Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Improve boarding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

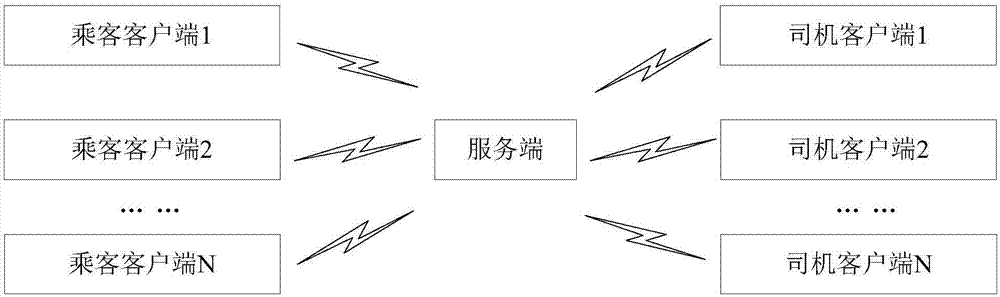

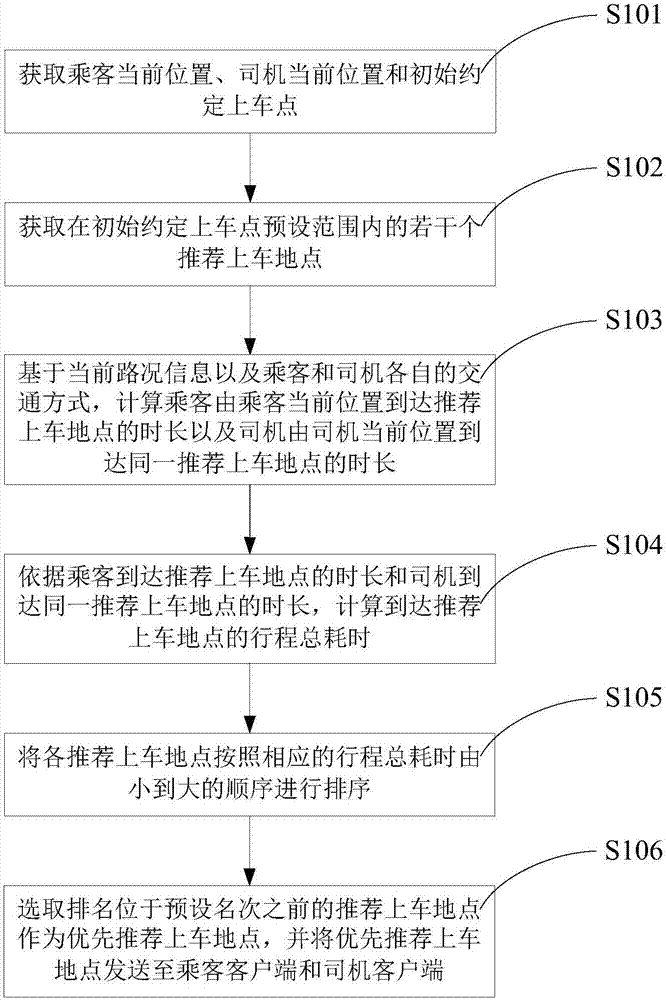

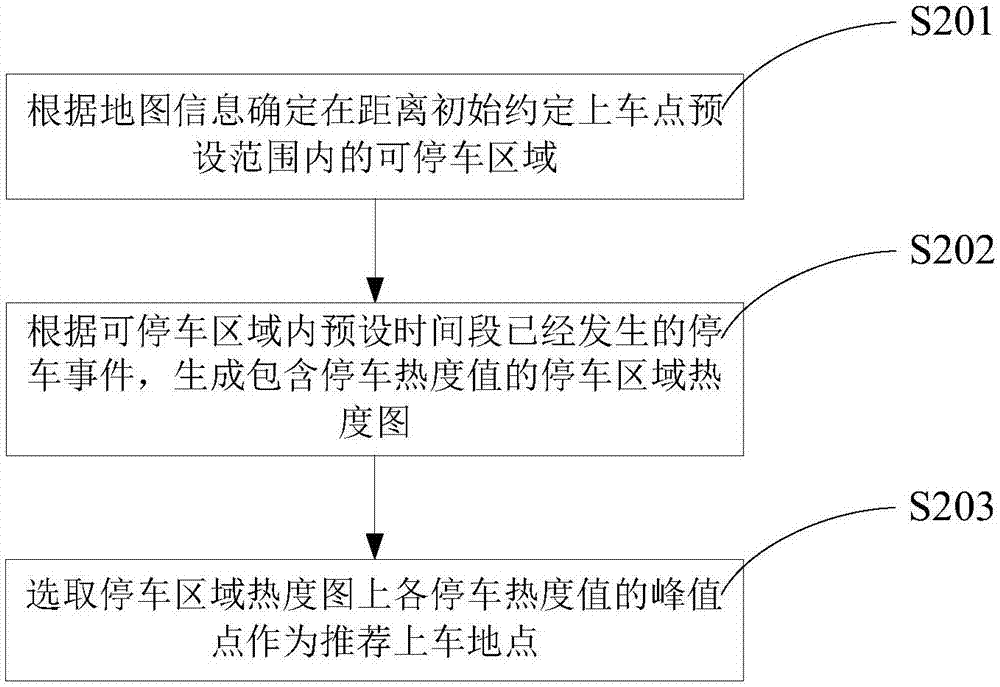

Method and device for recommending boarding locations

ActiveCN107403560AAvoid difficultiesReduce waiting timeRoad vehicles traffic controlSimulationRoad condition

The present invention discloses a method and device for recommending boarding locations. The method includes the following steps that: the current position of a passenger, the current position of a driver and an initial agreed boarding point are obtained; a plurality of recommended boarding locations within the preset range of the initial agreed boarding point are obtained; time for the passenger to arrive at each recommended boarding location and time for the driver to arrive at the same recommended boarding location are calculated according to current traffic information and the respective modes of transportation of the passenger and driver; total travel time for arriving at each recommended boarding location is calculated accord to the time for the passenger and the driver to arrive at the same recommended boarding location; the recommended boarding locations are sequined according to the small-to-large order of the corresponding total travel time; recommended boarding locations which rank before a preset place are selected as preferred recommended boarding locations; and the preferred recommended boarding locations are sent to a passenger client and a driver client. With the method and device adopted, when the passenger and driver need to change an agreed boarding location, they can select the preferred recommended boarding locations on the corresponding clients.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

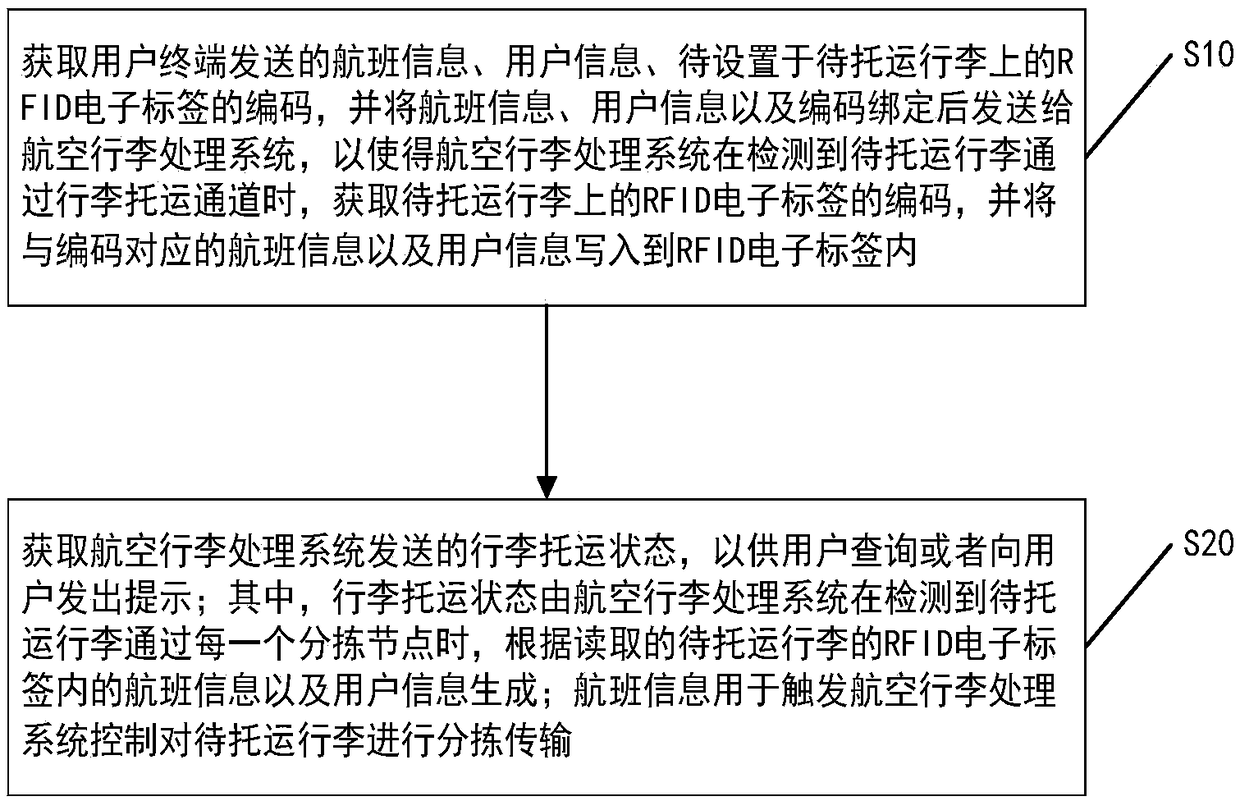

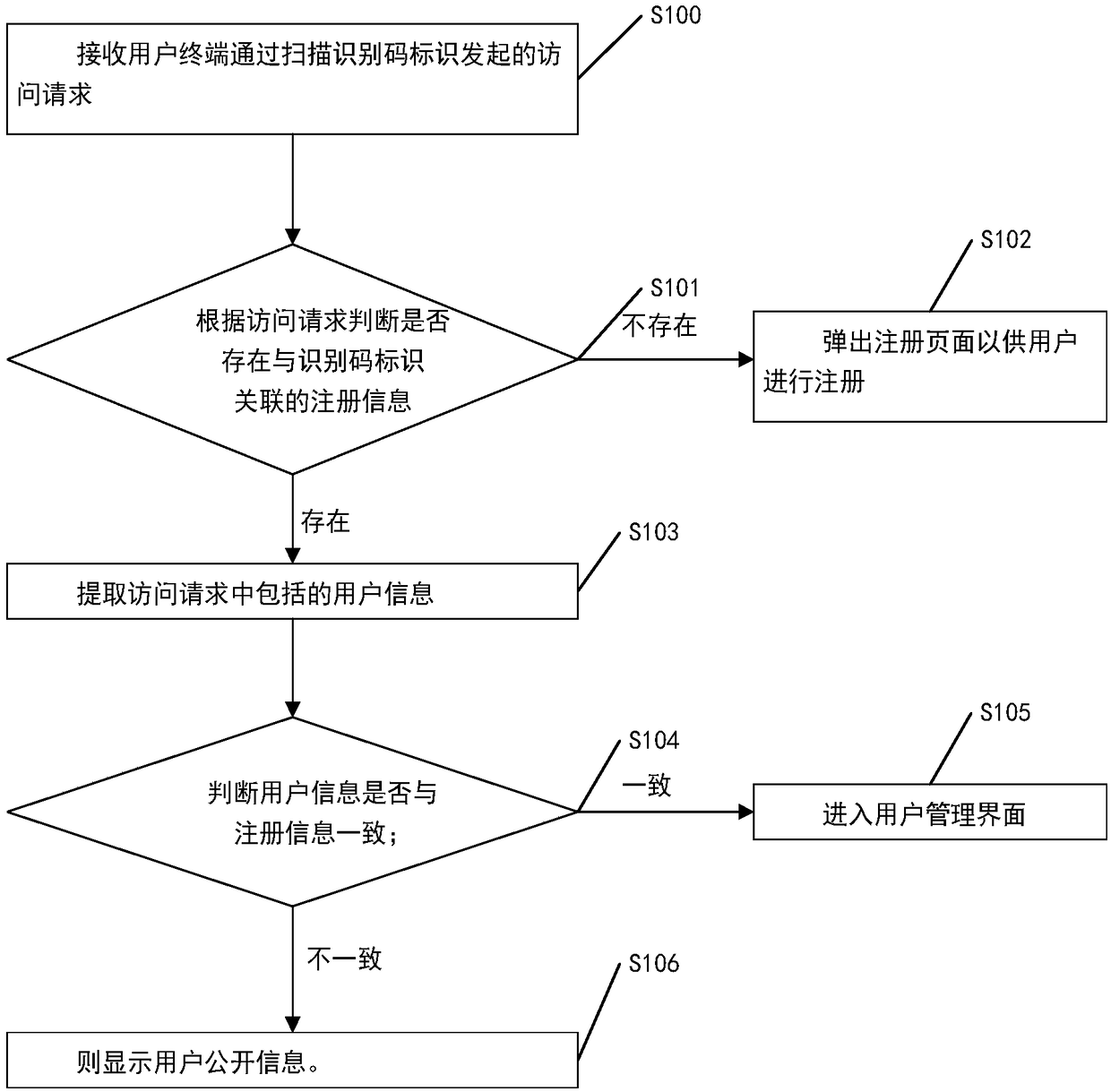

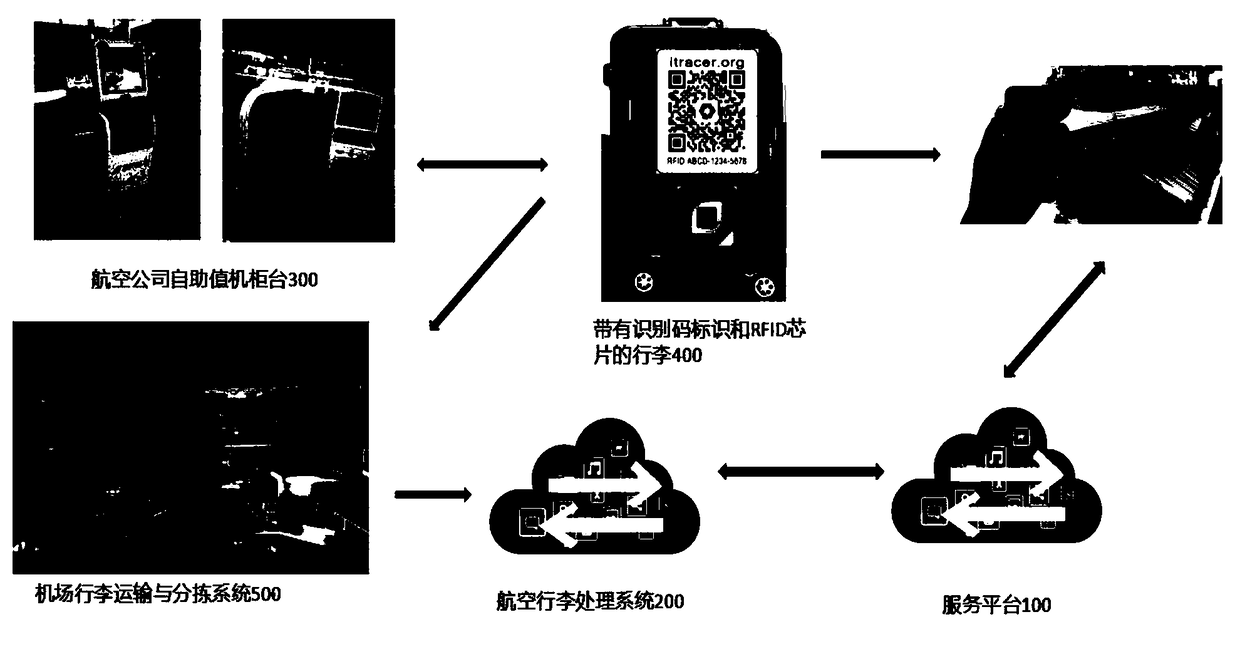

Baggage check method, device and system, service device and storage medium

ActiveCN109034289AImprove boarding efficiencyLow costCo-operative working arrangementsAviationComputer terminal

The invention relates to a baggage check method, device and system, a service device and a storage medium, the method comprising: obtaining flight information sent by a user terminal, user informationand codes of an RFID electronic tag arranged on a luggage to be checked, and binding the flight information, user information and codes and sending the codes to an aviation luggage handling system, wherein the air luggage handling system obtains the code of the RFID electronic tag on the luggage to be checked when detecting that the luggage to be checked passes through the luggage checking passage, and writes the flight information and user information corresponding to the code into the RFID electronic tag; acquiring the checked baggage status sent by the airline baggage handling system for user inquiry or prompting, wherein the air baggage handling system, when detecting that the baggage to be checked passes through each sorting node, controls the sorting and transmission of the baggageto be checked according to the flight information in the read RFID electronic tag of the baggage to be checked, and generates a checked state corresponding to the baggage to be checked,

