Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152 results about "Bleach activator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

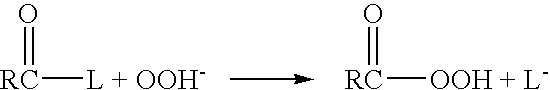

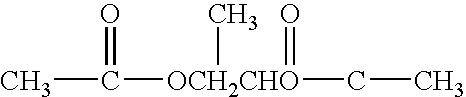

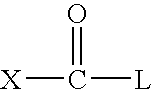

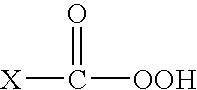

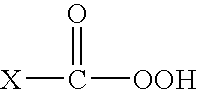

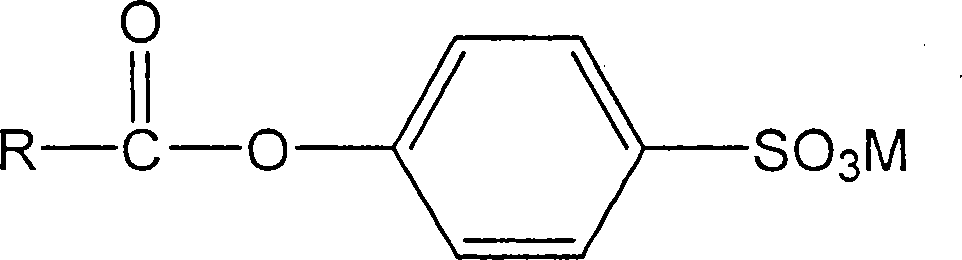

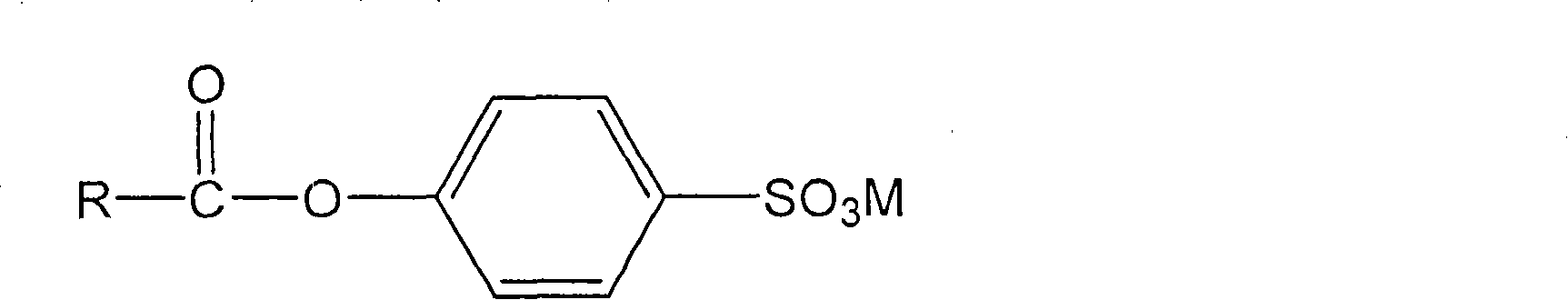

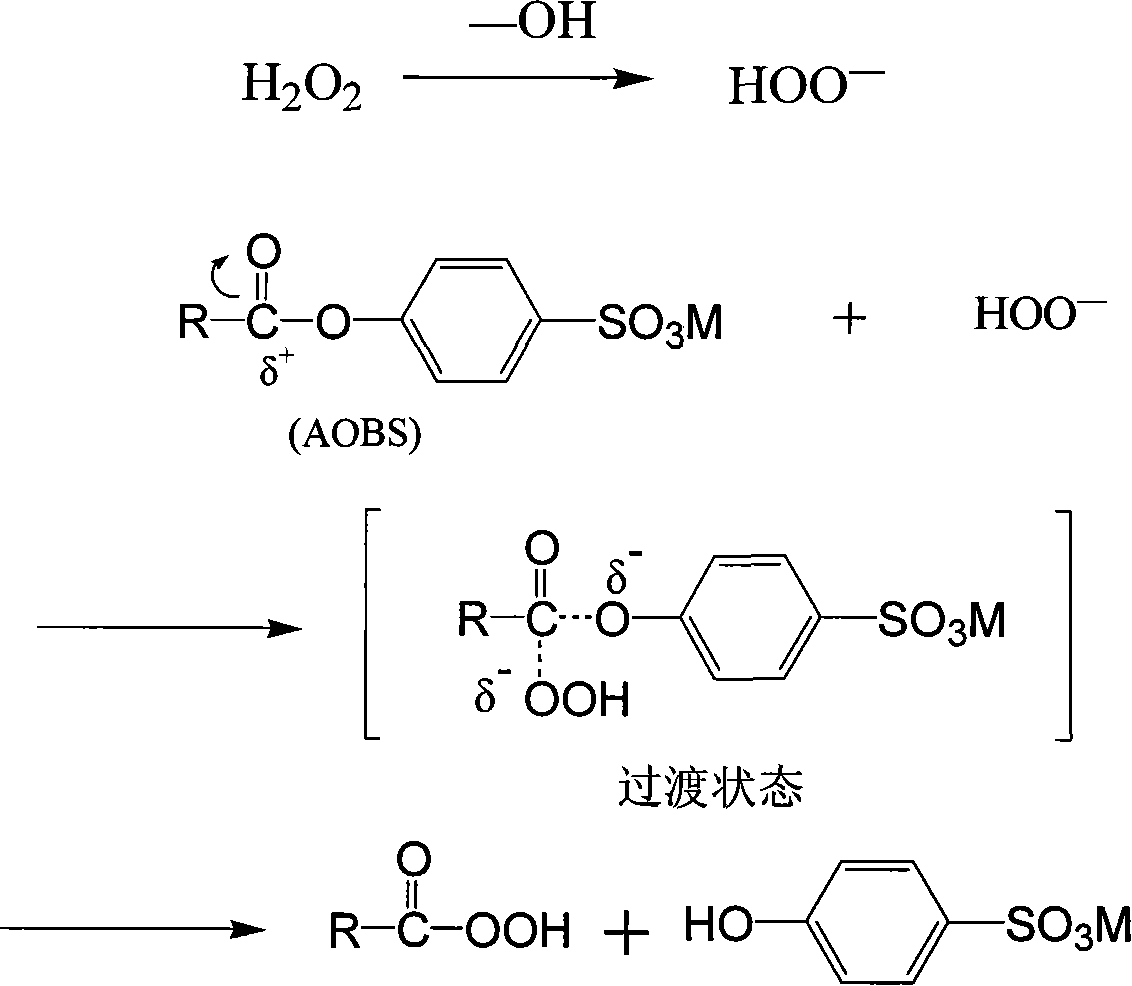

Bleach activators are compounds that allow a lower washing temperature than would be required otherwise to achieve the full activity of bleaching agents in the wash liquor. Bleaching agents, usually peroxides, are usually sufficiently active only from 60 °C on. With bleach activators, this activity can already be achieved at lower temperatures. Bleach activators react with hydrogen peroxide in aqueous solution to form peroxy acids, they are a component of most laundry detergents. Peroxy acids are more active bleaches than hydrogen peroxide at lower temperatures (<60 °C) but are too unstable to be stored in their active form and hence must be generated in situ.

Laundry multi-compartment pouch composition

InactiveUS20090011970A1Improve bleaching effectEasy to useDetergent materialsDetergent compounding agentsSolid componentWater soluble

This invention relates to a laundry pouch made from a water-soluble film and having at least two compartments, containing a solid component and a liquid component, wherein the solid phase contains a peroxide source and the liquid phase contains bleach activator. The present invention also relates to a method for treating laundry by placing the pouch, according to the present invention, in the drum of the washing machine.

