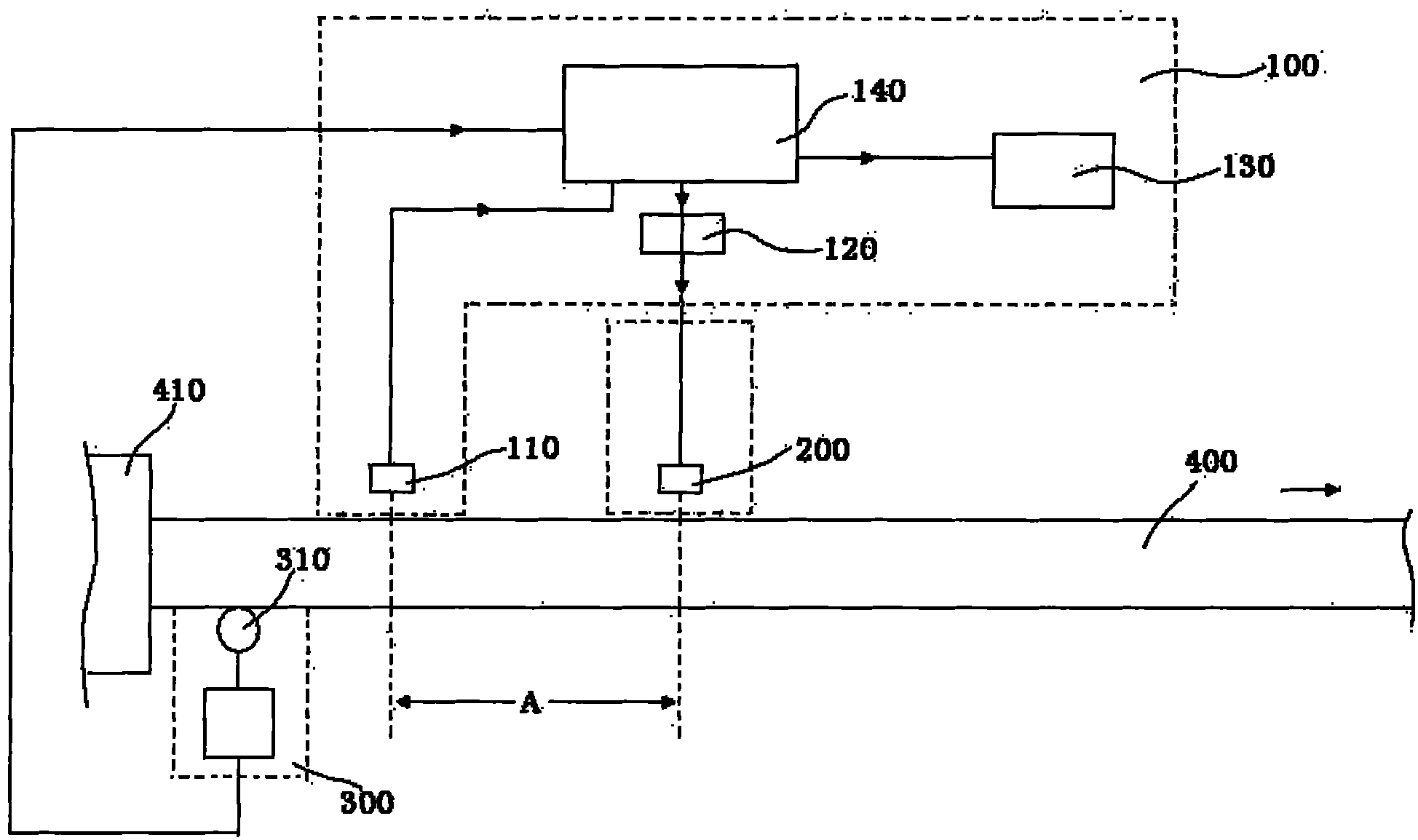

Online flaw detection process of pipeline forming and machining process

ActiveCN102371290BTimely detection of non-conformitiesReduce the number of generatedMetal working apparatusMaterial magnetic variablesEngineeringMachining process

The invention discloses an online flaw detection process of a pipeline forming and machining process, which comprises the following steps of: additionally arranging a high-temperature resisting flaw detection head of a through vortex flaw detector and a counting device behind a discharging port of forming and machining equipment, and spacing a distance A between the high-temperature resisting flaw detection head and the counting device; additionally arranging a drive device and an alarm device in the through vortex flaw detector, connecting the control end of a detection device with the drivedevice and the alarm device, connecting the drive device with the counting device, and connecting the high-temperature flaw detection head and a length measuring device with the detection device; passing a pipeline from the discharging port through the high-temperature resisting flaw detection head first, carrying out online detection by the high-temperature resisting flaw detection head, once flaw points are founded, conveying detection signals of the flaw points to the detection device in time through the high-temperature resisting flaw detection head, processing the detection signals by the detection device, calculating a pipeline forwarding distance according to a distance signal transmitted from the length measuring device, when the distance is equal to the spaced distance A, drivingthe counting device by the drive device to carry out counting on the flaw points, giving an alarm in time and notifying operation personnel for processing.