Owner:林煊煊 +1

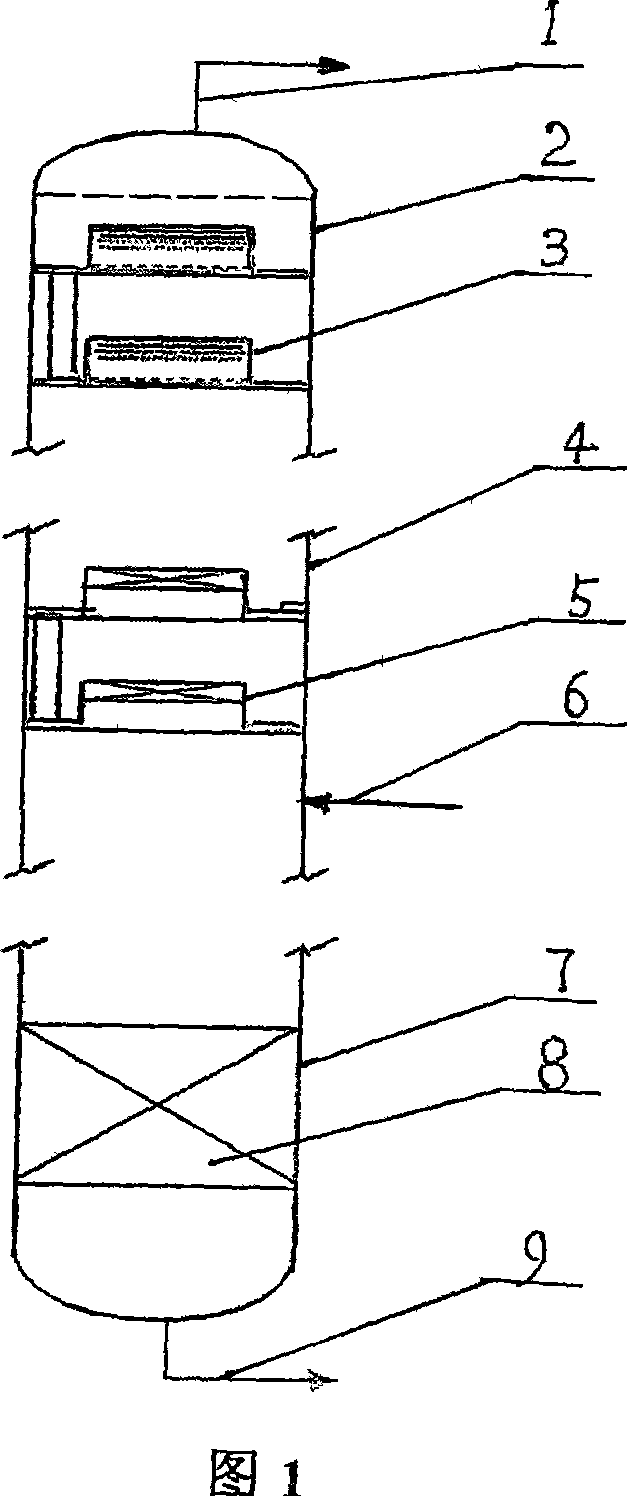

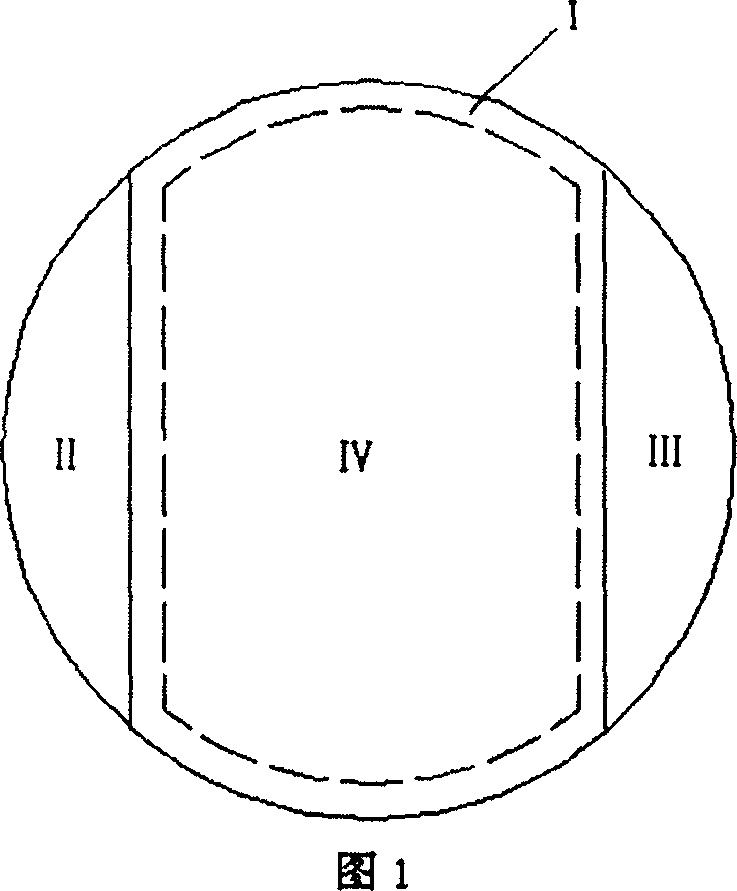

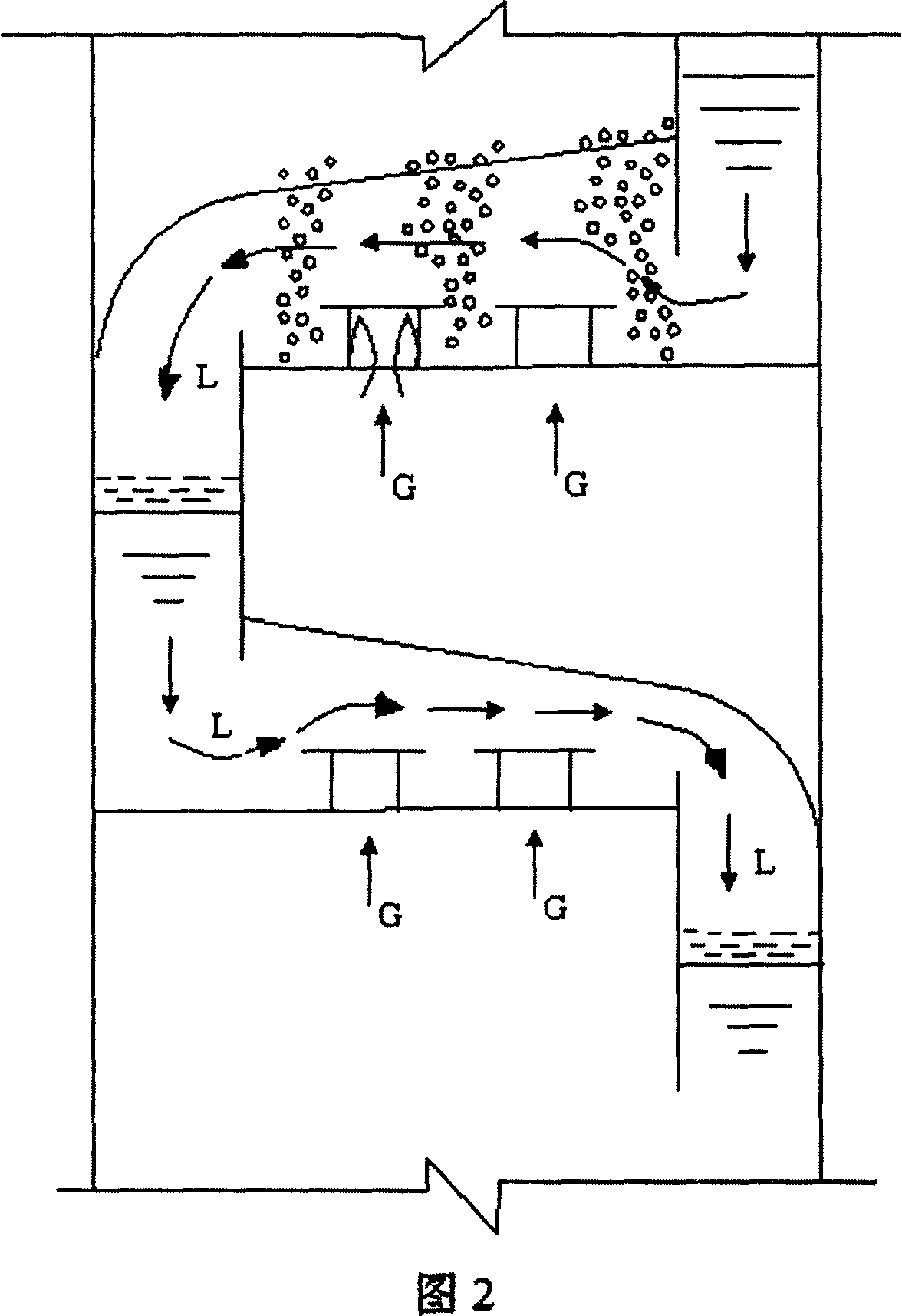

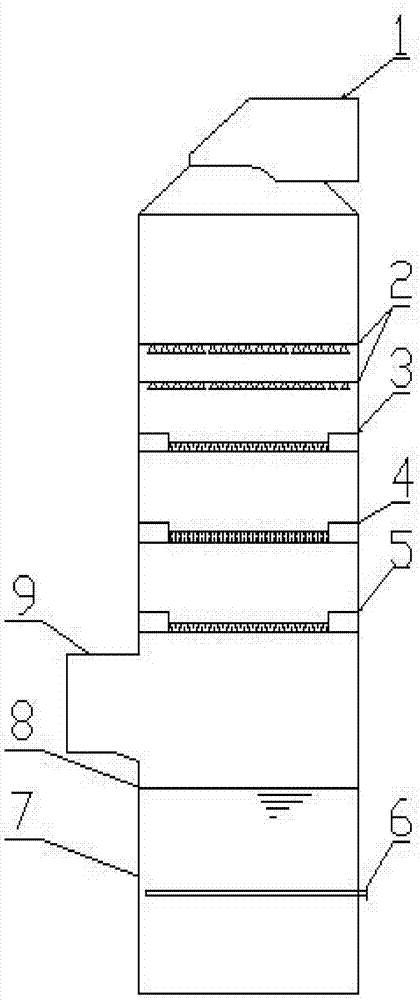

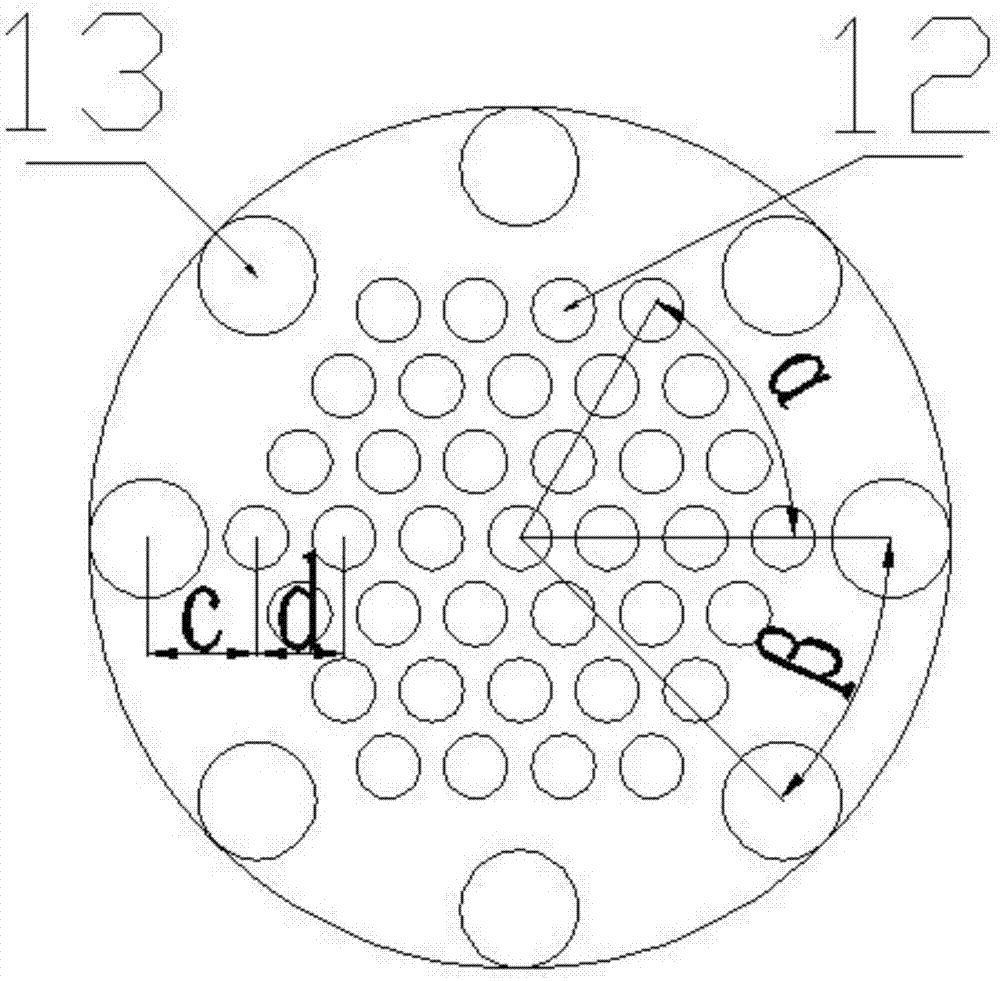

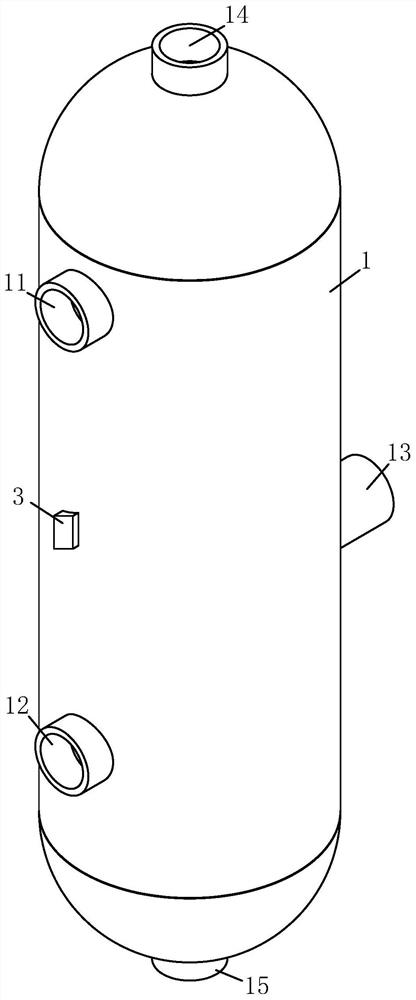

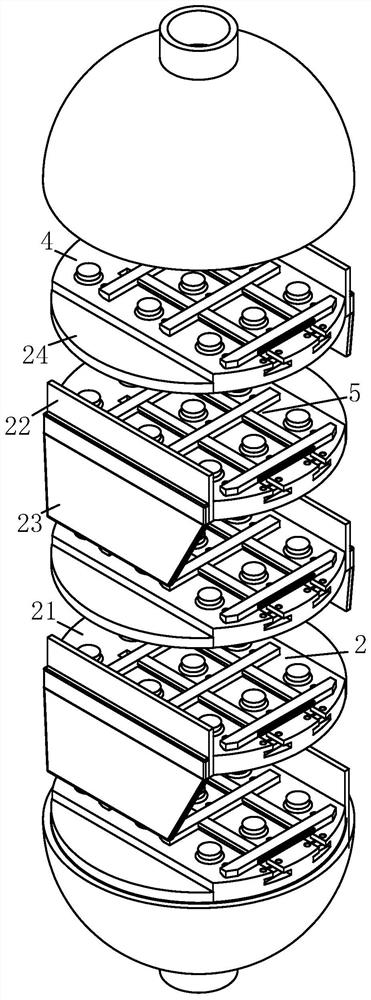

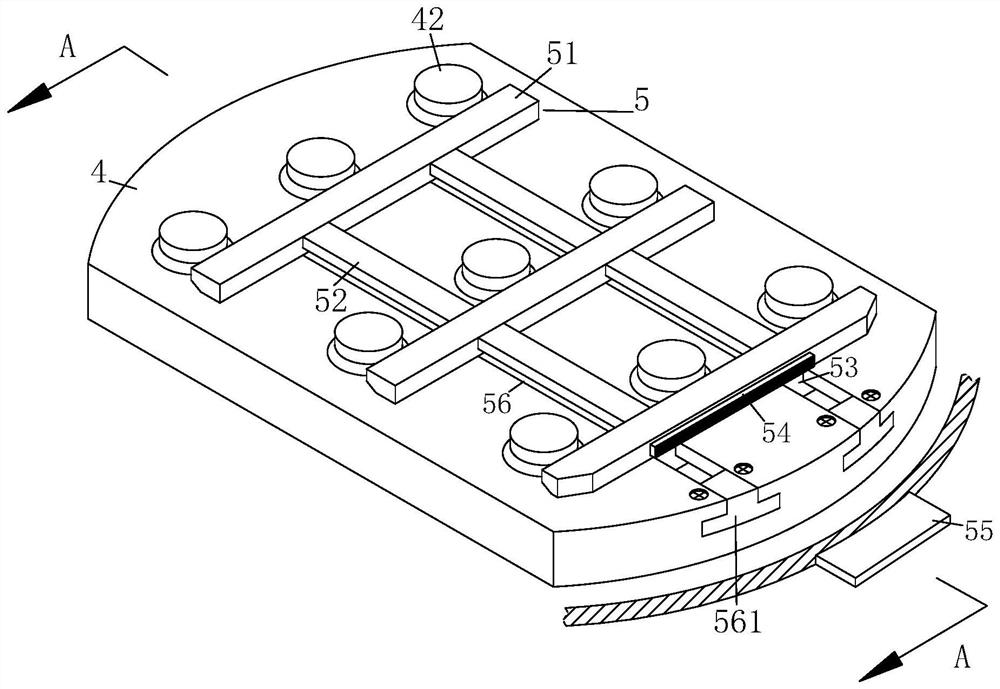

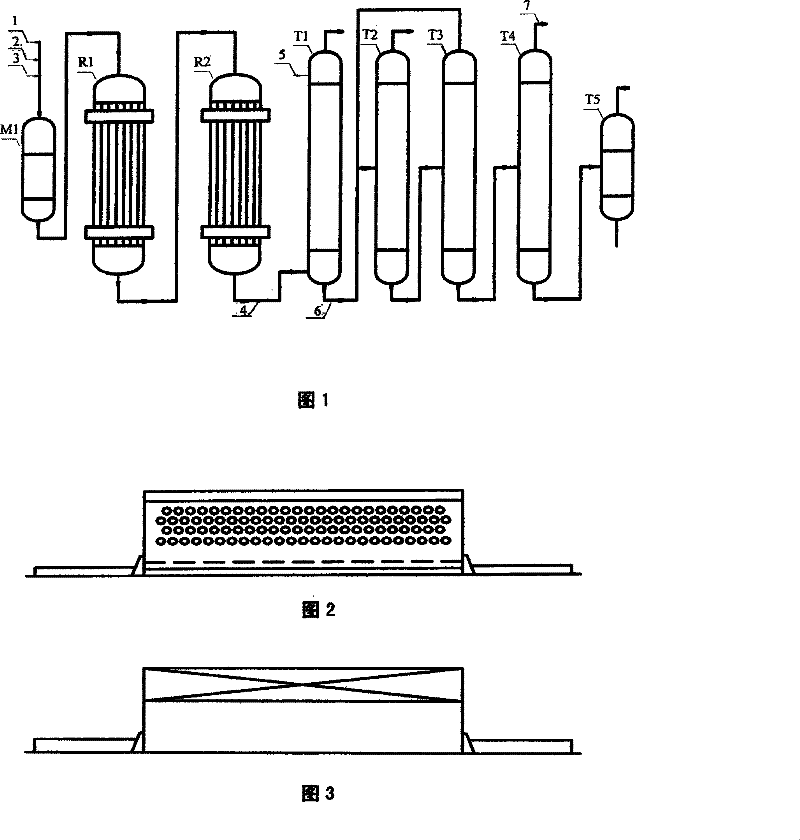

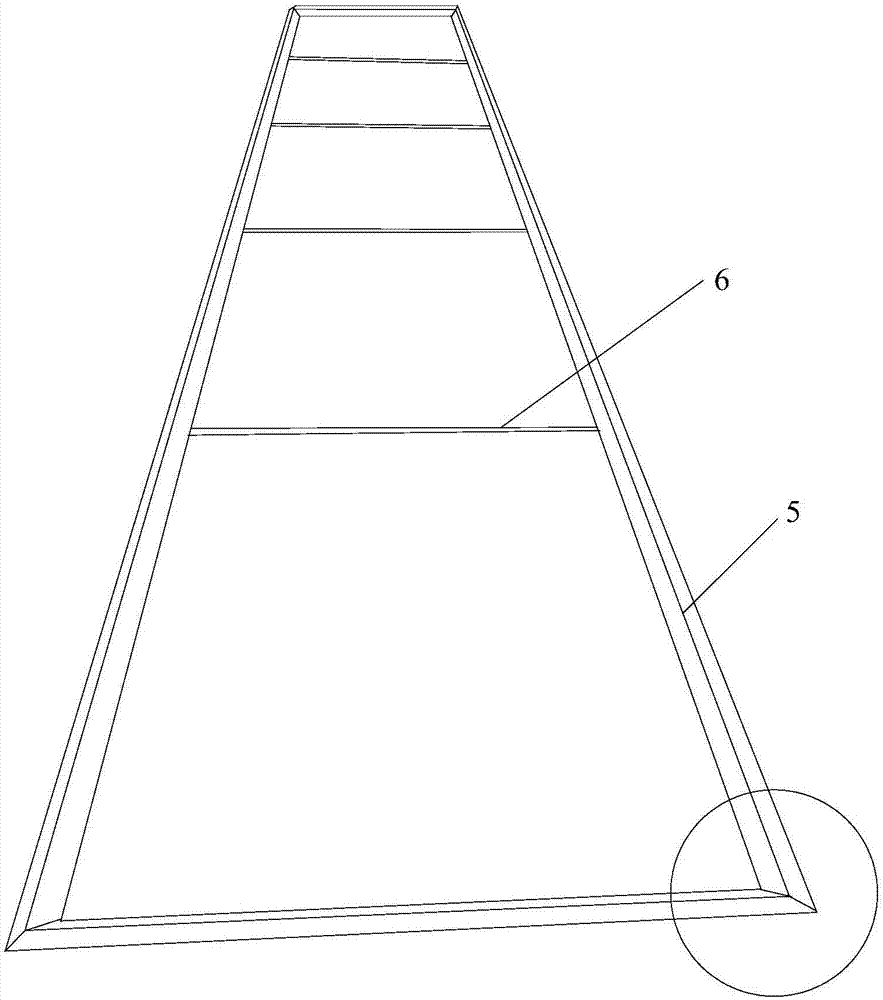

Fractionating tower for separating acrylic aldehyde from 3-hydroxypropionaldehyde solution

ActiveCN101033180AEasy to cleanSpeed up contactCarbonyl compound separation/purificationEngineeringTower

This invention provides a rectifying tower for separating and hydrate acrolein to prepare non-reacted acrolein in a 3-lactic aldehyde reacted product, the top of the tower applies a new vertical seeve plate and the lower part applies a parallel flow jet filling tower plate and the rectifying section applies structured packing, which can increase the separation ability of towers to reduce pressure drop of the tower and operation temperature, reduce aggregation trend and reduction and aggregation trend of 3-hydroxide propaldehyde so as to reduce the loss of acrolein in the top tower.