Owner:THE PROCTER & GAMBLE COMPANY

Decontamination formulations for disinfection and sterilization

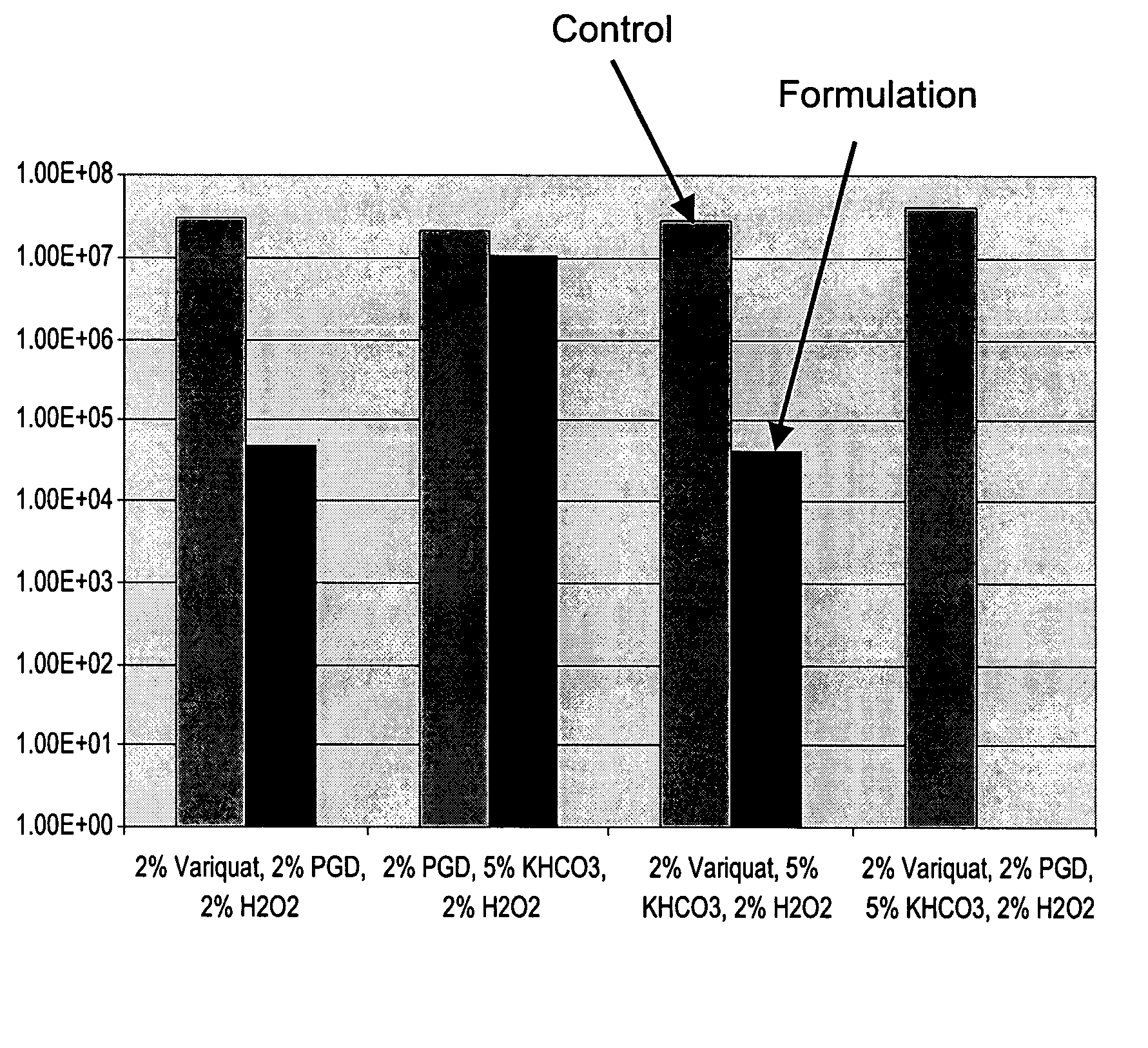

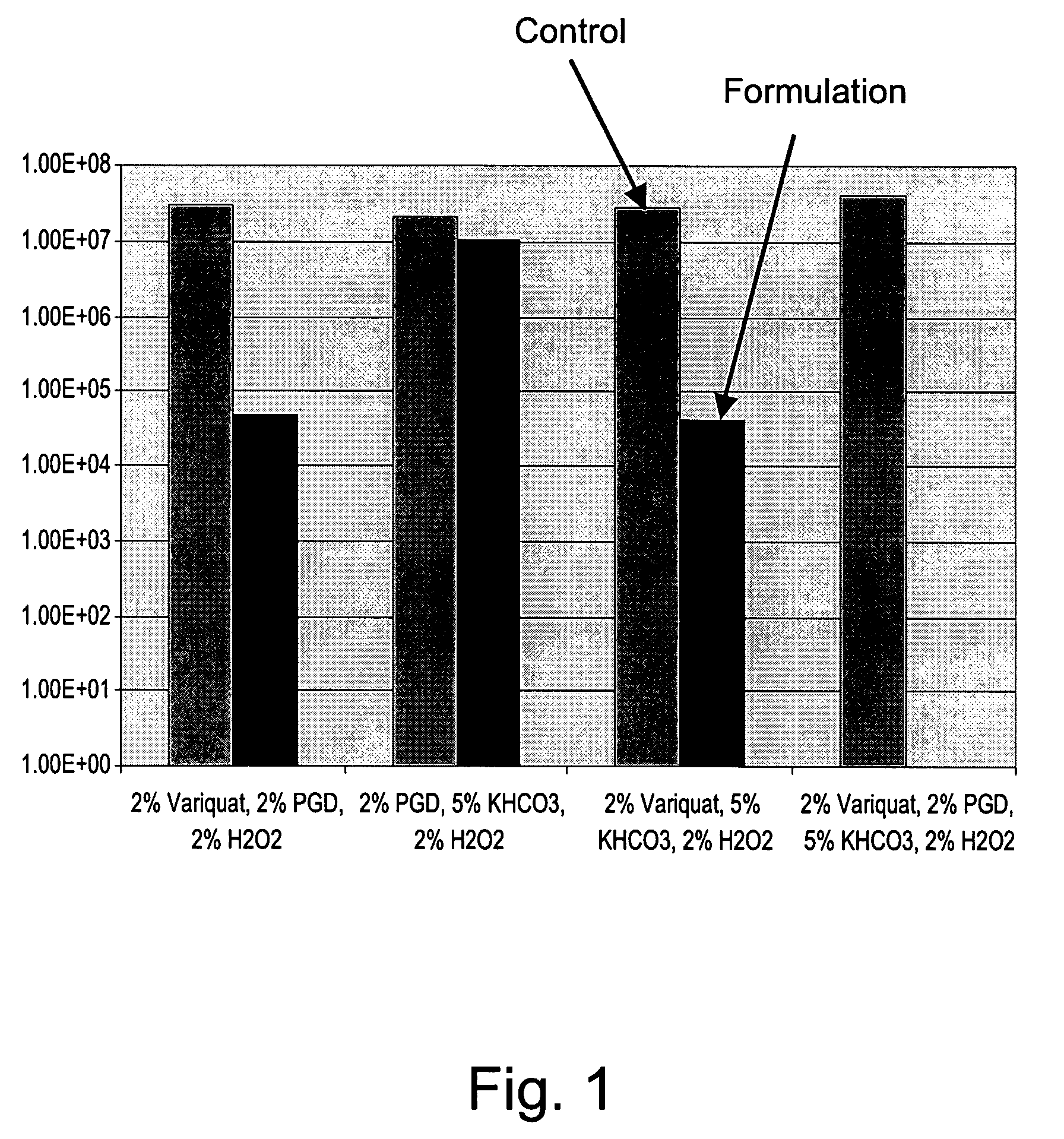

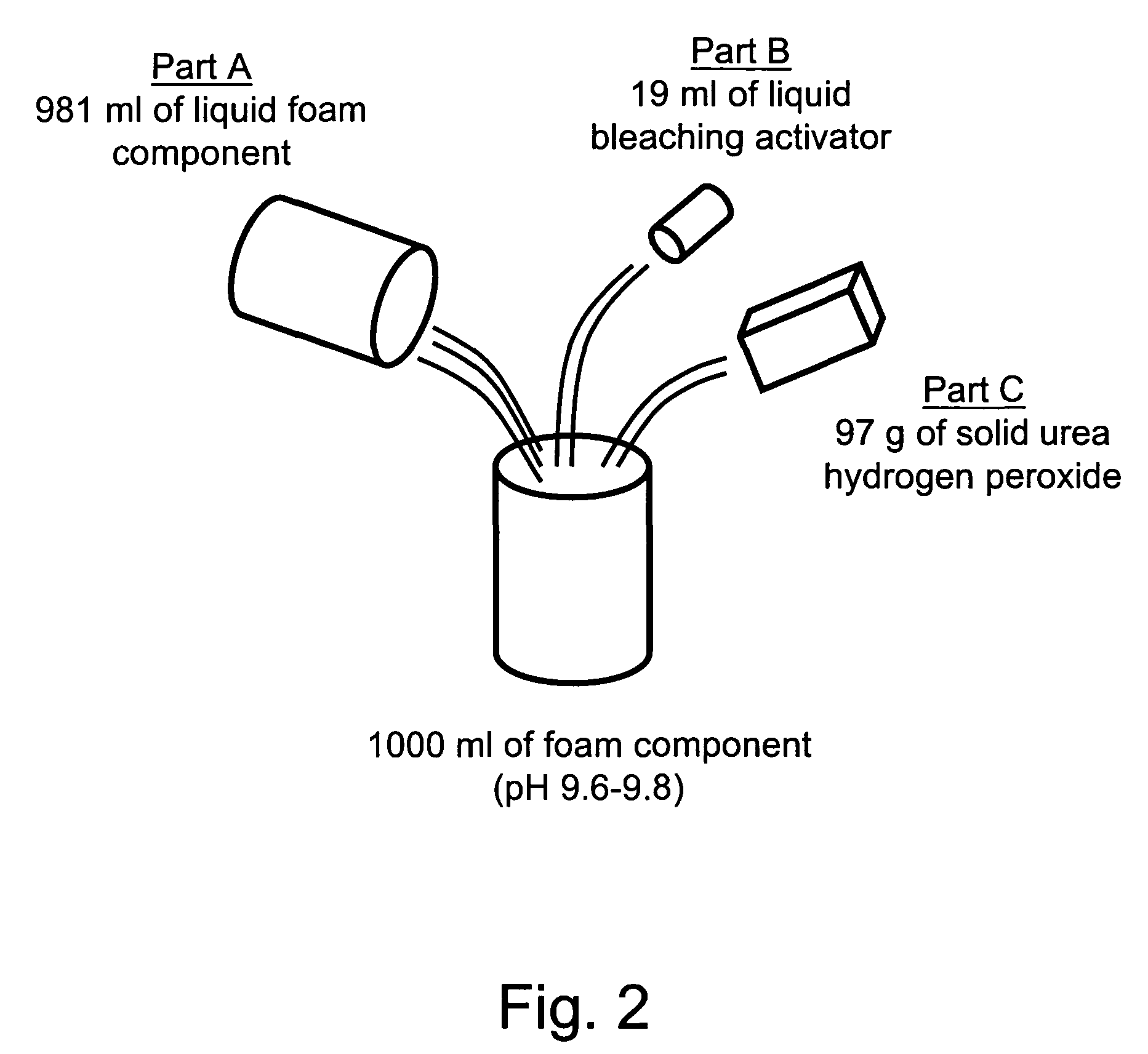

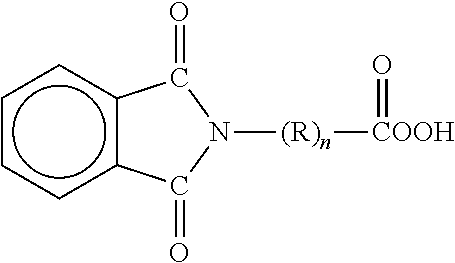

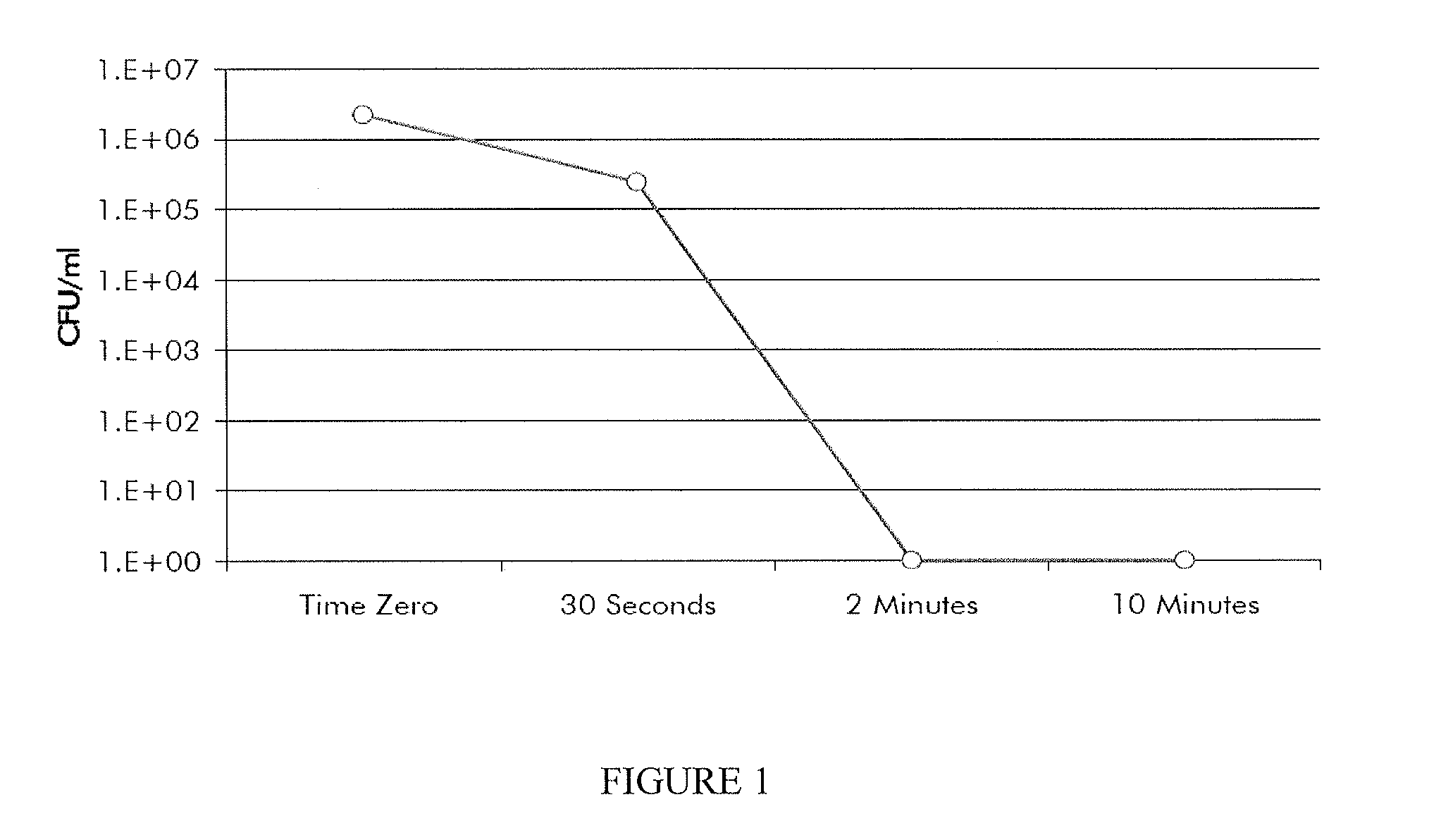

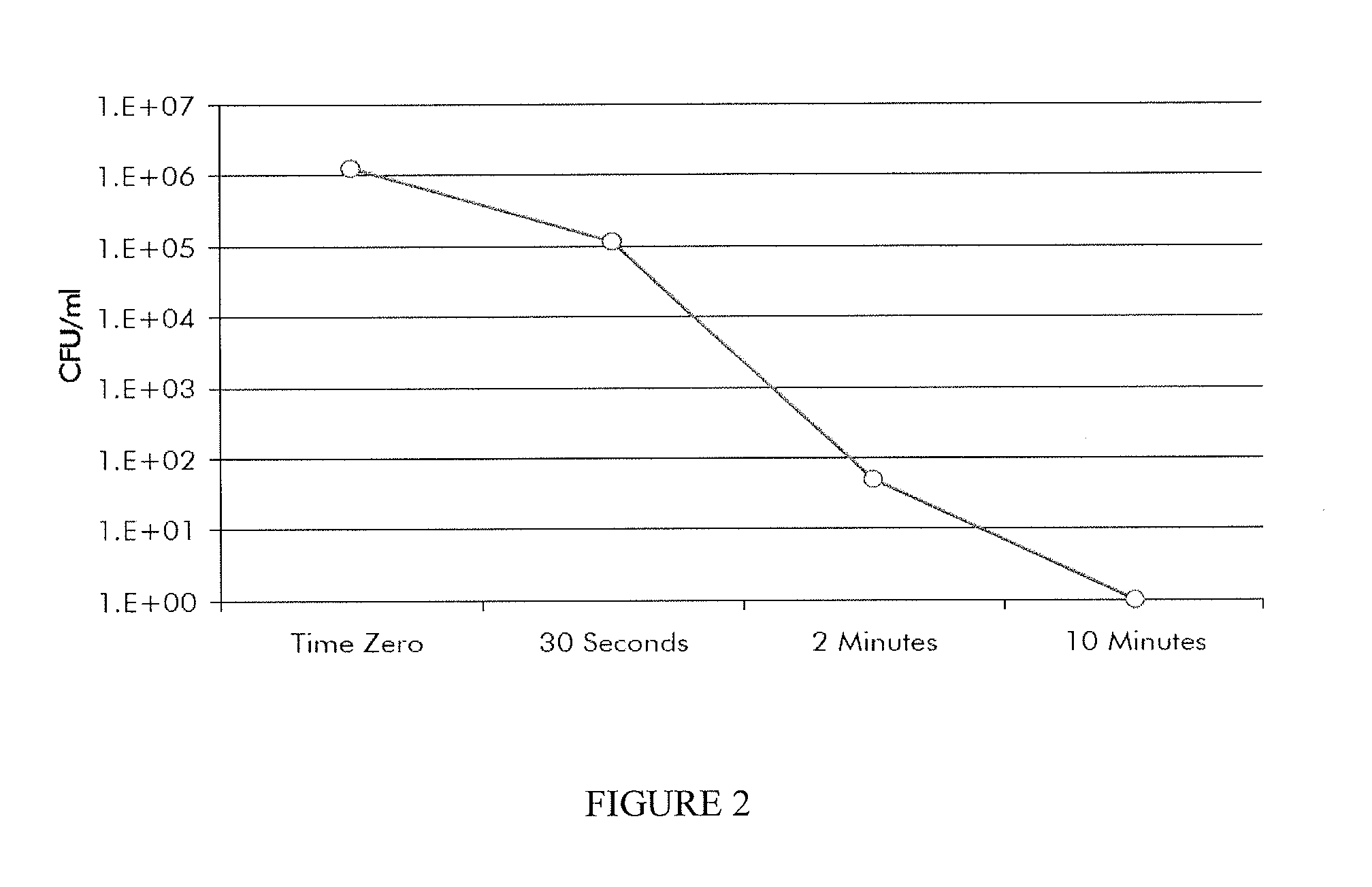

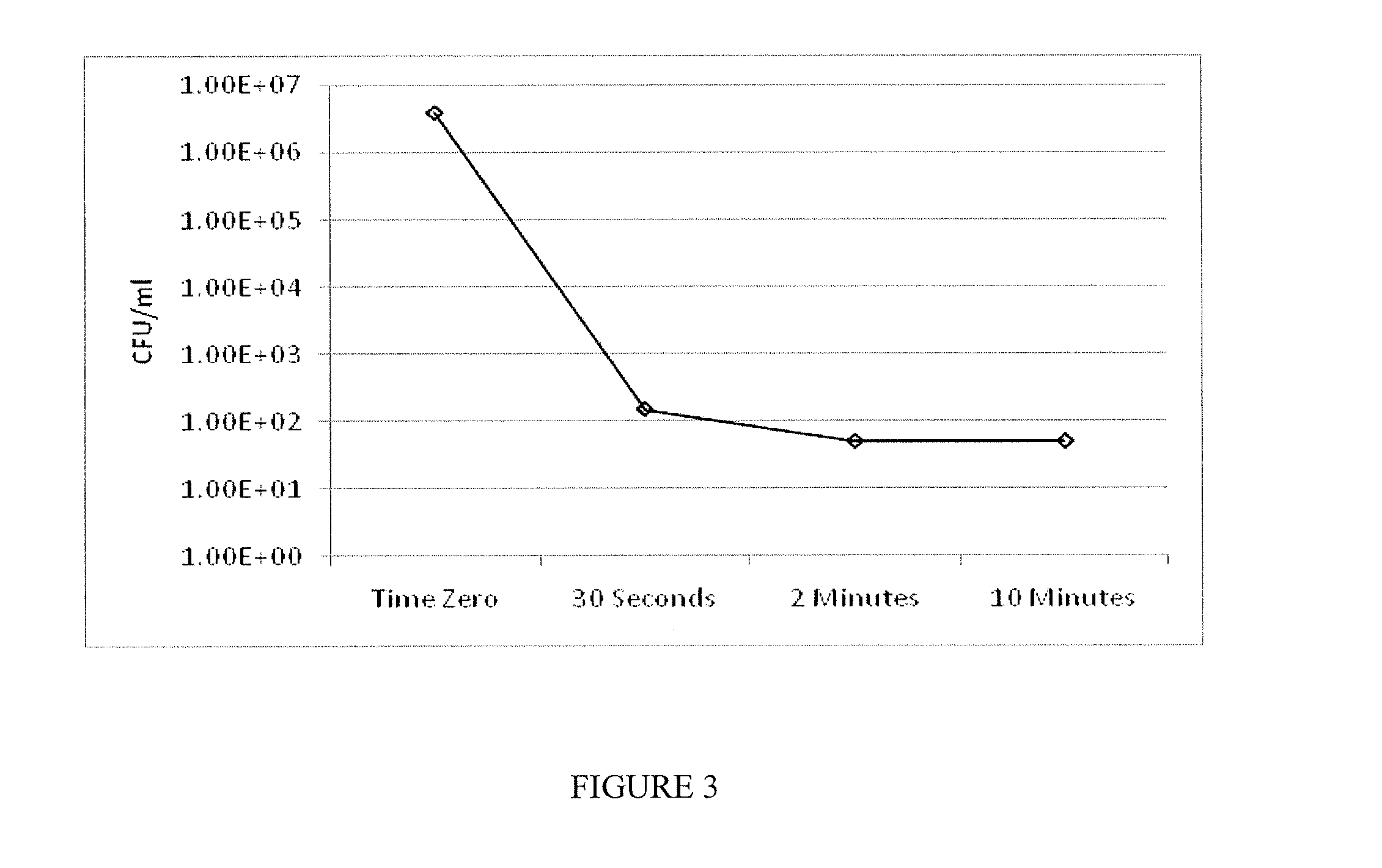

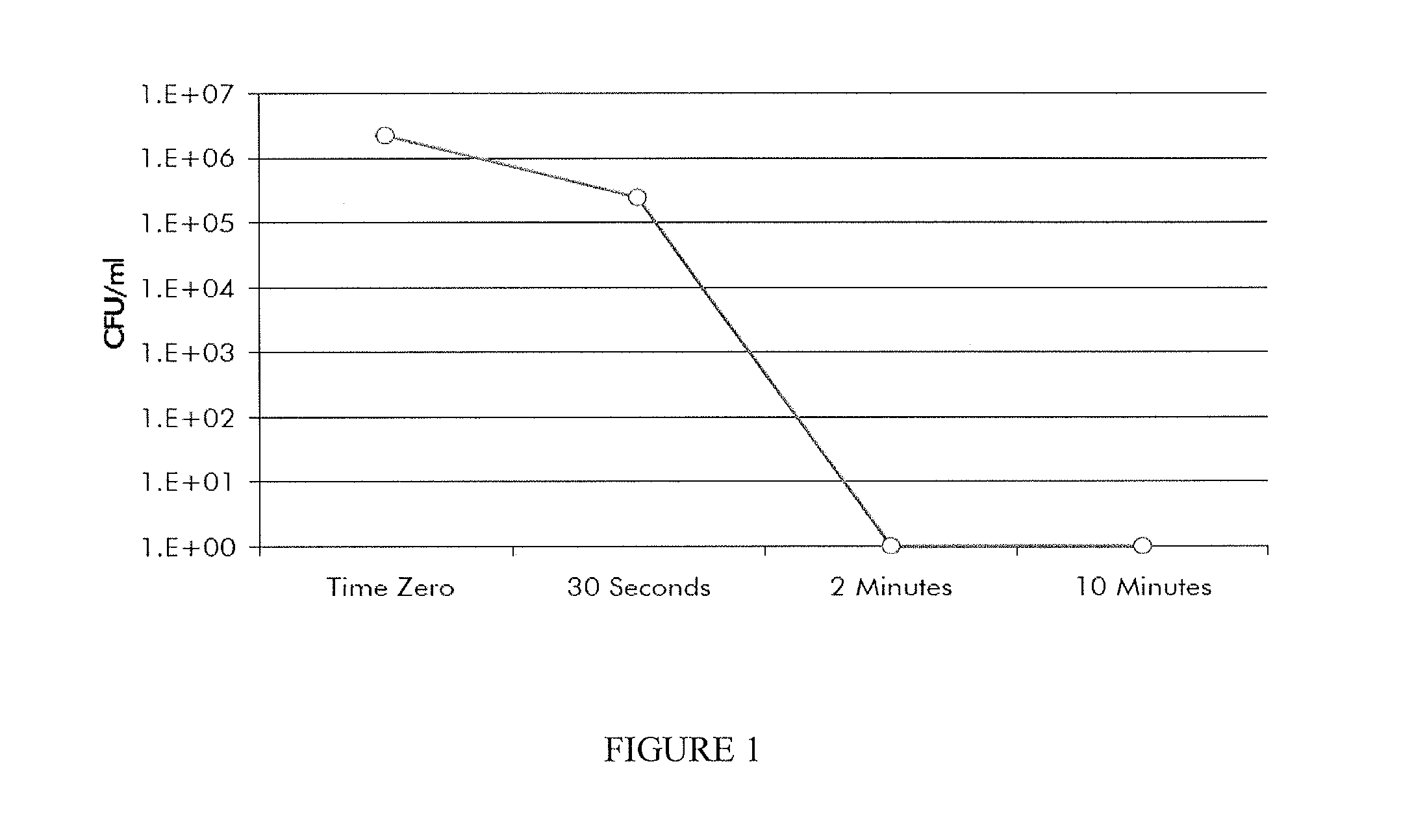

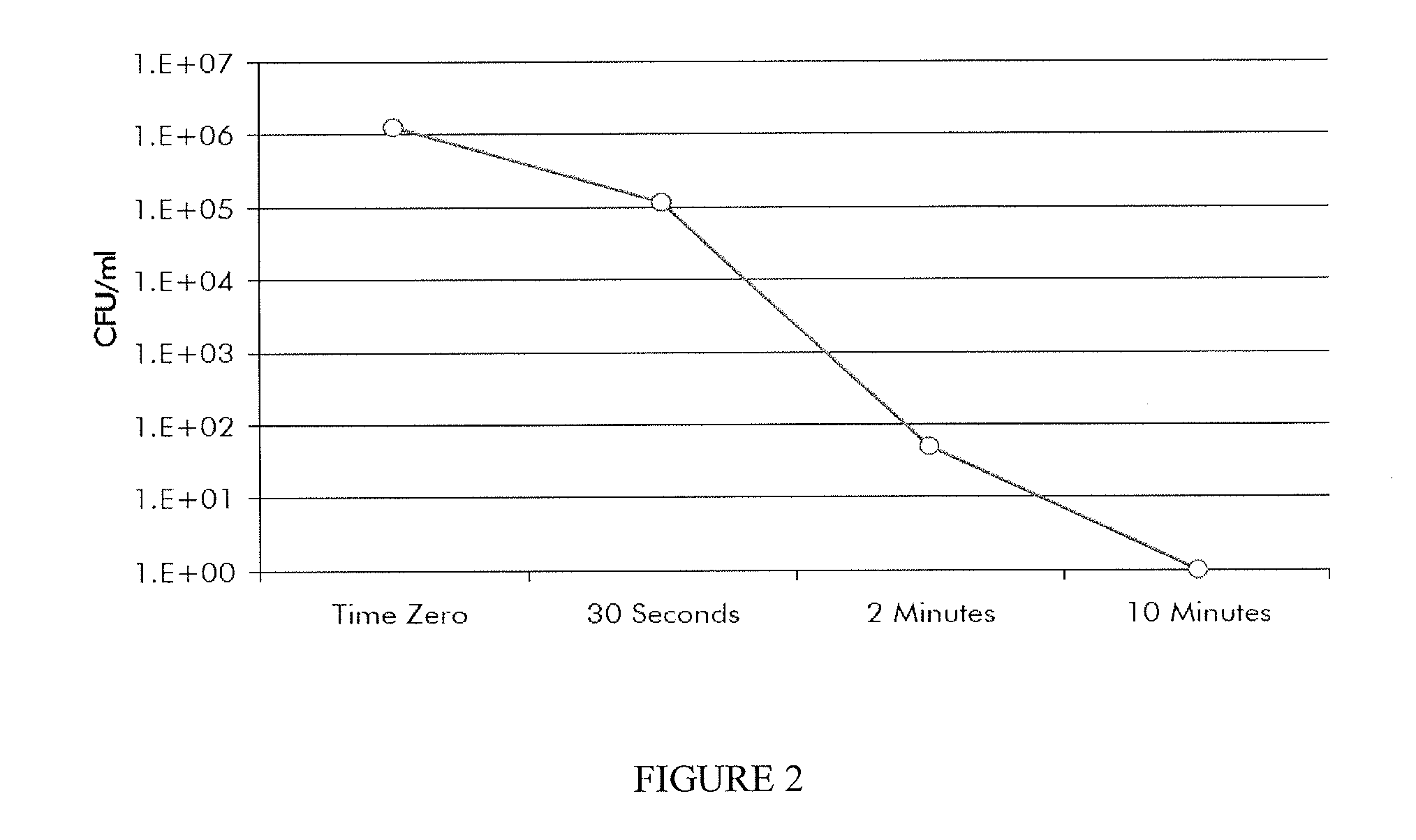

Aqueous decontamination formulations that neutralize biological pathogens for disinfection and sterilization applications. Examples of suitable applications include disinfection of food processing equipment, disinfection of areas containing livestock, mold remediation, sterilization of medical instruments and direct disinfection of food surfaces, such as beef carcasses. The formulations include at least one reactive compound, bleaching activator, inorganic base, and water. The formulations can be packaged as a two-part kit system, and can have a pH value in the range of 7-8.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Decontamination formulations for disinfection and sterilization

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Liquid Detergent Composition

InactiveUS20090249557A1Sufficient formImprove stabilityNon-ionic surface-active compoundsOrganic detergent compounding agentsBoric acidBleach activator