Owner:SHANGHAI LONGYANG PRECISE COMPOUND COPPER TUBE CO LTD

Online flaw detection process of pipeline forming and machining process

ActiveCN102371290ATimely detection of non-conformitiesReduce the number of generatedMetal working apparatusMaterial magnetic variablesEngineeringMachining process

The invention discloses an online flaw detection process of a pipeline forming and machining process, which comprises the following steps of: additionally arranging a high-temperature resisting flaw detection head of a through vortex flaw detector and a counting device behind a discharging port of forming and machining equipment, and spacing a distance A between the high-temperature resisting flaw detection head and the counting device; additionally arranging a drive device and an alarm device in the through vortex flaw detector, connecting the control end of a detection device with the drivedevice and the alarm device, connecting the drive device with the counting device, and connecting the high-temperature flaw detection head and a length measuring device with the detection device; passing a pipeline from the discharging port through the high-temperature resisting flaw detection head first, carrying out online detection by the high-temperature resisting flaw detection head, once flaw points are founded, conveying detection signals of the flaw points to the detection device in time through the high-temperature resisting flaw detection head, processing the detection signals by the detection device, calculating a pipeline forwarding distance according to a distance signal transmitted from the length measuring device, when the distance is equal to the spaced distance A, drivingthe counting device by the drive device to carry out counting on the flaw points, giving an alarm in time and notifying operation personnel for processing.

Owner:SHANGHAI LONGYANG PRECISE COMPOUND COPPER TUBE CO LTD

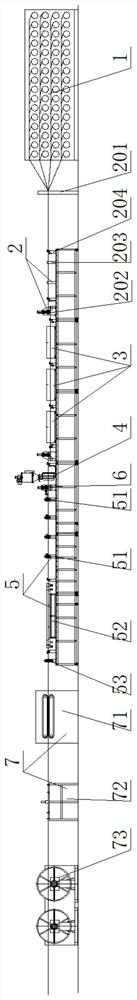

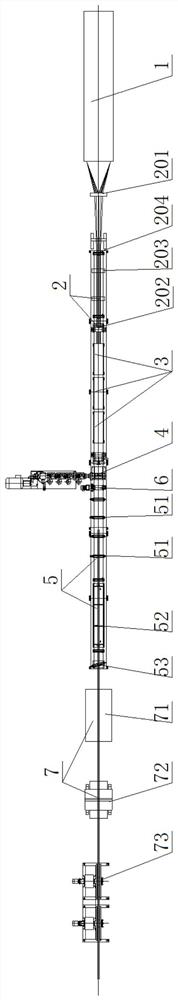

Reinforcing band production line, band manufacturing mold and reinforcing band production process

The invention discloses a reinforcing band production line. The reinforcing band production line comprises an unwinding frame, a wire sorting and carding assembly, a heating assembly, a band manufacturing mold, a shaping assembly, a cooling assembly and a collecting and arranging assembly, wherein the unwinding frame is used for unwinding a plurality of strands of reinforcing wires; the wire sorting and carding assembly is used for carrying out wire sorting treatment and wire carding treatment on the plurality of strands of unwound reinforcing wires according to strands; the heating assembly is used for heating the reinforcing wires subjected to wire carding treatment; the heated reinforcing wire can penetrate through a vacuum cavity and a composite cavity in sequence and is compounded with molten plastic in the composite cavity to form a strip-shaped reinforcing band; the shaping assembly allows the reinforcing band to penetrate through a position between two pressing rollers in the shaping assembly, the thickness of the reinforcing band is made to be equal to a distance between the two pressing rollers by adjusting the distance between the two pressing rollers, and therefore thereinforcing band is shaped; and the cooling assembly is used for cooling the reinforcing band. A band manufacturing mold and a reinforcing band production process are further provided. By means of thereinforcing band production line, the band manufacturing mold and the reinforcing band production process, the problem that bubbles exist in a reinforcing band is solved, and the combination compactness of plastic and reinforcing wires in the reinforcing band is enhanced.

Owner:SICHUAN GOLDSTONE-ORIENT NEW MATERIAL TECH CO LTD

Vacuum spraying treatment technology used for aluminum profile machining

InactiveCN111235530AImprove the firmness of the bondImprove dispersion uniformityVacuum evaporation coatingSputtering coatingThin metalMetal alloy

The invention discloses a vacuum spraying treatment technology used for aluminum profile machining and relates to the technical field of aluminum profile machining. The technology includes aluminum profile surface treatment, pre-spraying, pre-spraying layer heat treatment, continuous spraying and annealing treatment. By means of the vacuum spraying treatment technology used for aluminum profile machining, heat treatment is conducted on a thin metal coated layer generated on the surface of an aluminum profile, an aluminum and coated metal alloy layer is formed between the surface of the aluminum profile and a coated metal layer to serve as a transition layer, and the bonding firmness degree of aluminum and coated metal is improved; in the alloy layer generation process, ultrasonic waves areused for blowing a molten liquid aluminum layer and liquid coated metal atoms, mutual merging between the liquid aluminum layer and the coated metal atoms is promoted, and the dispersing uniformity of alloy particles is better improved; and due to heating, ultrasonic treatment and two-stage annealing in the subsequent continuous spraying process, the coated metal dispersing uniformity is better improved, the generation number of air holes and cracks is reduced, and the bonding firmness degree of the coated layer and the aluminum profile is further improved.