Owner:SHANGHAI HUAYI NEW MATERIAL

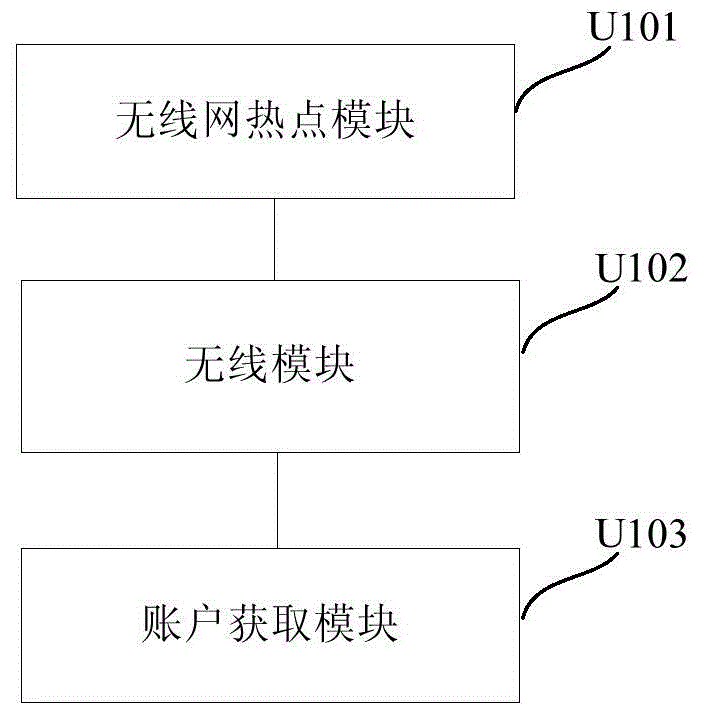

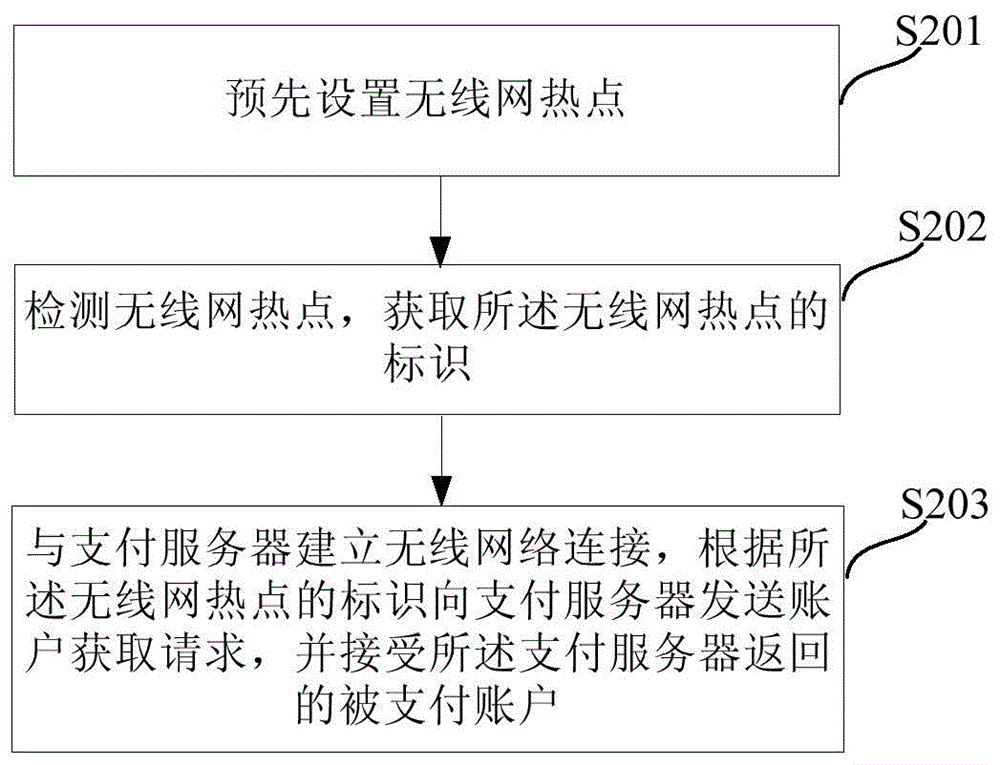

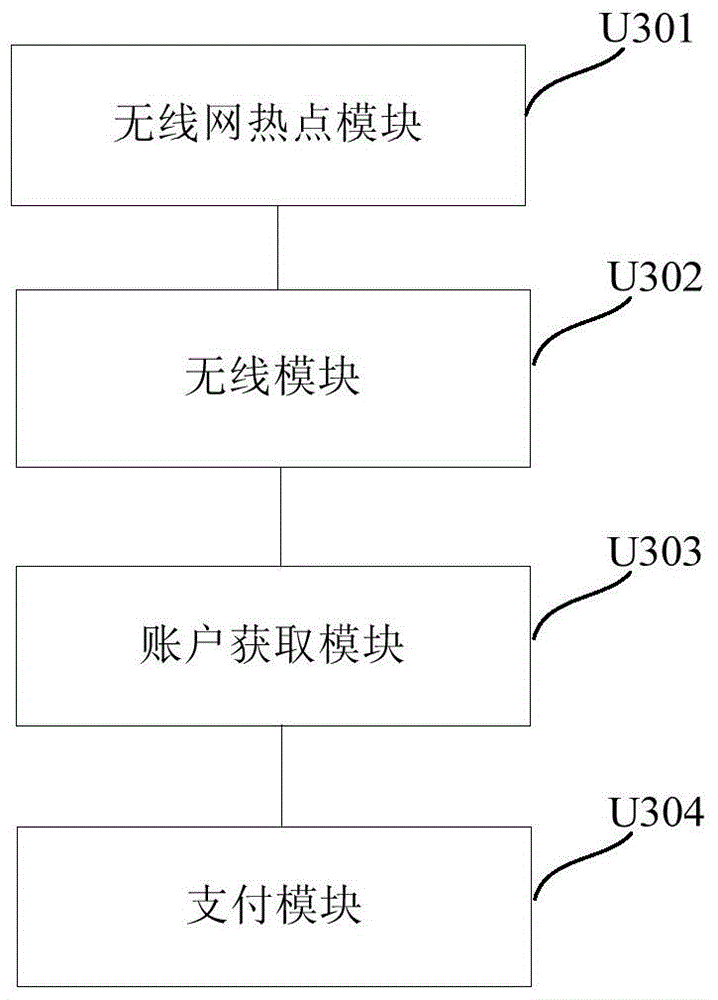

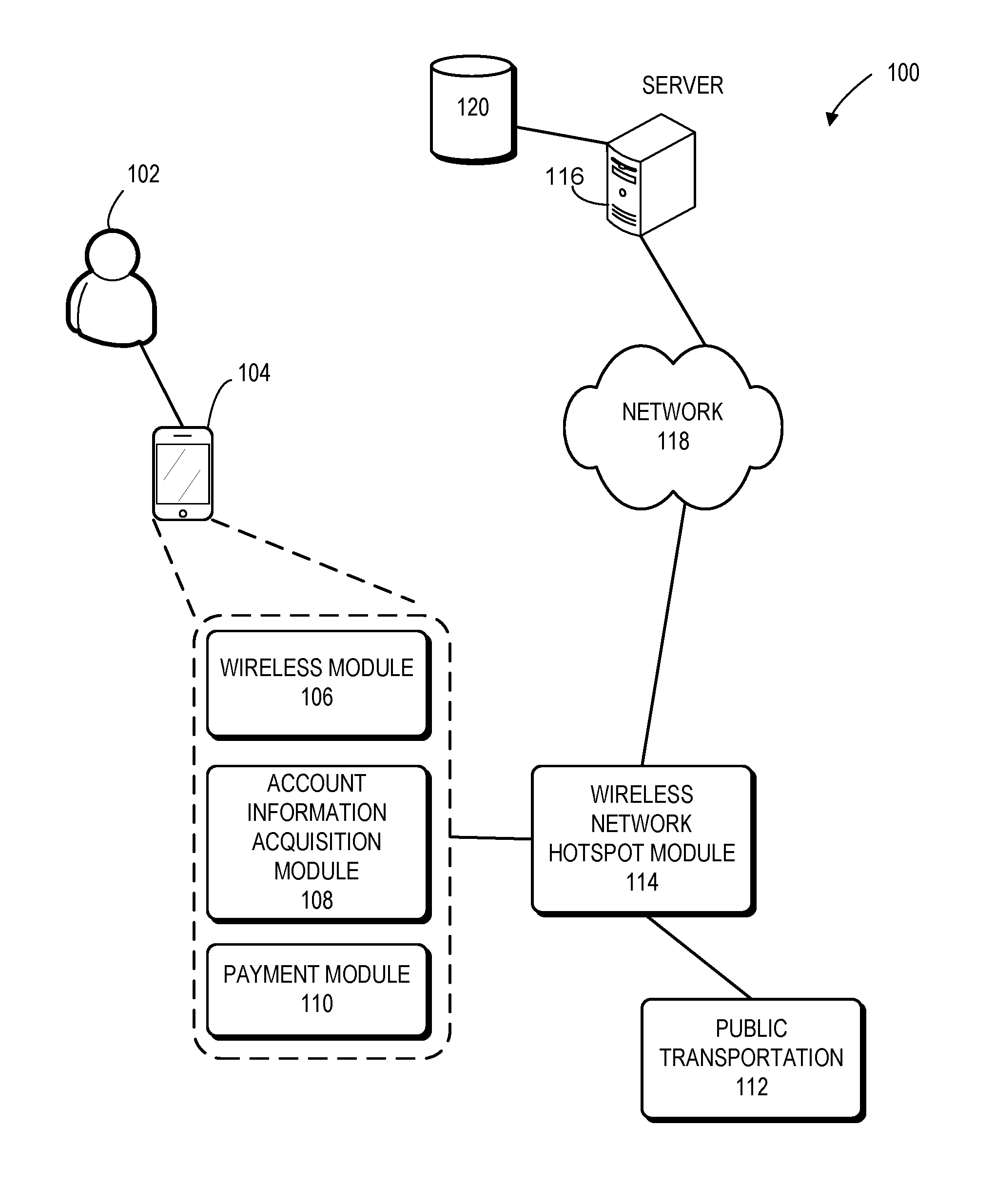

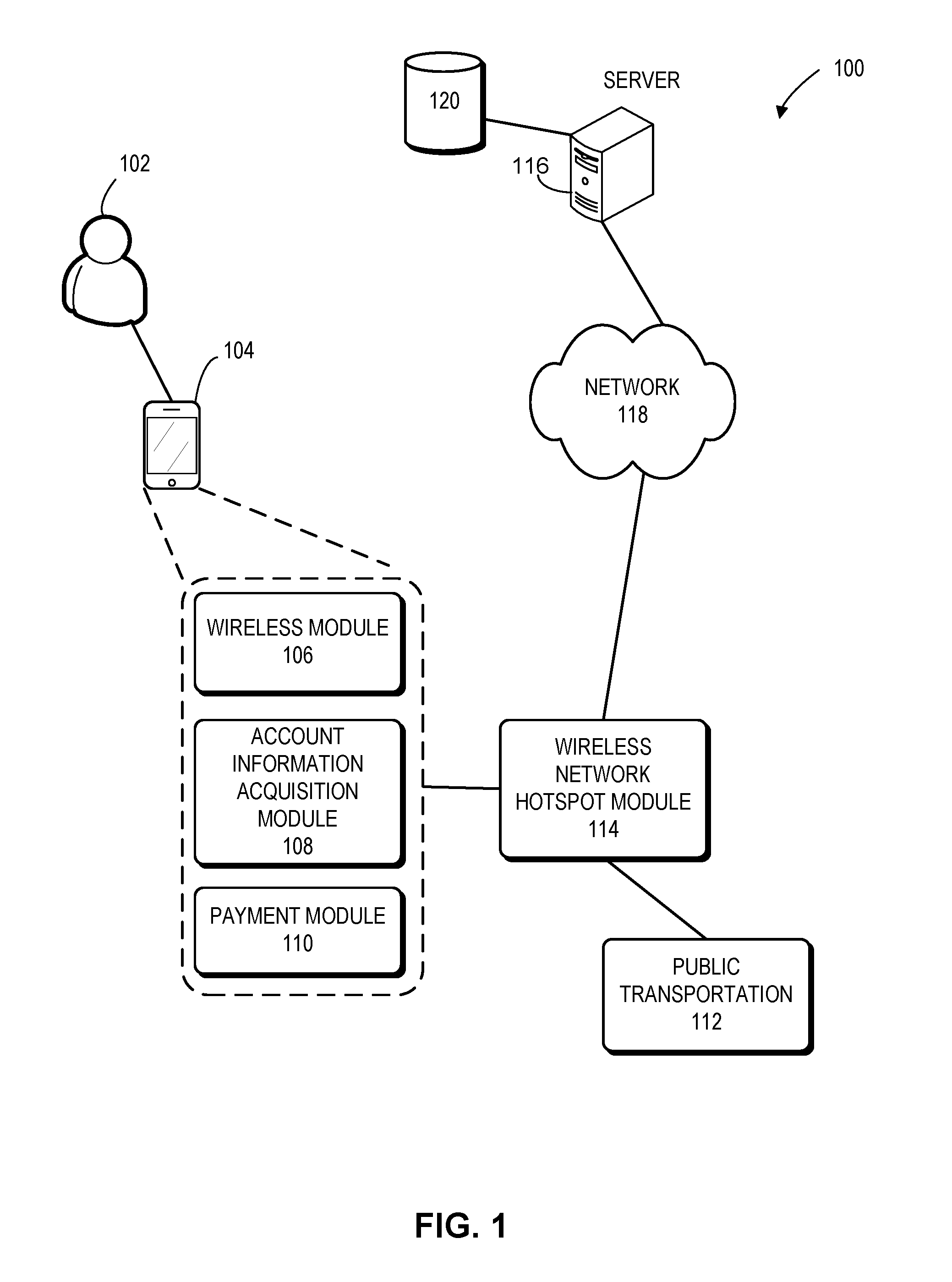

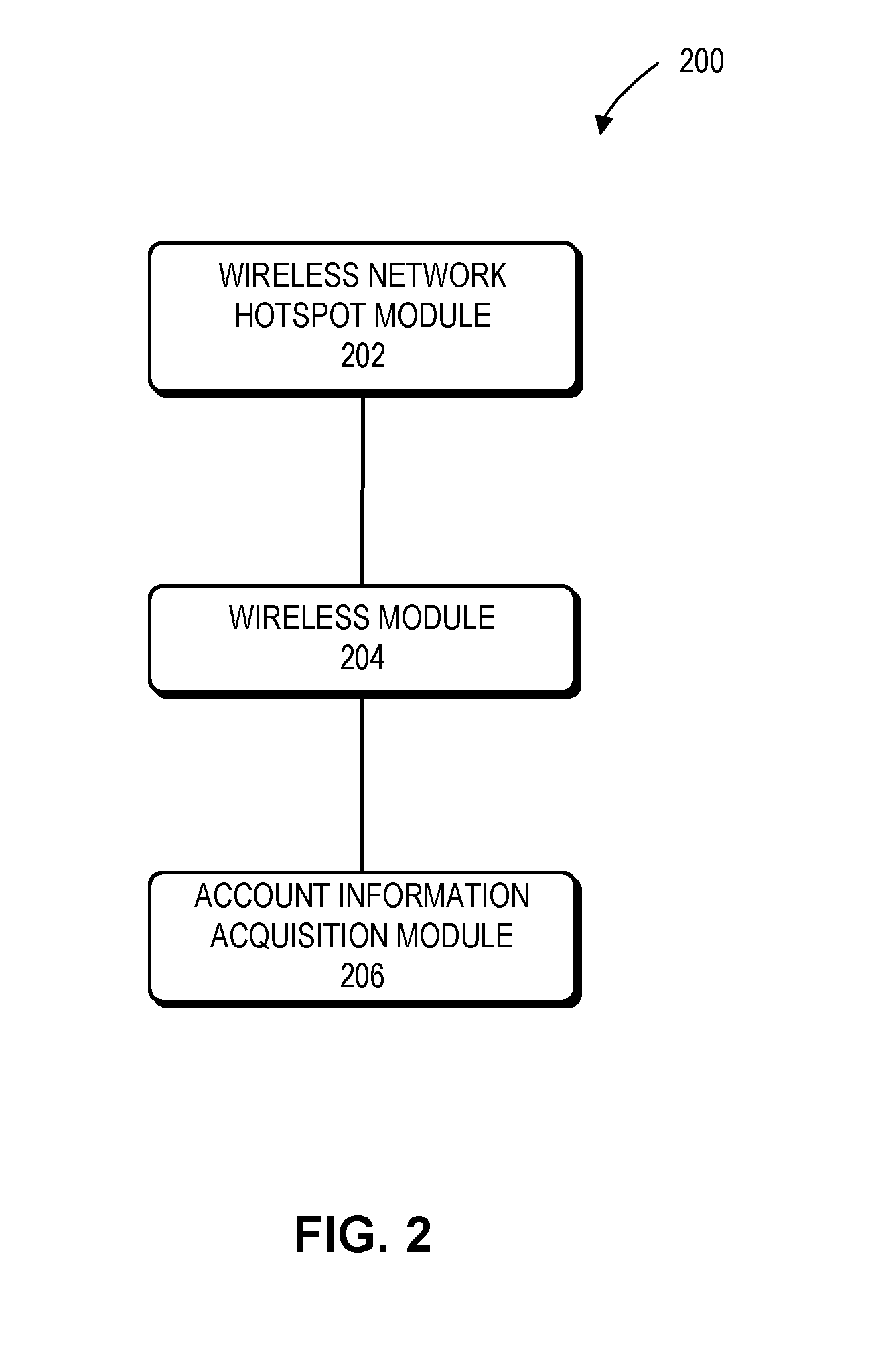

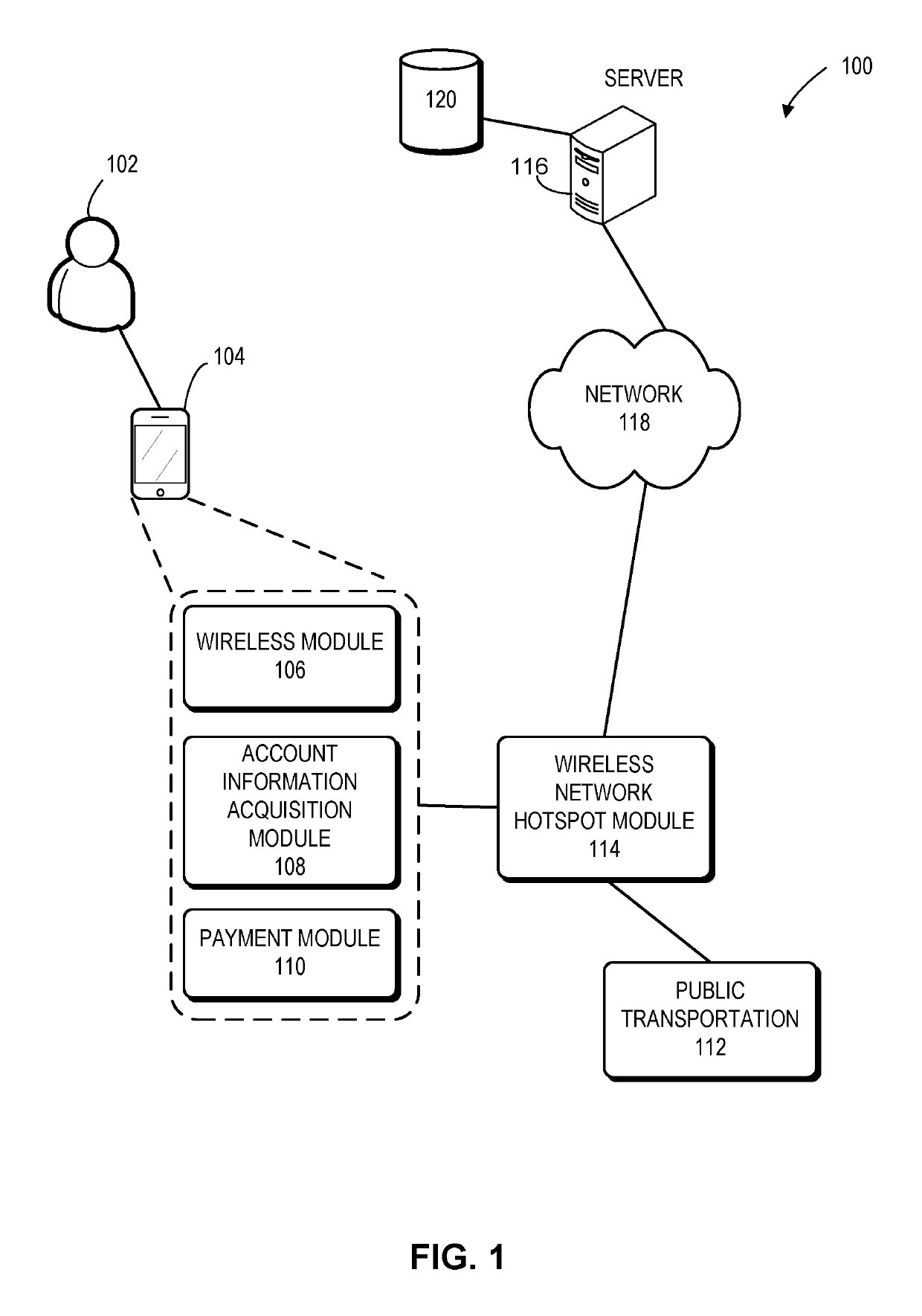

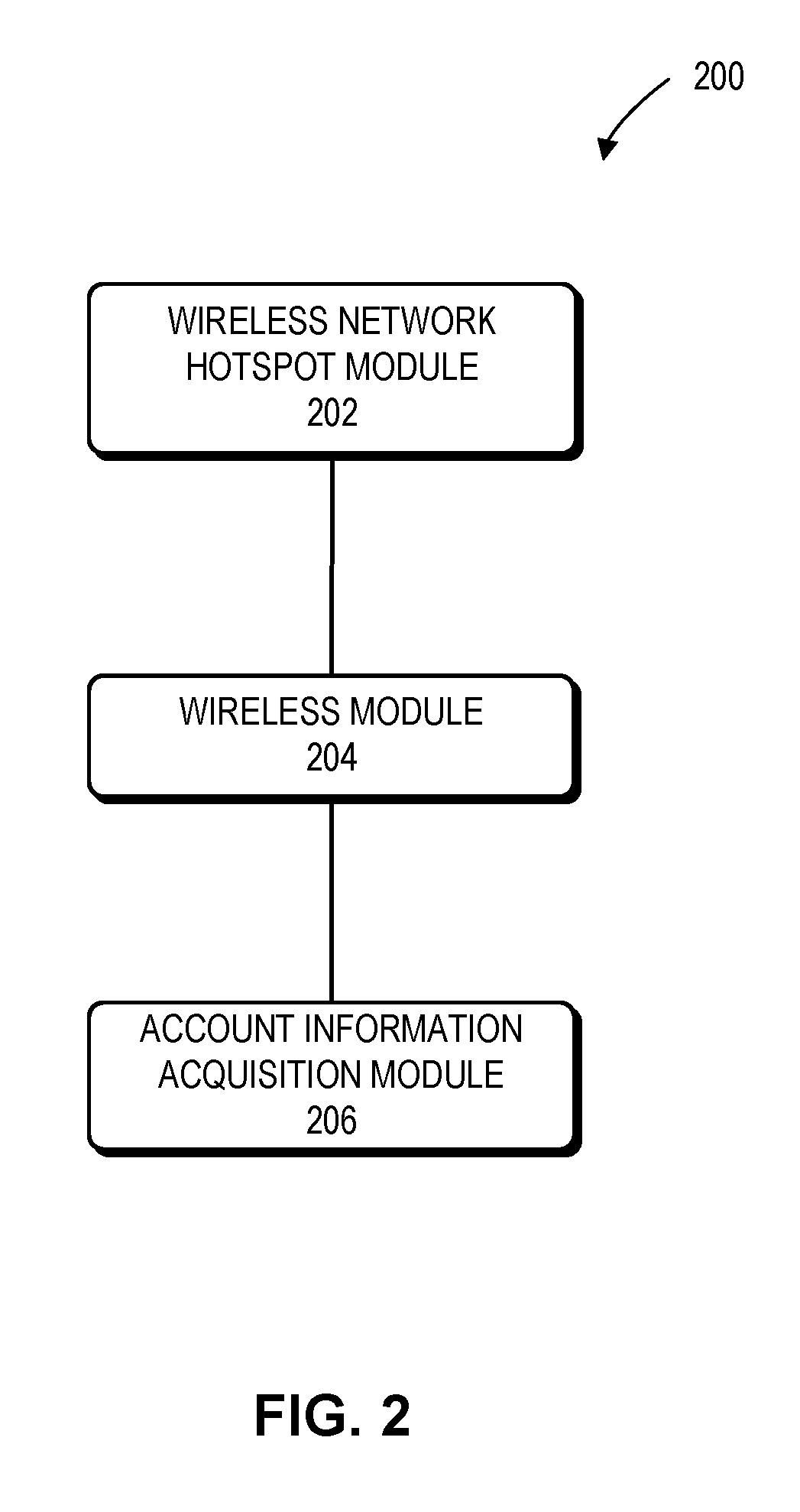

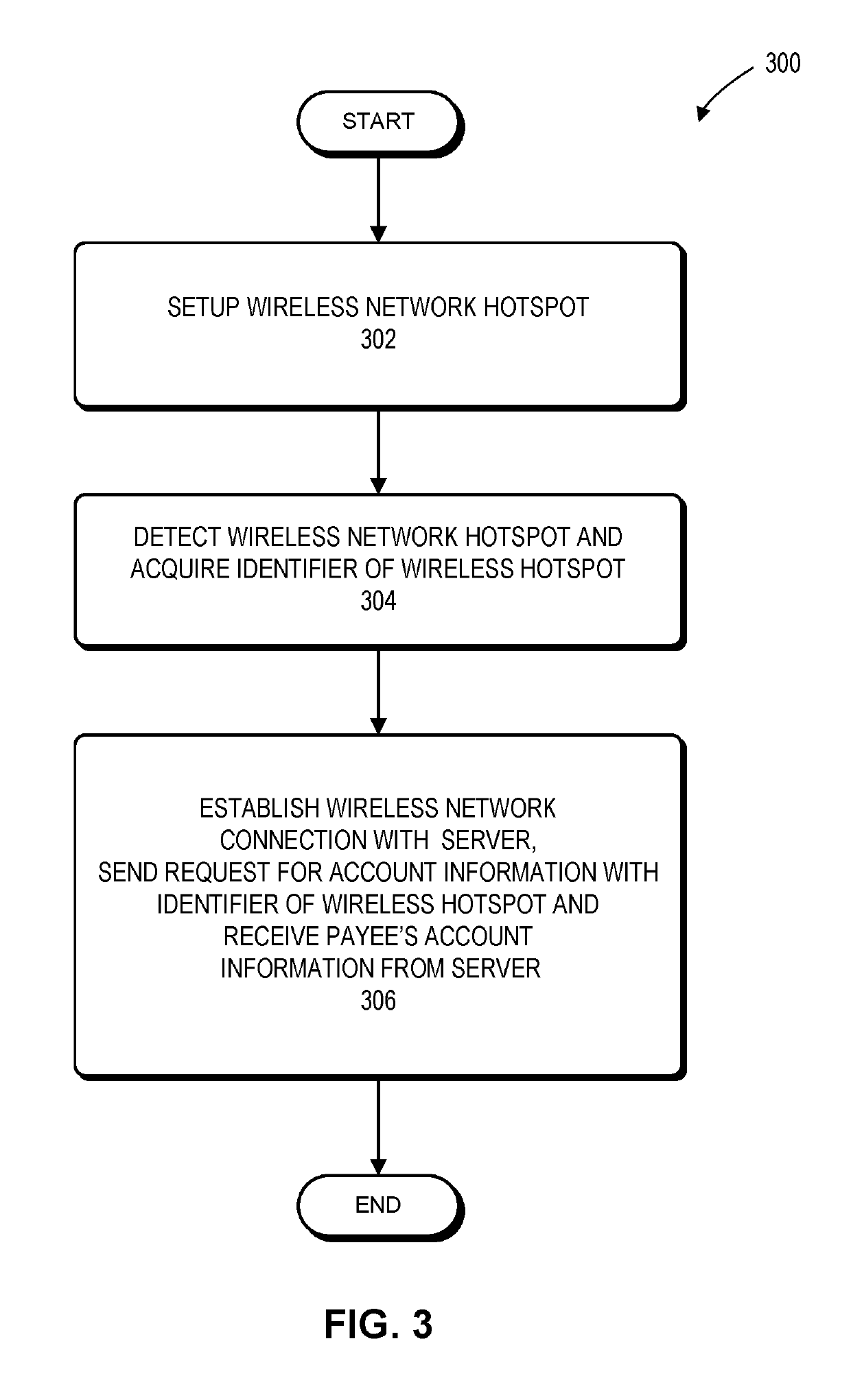

Wireless payment method, apparatus, vehicle ride fee check method and system

PendingCN105989467AGuaranteed correctnessConvenient payment processTicket-issuing apparatusPayment architectureTraffic congestionClient-side

The invention discloses a wireless payment method, a wireless payment apparatus, a vehicle ride fee check method, a vehicle ride fee check system, a payment client and a ride fee collection client. Based on a condition that a wireless network hotspot identifier is corresponding to a payee account, a wireless module obtains the wireless network hotspot identifier and transmits the wireless network hotspot identifier to an account acquisition module; the account acquisition module sends the wireless network hotspot identifier to a payment server; the payment server finds the corresponding payee account according to the received wireless network hotspot identifier and returns the payee account to the account acquisition module; and therefore, a user does not need to input the payee account by himself or herself, and the correctness of the payee account can be ensured, and a payment process is more convenient and fast. A wireless payment device is utilized to pay vehicle ride fees, passengers do not need to queue, and therefore, boarding efficiency of the passengers can be improved, and traffic congestion can be avoided; the number of passengers on vehicles can be identified, so that whether passengers who do not pay ride fees or wrongly pay the ride fees exist can be checked, and the correctness of vehicle fee collection can be ensured.