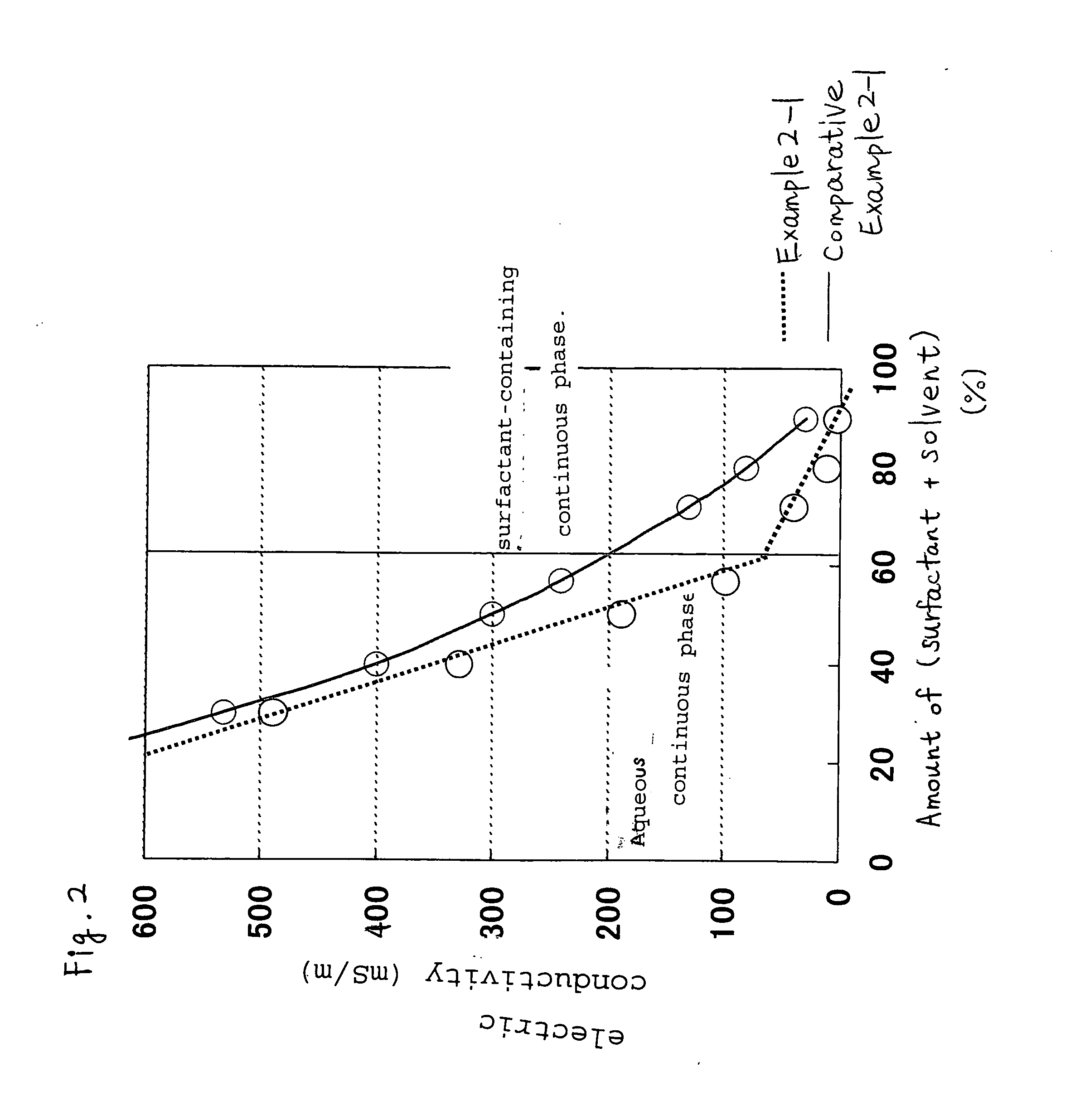

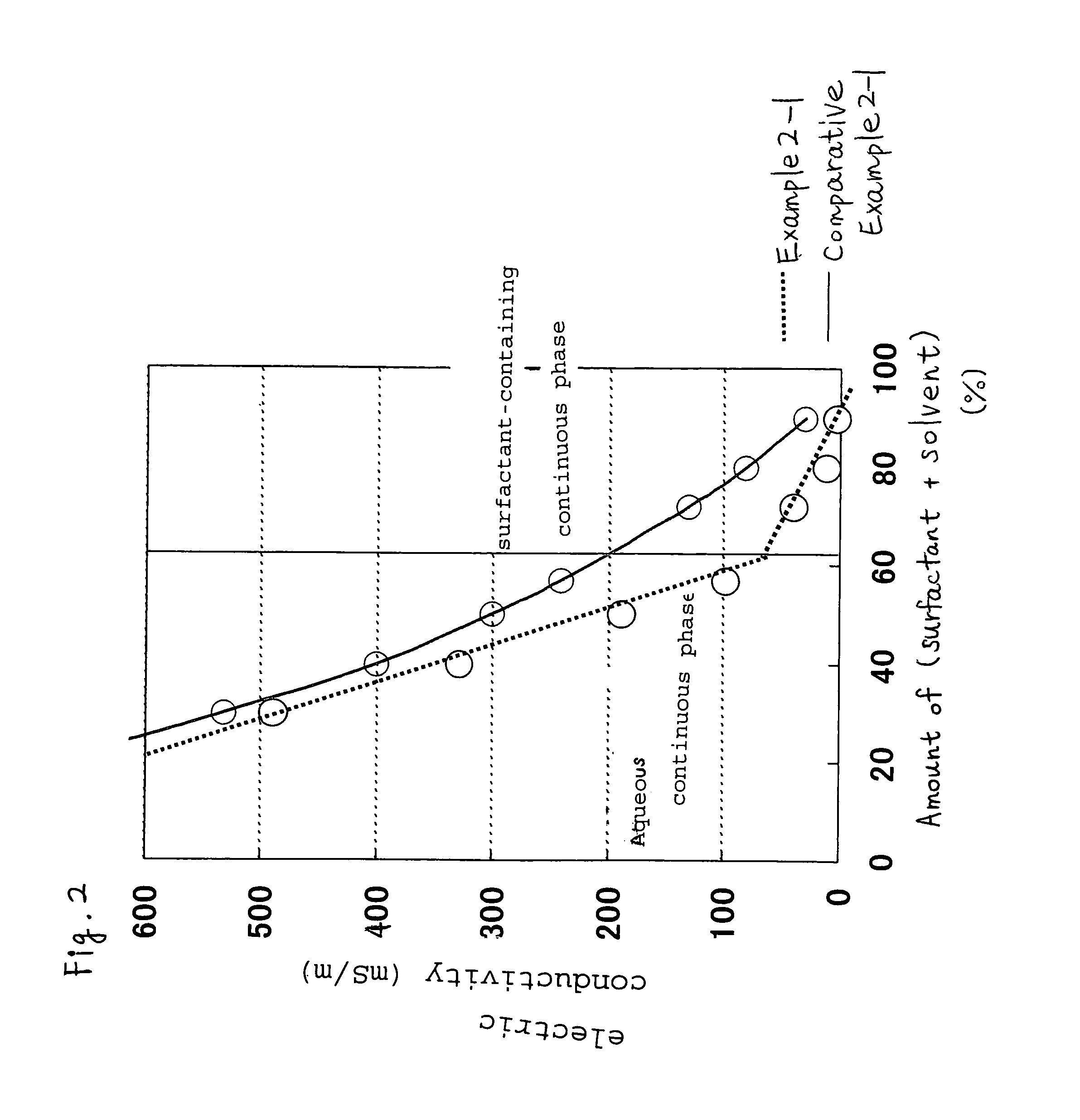

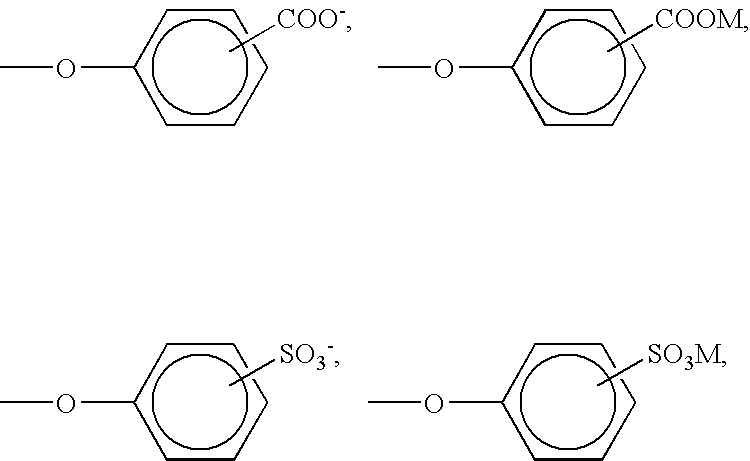

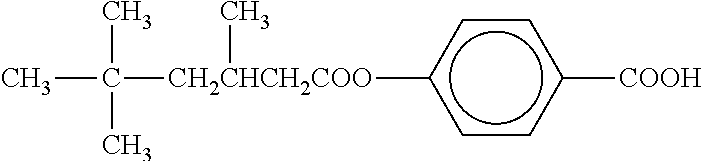

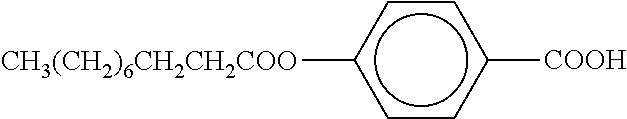

The present invention relates to a liquid detergent composition containing (a) hydrogen peroxide or a compound forming hydrogen peroxide in water, 0.1 to 10 mass % of (b) a bleaching activator, 45 to 80 mass % of (c) a nonionic surfactant, (d) water, (e) at least one or more compounds selected from boric acid, borax and borate, and (f) a polyol compound, said liquid detergent composition having a pH value of 4 to 7 at 20° C.

Owner:KAO CORP

Detergent compositions and components thereof

InactiveUS6878680B2Weight gain/lossImprove performanceAnionic surface-active compoundsOrganic/inorganic per-compounds compounding agentsMoistureBleach activator

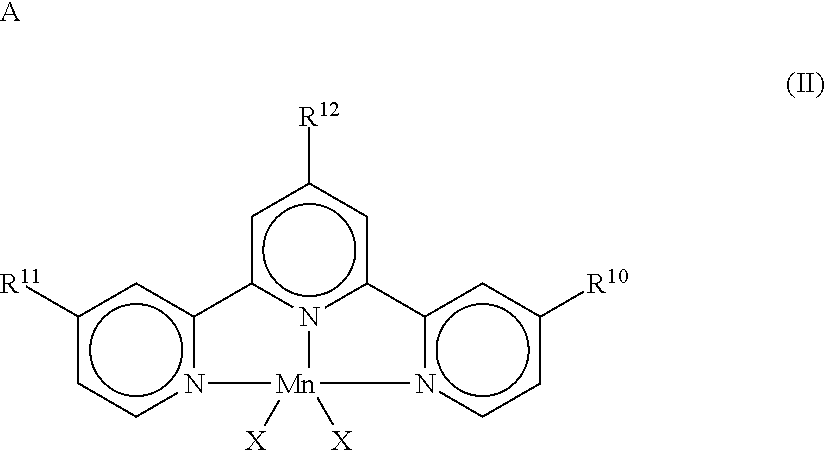

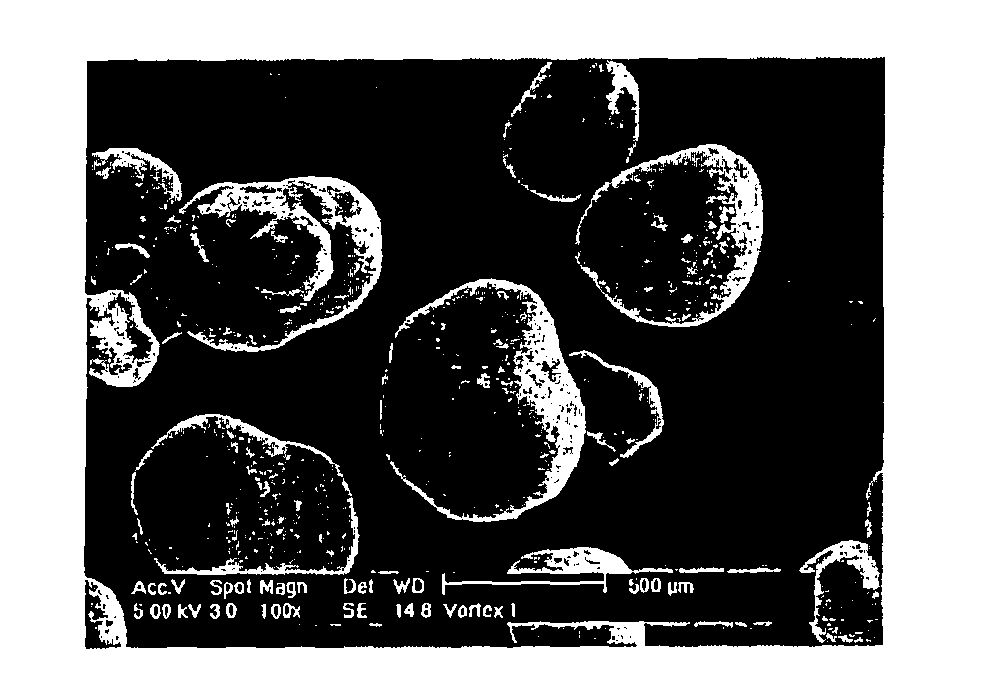

Detergent compositions comprising bleach catalysts or perfumes are disclosed. In particular, components comprising the bleach catalysts or perfumes are disclosed. In particular, the bleach catalysts are formed into stable particles having low moisture content and low moisture pick-up. Particles are also described having low surface area. Particles containing bleach catalysts or perfumes are also described comprising a protective agent which reacts with water to form non-water reaction products, particularly preferred protective agents being bleach activators.

Owner:PROCTER & GAMBLE CO

Bleach composition and bleaching detergent composition

InactiveUS20060293204A1High bleaching powerDamage and discoloration of clothes can be suppressedOrganic detergent compounding agentsNon-surface-active detergent compositionsWater insolubleWater soluble

A bleach composition containing (a) a peroxide generating hydrogen peroxide by being dissolved in water, (b) a water-insoluble or poorly water-soluble textile powder selected from powder cellulose, silk powder, wool powder, nylon powder and polyurethane powder, and (c) (c-1) a bleaching activating catalyst and / or (c-2) a bleaching activator. A bleaching detergent composition containing (a) a peroxide generating hydrogen peroxide by being dissolved in water, (b) a water-insoluble or poorly water-soluble textile powder selected from powder cellulose, silk powder, wool powder, nylon powder and polyurethane powder, and (c) (c-1) a bleaching activating catalyst or (c-1) a bleaching activating catalyst and (c-2) a bleaching activator, and (d) a surfactant.