Owner:董翠萍

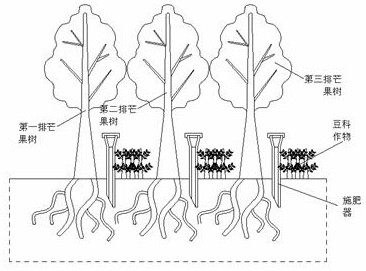

Multiple cropping mode for improving benefits of lychee orchard in South China and ecologically restoring soil

InactiveCN113099937AImprove fertilizer use efficiencyImprove cold and frost resistance and flower and fruit setting rateFabaceae cultivationCultivating equipmentsFertilizerOrchard

The invention discloses a multiple cropping mode for improving benefits of a lychee orchard in the south China and ecologically restoring soil. The crop intercropping mode of Feizixiao lychee and leguminous crops comprise the following steps: carrying out farrowing in a middle passage, filling fallen leaves, spraying cold-proof and anti-freezing agricultural input products, applying liquid fertilizer, spraying a biological decomposition agent and planting leguminous crops. The crop intercropping mode of the Feizixiao lychee and the leguminous crops mainly comprises the steps of carrying out furrowing in the lychee passage, filling fallen leaves, spraying the decomposition agent and planting the leguminous crops. According to the multiple cropping mode of the Feizixiao lychee and the leguminous crops, the utilization rate is increased by applying the liquid fertilizer; the biological decomposition agent is sprayed to accelerate decomposition of fallen leaves; and the cold-proof and anti-freezing agricultural input products are sprayed to improve the low-temperature resistance and the flower and fruit setting rate of the litchis, land-nourishing crops, leguminous crops, litchis fallen leaves and straw returning are planted to jointly supplement a biological carbon source and a nitrogen source for soil so as to restore the soil fertility, and synchronous improvement of the yield and the quality of the lychee and sustainable utilization of cultivated land in the lychee orchard are achieved.

Owner:GUANGDONG OCEAN UNIVERSITY

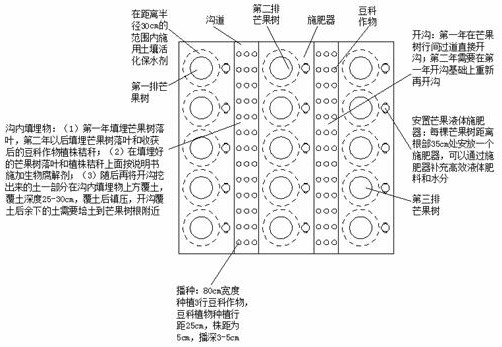

Multiple cropping mode for improving drought resistance of mangoes in Leizhou region and restoring orchard soil fertility

InactiveCN113099936AImprove fertilizer use efficiencyRestore soil fertilityFabaceae cultivationCultivating equipmentsFertilizerDrought resistance

The invention discloses a technical mode for improving the drought resistance of mangoes in the Leizhou region and restoring the orchord soil fertility. The multiple cropping mode of mangoes and leguminous crops comprises the following steps: carrying out farrowing in a passage between mango rows, filling farrows with litchis fallen leaves, applying a liquid fertilizer, spraying a biological decomposition agent, planting the leguminous crops and applying a soil activation water-retaining agent. The technical mode mainly comprises the steps of carrying out furrowing in the middle passage of two rows of mangoes and planting the leguminous crops. According to the technical mode for improving the drought resistance of the mangoes in the Leizhou region and restoring the orchard soil fertility, the fertilizer utilization rate is increased by applying efficient liquid fertilizer; the decomposition of fallen leaves is accelerated by spraying the biological decomposition agent; a biological carbon source and a nitrogen source are jointly supplemented for soil by planting land-nourishing leguminous crops, so that the orchard soil fertility is restored; and by applying the soil activation water-retaining agent, the drought resistance of the mangoes in winter and spring is improved, finally, the yield and quality of the mangoes are improved, sustainable utilization of mango orchard cultivated land is achieved, and social benefits, economic benefits and ecological benefits are synchronously improved.

Owner:GUANGDONG OCEAN UNIVERSITY

Defluorination flocculant for filtering out fluorine ions in frosting waste liquid, and use method thereof

PendingCN111732176AAchieve emission standardsReduce the number of generatedWater contaminantsWater/sewage treatmentChemistryChloride sodium

The invention discloses a defluorination flocculant for filtering out fluorine ions in a frosting waste liquid. The defluorination flocculant is prepared from, by mass, 32-40% of sodium chloride, 20-30%of calcium chloride, 36.8-39.8%of alum and 0.2% of polyaluminum chloride. The invention also discloses a use method of the defluorination flocculant for filtering out fluorine ions in the frosting waste liquid. The use method comprises the following steps: (1) proportionally preparing sodium chloride, calcium chloride, alum and polyaluminum chloride, mixing, and crushing to 200 meshes or less toobtain the defluorination flocculant; (2) adding the defluorination flocculant in step (1) into the frosting waste liquid; and (3) naturally flocculating and settling the frosting waste liquid for 2-3 hours, concentrating sludge, and finally discharging residues through a filter press. The method has the advantages of being simple, small in adding amount, convenient to treat, high in fluoride removal rate, small in waste residue amount, low in cost and the like.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

Method for reducing freezing damages of blueberry fruits

ActiveCN108684811AEasy to prepareReduce frostbiteFruits/vegetable preservation by irradiation/electric treatmentNatural extract food ingredientsHorticultureFruits and vegetables

The present invention belongs to the technical field of fruit and vegetable preservation, and specifically discloses a method for reducing freezing damages of blueberry fruits. The method comprises the following steps: blueberry fruit preferably selecting, ultraviolet ray treating, mixed solution soaking, preservation liquid treating, sealing, vacuum freezing, etc. The method combines the preservation liquid treating and vacuum freezing to carry out the preservation treatment, can effectively reduce the freezing damages of the blueberry fruits, prolongs the preservation time of the blueberry fruits, maintains the sensory quality of the blueberry fruits, and has a good market prospect.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Method for propagating sulzer braconid flies

ActiveCN101664017BIncreased proline contentLess nicotine accumulationHorticultureAnimal husbandryNicotiana tabacumPropagation time