Owner:ADVANCED NEW TECH CO LTD

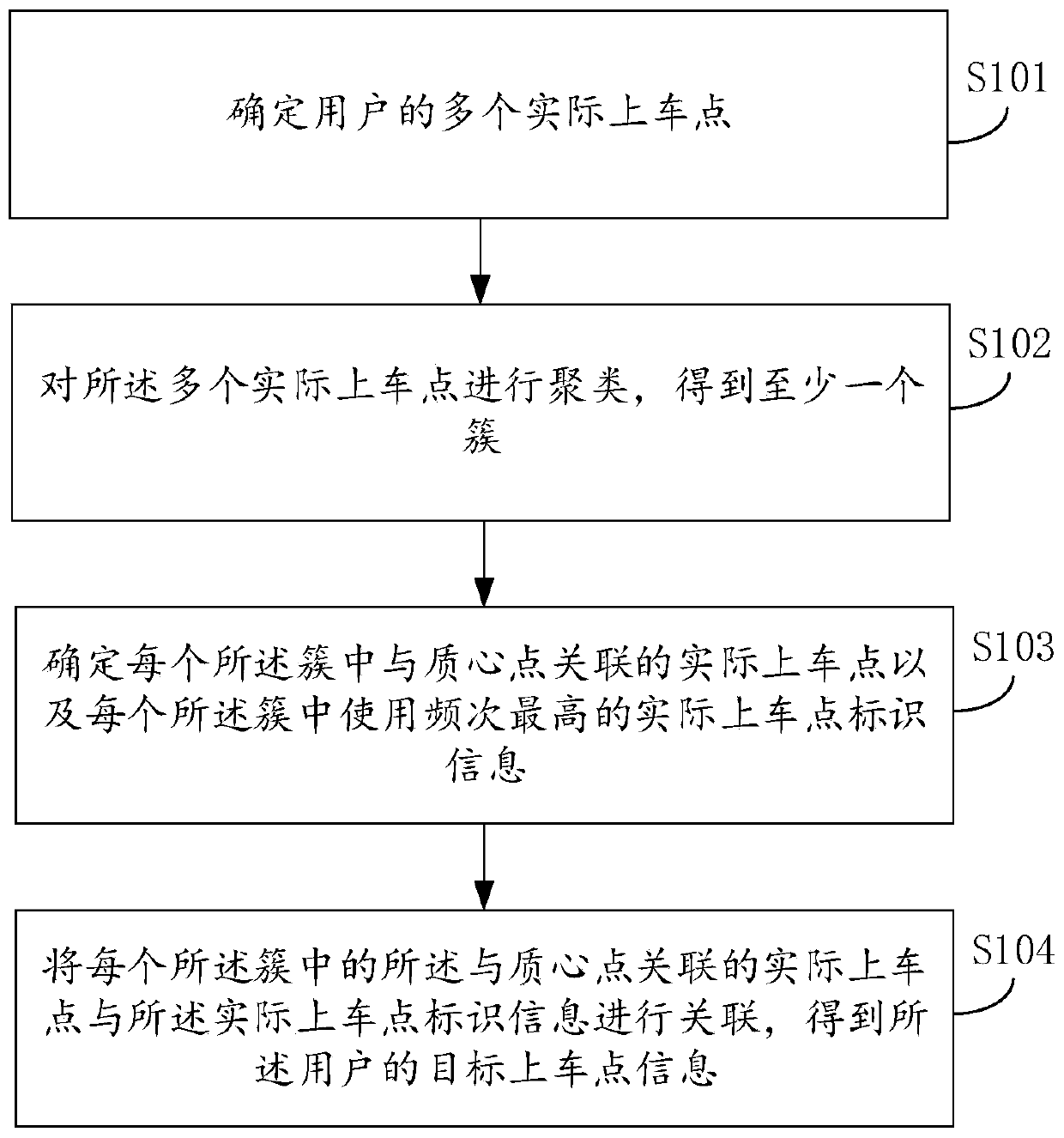

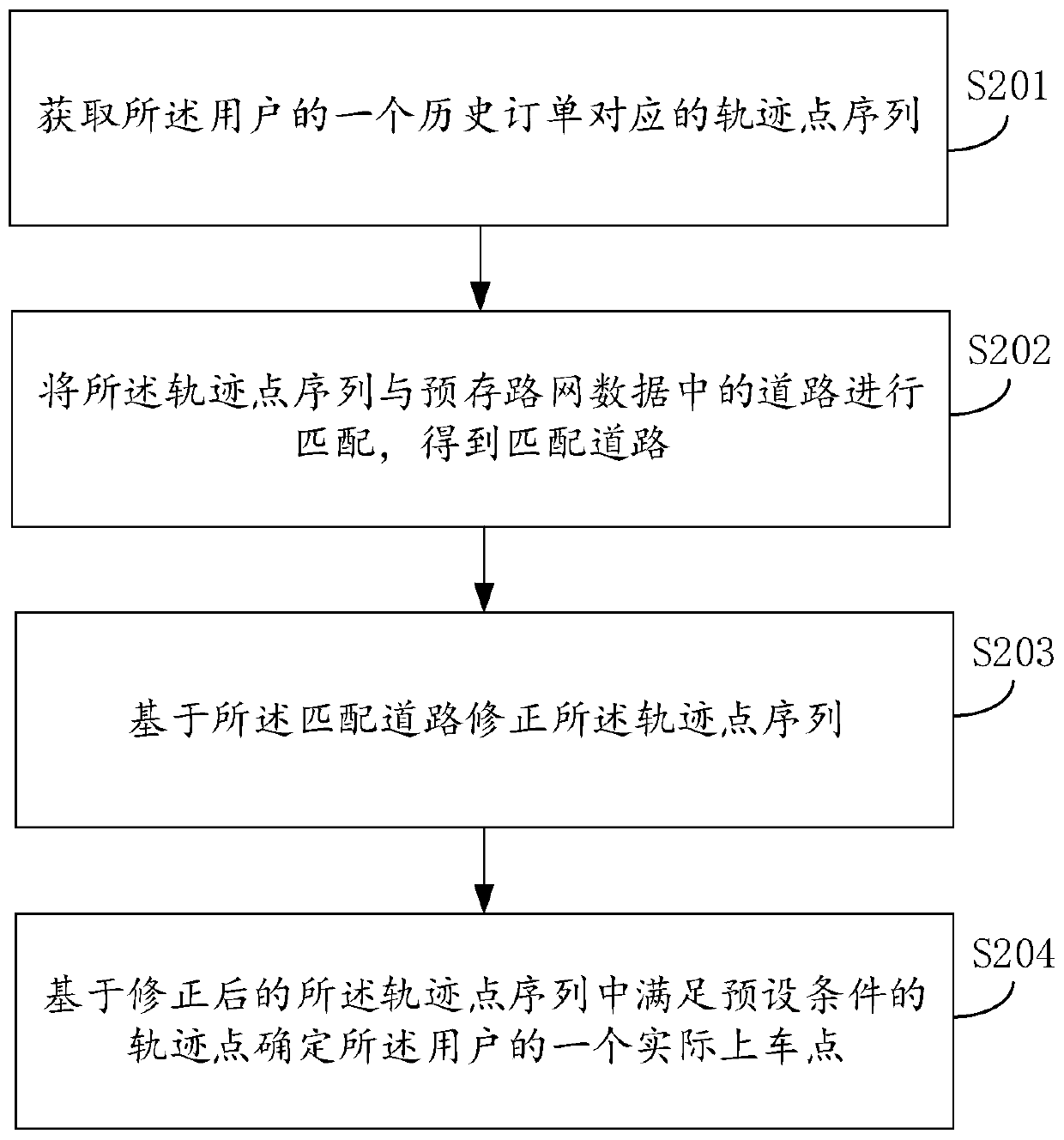

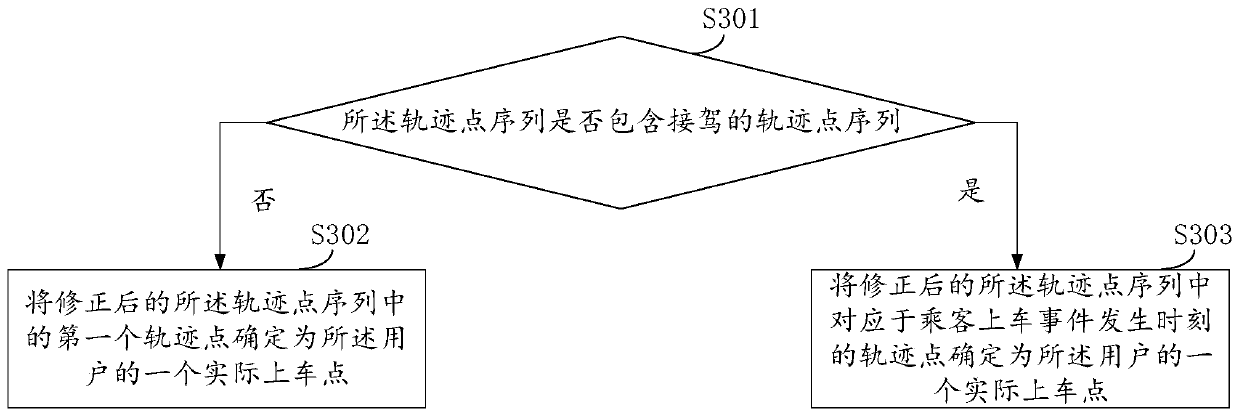

Method and device for determining boarding point information, equipment and storage medium

PendingCN110533081AMeet needsImprove physical examinationRelational databasesCharacter and pattern recognitionTime costComputer science

The invention provides a method and a device for determining boarding point information, equipment and a storage medium, and the method comprises the steps: determining a plurality of actual boardingpoints of a user; clustering the plurality of actual vehicle boarding points to obtain at least one cluster; determining an actual vehicle boarding point associated with the centroid point in each cluster and actual vehicle boarding point identification information with the highest use frequency in each cluster; and associating the actual vehicle boarding point associated with the centroid point in each cluster with the actual vehicle boarding point identification information to obtain target vehicle boarding point information of the user. According to the invention, the subsequently determined target boarding point information can meet the actual requirements of the user, the degree that the user accepts the target boarding point information is improved, the pick-up difficulty of the driver can be reduced, the pick-up time cost of the driver can be reduced, the pick-up efficiency of the driver and the boarding efficiency of passengers can be improved, and the user experience of drivers and passengers can be improved.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

Method and system for wireless payment of public transport fare

ActiveUS20160224974A1Improve boarding efficiencyImprove efficiencyTicket-issuing apparatusPayment architecturePaymentComputer network

Embodiments of the present application provide a method and system for wireless payment of transport fare. During operation, the system receives a request at a server from a mobile device for information of a payee's account, which is associated with a public transport and corresponds to a wireless network identifier of a wireless network located on the public transport. The server may determine information of the payee's account corresponding to the wireless network identifier. The server then sends the payee's account information to the mobile device. The system may then receive, from the mobile device, a payment order to make a payment to the payee's account.

Owner:ADVANCED NEW TECH CO LTD

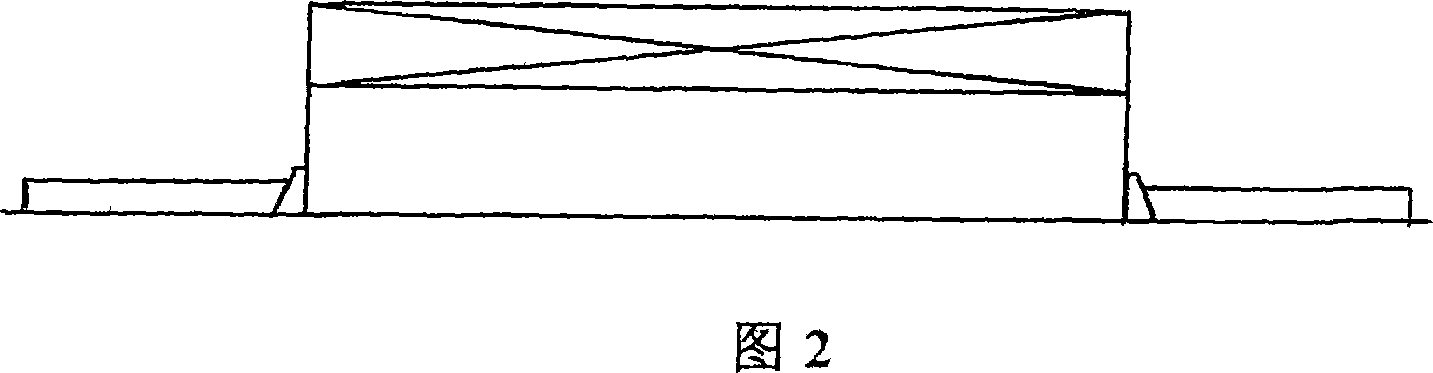

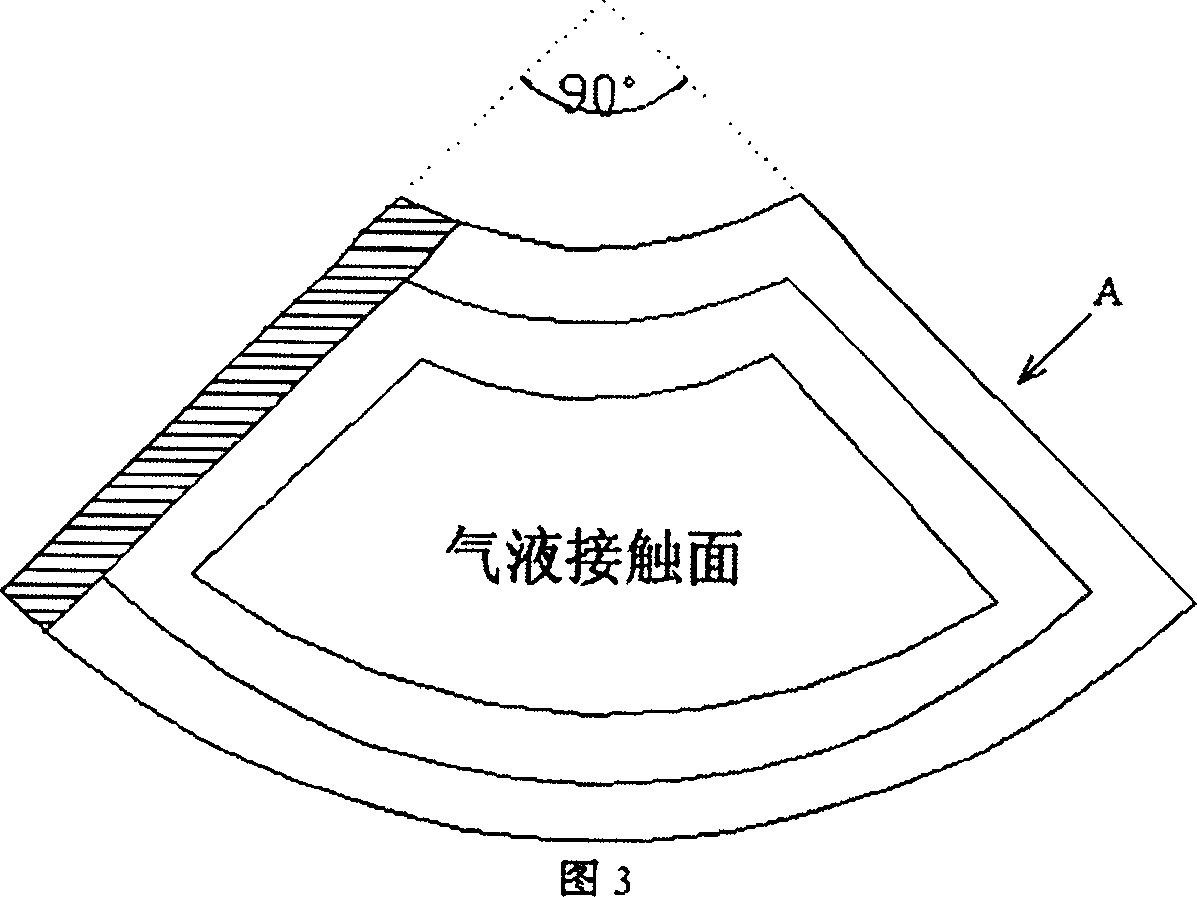

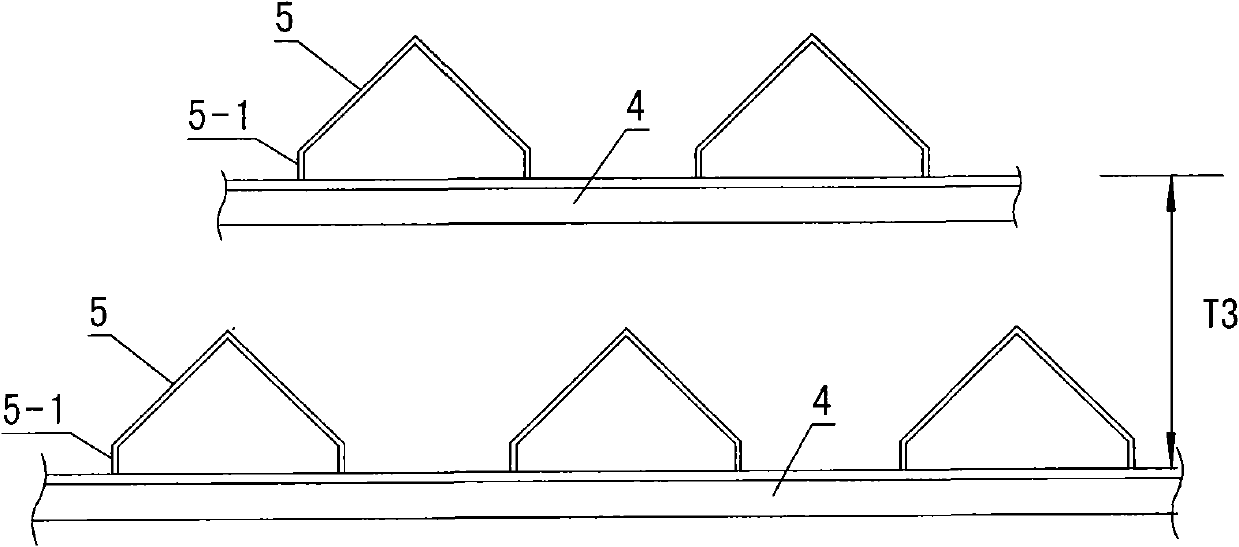

Spiral step falling distribution type separating tower column plate

InactiveCN101053699AIncrease the relative velocityMaintain uniformityDistillation separationPlate columnMass transfer

A separating tower plate in the type of helix steps down distribution, is an annular tower plate got from a whole traditional round tower plate after cutting a round of 1 / 25 to 1 / 4 of the area along the center. And then the annular tower plate is separated into n parts, wherein n is equal to 3 to 10, to get fan-shaped tower plates, which are mounted on the support pipe throughout the center of the separating tower in the type of helix steps down distribution. The total height between tower plates of a complete alternation circle is equivalent to the fixed height between plates of traditional tower. The adjacent two fan-shaped tower plates are connected by radial baffle, upper of which is higher than the former fan-shaped tower plate to form a liquid overflow weir. There are gas-liquid contacting components such as float valve, sieve pore or bubble cap and so on. The advantage of the separating tower plate in the type of helix steps down distribution of the invention resides that the utilization factor of the tower plate area is higher because whole or most liquid-falling area and liquid-accepting area are omitted, and resides that heat transfer and mass transfer between gas and liquid are more sufficiency because the liquid flows a longer way when flowing down a section tower height on the helix plate.

Owner:NANJING UNIV

Method for producing (methyl) acrylic acid

ActiveCN101456807AEasy to cleanIncreasing the thicknessCarboxylic preparation by oxidationCatalytic oxidationMethyl group

The invention provides a method for producing (methyl) acrylic acid. The method comprises: selecting at least one of C3 compounds such as propane, propylene, isopropanol, glycerin and acrolein, or at least one of C4 compounds such as isobutene, isobutene, tertiary butyl alcohol and acrylaldehyde as raw materials to carry out catalytic oxidation to prepare a gas mixture containing the (methyl)acrylic acid; absorbing the gas mixture, and separating the (methyl)acrylic acid water solution, wherein a rectifying section of a rectifying tower separating the (methyl)acrylic acid water solution adopts regular packing or parallel-current jet packing trays, or the upper part of the rectifying section adopts the regular packing and the lower part of the rectifying section adopts the parallel-current jet packing trays; and a stripping section adopts directed floating valve trays or vertical sieve trays, or the upper part of the stripping section adopts the directed floating valve trays and the lower part of the stripping section adopts the vertical sieve trays. The rectifying tower with combined tower internal structure embodies a concentrated reflection of the advantages of the regular packing, the parallel-current jet packing trays, the directed floating valve trays and / or vertical sieve trays in the same rectifying system, thereby effectively improving separating capability of the rectifying tower, lowering full-tower pressure drop and operational temperature, avoiding convergescence of the (methyl)acrylic acid at a high temperature, making the water content of tower-bottom discharged material reduced below 0.5 percent, the acetic acid content of the tower-bottom discharged material reduced below 2 percent and the (methyl)acrylic acid content of tower-top water phase reduced below 0.5 percent, further reducing unit consumption of the (methyl)acrylic acid products and improving product quality.

