Fractionating tower for separating acrylic aldehyde from 3-hydroxypropionaldehyde solution

A technology of hydroxypropionaldehyde and rectification tower, applied in the field of rectification tower, can solve the problems of high investment in thin-film evaporator equipment, condenser operation cost, difficulty in maintaining the operating temperature of the tower kettle, difficulty in polymerization and recovery of acrolein, etc. Effects of flux, increased thickness, increased throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

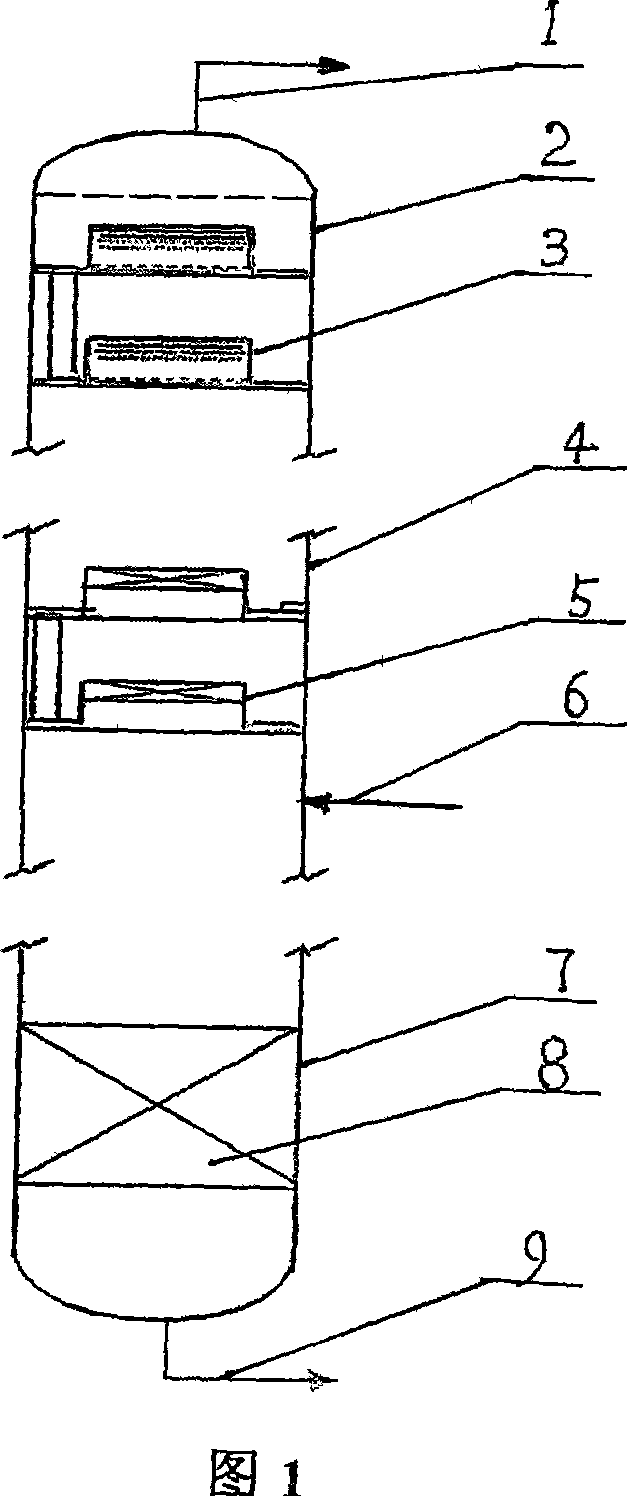

Embodiment 1

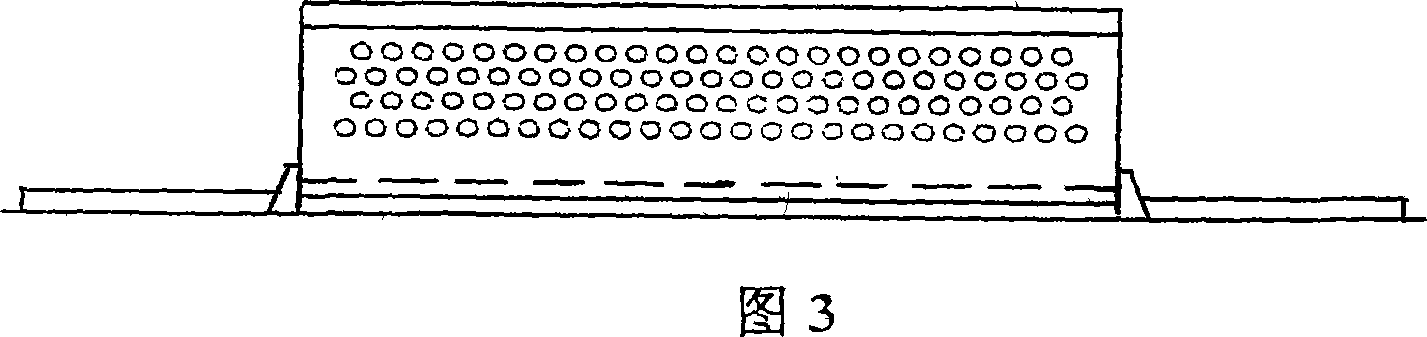

[0019] The 3-hydroxy propionaldehyde aqueous solution containing 4.5% (mass) of acrolein is continuously entered into the acrolein separation tower, and the material inlet [6] in the tower is fed. The tower height is 6000 mm, and the tower diameter is 800 mm. Corrugated ceramic structured packing with a porosity of 75% [8], and 10 vertical sieve trays in the upper part of the rectification section [2], the mass transfer unit of the tray can prevent a small amount of acrolein polymer that may be produced in the rectification section from clogging the tower If a small amount of polymer is generated, it is easy to remove, and the height of the overflow weir is 10mm. During the implementation process, the pressure drop of the whole tower is 5kPa, the operating temperature at the bottom of the tower is 60°C, and the mass content of acrolein in the 3-hydroxypropionaldehyde aqueous solution of the tower bottom material after removing acrolein is 0.5%, which fully meets the requirement...

Embodiment 2

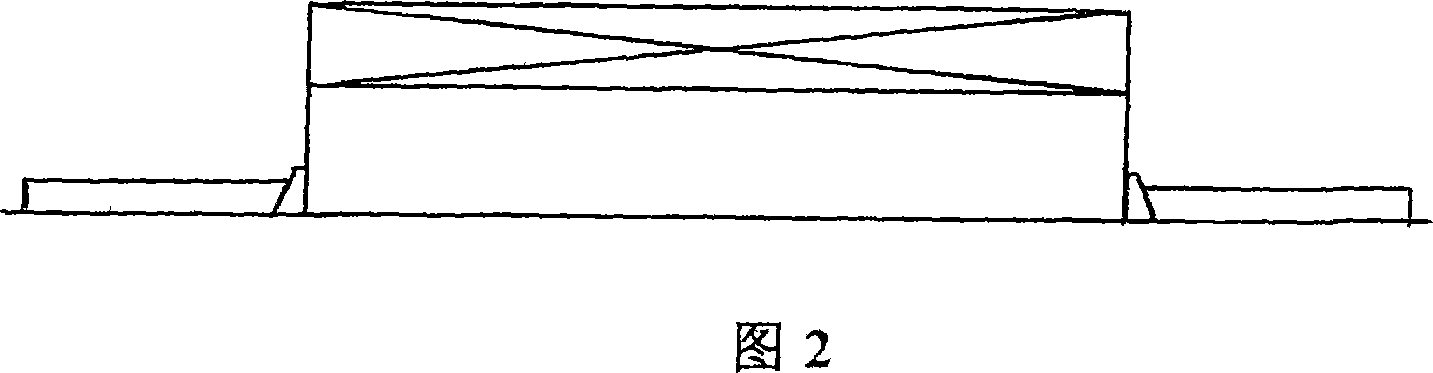