The invention discloses a method for propagating sulzer braconid flies. The method comprises the following steps: firstly, culturing a host plant of tobaccos, then propagating sulzers and afterwards propagating the sulzer braconid flies by the sulzers. By propagating the flies in batches, the multi-generation repeated propagation of the sulzer braconid flies is avoided, the generation quantity ofthe hyperparasite flies of the sulzer braconid flies is reduced, and the survival capability of the sulzer braconid flies in the field is enhanced. The propagation time and quantity of the sulzer braconid flies can be flexibly regulated and controlled according to the actual condition of the field, and different requirements on the sulzer braconid flies under different situations are met. The emergence rate of the stiff aphids of the sulzer braconid flies propagated by the invention is more than 90%, the male-female ratio is 0.8-1.0:1, and the utilization rate of the stiff aphids or the adultflies is more than 80%.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

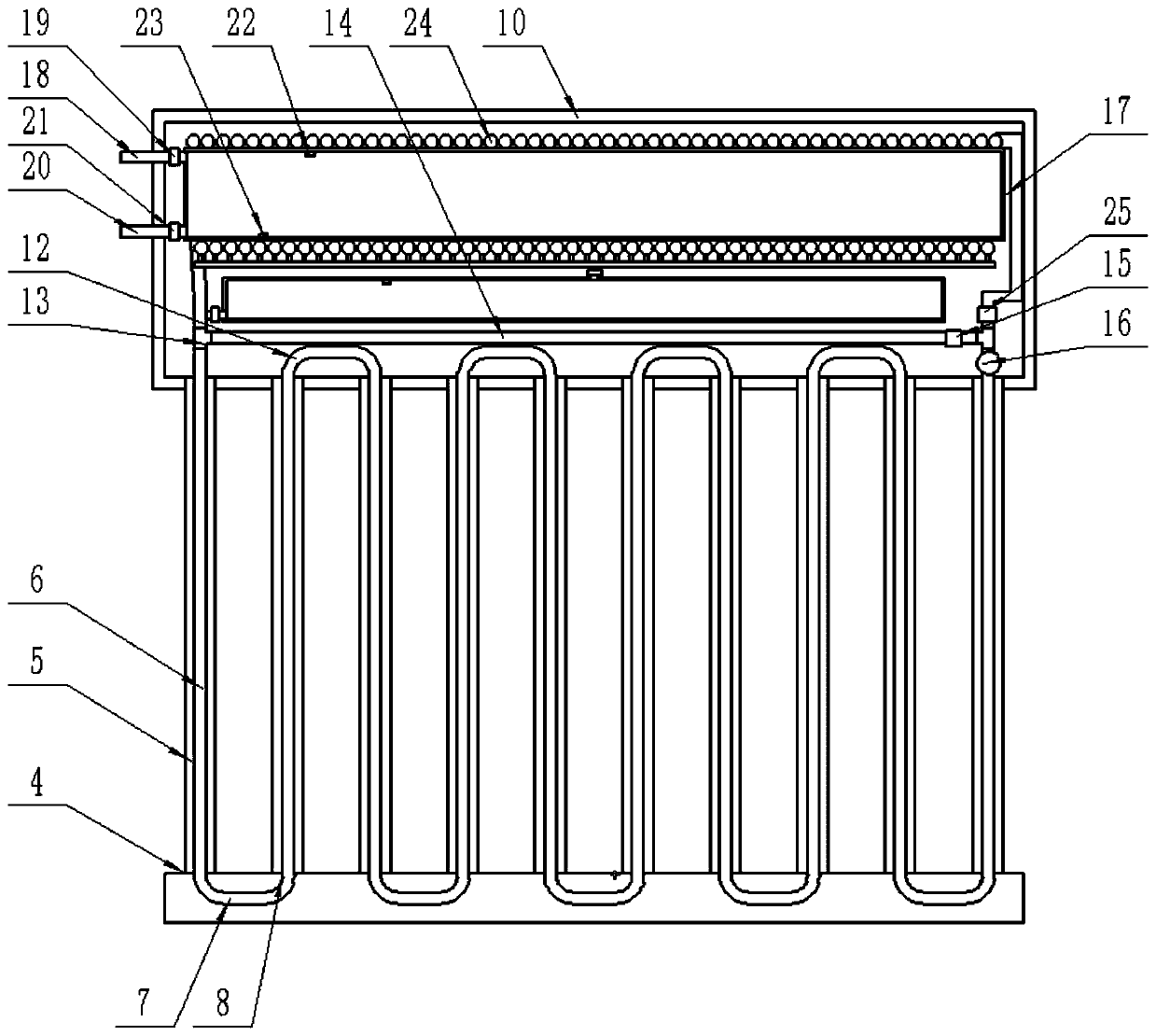

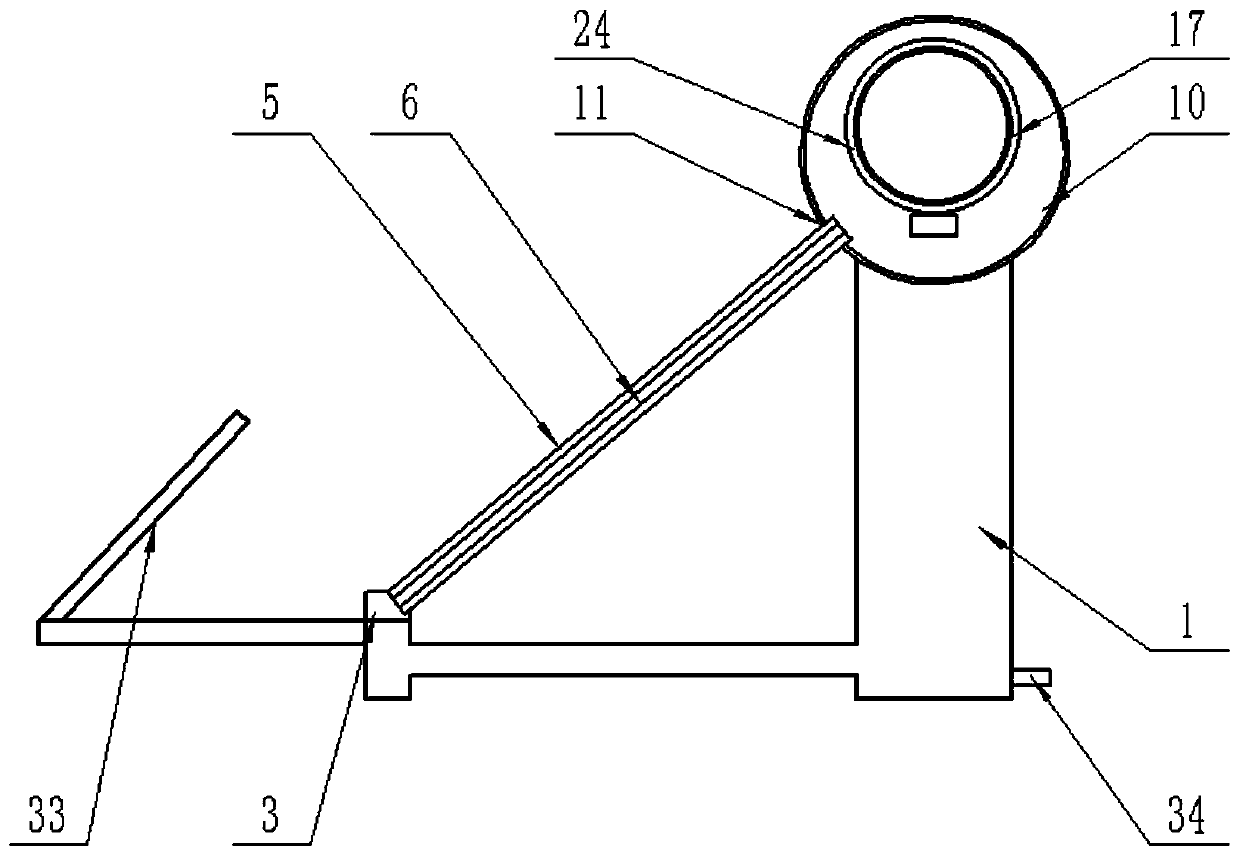

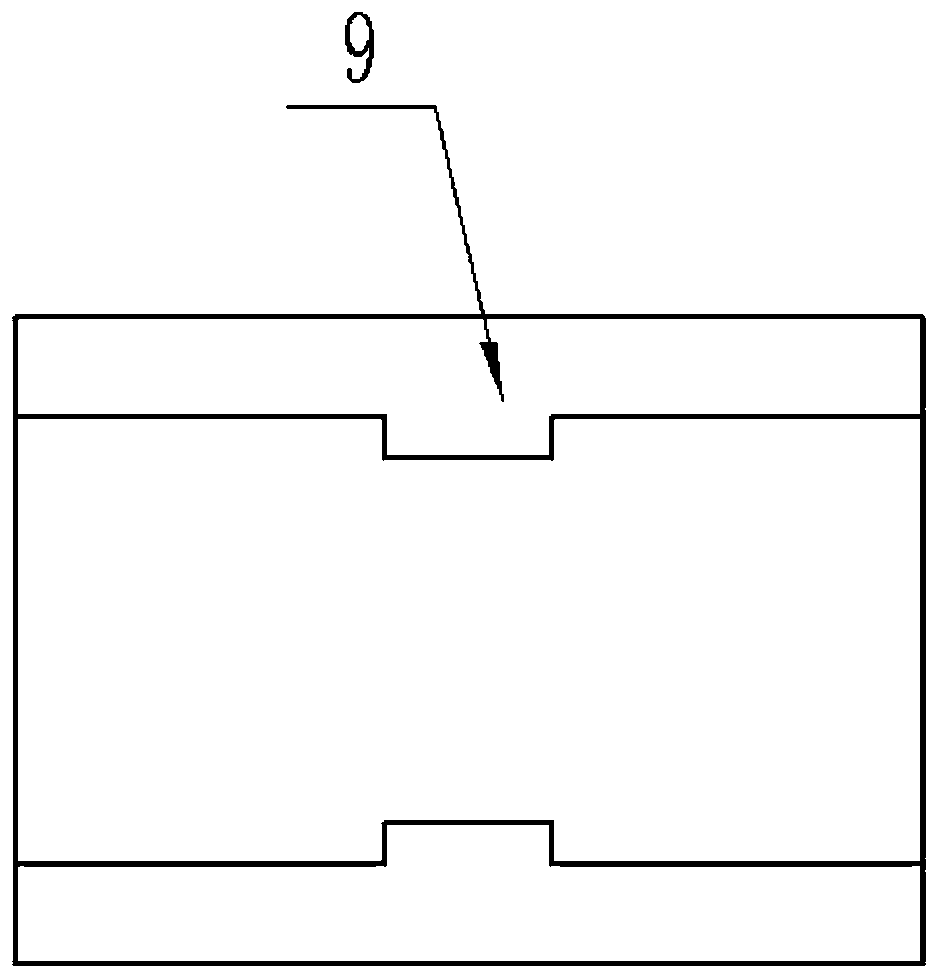

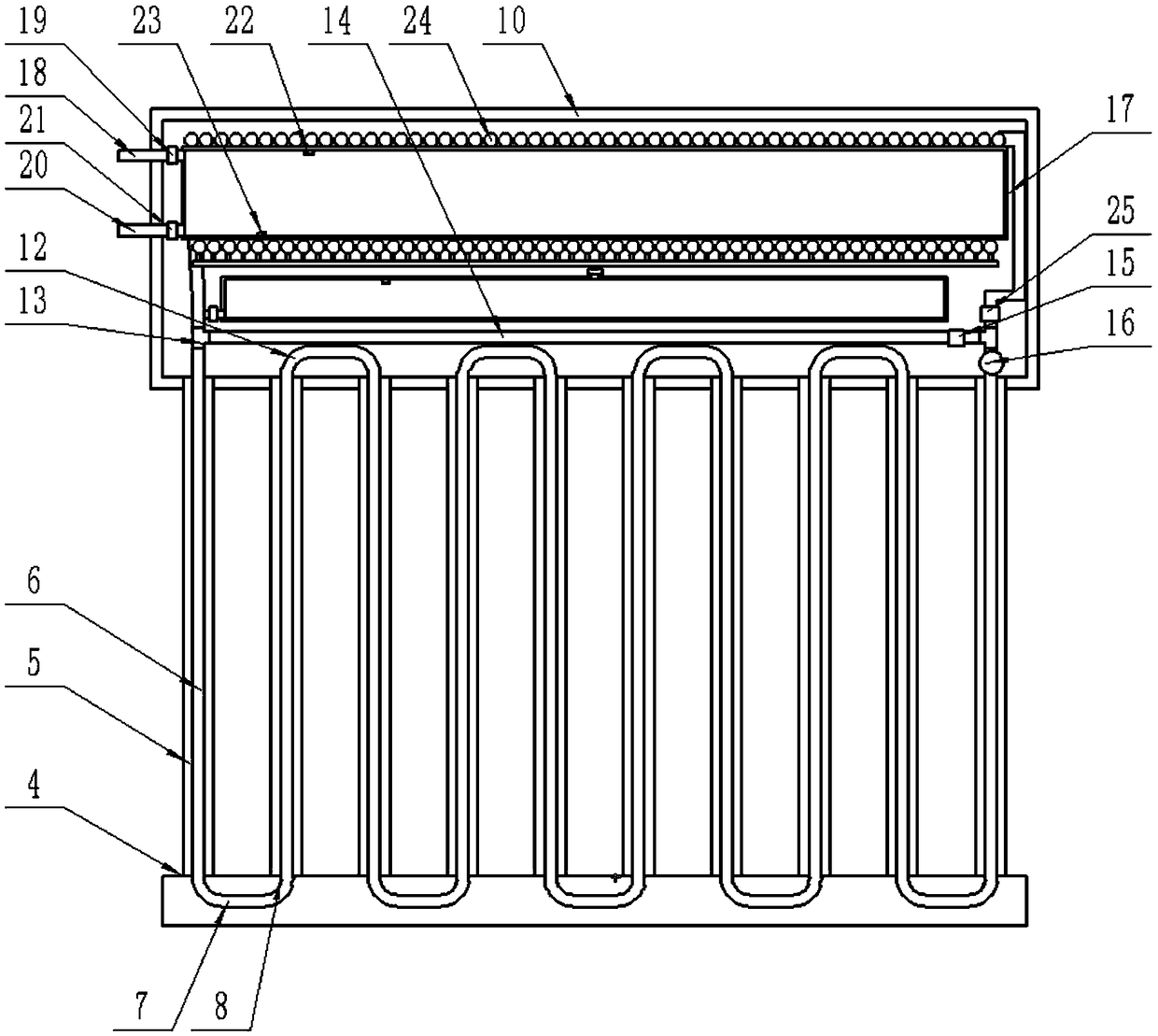

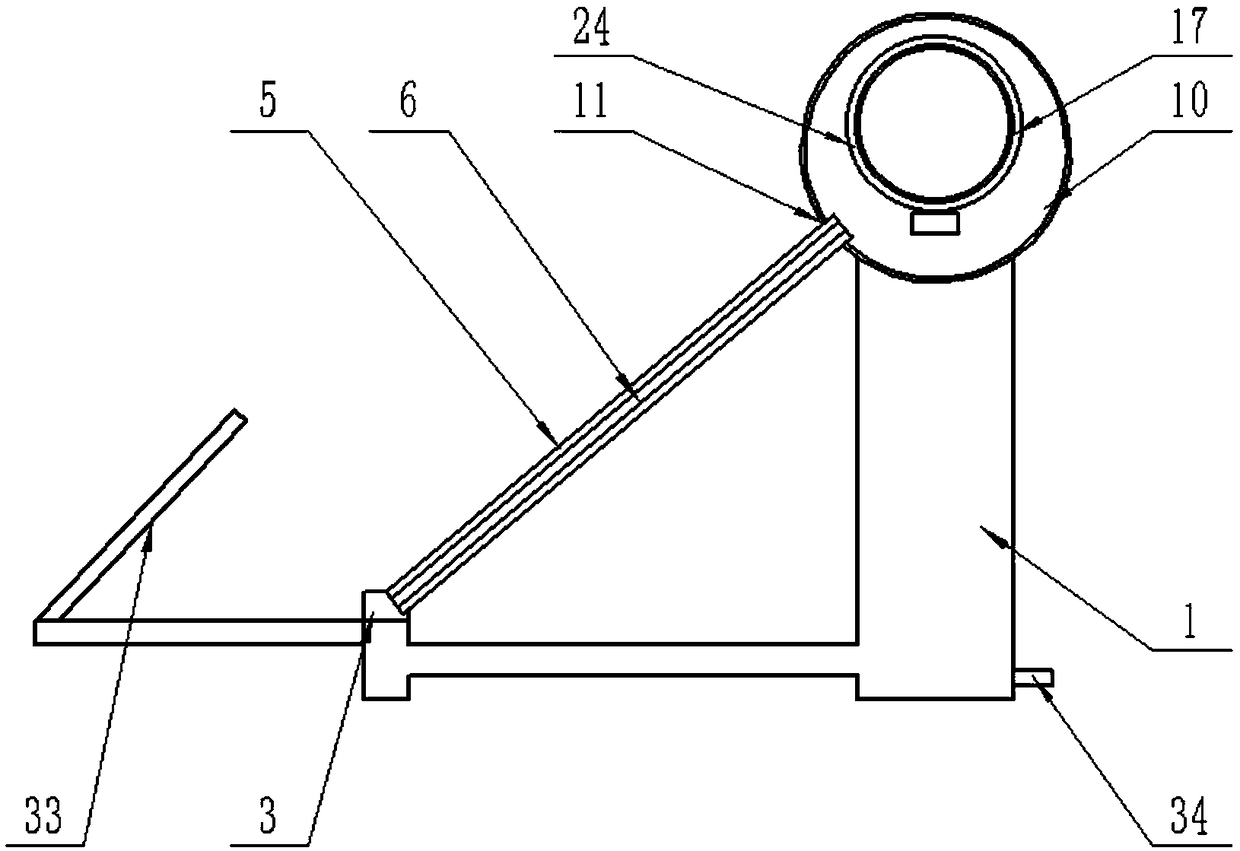

A solar water heater

ActiveCN108981192BReduce cleaning timesGuaranteed temperature balanceSolar heating energySolar heat collector controllersEngineeringSolar energy

The invention discloses a solar water heater. The solar water heater comprises a solar water heater support, the solar water heater support is fixedly installed outdoors, a solar automatic heating device is installed on the solar water heater support, an automatic temperature-setting heating device is arranged in the solar automatic heating