Owner:SHANGHAI HUAYI NEW MATERIAL

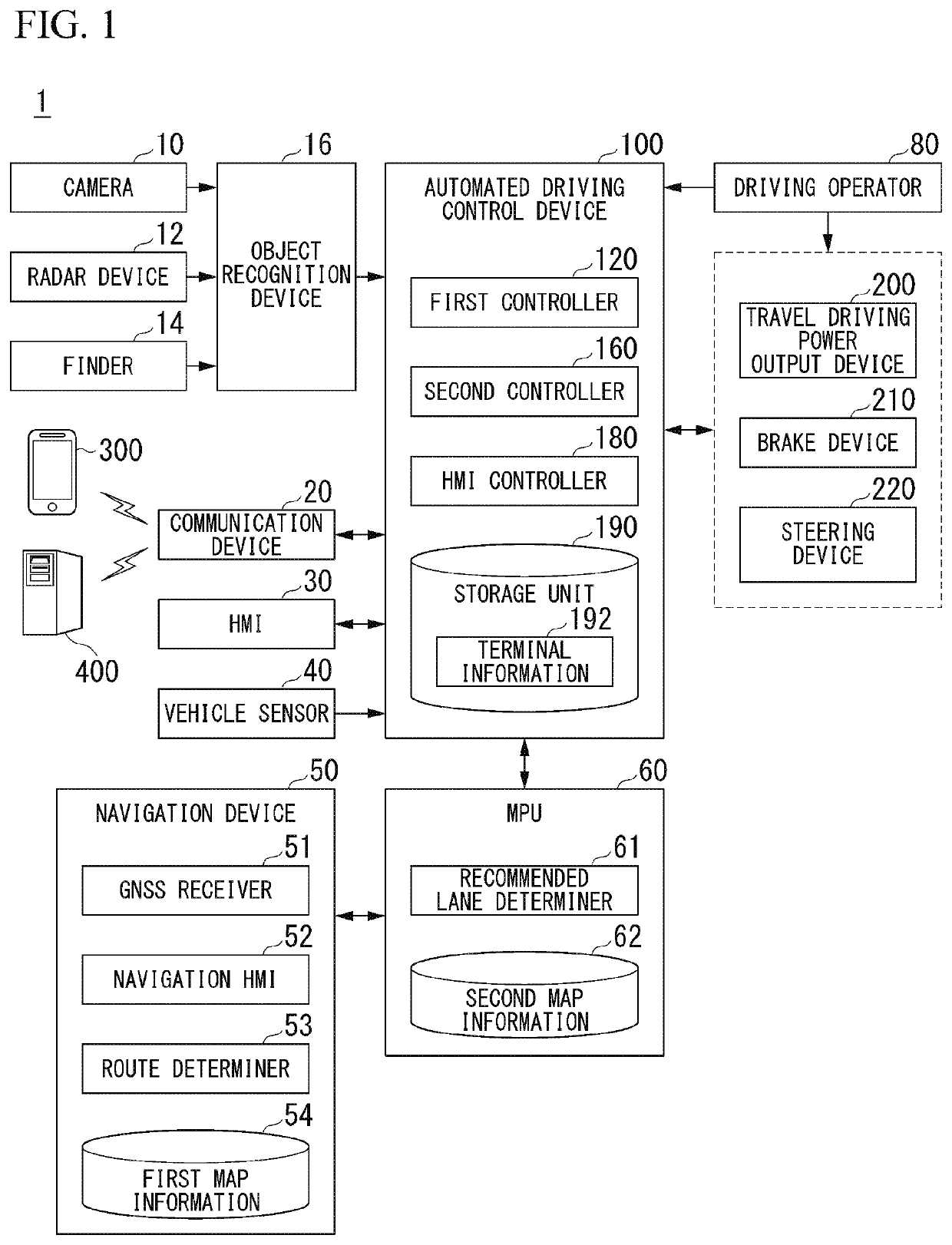

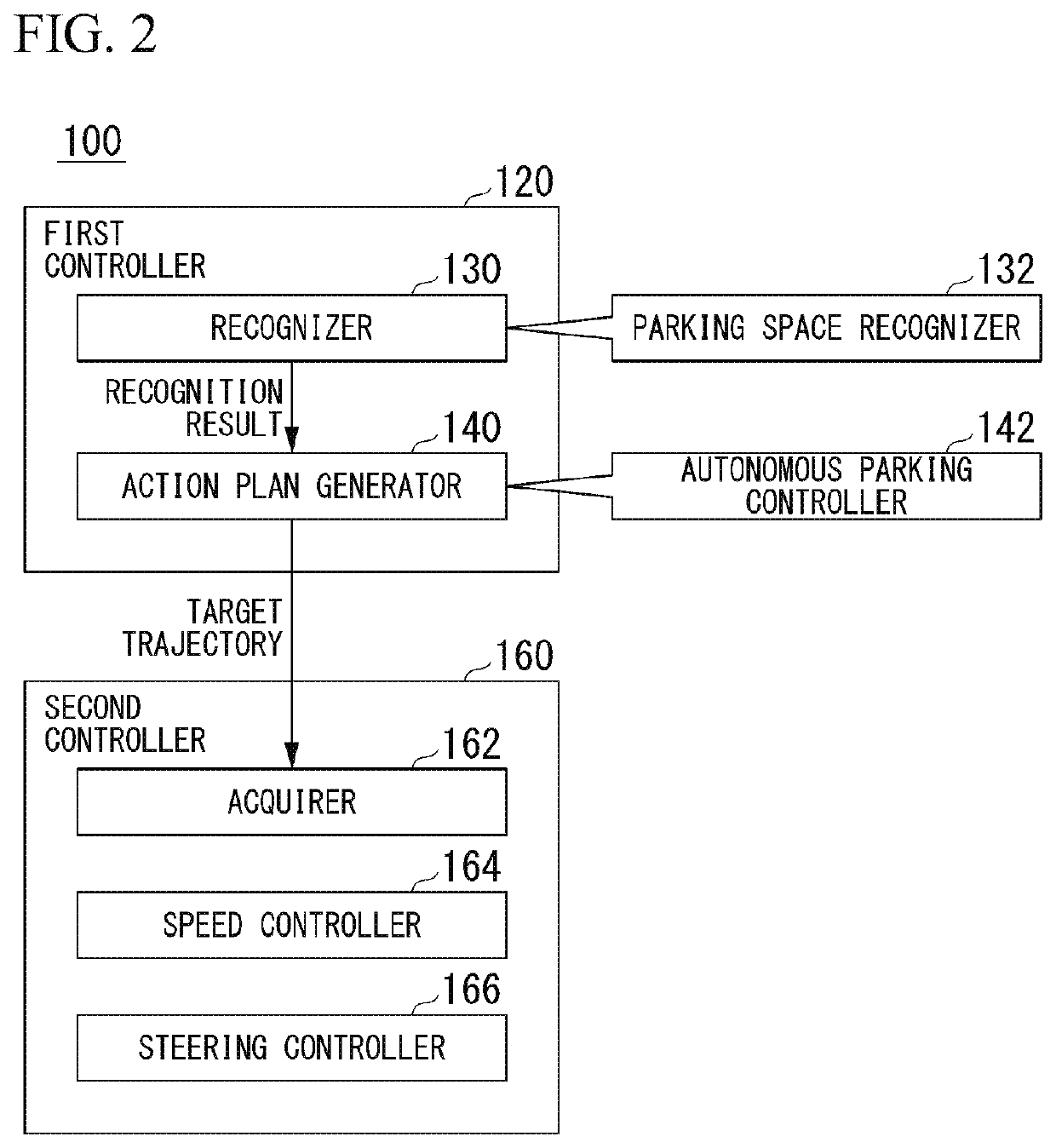

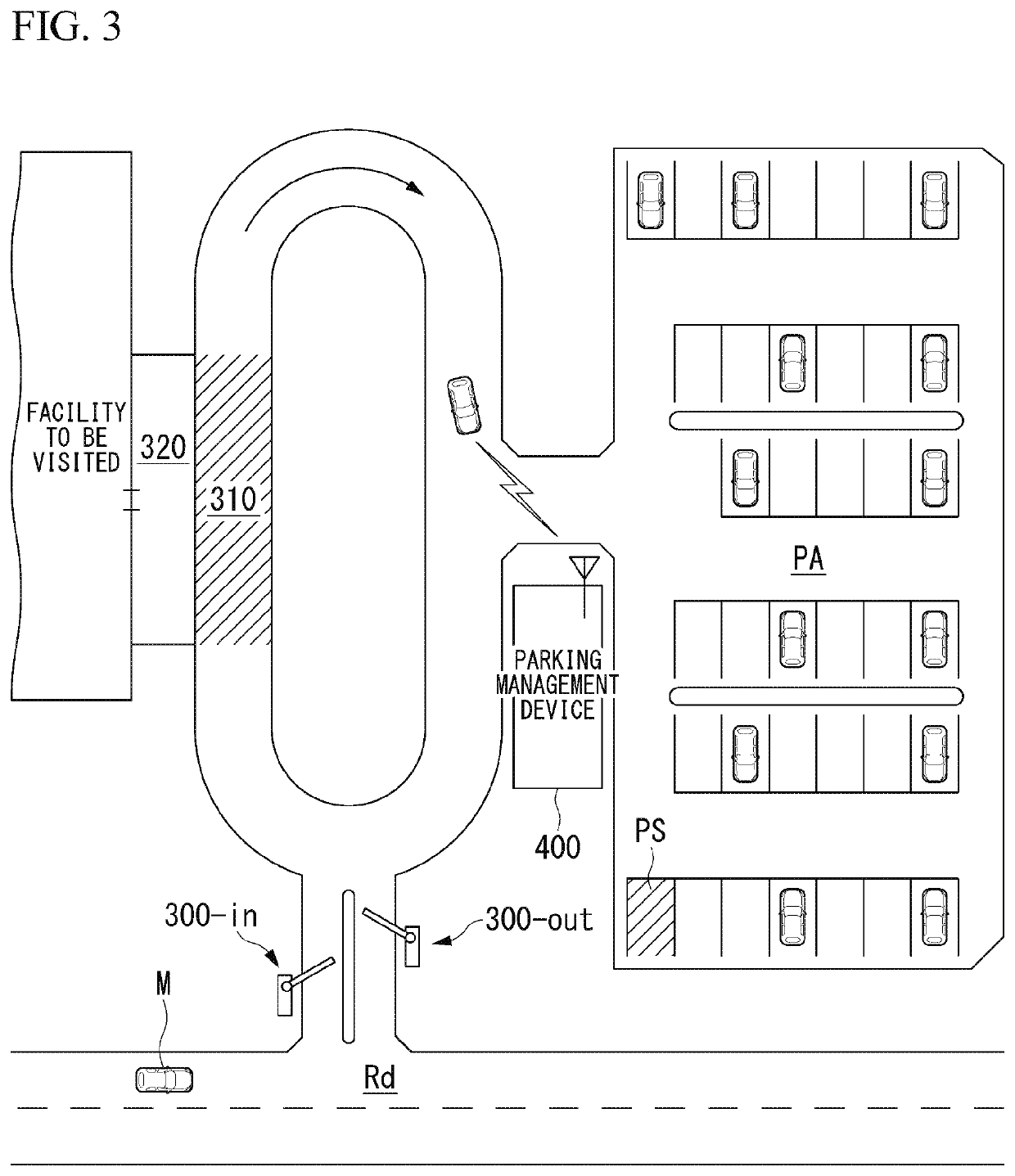

Parking management device, method of controlling parking management device, and storage medium

InactiveUS20200307557A1Improve boarding efficiencyPosition of parking is shortTicket-issuing apparatusAutonomous decision making processSimulationTerminal equipment

A parking management device includes: a communicator configured to communicate with a vehicle and a terminal device of a user of the vehicle; a return manager configured to determine a sequence in which the vehicle arrives at a boarding area in which the user boards based on a position of the user recognized based on information acquired by the communicator, whether there is a return request of the vehicle from a parking lot which is acquired by the communicator, and coincidence between a time at which the return request of the vehicle is acquired and a return reservation time of the vehicle acquired in advance by the communicator; and a vehicle controller configured to transmit information which is used by a return target vehicle in autonomous traveling from the parking lot to the boarding area to the return target vehicle based on a sequence of the return target vehicle determined by the return manager.

Owner:HONDA MOTOR CO LTD

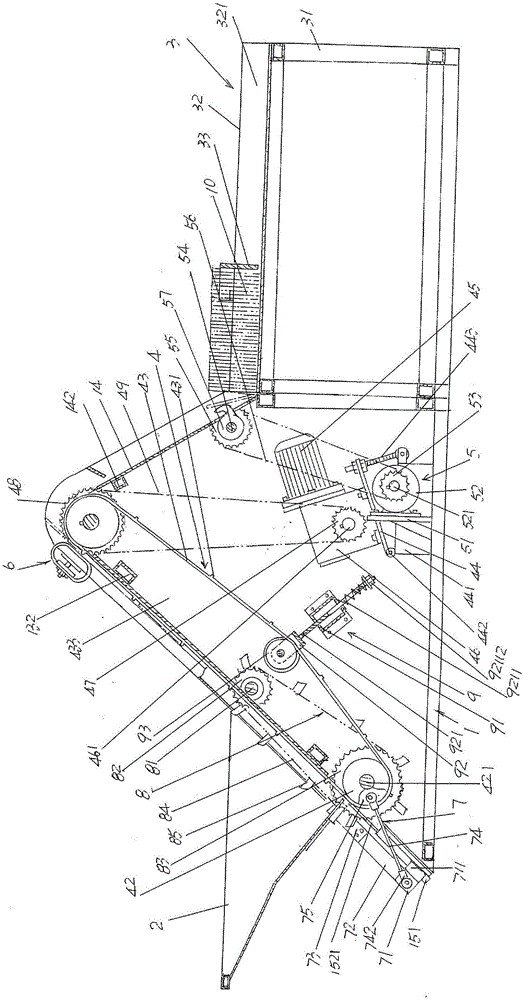

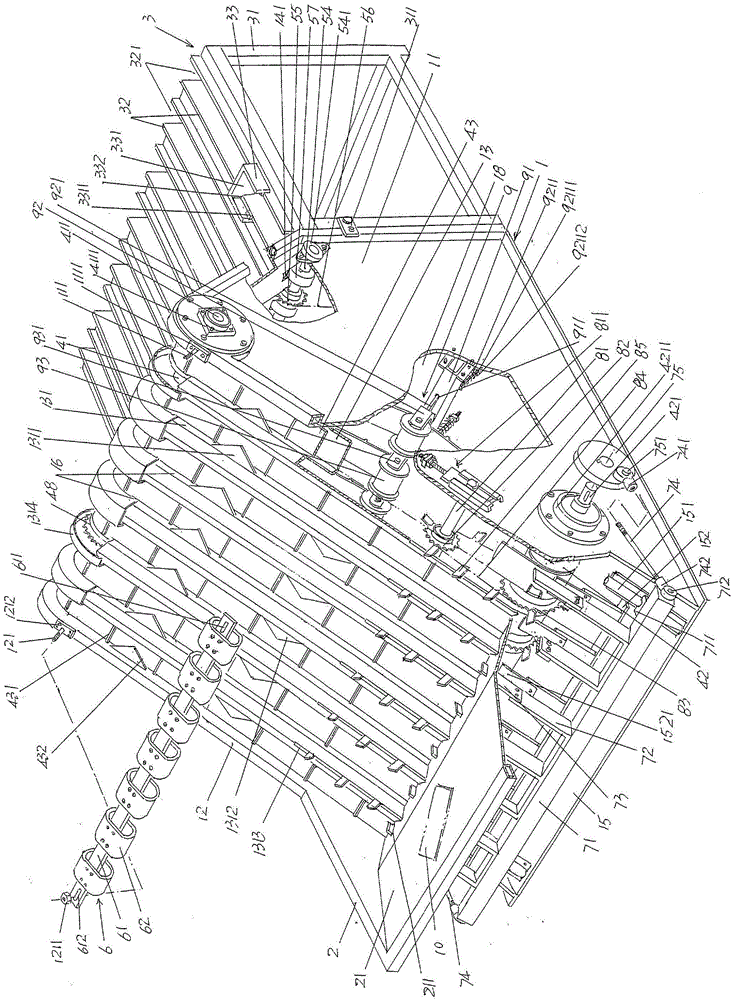

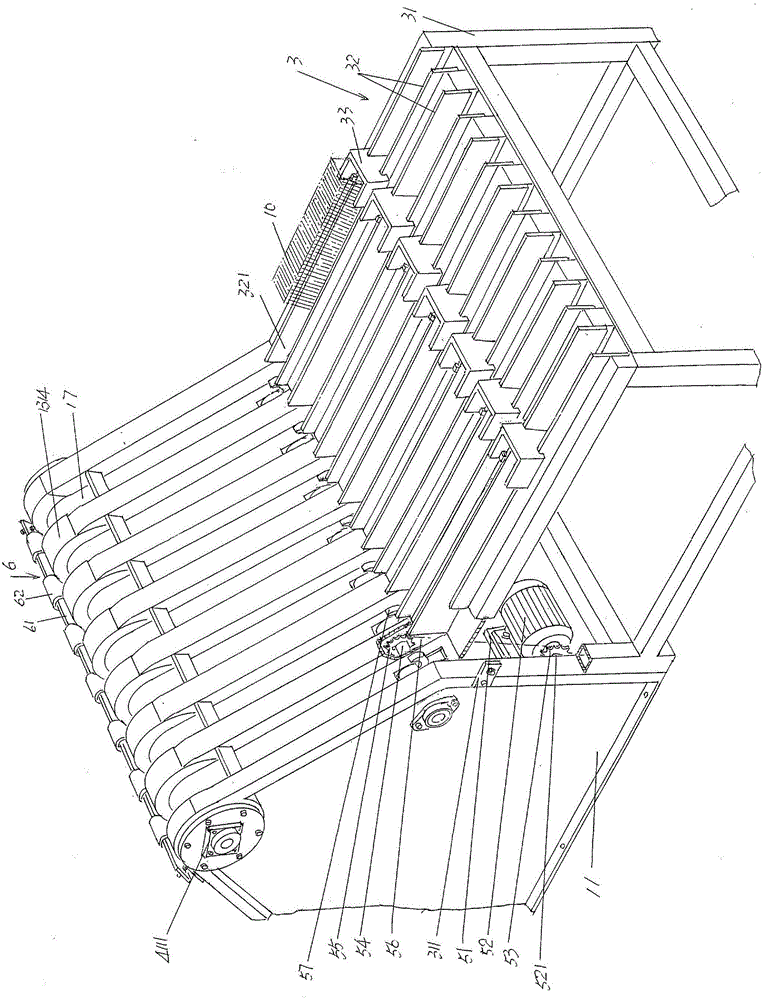

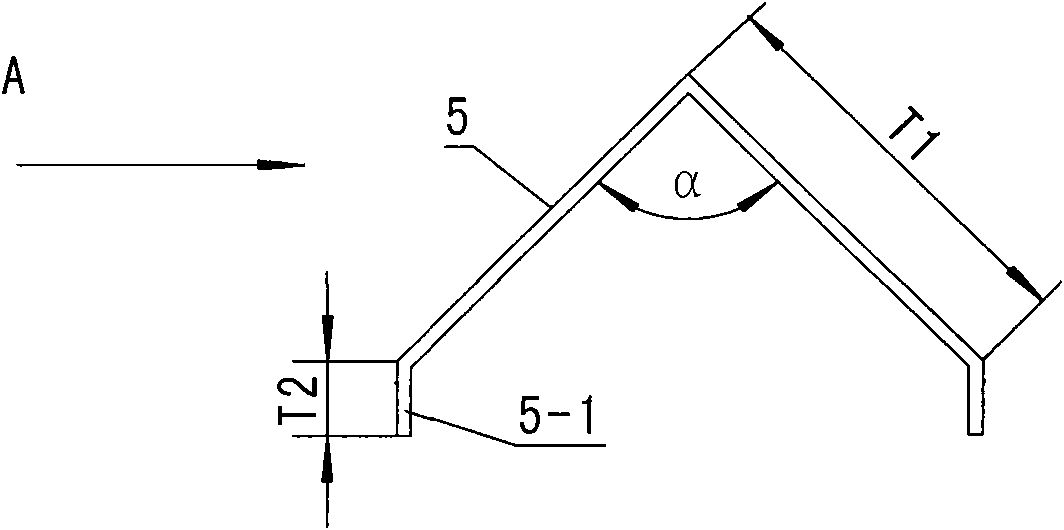

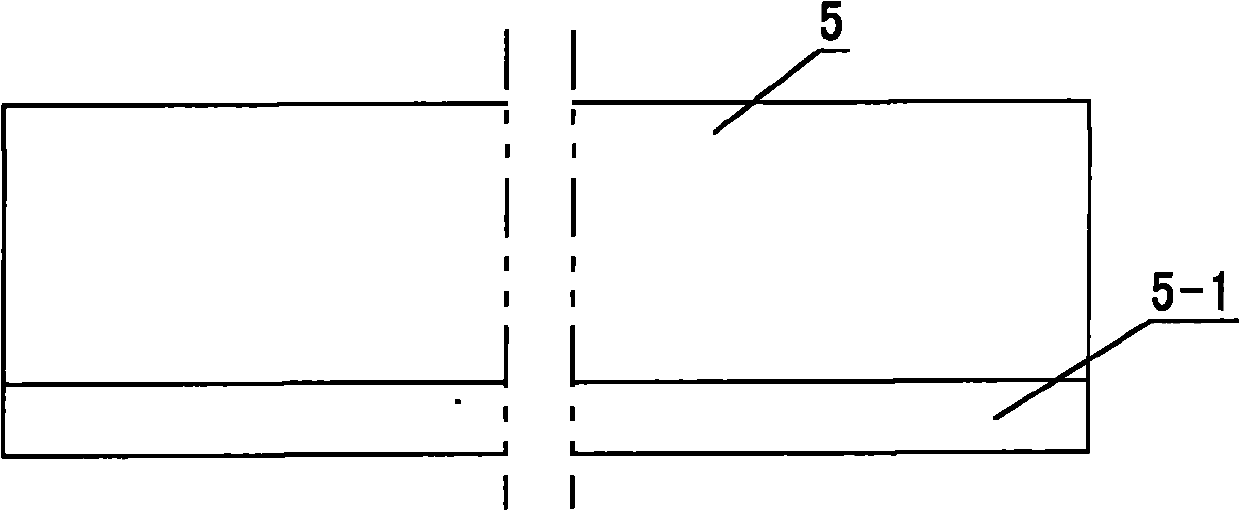

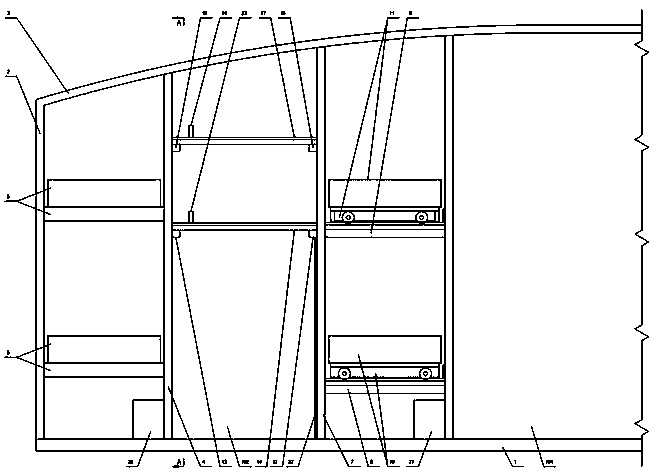

Automatic unscrambler for plate sheets

ActiveCN106697877AEscape situationArrive smoothly and orderlyConveyorsConveyor partsMechanical engineering

The invention discloses an automatic unscrambler for plate sheets and belongs to the technical field of pen making machinery. The automatic unscrambler comprises a machine frame of which the left side and the right side both incline downwards, a plate feeding hopper fixed to the lower portion of the left side of the machine frame, a plate receiving mechanism connected with the lower portion of the right side of the machine frame, a plate sheet conveying mechanism arranged on the machine frame, and a plate sheet transferring and pushing assisting mechanism arranged in the position, corresponding to the upper portion of the left side of the plate receiving mechanism, of the machine frame. The automatic unscrambler is characterized in that the automatic unscrambler is further provided with a plate sheet falling preventing guide mechanism, a plate pushing mechanism and a plate poking mechanism; the plate sheet falling preventing guide mechanism is arranged in the position, corresponding to the upper portion of the left side of the machine frame, of the machine frame and is matched with the plate sheet conveying mechanism; and the plate pushing mechanism is arranged in the position, corresponding to the lower portion of the plate feeding hopper, of the machine frame and is in transmission connection with the plate sheet conveying mechanism. The plate poking mechanism is arranged in the position, corresponding to the upper position of the plate pushing mechanism, of the machine frame and is in transmission connection with the plate sheet conveying mechanism. The effects that the plate sheets arrive at the plate receiving mechanism smoothly and orderly and are taken out effectively are ensured. The size is small, and the plate unscrambling efficiency is high.

Owner:常熟市时新热能设备有限公司

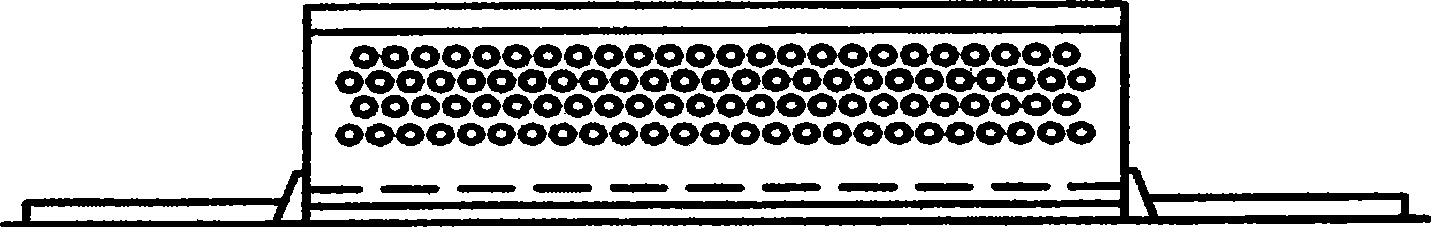

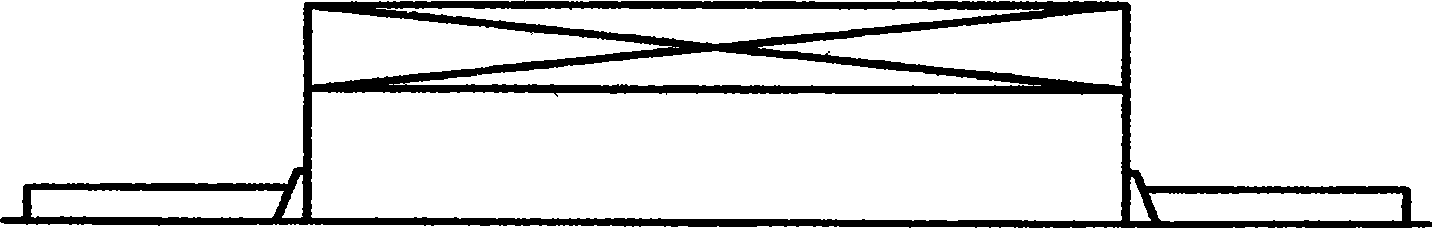

Flow crossing-baffling composite gasoline fractionating tower of ethylene device

InactiveCN101785931AAvoid cloggingNo clogging will occurGasoline stabilisationFractional distillationTO-18Gasoline

The invention discloses a flow crossing-baffling composite gasoline fractionating tower of an ethylene device. Micro baffling plates which are arrayed in an interlaced manner are arranged in parallel up and down at a quenching oil circulating section, and a vertex angle of each micro baffling plate is within 90 to 139 DEG; symmetrical bevel edges at the two sides of the vertex angle of the baffling plate are provided with symmetrical vertical folded edges; flow-crossing sieve plates with the diameter of sieve holes within Phi18 to 24mm are arrayed up and down at a medium oil circulating section; flow-crossing sieve plates with the diameter of the sieve holes within Phi13 to 24mm are arrayed up and down at a diesel oil separating section; and flow-crossing sieve plates with the diameter of sieve holes within Phi13 to 18mm are arrayed up and down at a gasoline separating section. The gasoline fractionating tower of the invention overcomes the problem of polymer blockage frequently occurring in the present plate-type fractionating tower and has the remarkable advantages of strong impact and vibration resisting capability, low tower pressure, high ethylene yield, obvious energy saving effect and long-term stable running.

Owner:TIANJIN UNIVTECH CO LTD

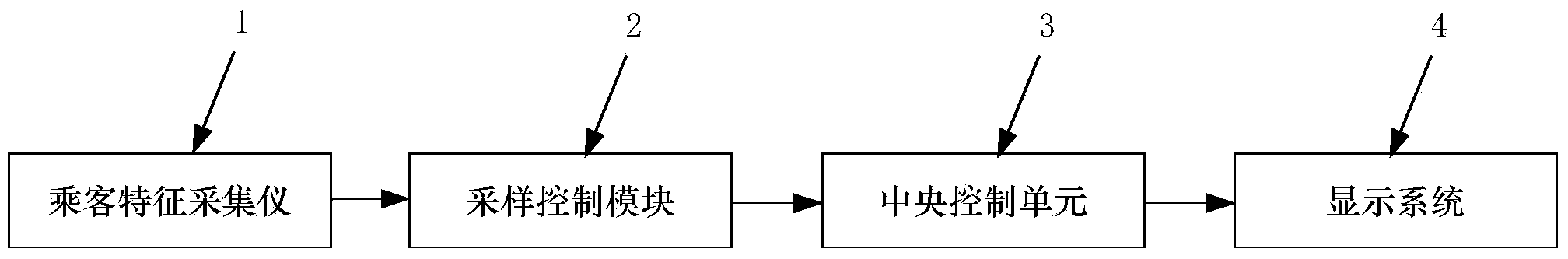

Boarding system based on passenger attributes

ActiveCN104077826AImprove boarding speedShorten boarding timeIndividual entry/exit registersComputer moduleSecurity check

The invention provides a boarding system based on passenger attributes, and belongs to the field of self-service boarding systems in airports. The boarding system comprises a passenger attribute acquirer, a sampling control module, a center control unit and a display system, wherein the passenger attribute acquirer acquires information of passengers and sends the information to the sampling control module; the sampling control module filters and processes the information, stores the processed information and sends available information into the center control unit; the center control unit determines a boarding sequence of the passengers passing through the security check by adopting a control program and an algorithm; the passengers who does not pass through the security check within half an hour ahead of the departure time of an airplane can board orderly according to the arrival sequence. Parts in the boarding system are common in the market; the system is low in development cost, and the boarding efficiency of the passengers can be effectively improved; the jam and the stagnation of the passengers in the boarding process and on the airplane can be reduced; the staying time of the airplane in the airport is shortened; and therefore, the flight times can be increased, and giant benefits are brought to a civil aviation system.