Owner:CIBA SPECIALTY CHEM CORP

Machine cleaning method

InactiveUS20120214723A1Non-surface-active detergent compositionsHollow article cleaningEngineeringCleansing Agents

An automatic dishwashing method or automatic textile washing method uses a cleaning-agent including: a) a liquid cleaning-agent preparation A including at least one bleach activator as well as at least one builder; and b) a liquid cleaning-agent preparation D including at least one oxygen bleaching agent. The cleaning-agent preparations A and D are dispensed into the interior of the machine from a cartridge located in the interior of the machine. Sub-quantities a and d of the cleaning-agent preparations A and D are respectively dispensed into the interior of the machine, residual quantity of the cleaning-agent preparations A and D remaining in the cartridge until the end of the washing method, the residual quantities corresponding to at least twice the sub-quantities a and d, respectively.

Owner:HENKEL KGAA

Multi-Compartment Pouch

InactiveUS20110303576A1Promote recoveryImproved result upon visual gradingOrganic detergent compounding agentsSurface-active detergent compositionsSolventOxygen

A multi-compartment pouch comprising a first compartment and a second compartment,wherein,the first compartment comprises a solid composition, wherein the solid composition comprises;an oxygen bleach source;a bleach activator;a polycarboxylate polymer;and the second compartment comprises a liquid composition, wherein the liquid composition comprises;a low molecular weight solvent.

Owner:THE PROCTER & GAMBLE COMPANY

Detergent compositions and components thereof

InactiveUS20030232734A1Weight gain/lossImprove performanceAnionic surface-active compoundsNon-surface-active detergent compositionsPtru catalystBleach activator

Detergent compositions comprising bleach catalysts or perfumes are disclosed. In particular, components comprising the bleach catalysts or perfumes are disclosed. In particular, the bleach catalysts are formed into stable particles having low moisture content and low moisture pick-up. Particles are also described having low surface area. Particles containing bleach catalysts or perfumes are also described comprising a protective agent which reacts with water to form non-water reaction products, particularly preferred protective agents being bleach activators.

Owner:THE PROCTER & GAMBLE COMPANY

Detergent Composition

ActiveUS20090325840A1Good bleaching propertyImprove bleaching effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsKetoneBleach activator

A hard surface detergent composition is provided, said composition comprising a peroxygen bleach capable of exhibiting bleaching properties at a pH of below 9, and an amino ketone or derivative thereof bleach activator, and wherein a 1% wt solution in distilled water at 25° C. of the composition has a pH lower than 9. Potassium monopersulphate is the preferred bleach compound and diethyl amino acetone or derivative thereof is the preferred bleach activator. The compositions exhibit good bleaching performance at pHs of less than 9.

Owner:RECKITT BENCKISER VANISH BV

Liquid dishwasher detergent

InactiveUS20120208734A1Detergent materialsDetergent compounding agentsCleansing AgentsBleach activator

The invention relates to dishwasher detergents, comprising a packaging means and two liquid washing or cleaning agents A and B, which are present in said packaging means separate from each other and which have the following composition: A: −10 to 55 wt. % builder(s); −0.1 to 15 wt. % enzyme(s); −0.001 to 30 wt. % bleach activator; −20 to 70 wt. % water; and B: −50 to 99.9 wt. % water; −0.1 to 50 wt. % oxygen bleaching agent, −<20 wt. % further ingredients, characterized in that the liquid cleaning agents A and B have a pH value (20° C.) of less than 9. The dishwasher detergents are characterized by good cleaning power when dishes are washed in the dishwasher.

Owner:HENKEL KGAA

Cold-pad-batch method for textile materials

InactiveCN101135113AAchieve the bleaching effectAvoid damageTextile storage in wounded formFibre treatmentEngineeringBatch method

The present invention discloses process of cold padding, stacking and actively bleaching fabric. The process includes through steps, including one step of compounding bleaching solution and padding, one step of winding and stacking, and one step of hot water washing and cold water washing. The present invention adopts alkanoylxy benzene sulfonate bleaching activator, hydrogen peroxide / activator bleaching system, and cold padding and stacking treatment to reach excellent fabric bleaching effect. Compared with traditional bleaching technology, the present invention has the advantages of excellent fabric bleaching effect, lowered alkali consumption, reduced stacking time, less fabric damage, raised production efficiency and environment friendship.

Owner:ZHEJIANG SCI-TECH UNIV

Disposable absorbent articles comprising odor controlling materials

InactiveUS20090148686A1Effective controlInhibition formationCellulosic plastic layered productsPaper/cardboard layered productsPolymer chemistryBleach activator

The present inventions relates to a disposable absorbent articles, including diapers and sanitary napkins, comprising a bleach activator system for controlling odors associated with bodily fluids. The bleach activator system may comprise a peroxygen bleach compound (including a source of hydrogen peroxide) and a bleach activator compound capable of generating a peroxyacid in-situ within the absorbent article.

Owner:THE PROCTER & GAMBLE COMPANY

Liquid detergent composition

InactiveUS7863234B2Sufficient formImprove stabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBoric acidBleach activator

The present invention relates to a liquid detergent composition containing (a) hydrogen peroxide or a compound forming hydrogen peroxide in water, 0.1 to 10 mass % of (b) a bleaching activator, 45 to 80 mass % of (c) a nonionic surfactant, (d) water, (e) at least one or more compounds selected from boric acid, borax and borate, and (f) a polyol compound, said liquid detergent composition having a pH value of 4 to 7 at 20° C.

Owner:KAO CORP

Liquid bleaching agent composition

InactiveUS20100308260A1Hydrogen peroxideNon-ionic surface-active compoundsBoric acidSURFACTANT BLEND

The present invention relates to a liquid bleaching agent composition containing (a) hydrogen peroxide, (b1) a nonionic surfactant, (b2) an anionic surfactant, (c) a bleaching activator, (d) at least one compound selected from boric acid, borax and a borate, and (e) a compound having one or more groups in which a hydroxyl group is present on each of the adjacent carbon atoms to each other, wherein the respective contents of component (b1), component (b2) and the mass ratio of component (b2) to component (b1) are all within a specific range and the composition has pH 2.5-4.5 at 20° C.

Owner:KAO CORP

Bleach activator granules

InactiveUS6214785B1Increase resistanceImprove stabilityOrganic detergent compounding agentsDetergent mixture composition preparationWater solubleBleach activator

What is claimed are bleach activator granules which are obtained by mixing a bleach activator with a binder and x% by weight of the total amount of a water-soluble polymer, spraying of water which comprises 100-x% by weight of the total amount of the water-soluble polymer, where x is a number from 0 to 100, and subsequent granulation and drying.