device, and a controller is arranged outside the solar water heater support; and a signal receiving end of the controller is electrically connected with a water level sensor and a temperature sensor, and a control signal output end of the controller is electrically connected with a micro circulating pump, a circulating electromagnetic valve, a water inlet electromagnetic valve, a water outlet electromagnetic valve, a clearing electromagnetic valve, a heating electromagnetic valve and a backflow electromagnetic valve. The solar water heater has the beneficial effects of being simple in structure and high in practicability.

Owner:临沂兴创达知识产权运营有限公司

Solar water heater

ActiveCN108981192AReduce cleaning timesGuaranteed temperature balanceSolar heating energySolar heat collector controllersControl signalSolar water

The invention discloses a solar water heater. The solar water heater comprises a solar water heater support, the solar water heater support is fixedly installed outdoors, a solar automatic heating device is installed on the solar water heater support, an automatic temperature-setting heating device is arranged in the solar automatic heating device, and a controller is arranged outside the solar water heater support; and a signal receiving end of the controller is electrically connected with a water level sensor and a temperature sensor, and a control signal output end of the controller is electrically connected with a micro circulating pump, a circulating electromagnetic valve, a water inlet electromagnetic valve, a water outlet electromagnetic valve, a clearing electromagnetic valve, a heating electromagnetic valve and a backflow electromagnetic valve. The solar water heater has the beneficial effects of being simple in structure and high in practicability.