[0021]The 3-hydroxy propionaldehyde aqueous solution containing 4.5% (mass) of acrolein is continuously entered into the acrolein separation tower, and the material inlet [6] in the tower is fed. The tower height is 6000 mm, and the tower diameter is 800 mm. Corrugated ceramic structured packing with a porosity of 75%, the five vertical sieve trays [3] in the upper part [2] of the rectifying section in Example 1 are replaced with co-current injection packed trays [5], and the remaining five vertical sieve trays are [3] remain unchanged, and open holes in the upper part of the mass transfer unit to further reduce the pressure drop of the device. At the same time, in order to enhance the effect of gas-liquid mass transfer, the height of the overflow weir is increased to 15mm. During the implementation process, the mass content of acrolein in the 3-hydroxypropionaldehyde material at the bottom of the tower is controlled at 0.4%, the pressure drop of the whole tower is kept at abo...

Embodiment 3

[0023] The 3-hydroxy propionaldehyde aqueous solution containing 4.5% (mass) of acrolein is continuously entered into the acrolein separation tower, and the material inlet [6] in the tower is fed. The tower height is 6000 mm, and the tower diameter is 800 mm. For the corrugated ceramic structured packing with a porosity of 75%, the 8 new vertical sieve trays [3] in the upper part [2] of the rectification section in Example 1 are replaced with co-current injection packed trays [5], and the remaining 2 vertical sieve trays are The plate [3] remains unchanged and is perforated in the upper part of the mass transfer unit to further reduce the pressure drop of the unit. At the same time, in order to enhance the effect of gas-liquid mass transfer, the height of the overflow weir is increased to 15mm. During the implementation process, the mass content of acrolein in the 3-hydroxypropionaldehyde material at the bottom of the tower is controlled at 0.3%, the pressure drop of the whole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com