Owner:WEYLCHEM WIESBADEN

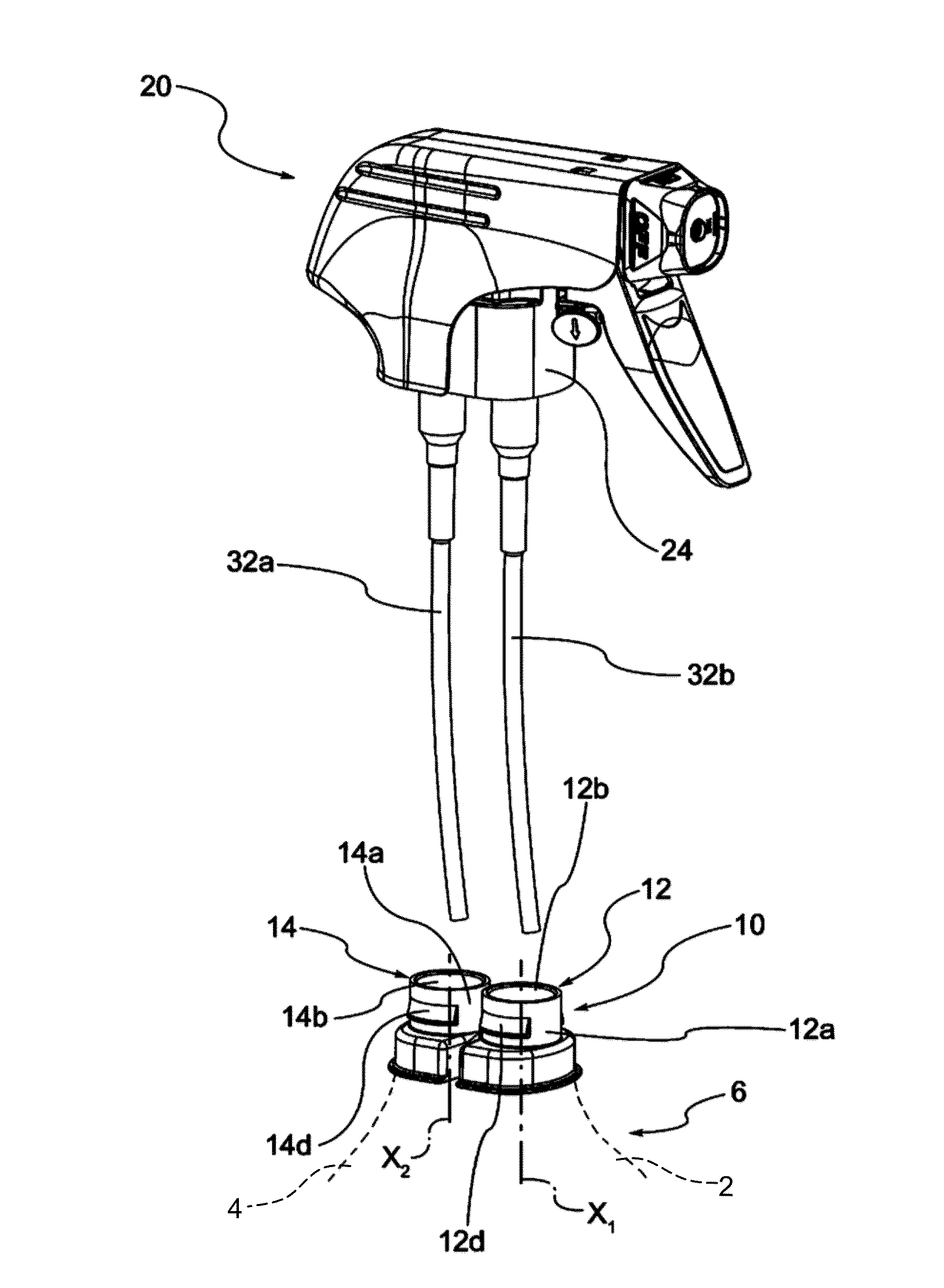

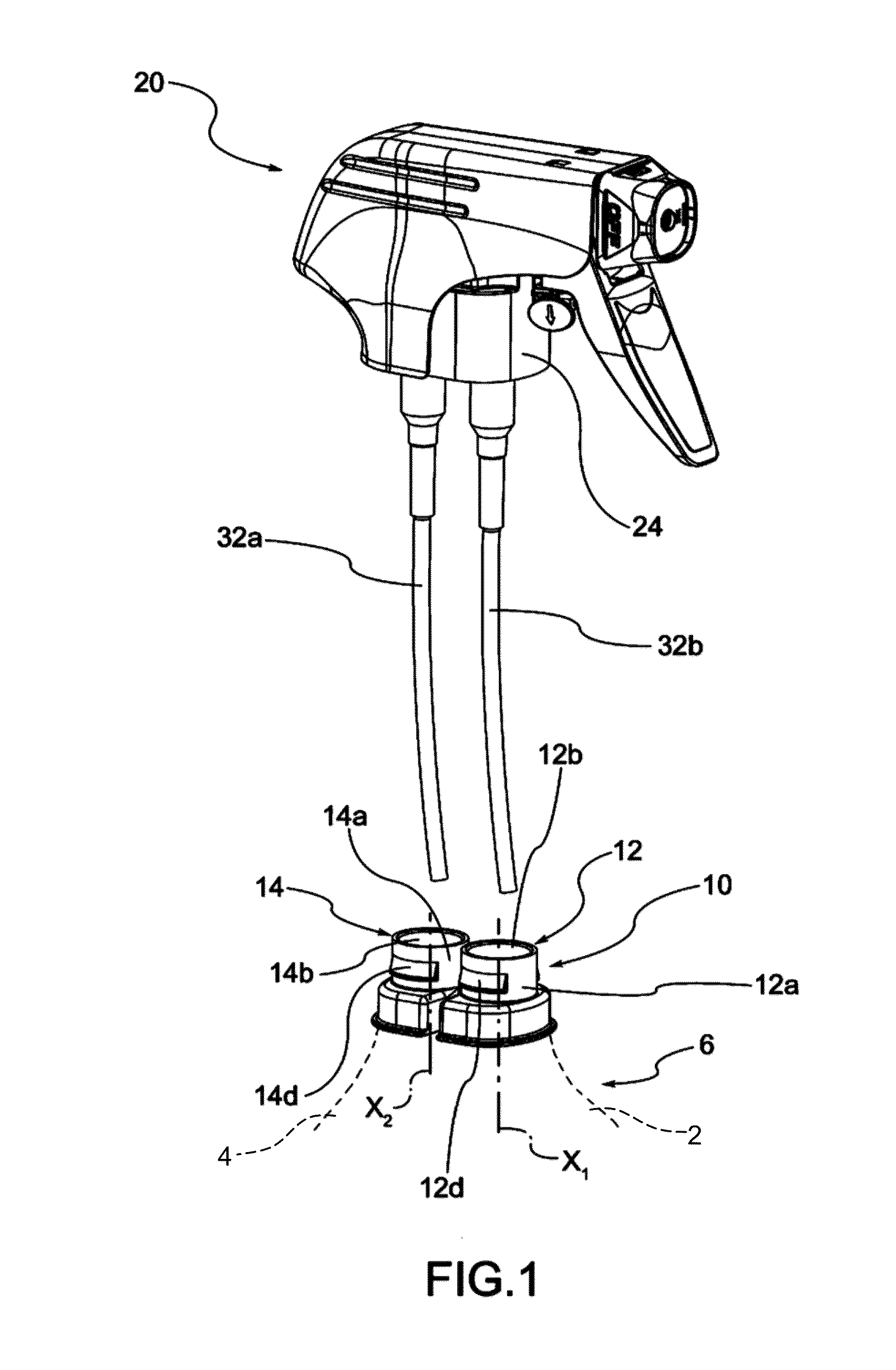

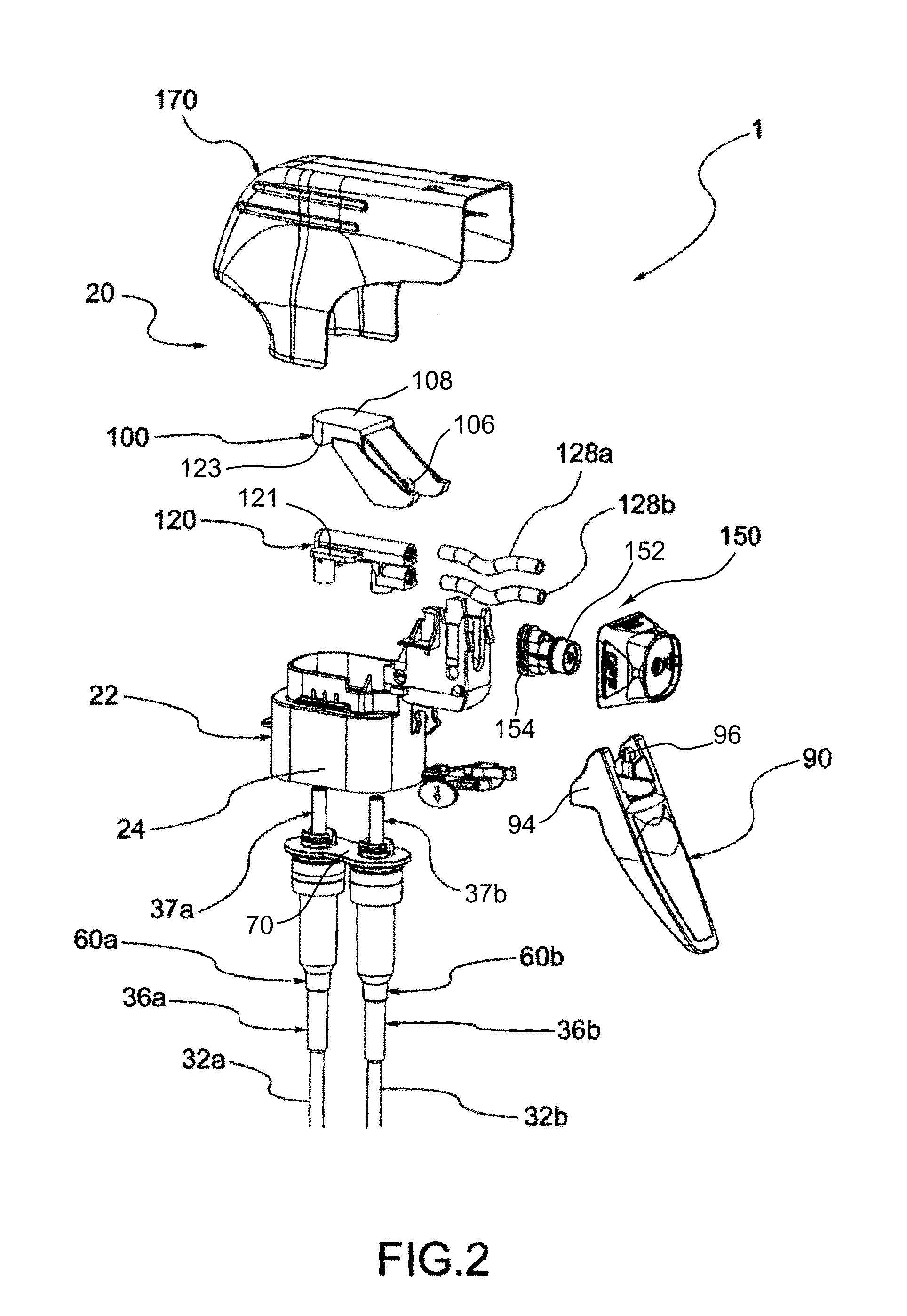

Dual chamber spray dispenser with a single delivery tube

The present invention relates to fluid dispensing devices for use in dispensing different liquids (e.g., bleach and bleach activator) from a bottle having first and second compartments. To minimize the presence of mixed composition residually present within the fluid dispensing device, it may be helpful to delay mixing. Separate dip tubes may be provided to pull liquid from the separate compartments, each with its own separate pump. Each pump may deliver the separate compositions to a spray nozzle of the device through separate delivery tubes (e.g., from the pumps to the nozzle). In other embodiments, a single delivery tube, and / or a single pump may be provided, e.g., where the volume of mixed composition that may be present in such pump and / or delivery tube may be sufficiently small so as to still provide overall desired efficacy characteristics. Dual delivery tube configurations may eliminate any need to prime the device by spraying out old, residual mixed composition.

Owner:THE CLOROX CO

Oxygen-bearing detergent and its prepn.

InactiveCN1389554ARemove dirtEliminate odorNon-surface-active detergent compositionsAlkaline proteaseOxygen

There is a kind of oxygenic detergent and the manufacturing method, which is is mainly made up of bleacher and aid detergent. Its characters lie in that the bleacher is one of sodium superborate, sodium supercarbonate and painted sodium supercarbonate or compound with more of them; aid detergent is one of sodium carbonate, sodium sulfate and sodium silicate or compound with more of them; the invention still may add alkaline protease, anti-dirt sediment agent, bleaching and activating agent. The manufacturing method is: bleacher, aid-detergent, alkaline protease, anti-dirt sediment agent, bleaching and activating agent are put into mixing machine, then the machine starts to mix them about 5-25 minutes, after that, it gives out materials, oxygen detergent is obtained.

Owner:陶华西

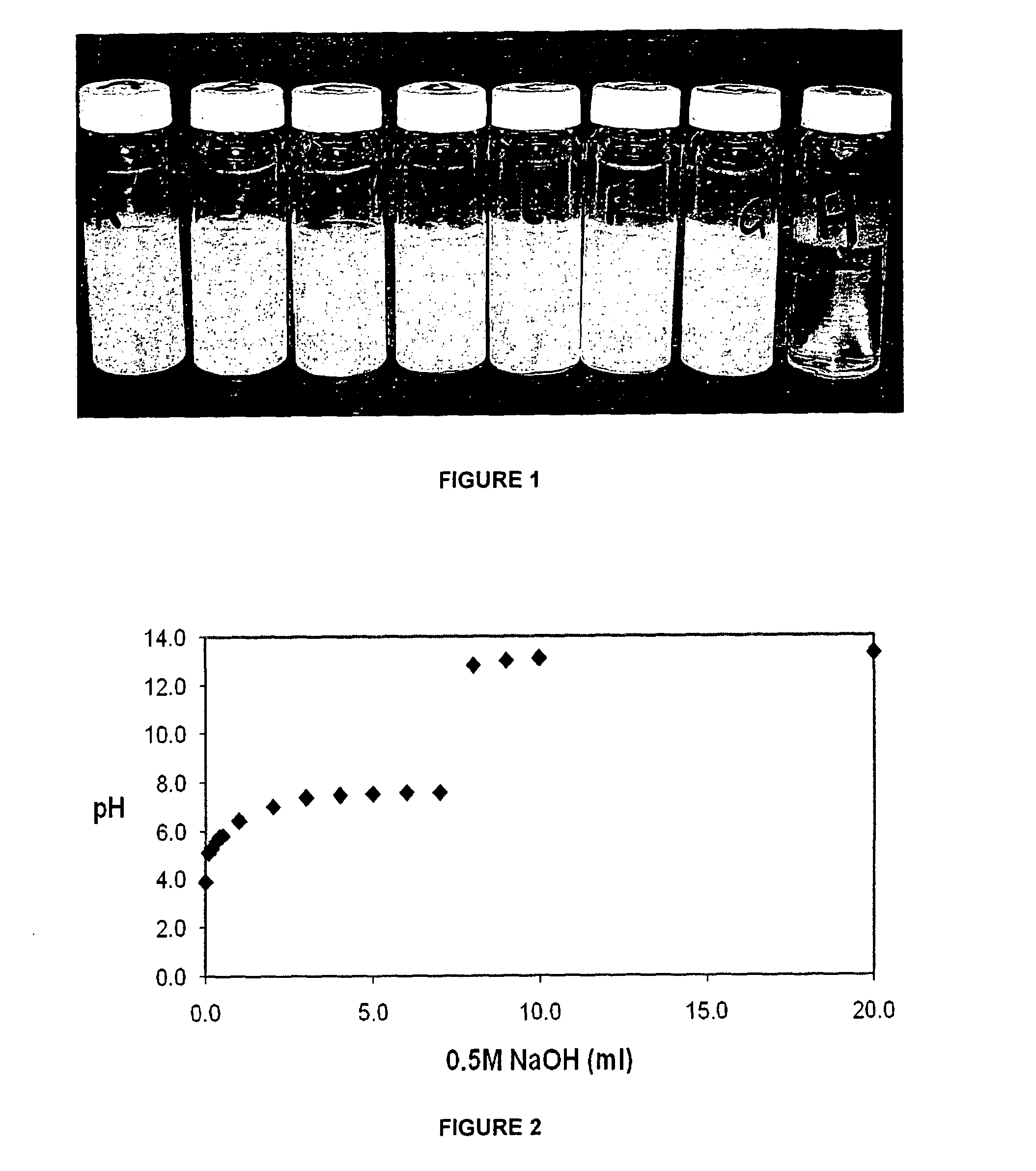

Decontamination formulation with sorbent additive

InactiveUS7282470B2Extended shelf lifeEasy to handleBiocideSolid waste disposalMANNITOL/SORBITOLSorbent