Owner:临沂兴创达知识产权运营有限公司

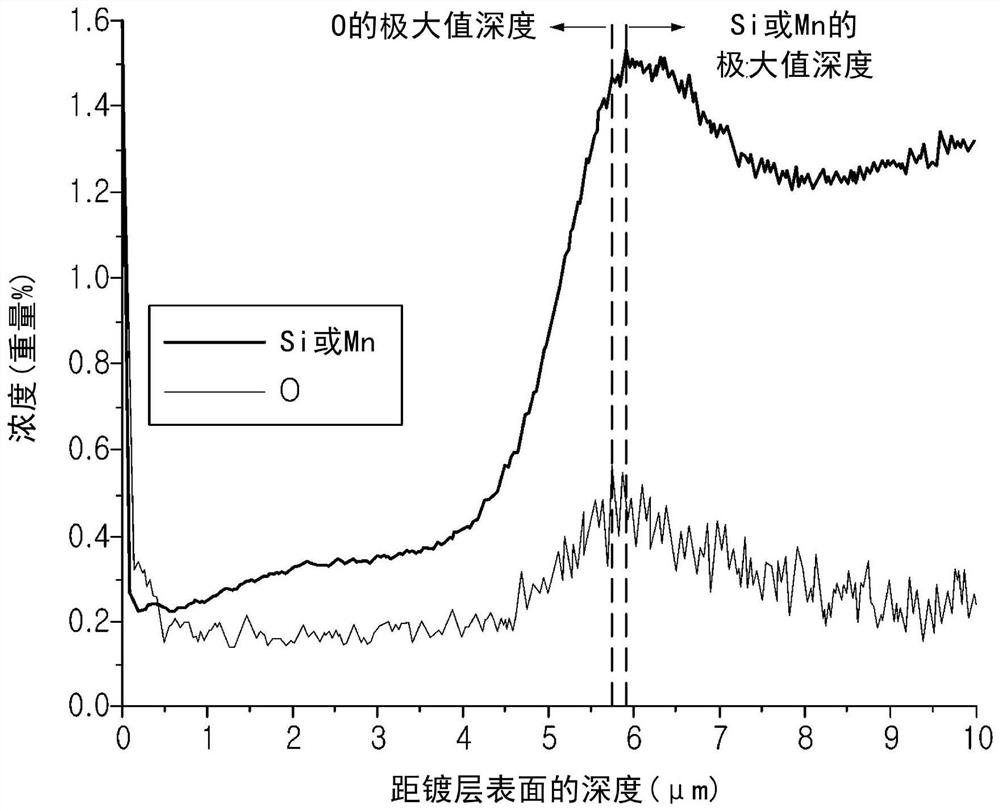

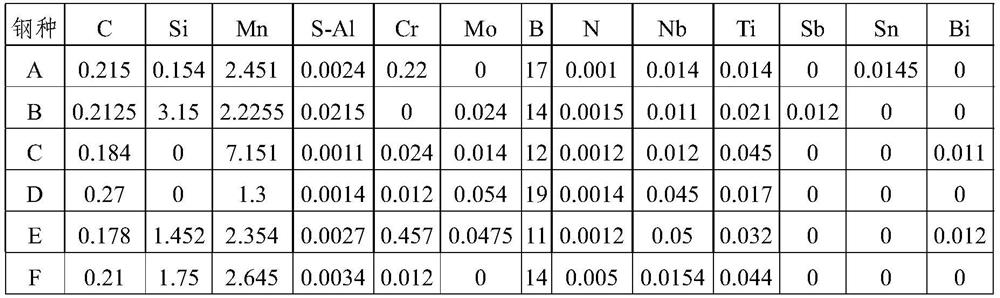

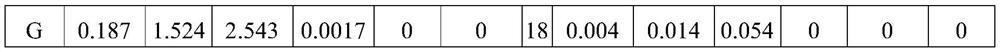

Galvanized steel sheet having excellent fatigue strength in resistance spot welding portion, and method for manufacturing same

PendingCN114746571ARelieve tensile stressReduce generation quantity and lengthHot-dipping/immersion processesFurnace typesSteel platesZinc

Owner:POSCO

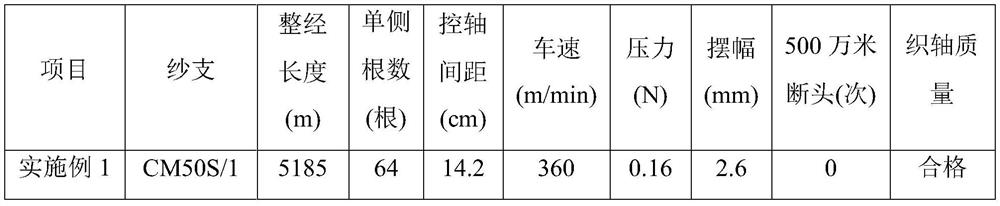

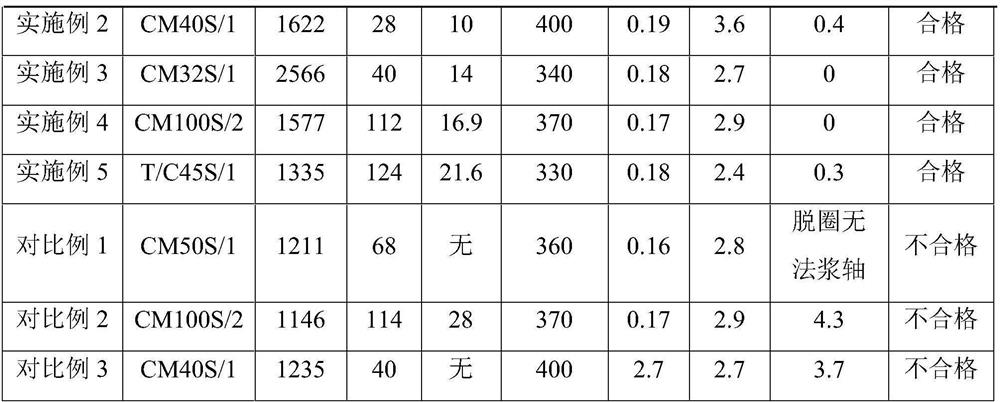

Yarn-dyed fabric edge yarn warping method

PendingCN113279100AReduce the use of normal raw yarnReduce the number of stainsWarping machinesOther manufacturing equipments/toolsYarnStructural engineering

The invention relates to the technical field of yarn warping, in particular to a yarn-dyed fabric edge yarn warping method. The yarn-dyed fabric edge yarn warping method comprises the steps that defective yarn or secondary recycled yarn is spun into tight warp yarn, the tight warp yarn and grey yarn share the same vertical center line, warping is carried out, a batch warping machine is adopted as a warping machine, two distance control shaft discs are additionally arranged in a warp beam, the distance control shaft discs are 9-25 cm away from a warp beam fixing shaft disc, and the number of single-side warping is 28-150. According to the yarn-dyed fabric edge yarn warping method, workshop defective yarn or secondary recovery yarn is adopted to be spun into tight warp yarn, then the tight warp yarn and grey yarn are subjected to warping, normal grey yarn use is reduced, grey yarn is saved by 1-2%, the yarn dyeing number is reduced, the dyeing cost is saved, and meanwhile, the waste yarn generation number is reduced.

Owner:LUTAI TEXTILE

A method for reducing freezing damage of blueberries

ActiveCN108684811BEasy to prepareReduce frostbiteFruits/vegetable preservation by irradiation/electric treatmentNatural extract food ingredientsFreeze injuryBerry

The invention belongs to the technical field of fresh-keeping of fruits and vegetables, and specifically discloses a method for reducing freezing damage of blueberries. The method of the invention comprises the following steps: selecting blueberry fruit, ultraviolet treatment, soaking in mixed solution, treatment with fresh-keeping solution, sealing, vacuum freezing and the like. The method of the invention combines fresh-keeping liquid treatment and vacuum freezing to carry out fresh-keeping treatment, can effectively reduce freezing damage of blueberries, prolong the fresh-keeping time of blueberries, maintain the sensory quality of blueberries, and has good market prospects.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com