Machining method for utilizing radial forging machine for producing multi-step cold-rolled work roller blank

A technology of cold-rolled work rolls and processing methods, which is applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., and can solve the problems of high manufacturing costs, reduced profit margins, and increased forging surplus blocks. Achieve high production efficiency, improved yield, and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

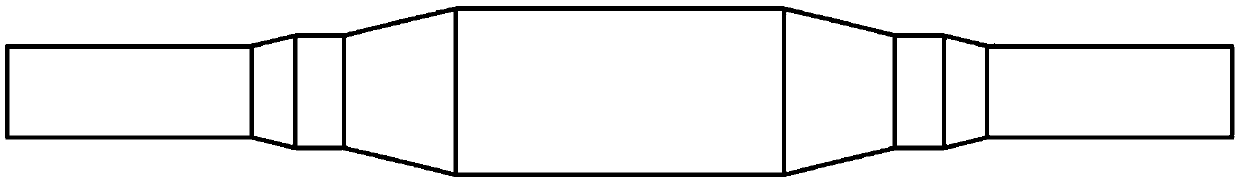

Image

Examples

specific Embodiment approach 1

[0031] A processing method for producing a multi-step cold-rolled work roll billet by using a radial forging machine, comprising the following steps:

[0032] Step a, pouring the molten steel after electric furnace smelting, LF furnace refining, and VD vacuum treatment into MC6B multi-step cold-rolled work roll billet electrode ingot;

[0033] Step b. The MC6B multi-step cold-rolled work roll billet electrode ingot prepared in step a is subjected to fire cutting, annealing, surface shot blasting, gas baking, and electroslag remelting to obtain MC6B multi-step cold-rolled work roll billet electroslag ingot ;

[0034] Step c, the MC6B multi-step cold-rolled work roll billet electroslag ingot prepared in step b is annealed, the surface is cleaned, and the gas furnace heating and holding time is ≧24h, and the MC6B multi-step cold-rolled work roll billet steel ingot is obtained for use;

[0035] Step d, the MC6B multi-step cold-rolled work roll billet steel ingot obtained in step ...

specific Embodiment approach 2

[0053] A processing method for producing a multi-step cold-rolled work roll billet by using a radial forging machine, comprising the following steps:

[0054] Step a, pouring the molten steel after electric furnace smelting, LF furnace refining, and VD vacuum treatment into MC6B multi-step cold-rolled work roll billet electrode ingot;

[0055] Step b. The MC6B multi-step cold-rolled work roll billet electrode ingot prepared in step a is subjected to fire cutting, annealing, surface shot blasting, gas baking, and electroslag remelting to obtain MC6B multi-step cold-rolled work roll billet electroslag ingot ;

[0056] Step c, the MC6B multi-step cold-rolled work roll billet electroslag ingot prepared in step b is annealed, the surface is cleaned, and the gas furnace heating and holding time is ≧24h to prepare the MC6B multi-step cold-rolled work roll billet steel ingot for use;

[0057]Step d, the MC6B multi-step cold-rolled work roll billet steel ingot obtained in step c is su...

specific Embodiment approach 3

[0061] According to a processing method for producing multi-step cold-rolled work roll blanks with a radial forging machine described in the second specific embodiment, the electric furnace smelting in step a is that the proportion of molten iron or pig iron in each furnace is 30-32%, and the tapping temperature is 1640-300%. At 1700°C, carbon increase is completed in the tapping process, and alloy and slag are poured in when the tapping amount reaches 15-30 tons; in step a, LF furnace refining adds aluminum wire at 2-4m / t, and the amount of aluminum beans and carbon powder The dosage of the mixture is 1-1.5kg / t, and the white slag refining time is 20-25 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com