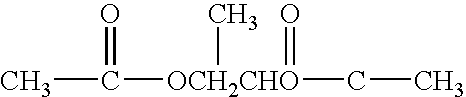

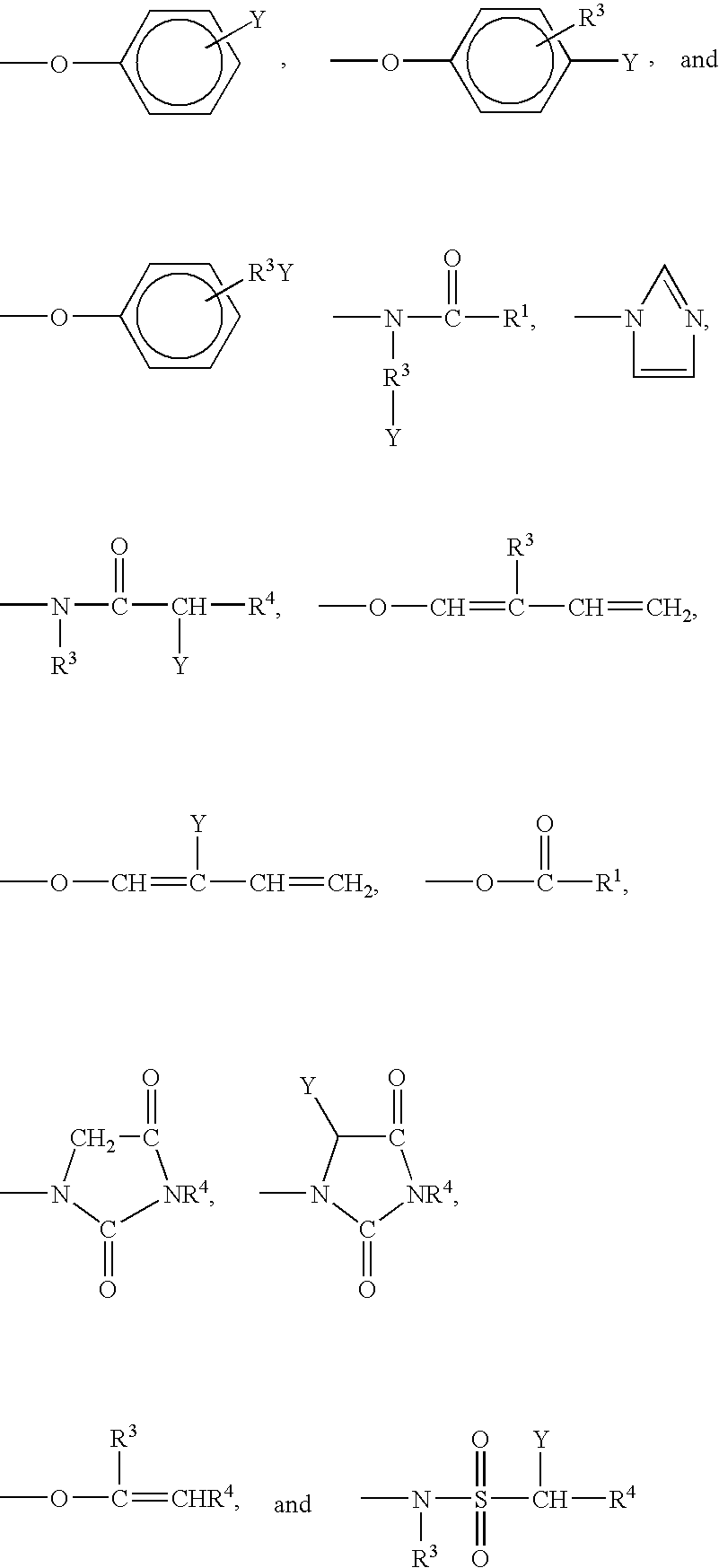

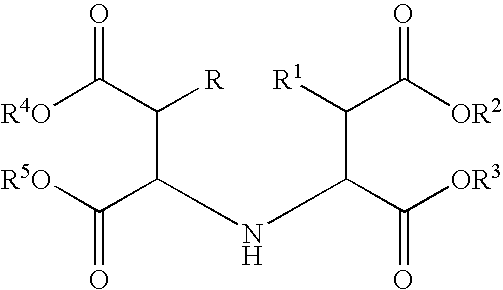

A decontamination formulation and method of making that neutralizes the adverse health effects of both chemical and biological compounds, especially chemical warfare (CW) and biological warfare (BW) agents, and toxic industrial chemicals. The formulation provides solubilizing compounds that serve to effectively render the chemical and biological compounds, particularly CW and BW compounds, susceptible to attack, and at least one reactive compound that serves to attack (and detoxify or kill) the compound. The formulation includes at least one solubilizing agent, a reactive compound, a bleaching activator, a sorbent additive, and water. The highly adsorbent, water-soluble sorbent additive (e.g., sorbitol or mannitol) is used to “dry out” one or more liquid ingredients, such as the liquid bleaching activator (e.g., propylene glycol diacetate or glycerol diacetate) and convert the activator into a dry, free-flowing powder that has an extended shelf life, and is more convenient to handle and mix in the field.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