Owner:BEIHANG UNIV

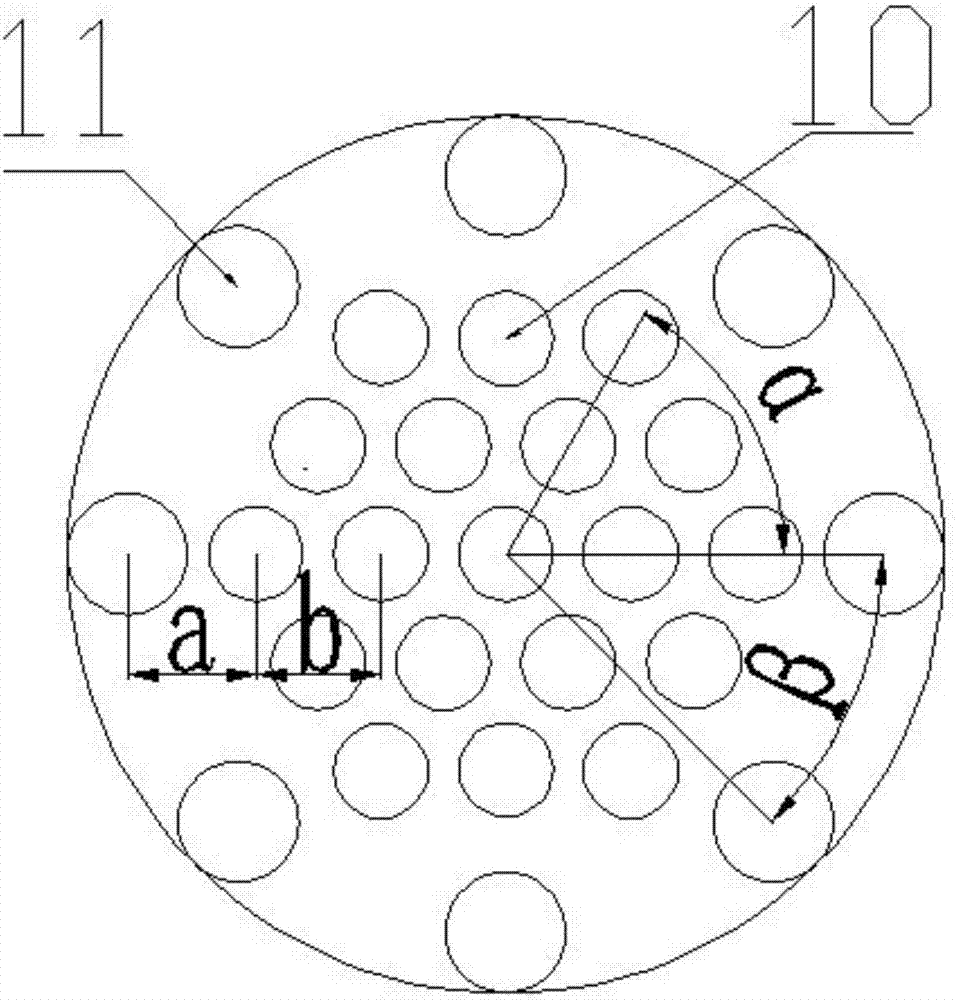

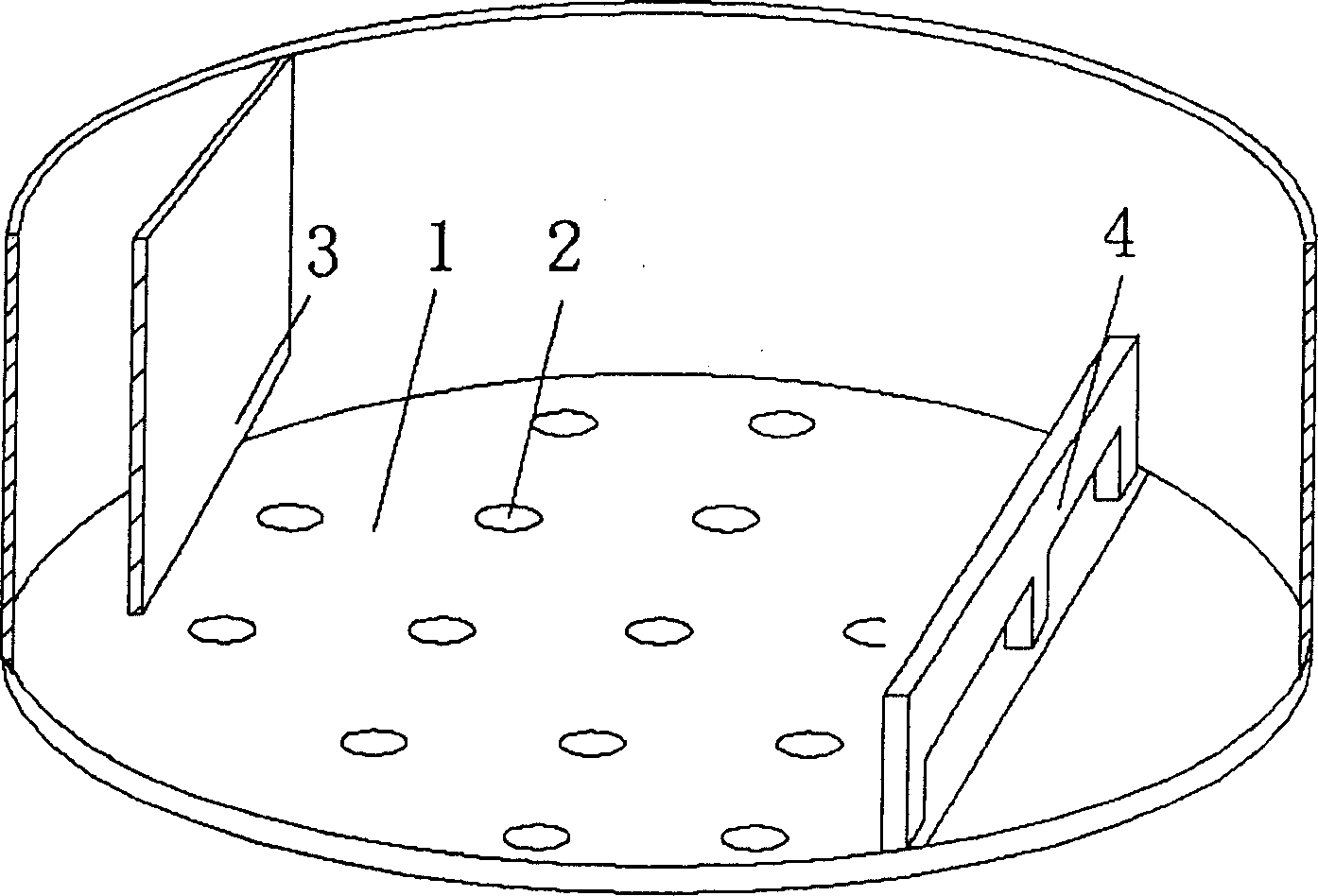

Graded type dual-hole-diameter sieve plate tower

InactiveCN107486006AIncreased turbulenceIncrease gas-solid contact areaUsing liquid separation agentFlue gasPulp and paper industry

The invention discloses a graded type dual-hole-diameter sieve plate tower. The graded type dual-hole-diameter sieve plate tower comprises a tower body adopting a hollow cylindrical structure, wherein sprinkling layers are arranged at the upper part of the tower body, and a pulp pond is arranged at the lower part of the tower body; a flue gas inlet is formed in the tower body between the pulp pond and the sprinkling layers; a flue gas outlet is formed in the topmost end of the tower body; two or more sieve plates which are horizontally arranged are arranged in the tower body between the flue gas inlet and the sprinkling layers; gas through holes and liquid through holes are formed in each sieve plate; the hole wall of each liquid through hole is higher than the upper surface of the corresponding sieve plate, and the liquid through holes are distributed in the periphery of the outer side of each sieve plate; and the gas through holes are distributed in the inner side of each sieve plate. According to the graded type dual-hole-diameter sieve plate tower disclosed by the invention, a graded type structure is adopted, the hole diameters of the gas through holes are sequentially declined from bottom to top, the hole wall heights of the liquid through holes are sequentially increased from bottom to top, the pressure drop is sequentially increased from bottom to top, and the processing load is sequentially declined from bottom to top, so that the flue gas can be accelerated when passing through the sieve holes, pulp forms high-speed small liquid drops, and gas-liquid turbulence is strengthened; and besides, the gas-solid contact area can be increased, and inertial impaction kinetic energy of the gas-solid contact can also be enlarged, so that the dust removing efficiency achieves 50% or above.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

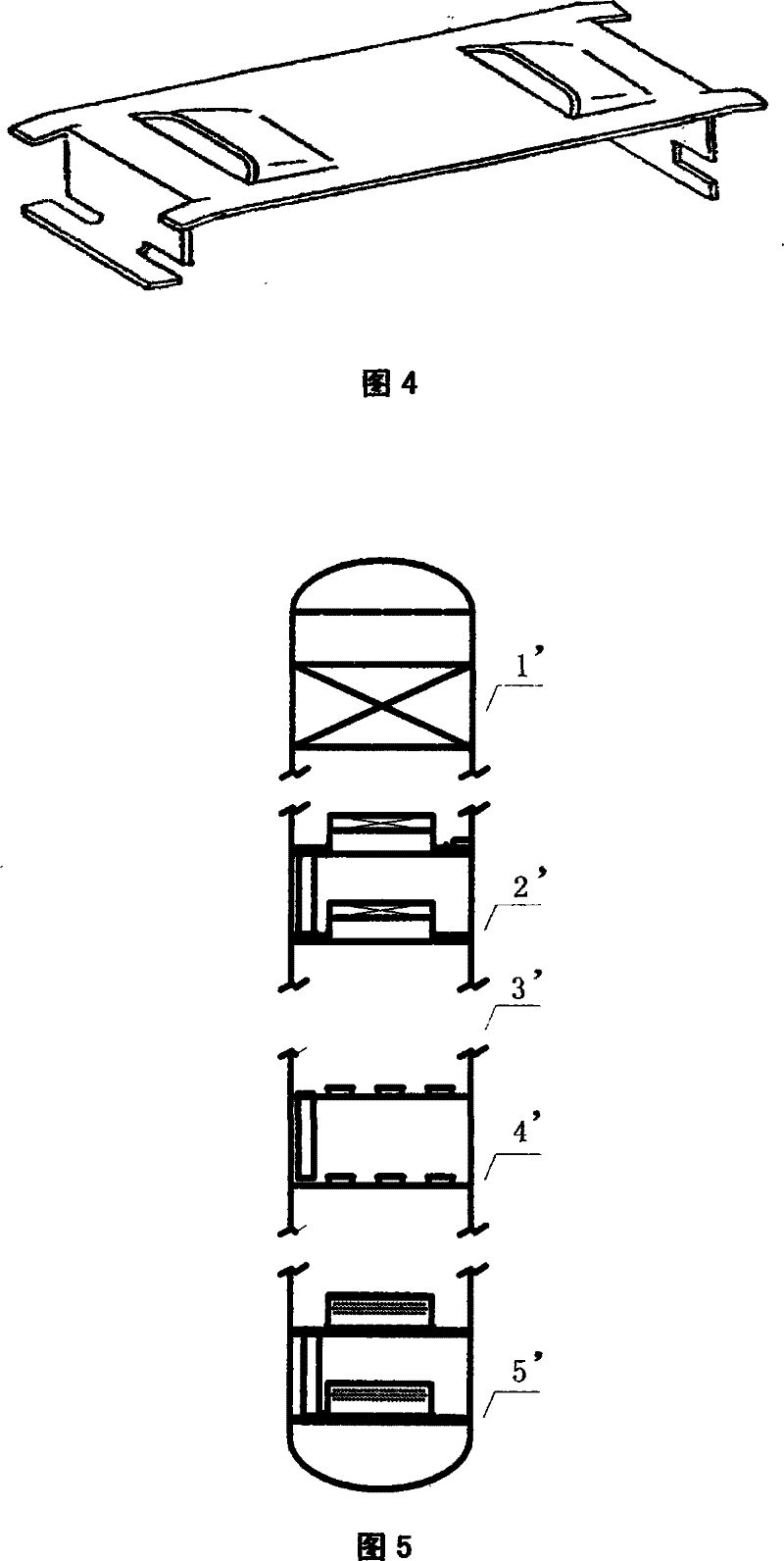

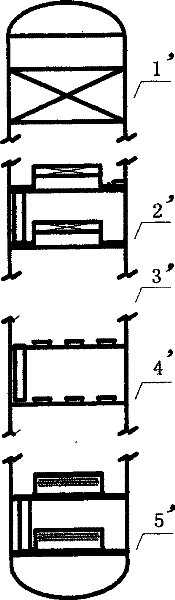

Plate-type packed rectifying tower

PendingCN111744225AExtended service lifeIncrease air pressureFractional distillationTowerControl theory

The invention belongs to the technical field of chemical equipment, and particularly relates to a plate-type packed rectifying tower. The plate-type packed rectifying tower comprises a tower body, a tower tray and a controller; a liquid backflow pipeline is arranged on the upper portion of one side of the tower body; an air inlet is formed in the lower portion of the same side of the tower body; afeeding port is formed in the lower portion of the other side of the tower body; an air outlet is formed in the center of the top of the tower body; a discharging port is formed in the center of thebottom of the tower body; the tower tray comprises a tower plate, an overflow weir, a downcomer and a liquid receiving tray; the controller is mounted in the middle of the outer wall of the tower bodyand used for controlling the rectifying tower to automatically operate; and an adjusting module and a sealing module are arranged on the tower plate. According to the plate-type packed rectifying tower of the invention, the adjusting module is arranged to sense the liquid leakage degree in the tower, and the sealing module is triggered in due time; the sealing module changes the working state ofthe tower plate through movement, so that gas is manually pressurized, a gas-liquid contact area is increased, and therefore, liquid leakage phenomena are reduced, and the efficiency of the plate is improved.

Owner:邓健

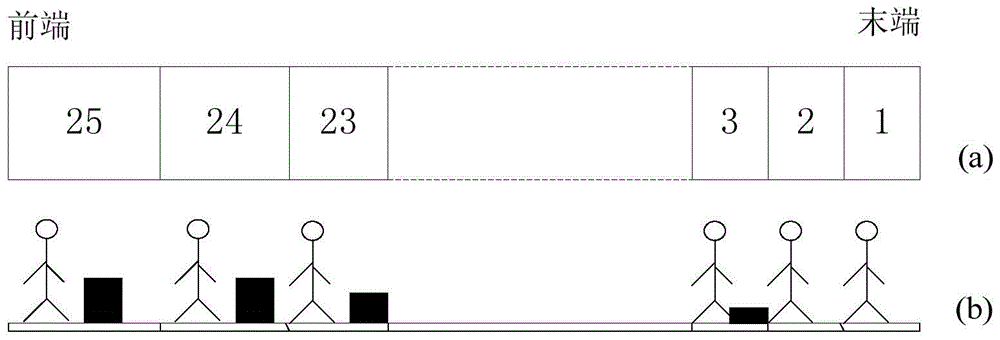

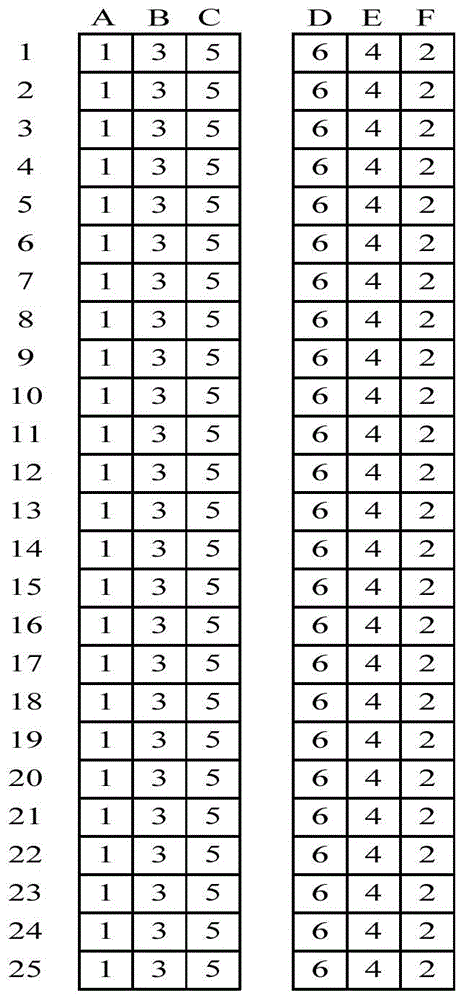

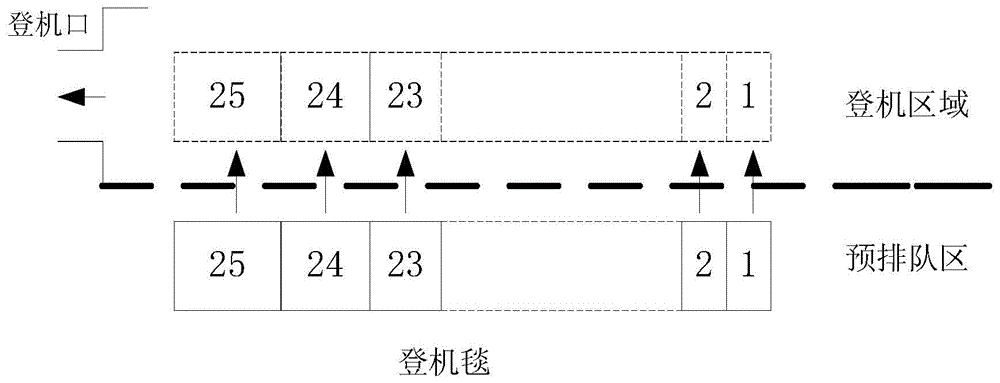

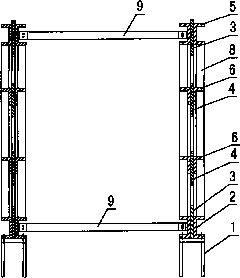

A civil aviation passenger aircraft boarding facility and method

InactiveCN104386261BSimple structureReduce the number of aisle conflictsPassenger handling installationsFloor carpetsAerospace engineering

The invention discloses a passenger aircraft boarding facility. The passenger aircraft boarding facility comprises a boarding carpet, wherein an independent identifiable marking region is formed on the boarding carpet; the size and shape of the marking region are designed in such a manner that only one passenger is allowed to be positioned in the marking region at any time; the boarding carpet is used by a plurality of passengers to queue up in advance before getting into a passenger aircraft according to a predetermined sequence. The invention further discloses a method for boarding by using the facility. By adopting the facility and the corresponding boarding method, the boarding time can be shortened greatly, and the boarding efficiency is increased.

Owner:BEIJING JIAOTONG UNIV

Lattice girder for supporting multiple trays of large-size plate type column

The invention relates to a lattice girder for supporting multiple trays of a large-size plate type column. At least one middle parallel chord parallel to the upper parallel chord and the lower parallel chord is arranged between the paratactic upper parallel chord and lower parallel chord of the lattice girder, and the positions of the paratactic middle parallel chords are symmetrical, wherein the upper parallel chord, the lower parallel chord and the middle parallel chords are formed by splicing symmetrical profile steels, and rectangular chord plates are respectively clamped and fixed among the spliced profile steels; both sides of each rectangular chord plate are respectively welded and fixed with a vertical rod and an inclined rod; and the paratactic upper parallel chord, the lower parallel chord and each middle parallel chord respectively and horizontally support a plate type tray. The lattice girder has the outstanding characteristics of large rigidity and small deflection and can achieve the purpose of supporting multiple layers of trays by one girder and also meet the requirement that the levelness of a large-diameter tray is not larger than 3mm. When the lattice girder is applied to a multi-overflow tray, corresponding parallel chords have the effect of reducing liquid pipes, can avoid local vortex interferences to liquid plane propelling flows on odd trays at the parts of the vertical rods and the inclined rods of the traditional lattice girder and also simplify the structural design.

Owner:TIANJIN UNIVTECH CO LTD

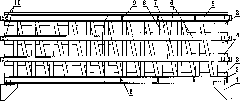

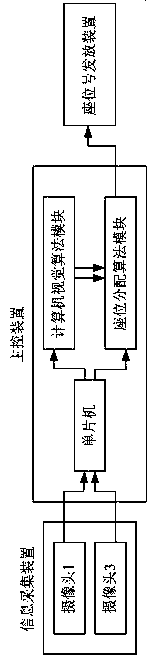

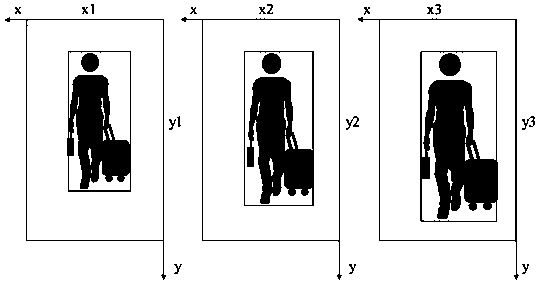

Dynamic boarding method based on passengers and baggage

InactiveCN108470393AImprove traffic efficiencyReduce length of stayLottery apparatusIndividual entry/exit registersEconomic benefitsSimulation

The invention discloses a dynamic boarding method based on passengers and baggage. According to the method, a dynamic boarding system is firstly constructed, an information collecting device of the system collects passenger image information, a computer visual algorithm module of a main control device calculates passenger agility degree coefficient alpha and baggage coefficient beta, and a seat allocation algorithm module of the main control device performs seat allocation based on the situation of group passengers and reserved seats; a seat number issuing device issues a seat number to each passenger at a boarding gate based on the obtained seat number. The dynamic boarding method designs a new seat allocation algorithm, solves the actual execution problem of boarding, increases the dynamic boarding method, improves the passenger passing efficiency at the boarding gate, and shortens the sojourn time of an aircraft at an airport, thereby bringing huge economic benefits to airlines.

Owner:CIVIL AVIATION UNIV OF CHINA

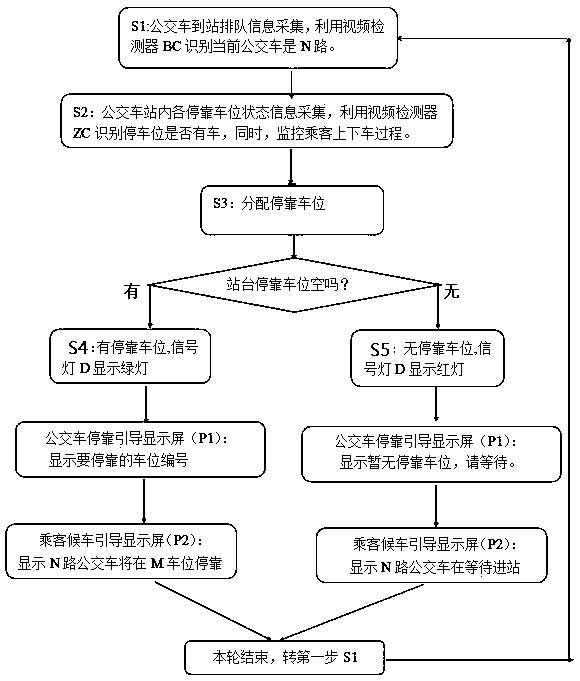

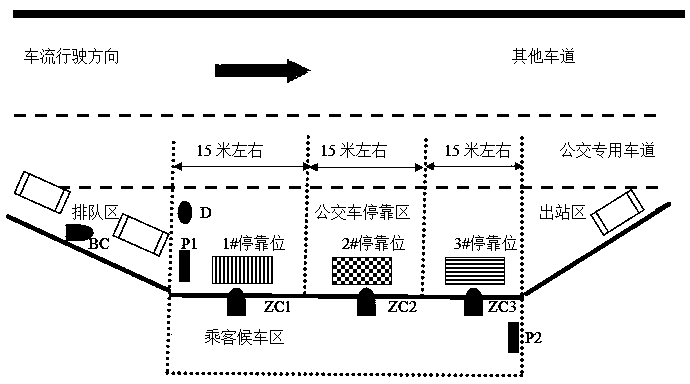

Parking position distribution method of stop with multiple routes of buses

InactiveCN108510765AImprove management levelGet on the bus in an orderly mannerArrangements for variable traffic instructionsIndication of parksing free spacesDistribution methodConfusion

The invention relates to a parking position distribution method of a stop with multiple routes of buses. Different routes of buses queue up when arriving at the bus stop, wait for parking position distribution information according to parking state in the bus stop, and enter the stop and park according to ordered and safe guiding information; and at the same time, passengers queue up and get on the corresponding bus in the known bus parking position according to the guiding information. Thus, parking confusion of the buses and confusion in getting-on of the passengers are avoided, and the buses and passengers are guided orderly, efficiently and safely according to requirements respectively.

Owner:FUZHOU UNIV

Method and system for wireless payment of public transport fare

ActiveUS10249013B2Improve boarding efficiencyImprove efficiencyTicket-issuing apparatusPayment architecturePaymentComputer network

Embodiments of the present application provide a method and system for wireless payment of transport fare. During operation, the system receives a request at a server from a mobile device for information of a payee's account, which is associated with a public transport and corresponds to a wireless network identifier of a wireless network located on the public transport. The server may determine information of the payee's account corresponding to the wireless network identifier. The server then sends the payee's account information to the mobile device. The system may then receive, from the mobile device, a payment order to make a payment to the payee's account.

Owner:ADVANCED NEW TECH CO LTD

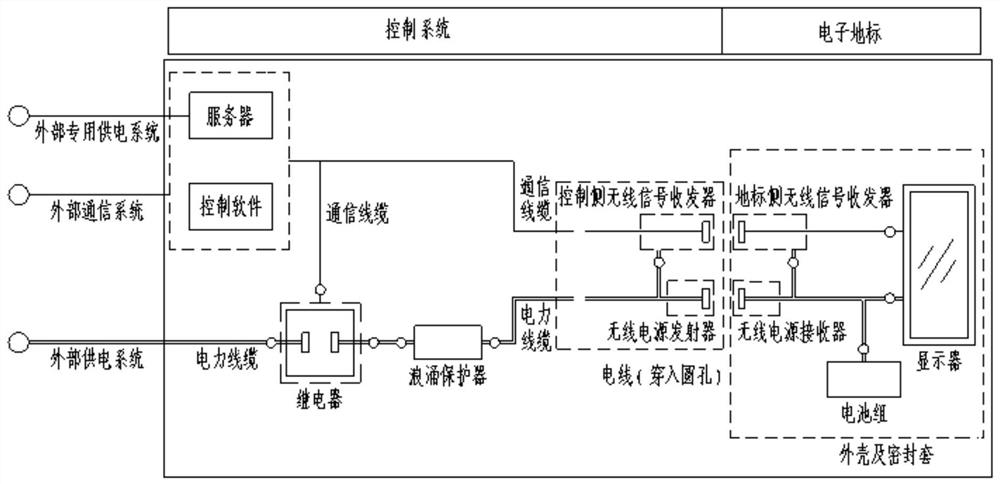

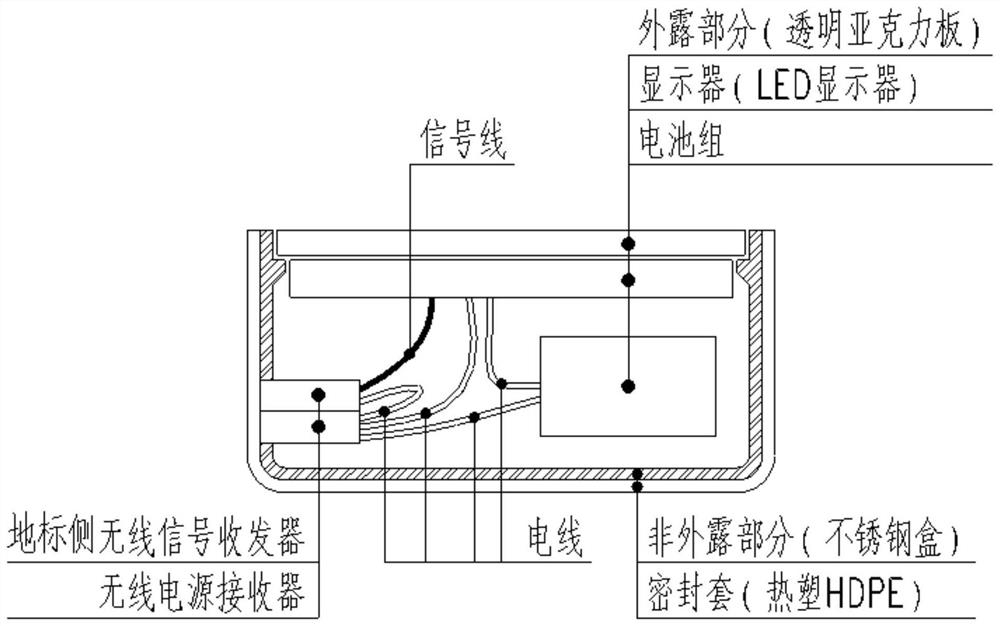

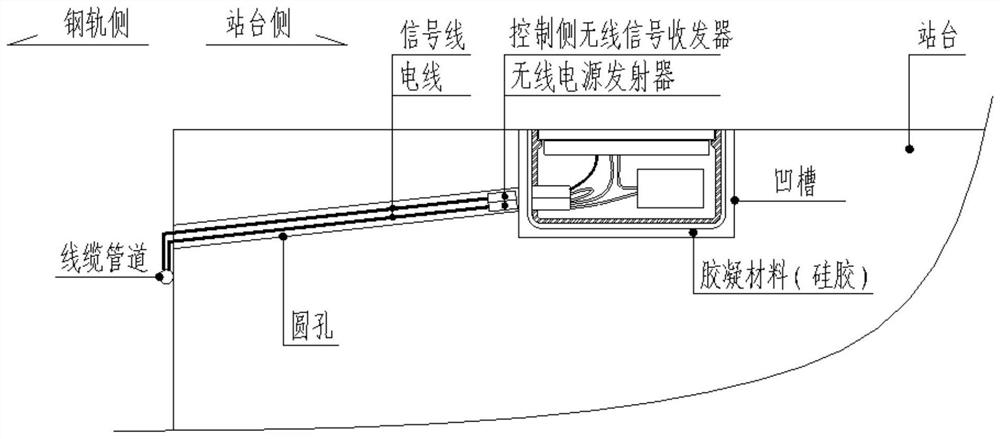

Platform carriage number dynamic display landmark system based on wireless signal and power supply technology

The invention discloses a platform carriage number dynamic display landmark system based on a wireless signal and power supply technology. The system comprises a plurality of electronic landmarks; the electronic landmark is used for displaying train numbers, carriage numbers, carriage seat small-size directions and / or carriage seat large-size directions, and comprises a shell, and a display, a landmark side wireless signal transceiver and a wireless power receiver which are arranged in the shell; the ground of the platform is provided with a matched groove corresponding to the electronic landmark; signal lines and electric wires are arranged in the side walls, close to the steel rails, of the grooves; one end of the signal line is connected with the control system through a cable pipeline, and the other end of the signal line is matched with the corresponding landmark side wireless signal transceiver through the control side wireless signal transceiver to realize wireless communication; one end of the wire is connected with a power supply part of the control system through a cable pipeline, and the other end of the wire is paired with the corresponding wireless power receiver through the wireless power transmitter to realize wireless power supply. Passengers can find correct carriages on the platform more conveniently, platform confusion is avoided, and safety risks are reduced.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

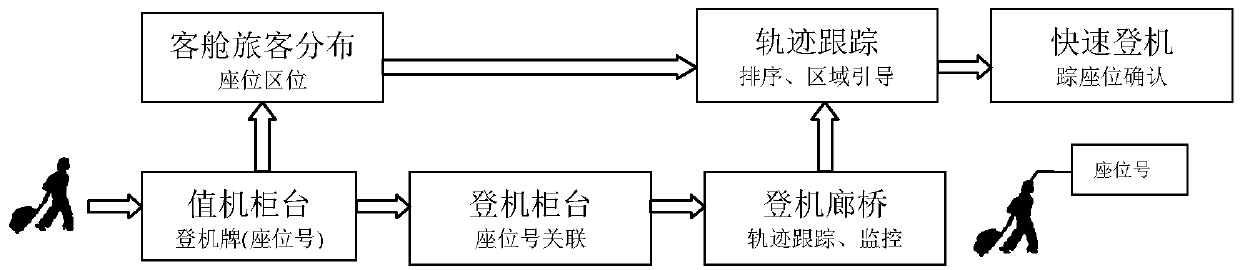

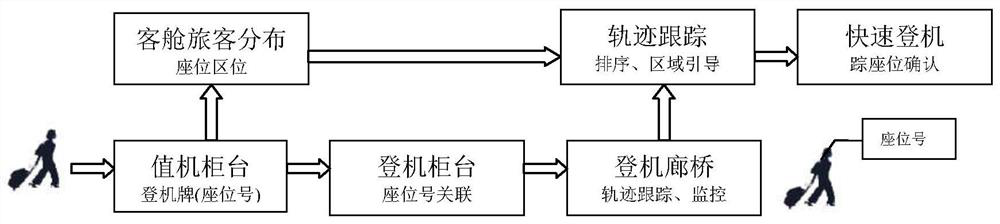

Sequencing boarding method through boarding passenger information correlation and real-time trajectory tracking

ActiveCN109636995AImprove boarding efficiencyReduce boarding process timeChecking apparatusResourcesTime trajectoryInformation monitoring

The invention discloses a sequencing boarding method through boarding passenger information correlation and real-time trajectory tracking. The method comprises the following steps of passenger checking-in, seat service area dividing and area identifier establishing, boarding passenger boarding, boarding passenger entering gallery bridge, boarding passenger queuing sequence information monitoring,boarding passenger sequentially arriving at cabin door, entering passenger cabin for placing luggage, seating and the like. The method has the advantages that modern information are fully utilized forfusing principle and technology, through the modes such as intra-cabin area division, boarding passenger identification, gallery bridge walking track monitoring, and free sequence and extraction, anyone boarding passengers can complete the process without stay in the channel, can directly and accurately reach the corresponding seat area, then confirm the seat, place the luggage and seat; so thatthe boarding efficiency can be remarkably improved, and the boarding process time can be shortened. On the premises that the personal habits of the passengers are honed and extra burdens are not increased, the time of finding the seat and arranging the luggage of the passenger in the cabin is shortened, and the boarding speed is greatly improved.

Owner:CIVIL AVIATION UNIV OF CHINA

Anti-scaling and dirty-proof block tower-plate

InactiveCN1817401AStrong anti-adhesionStrong deposition and fouling abilityFractional distillationHigh resistanceGas phase

An antiscaling, antidirt and antiblocking tower plate is composed of a flat plate made of graphite or teflon and with inclined guide holes for flushing the surface of plate, down-flow spout, and overflow dam with bottom slits for preventing solid collection. Its advantages are long service life, high resistance to high temp, corrosion and solvent, and high effect.

Owner:NANJING UNIV

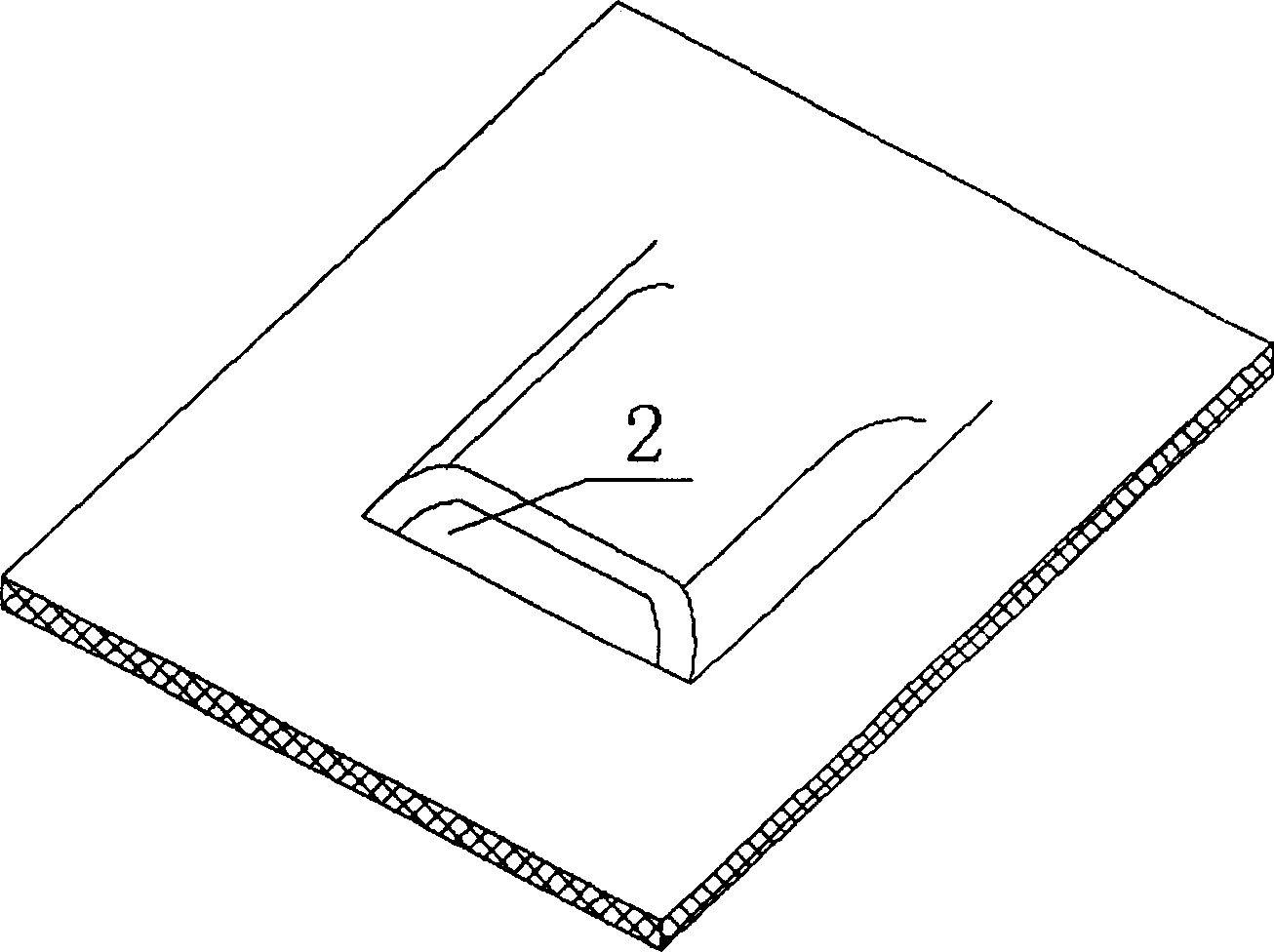

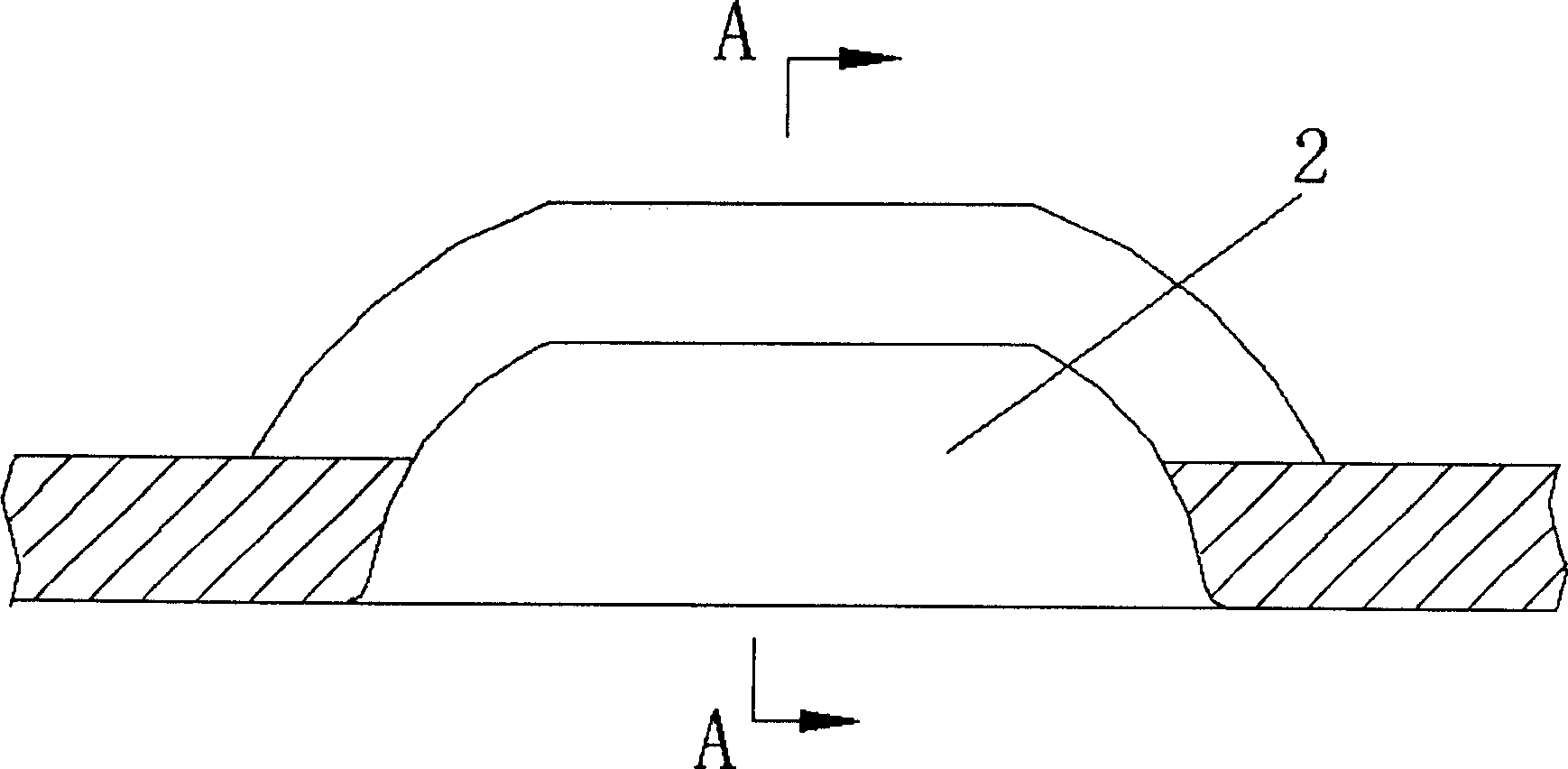

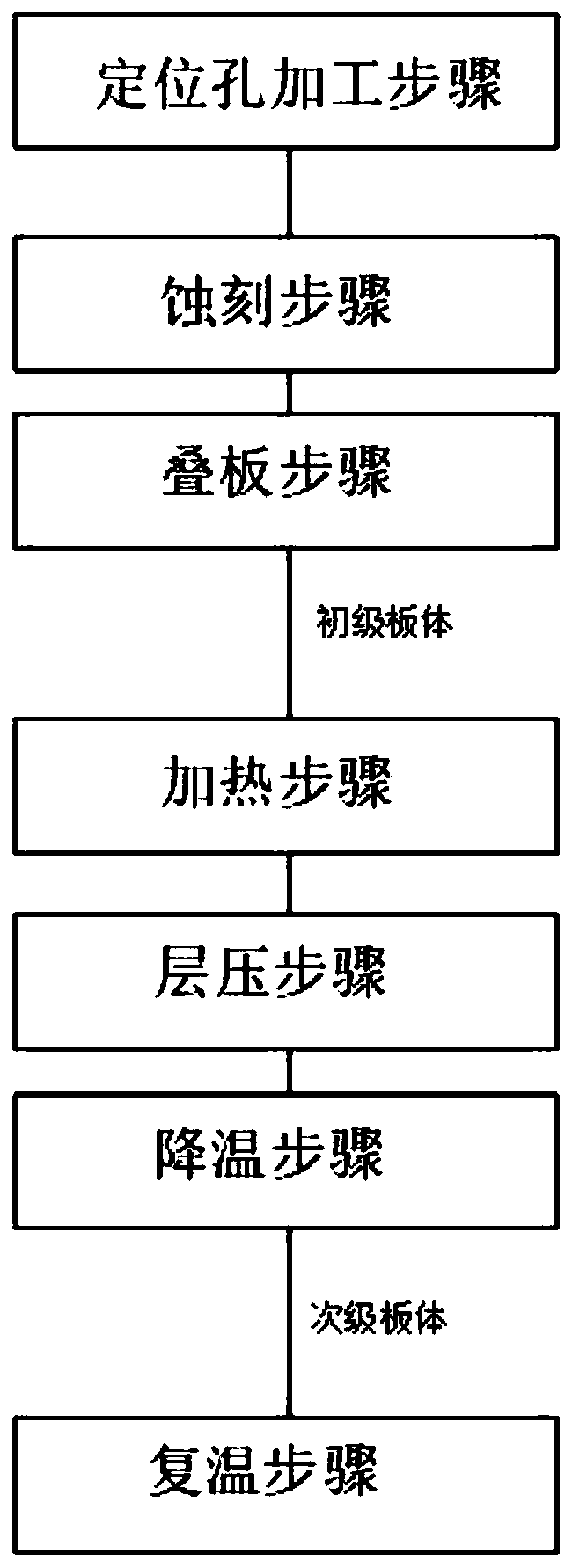

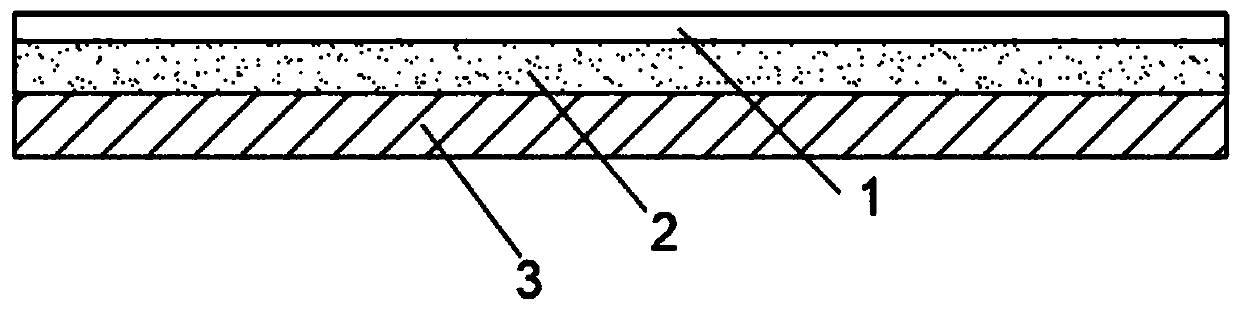

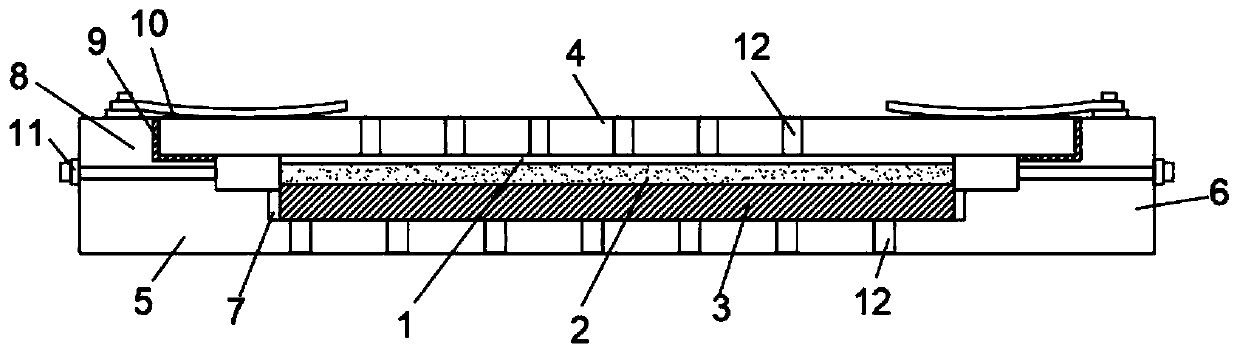

Laminating process of aluminum substrate

InactiveCN111479409AShorten the timeImprove boarding efficiencyLaminationLamination apparatusEngineeringCopper foil

A laminating process of an aluminum substrate at least comprises the following steps: a heating step of heating a primary plate body formed by sequentially laminating a copper foil, a prepreg and a substrate to a rated high temperature; a laminating step of laminating the primary plate body at the rated high temperature by using a laminating machine; a cooling step of cooling the laminated primaryplate body to a rated low temperature to form a secondary plate body; and a rewarming step of putting the secondary plate body into an oven, and heating for 0.8-1.2 hours at a rewarming temperature.A traditional heat preservation step is needed, a reheating step is added after the cooling step is finished to shorten the overall plate forming time, and the production efficiency is improved.

Owner:杭州盛浙电子有限公司

Method for producing (methyl) acrylic acid

ActiveCN101456807BEasy to cleanIncreasing the thicknessCarboxylic preparation by oxidationCatalytic oxidationMethyl group

The invention provides a method for producing (methyl) acrylic acid. The method comprises: selecting at least one of C3 compounds such as propane, propylene, isopropanol, glycerin and acrolein, or at least one of C4 compounds such as isobutene, isobutene, tertiary butyl alcohol and acrylaldehyde as raw materials to carry out catalytic oxidation to prepare a gas mixture containing the (methyl)acrylic acid; absorbing the gas mixture, and separating the (methyl)acrylic acid water solution, wherein a rectifying section of a rectifying tower separating the (methyl)acrylic acid water solution adopts regular packing or parallel-current jet packing trays, or the upper part of the rectifying section adopts the regular packing and the lower part of the rectifying section adopts the parallel-current jet packing trays; and a stripping section adopts directed floating valve trays or vertical sieve trays, or the upper part of the stripping section adopts the directed floating valve trays and the lower part of the stripping section adopts the vertical sieve trays. The rectifying tower with combined tower internal structure embodies a concentrated reflection of the advantages of the regular packing, the parallel-current jet packing trays, the directed floating valve trays and / or vertical sieve trays in the same rectifying system, thereby effectively improving separating capability of the rectifying tower, lowering full-tower pressure drop and operational temperature, avoiding convergescence of the (methyl)acrylic acid at a high temperature, making the water content of tower-bottom discharged material reduced below 0.5 percent, the acetic acid content of the tower-bottom discharged material reduced below 2 percent and the (methyl)acrylic acid content of tower-top water phase reduced below 0.5 percent, further reducing unit consumption of the (methyl)acrylic acid products and improving product quality.