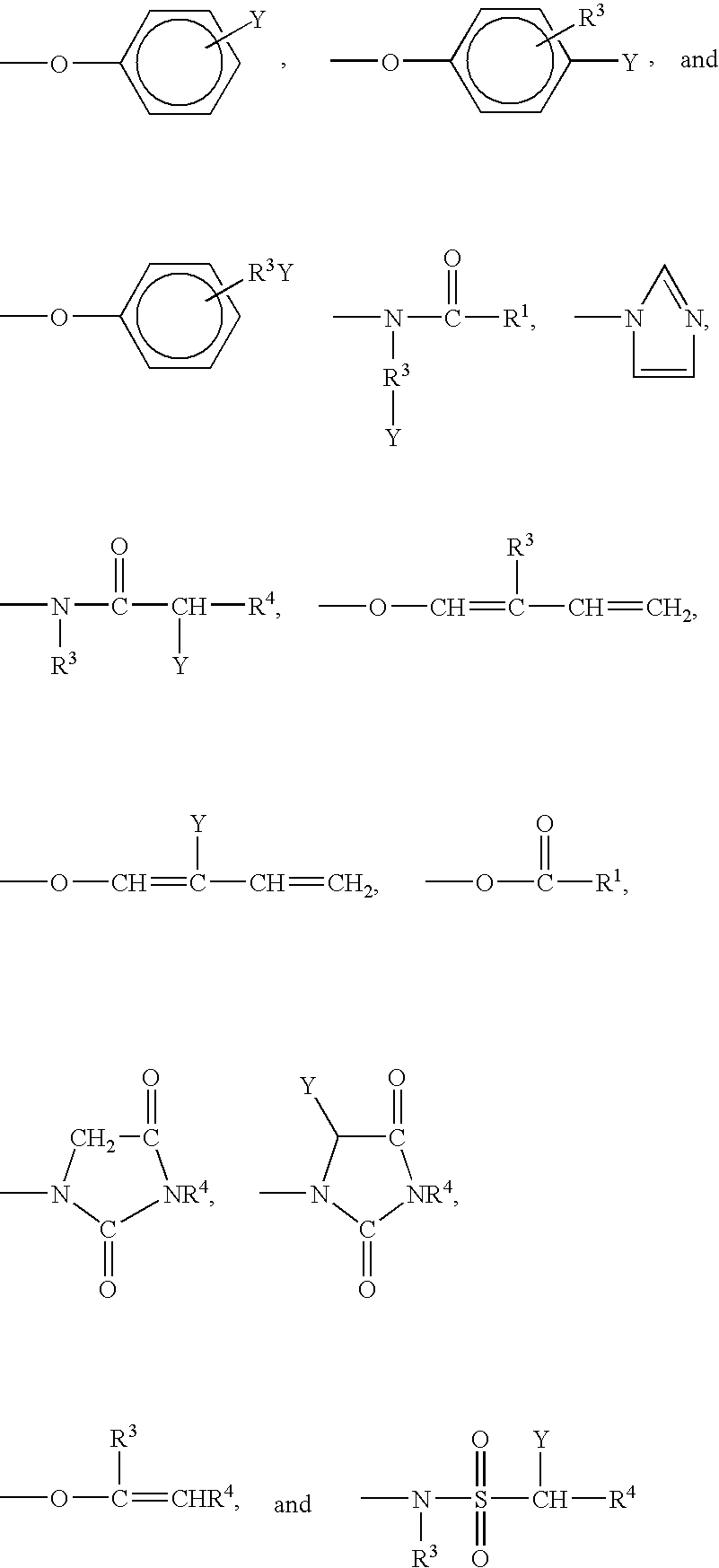

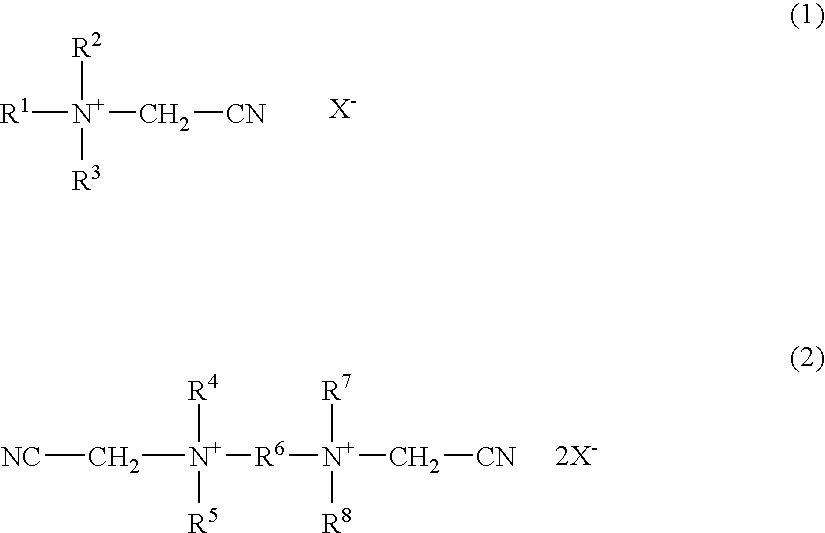

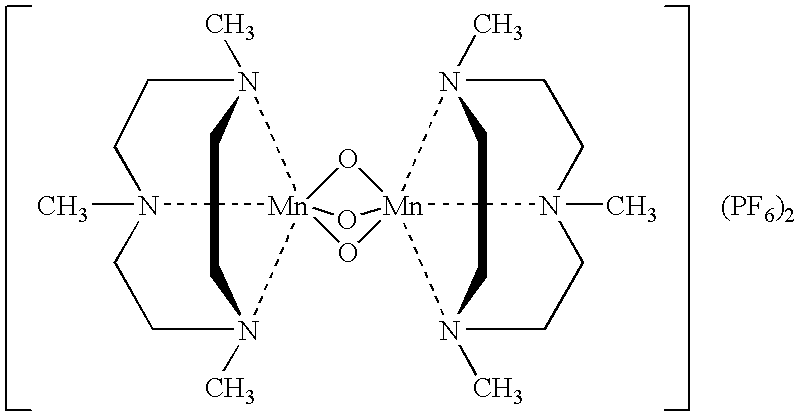

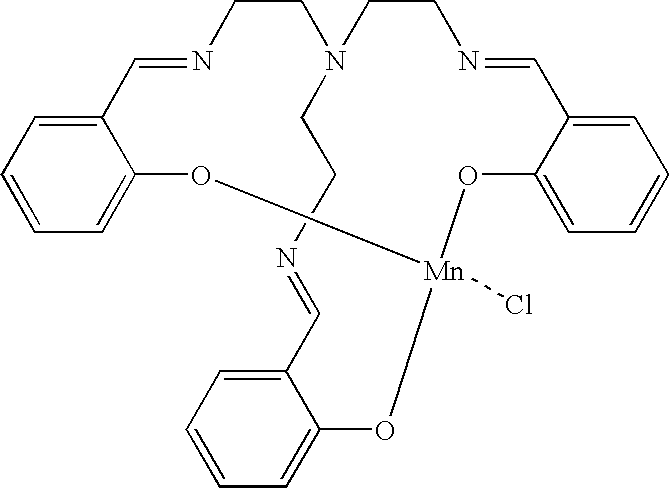

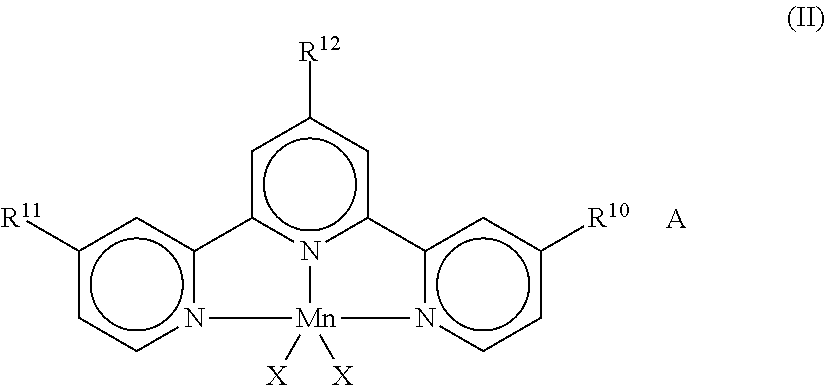

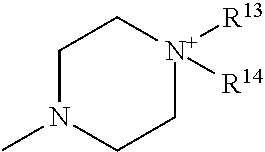

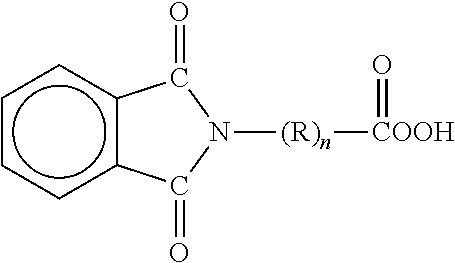

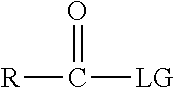

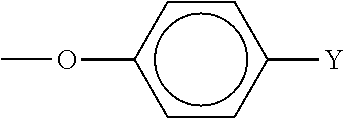

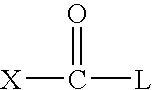

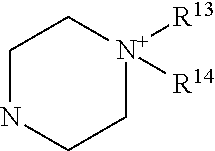

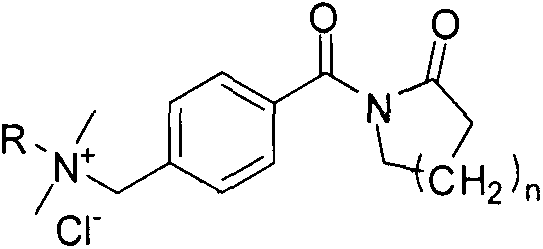

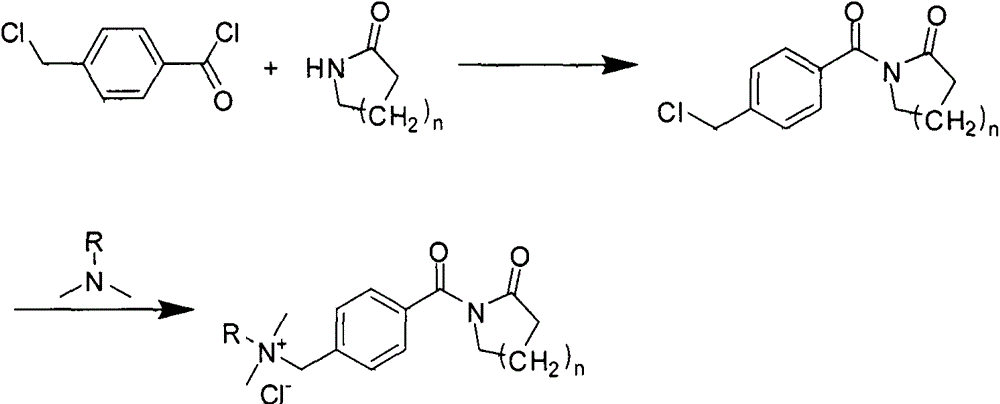

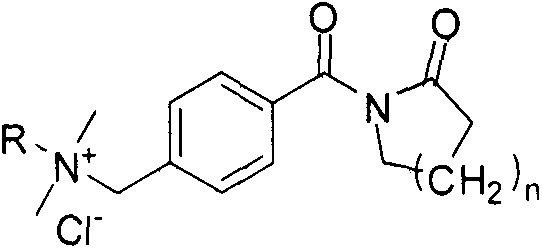

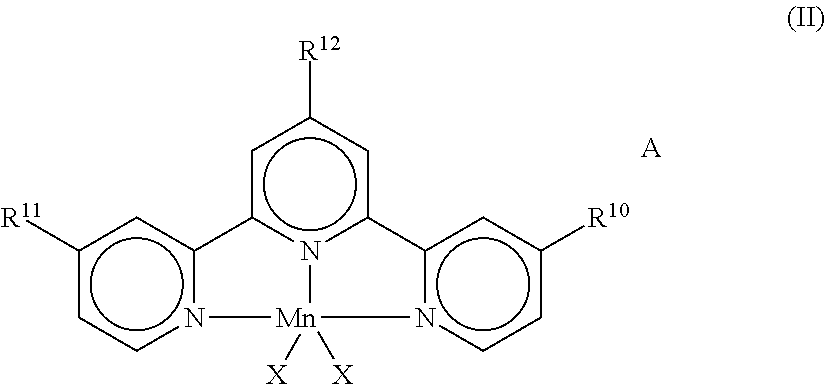

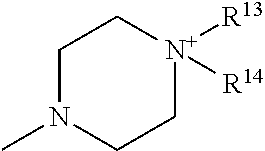

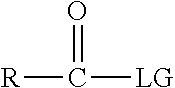

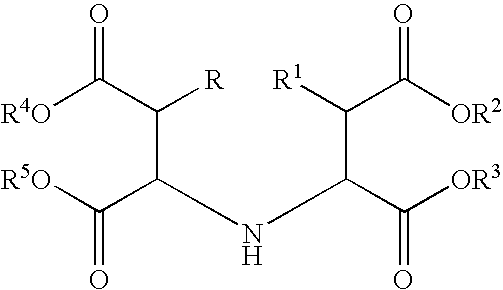

Synthesis method for cationic bleaching activating agents with surface activity

InactiveCN103554024AOrganic detergent compounding agentsOrganic chemistryQuaternary ammonium cationSynthesis methods

The invention relates to a synthesis method for cationic bleaching activating agents with surface activity, belonging to the field of fine chemical engineering. According to the method, a series of cationic bleaching activating agents with different carbon chain-length quaternary ammonium salt groups are synthesized by adopting alkyl dimethyl tertiary amine, 4-(chloromethyl)benzoyl chloride and lactam as intermediates. The leaching activating agent has stronger affinity on the surface of a material with surface electronegativity in an aqueous solution, can react with hydrogen peroxide on the surface of the material to produce extremely active peroxy acid, can bleach the material at a low temperature so as to effectively remove the pigment impurities on the surface of the material. The cationic bleaching activating agent can be used for industrial bleaching and household washing of textiles.

Owner:JIANGNAN UNIV

Machine cleaning method

InactiveUS20120204356A1Detergent mixture composition preparationHollow article cleaningCleaning methodsEngineering

An automatic dishwashing or automatic textile washing method includes the step of dispensing a cleaning-agent presentation form into the interior of an automatic dishwasher or textile washing machine from a cartridge located in the interior of the automatic dishwasher or textile washing machine. The cleaning-agent presentation form includes a liquid cleaning-agent preparation A having a pH (10% solution in H2O; 20° C.) above 8.0, comprising at least one builder as well as at least one oxygen bleaching agent, and a liquid cleaning-agent preparation B comprising at least one bleach activator. Sub-quantities a and b of the cleaning-agent preparations A and B are respectively dispensed so that a residual quantity of the cleaning-agent preparations A and B remain in the cartridge until the end of the dishwashing method or textile washing method, and the residual quantities corresponds to at least twice the quantity of sub-quantities a and b.

Owner:HENKEL KGAA

Multi-compartment pouch

InactiveUS8524646B2Organic detergent compounding agentsSurface-active detergent compositionsSolventOxygen

A multi-compartment pouch comprising a first compartment and a second compartment,wherein,the first compartment comprises a solid composition, wherein the solid composition comprises;an oxygen bleach source;a bleach activator;a polycarboxylate polymer;and the second compartment comprises a liquid composition, wherein the liquid composition comprises;a low molecular weight solvent.

Owner:THE PROCTER & GAMBLE COMPANY

Antimicrobial surface treatment

ActiveUS20130052342A1Inhibit microbial growthGrowth inhibitionFireproof paintsBiocideMicroorganismPhosphate

A surface treatment powder comprising (a) about 50 wt. % or more of a percarbonate, perphosphate, persulfate, peroxide or perborate salt; (b) about 0.2-10 wt. % of a chlorinated isocyanurate salt; and (c) a bleach activator, and method of using same to inhibit the growth of a microorganism on a surface.

Owner:DEVERE

One-bath low-temperature desizing, refining and bleaching pretreatment method of cotton woven fabric

ActiveCN104233826AShort process flowAvoid strong damageBiochemical fibre treatmentBleaching apparatusPretreatment methodDesizing

The invention discloses a one-bath low-temperature desizing, refining and bleaching pretreatment method of cotton woven fabric. The method comprises the steps of adding 1-5g / L of bio-enzyme for desizing, 3-8g / L of bio-enzyme for refining, 2-6g / L of hydrogen peroxide, 1-4g / L of a bleach activator, 2-6g / L of a chelating agent and 0.5-4g / L of an auxiliary agent into a one-bath system, adjusting the pH value to 6.0-7.5, putting the fabric into a dye bath according to the bath ratio of 1: (10-100), heating up to 50-70 DEG C at the speed of 0.5-2 DEG C / minute, carrying out heat preservation for 40-120 minutes, finally, washing the fabric with water, and drying or airing. The bio-enzyme for desizing, the bio-enzyme for refining and the bleach activator are added into a pretreatment system of the cotton woven fabric, so that the processes of desizing, refining and bleaching of the cotton woven fabric can be carried out in one bath at a low temperature, the strength damage to the fabric is avoided, the technological process of the dyeing and finishing pretreatment of the cotton woven fabric can be shortened, the energy consumption is reduced, and the production efficiency is increased.

Owner:HENAN INST OF ENG

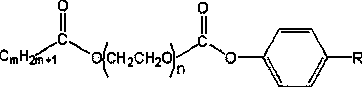

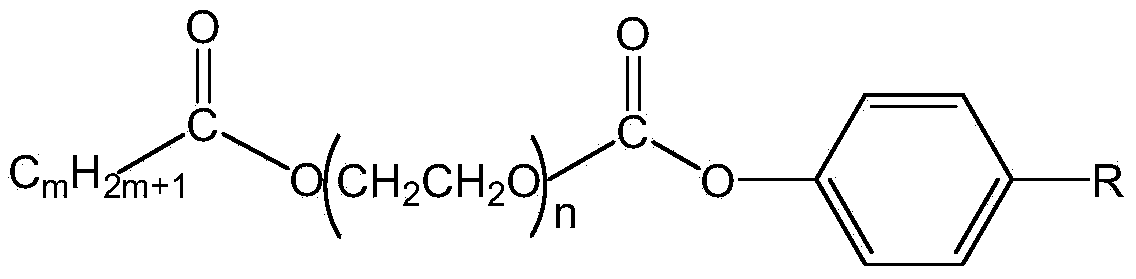

Method for the use of hydrophobic bleadching systems in textile preparation

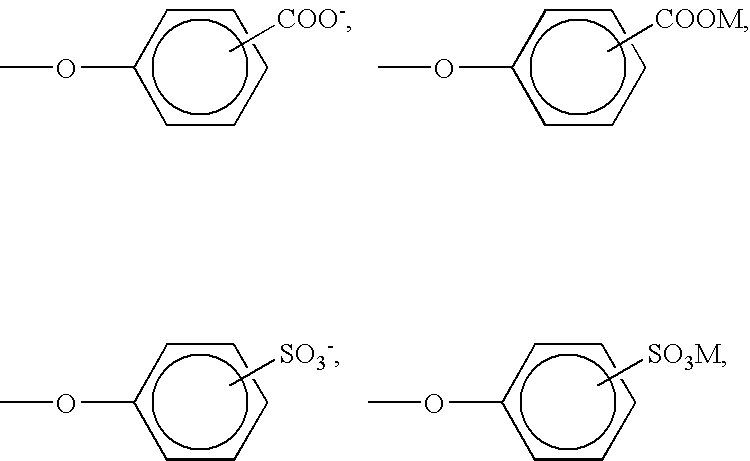

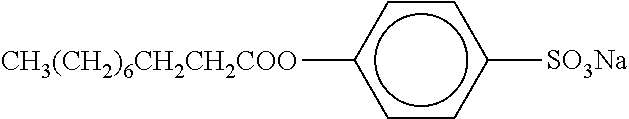

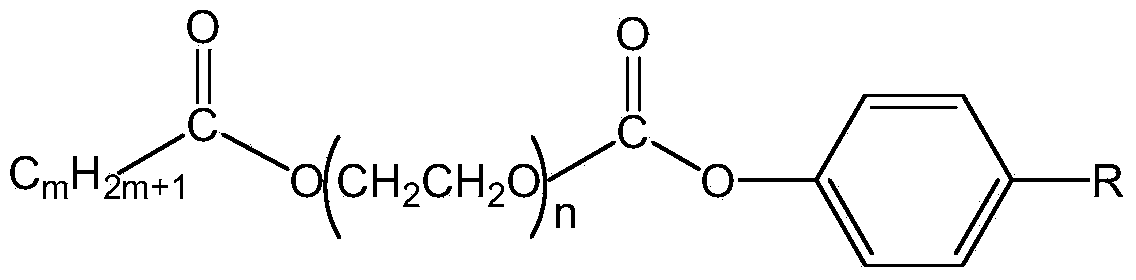

InactiveCN1439070AExcellent BleachHigh whitenessOrganic/inorganic per-compounds compounding agentsBleaching apparatusFiberSulfonate

A method for the treatment of a non-finished textile component is provided. The method comprises the steps of treating a non-finished textile component in an aqueous bleaching solution of hydrogen and a hydrophobic bleach activator or hydrophobic peracid. Preferred bleach activators include the alkanoyloxybenzene sulfonates and in particular noanoyloxybenzene sulfonate. The method provides superior fiber protection and fabric strength benefits versus conventional processing as well as significant savings in both energy and time due to the lower bleaching temperatures.

Owner:THE PROCTER & GAMBLE COMPANY

Antimicrobial surface treatment

ActiveUS20160066580A1Inhibit microbial growthGrowth inhibitionBiocidePeroxide active ingredientsSulfatePhosphate

A surface treatment powder comprising (a) about 50 wt. % or more of a percarbonate, perphosphate, persulfate, peroxide or perborate salt; (b) about 0.2-10 wt. % of a chlorinated isocyanurate salt; and (c) a bleach activator, and method of using same to inhibit the growth of a microorganism on a surface.

Owner:DEVERE

Fast decorizing and whitening method of color feather and down

The present invention is fast decolorizing and whitening method of color feather and down. FeSO4 is adopted as the bleaching activator for oxygen bleaching decolorizing of color feather and down at 20-25 deg.c, and dilute hydrochloric acid solution is then used in reducing Fe3+ ion before clear water washing. The present invention has simple technological process, and can decolorize color feather and down effectively, and the treated feather and down is fluffy and has the original state maintained and no damage.

Owner:孙雪保

Composite

InactiveUS20120302487A1Maximizing their barrier propertyNot impairing abilityLiquid surface applicatorsOrganic/inorganic per-compounds compounding agentsPhysical chemistrySoluble polymer

A composite includes: one or more core units comprising a bleach activating agent; and an alkali soluble polymer coating on the surface of said one or more core units.

Owner:REVOLYMER

Detergent composition

ActiveUS8173587B2Improve bleaching effectGood bleaching propertyInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPotassiumDistilled water

A hard surface detergent composition is provided, said composition comprising a peroxygen bleach capable of exhibiting bleaching properties at a pH of below 9, and an amino ketone or derivative thereof bleach activator, and wherein a 1% wt solution in distilled water at 25° C. of the composition has a pH lower than 9. Potassium monopersulphate is the preferred bleach compound and diethyl amino acetone or derivative thereof is the preferred bleach activator. The compositions exhibit good bleaching performance at pHs of less than 9.

Owner:RECKITT BENCKISER VANISH BV

Low-temperature bleaching method of pure cotton or cotton-containing fabric

The invention discloses a low-temperature bleaching method of pure cotton or cotton-containing fabric. The method comprises the steps of adding 1-4g / L of a bleach activator, 3-10g / L of hydrogen peroxide, 2-6g / L of a bleaching stabilizing agent and 0.5-5g / L of a pH regulator into a bleaching system; putting the unbleached pure cotton or cotton-containing fabric into a dye bath according to the bath ratio of 1: (10-100), heating up to 30-70 DEG C at the speed of 0.5-3 DEG C / minute, carrying out heat preservation for 20-90 minutes, finally, washing the bleached fabric with water, and drying or airing. The novel acyloxy bleach activator is added into a breaching system of the pure cotton or cotton-containing fabric, so that the breaching system can be implemented at a low temperature, and the bleaching effect of an oxidizing agent is improved; compared with the traditional oxygen bleaching system, the method is capable of reducing the damage to the fabric while improving the whiteness of the fabric.

Owner:HENAN INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com