Owner:SHANGHAI HUAYI NEW MATERIAL

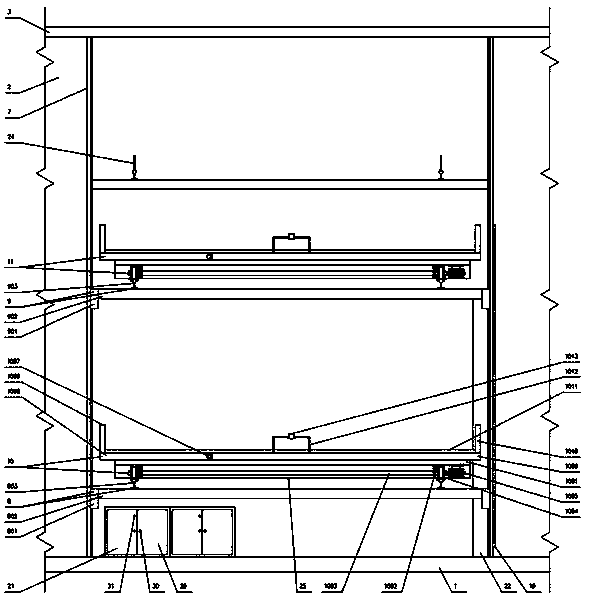

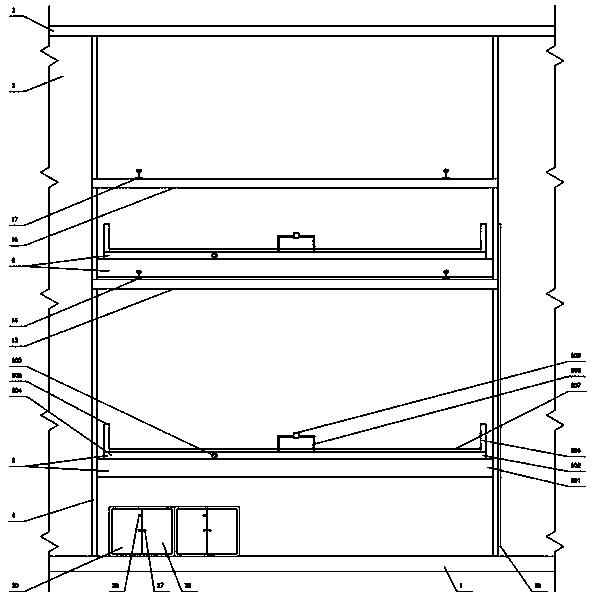

Lifting type aircraft sleeper

ActiveCN110271675AImprove boarding efficiencyImprove comfortRest berthsStowage devicesNacelleStructural engineering

The invention relates to a lifting type aircraft sleeper. Supporting arms are oppositely arranged on the right side of the left side wall of a nacelle. A sleeper assembly A is arranged between the left side wall of the nacelle and the supporting arms, and a sleeper assembly B is arranged between the left side wall of the nacelle and the supporting arms. Linear motor guide rails are oppositely arranged on the right sides of the supporting arm in parallel, lifting assemblies A are arranged on the lower parts of the linear motor guide rails, lifting assemblies B are arranged on the upper parts of the linear motor guide rails, sleeper assemblies C are arranged on the upper parts of the lifting assemblies A, sleeper assemblies D are arranged on the upper parts of the lifting assemblies B, supporting beams A are arranged on the upper parts of the left side walls of the linear motor guide rails, supporting beams B are arranged on the upper parts of the right side walls of the supporting arms, guide rails C are separately arranged on the left sides and the right sides of the supporting beams A and the supporting beams B, supporting arms C are fixed to the left side walls of the linear motor guide rails opposite to the left sides of the supporting arms, supporting beams D are fixed to the right side walls of the oppositely disposed supporting arms, and guide rails D are separately arranged on the left sides and the right sides of the supporting arms C and the supporting arms D. The lifting type aircraft sleeper has the beneficial effects that the passenger boarding efficiency is high, and the sleeper comfort is high.

Owner:曲阜市铸造材料厂

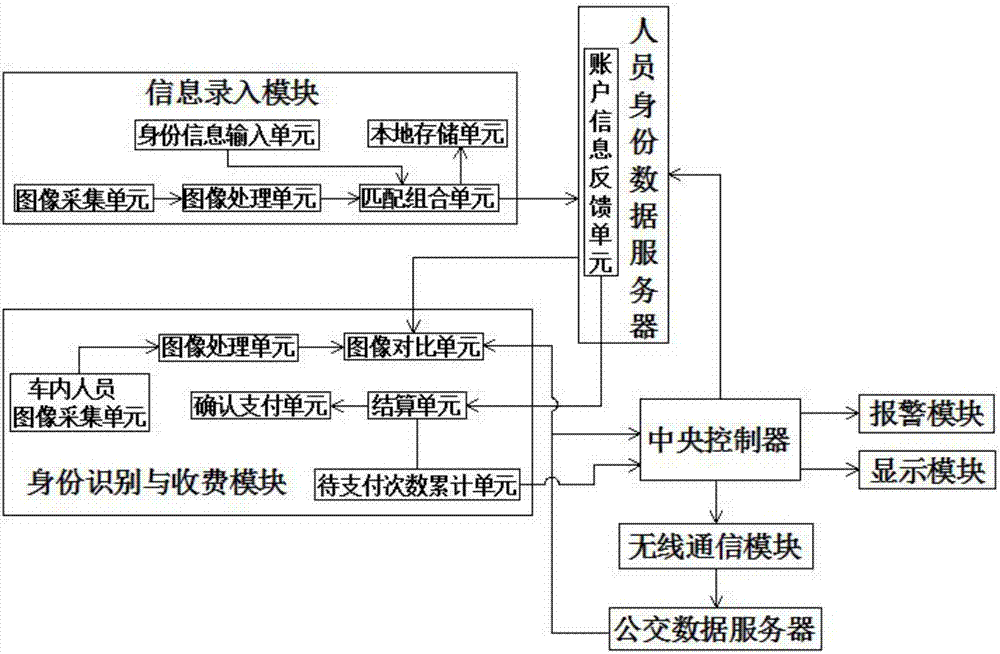

Bus fee-paying control system based on identity identification

InactiveCN107491951AImprove boarding efficiencyReduce waiting time for card swipingPayment architectureCoded identity card or credit card actuationControl systemUser fee

The invention discloses a bus fee-paying control system based on identity identification. The system comprises an information recording module, a personnel identity data server, an identity identification and charging module, a central processor, a wireless communication module, a displaying module and a bus data server. The identity identification and charging module is used for identifying the identity of the passenger who enters a bus. After successful identification, the identity identification and charging module transmits a sum to the mobile phone of the user for reminding the passenger of fee paying. If the number of to-be-paid times exceeds a preset number, the central controller transmits an alarming signal to an alarm module. According to the bus fee-paying control system, through mounting the identity identification and charging module on the bus, identity identification is performed on the passenger who enters the bus. After identification, the to-be-charged sum is transmitted to the mobile phone of the passenger. When the number of the to-be-paid times exceeds the preset number, the alarming signal is transmitted. Not only is getting-on efficiency of the passenger improved for reducing time in waiting for card swiping by the passenger, but also financial safety in traveling by the bus is improved. The bus fee-paying control system has a profound effect in future.

Owner:安徽实运信息科技有限责任公司

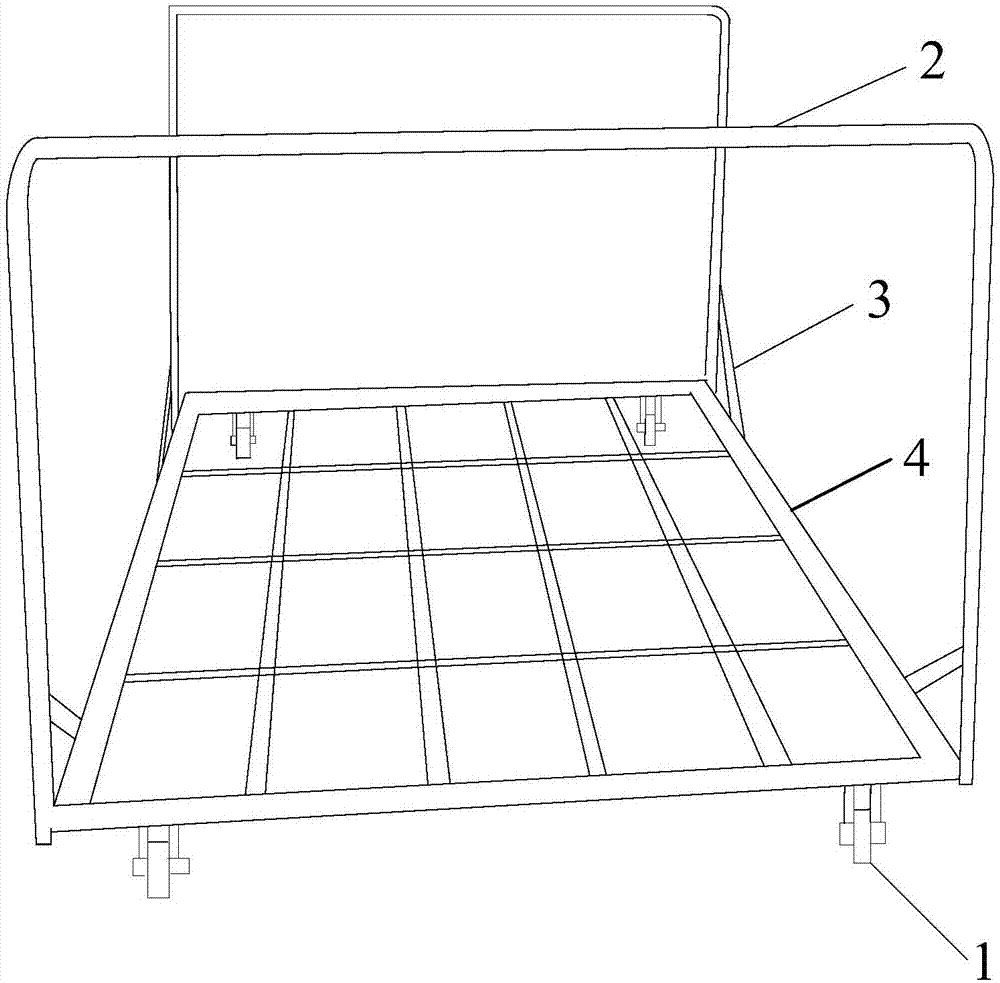

Rail rice seedling conveying vehicle

InactiveCN107472267AImprove boarding efficiencyImprove labor efficiencyCarriagesUltimate tensile strengthAutomotive engineering

The invention discloses a rail seedling transporting vehicle, which comprises a seedling transporting track and a seedling transporting vehicle. The seedling transporting track is composed of two right-angle steel rails and a plurality of crossties. The convex line of the right-angle steel faces upward, and the seedling transporting vehicle includes a car body and wheels, and the wheel is a concave wheel, and the convex line of the right-angle steel is nested and matched with the concave wheel. Using the track seedling transport vehicle provided by the invention to work in the seedling pond can improve the efficiency of transporting the seedlings to the field after machine transplanting and sowing, and transporting the seedlings to the road for boarding after the seedlings are raised. Reduce labor intensity, improve labor efficiency, and reduce labor costs.

Owner:长沙利诚种业有限公司

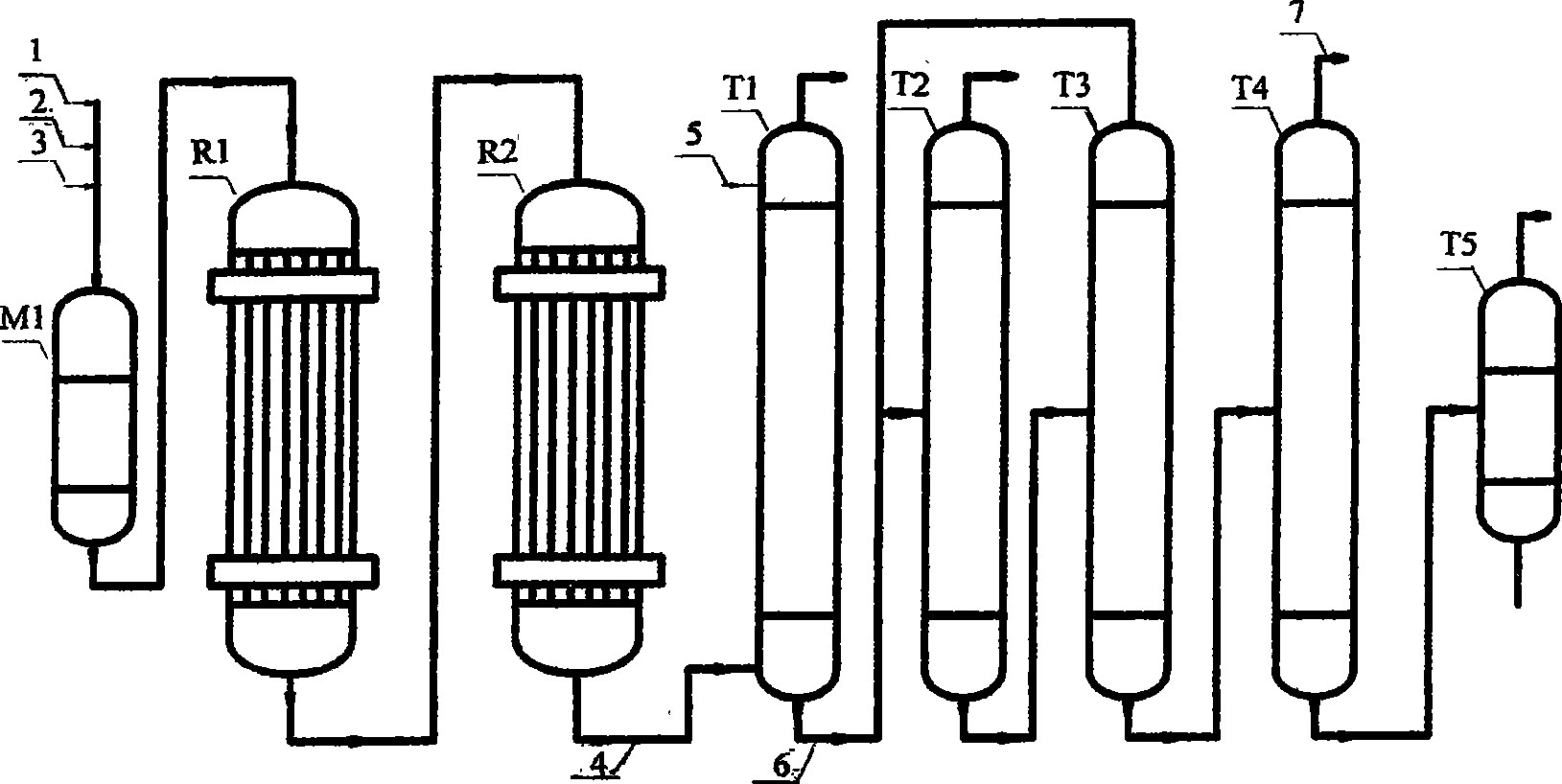

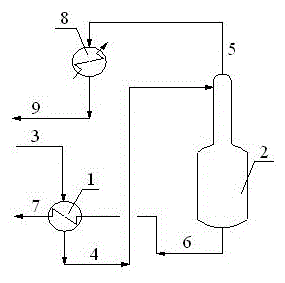

Hexane recovery heat exchange method

ActiveCN103360520BLow viscositySpeed up the flowChemical industryHydrocarbon purification/separationEngineeringTower

The invention relates to a heat exchange method for recycling hexane, mainly solving the problems of high consumption of low-pressure steam and circulating cooling water, unreasonable energy utilization, high equipment construction investment and low plate efficiency in the prior art. The heat exchange method for recycling hexane comprises the following steps that a) water containing undercooling liquid phase hexane material flow 3 enters a hexane liquid phase heat exchanger 1, and after heat exchange, a material flow 4 is obtained, wherein the temperature of the undercooling liquid phase hexane material flow 3 is 30-50 DEG C and the temperature of the material flow 4 is 65-85 DEG C; b) the material flow 4 enters the upper part of a hexane dehydrating tower 2, and after the material flow is separated, a material flow 5 is obtained at the top of the tower and a material flow 6 is obtained at the bottom of the tower; and c) the material flow 6 enters a hexane liquid phase heat exchanger 1 and exchanges heat with the material flow 3 so as to obtain a material flow 7, and the material flow 7 enters in the following processes, wherein the temperature of the material flow 6 is 85-105 DEG C, and the temperature of the material flow 7 is 50-70 DEG C. The problems in the prior art are well solved by the technical scheme, and the heat exchange method can be used for recycling hexane in the industrial production of high-density polyethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

A sorting and boarding method for boarding passenger information association and real-time trajectory tracking

ActiveCN109636995BImprove boarding efficiencyImprove boarding speedChecking apparatusResourcesComputer scienceTransport engineering

A sorting boarding method for boarding passenger information association and real-time trajectory tracking. It includes passenger check-in; dividing seat service areas and establishing area signs; boarding passengers boarding; boarding passengers entering the corridor bridge; monitoring boarding passengers queuing sequence information; boarding passengers arriving at the door in sequence; entering the cabin to place luggage and take seats and other steps. Advantages of the present invention: make full use of the modern information fusion principle and technology, through modes such as cabin area division, boarding passenger identification, corridor bridge walking trajectory monitoring, free sorting and extraction, so that any boarding passenger can not stay in the middle of the passage Directly and correctly arrive at the corresponding "seat area" to complete the process of confirming the seat, placing luggage and taking a seat, so it can significantly improve the boarding efficiency and reduce the boarding process time. On the premise of respecting the personal habits of passengers and not adding additional burdens, the time for passengers to find seats and arrange luggage in the cabin is shortened, and the boarding speed is greatly improved.

Owner:CIVIL AVIATION UNIV OF CHINA

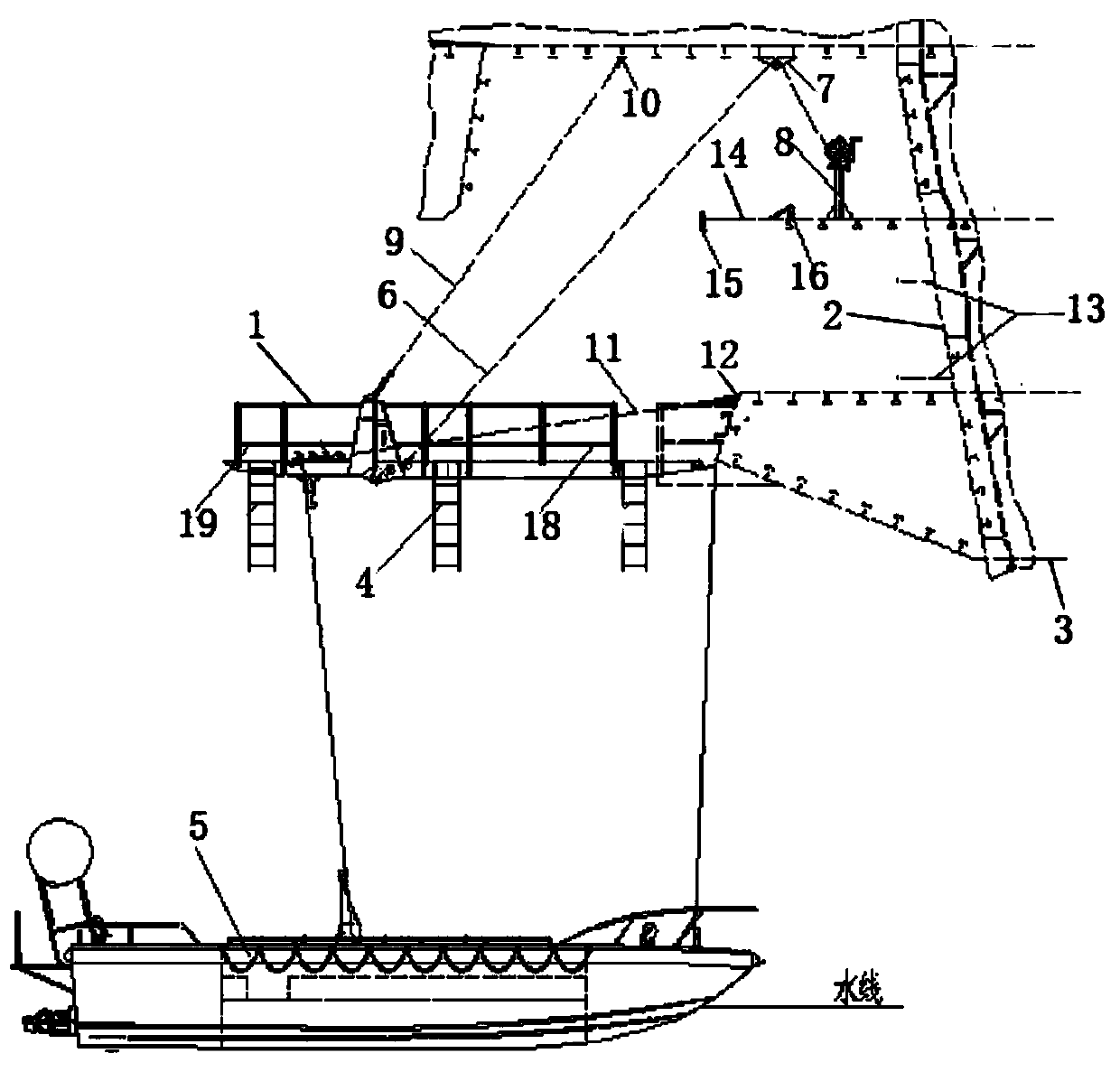

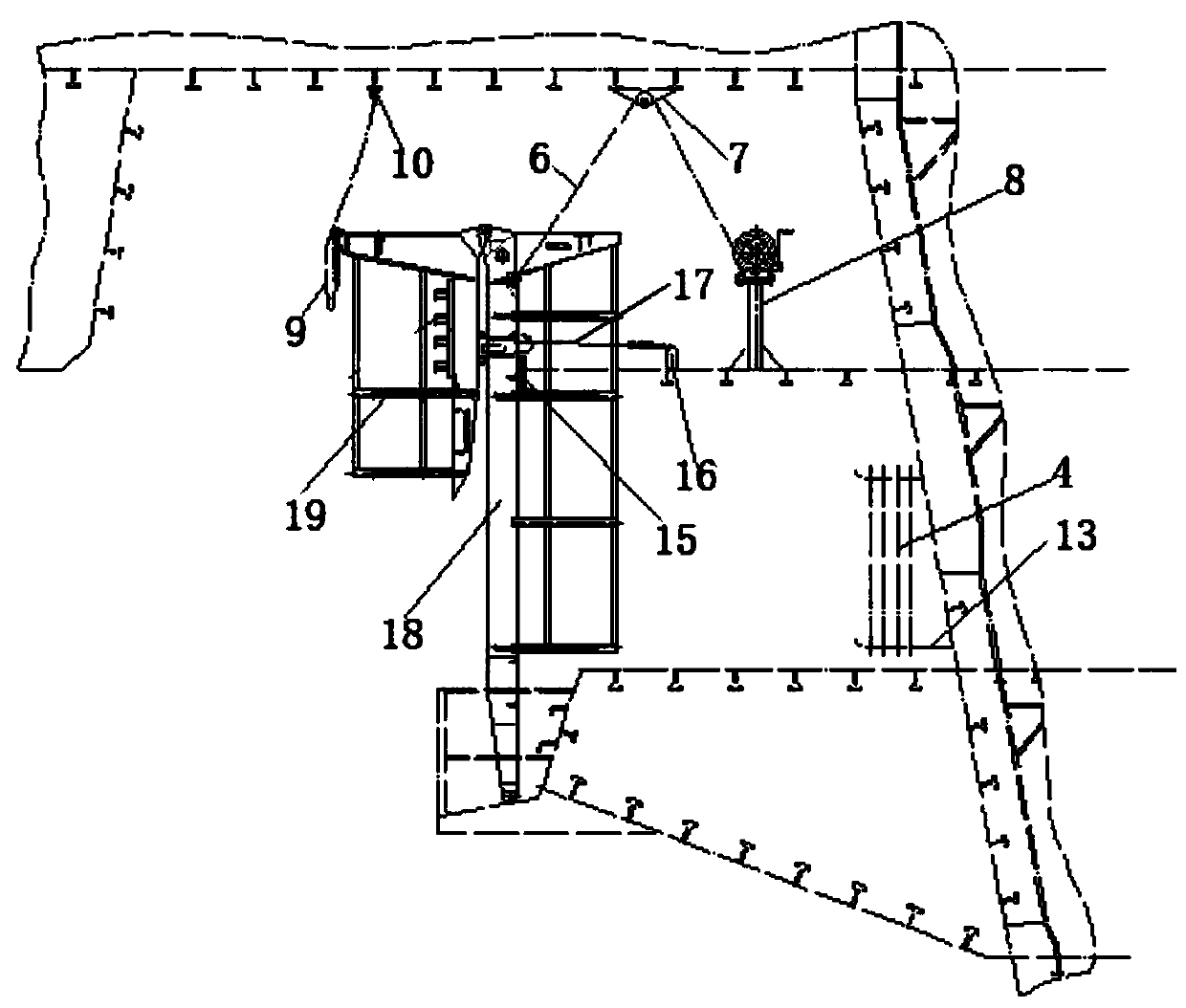

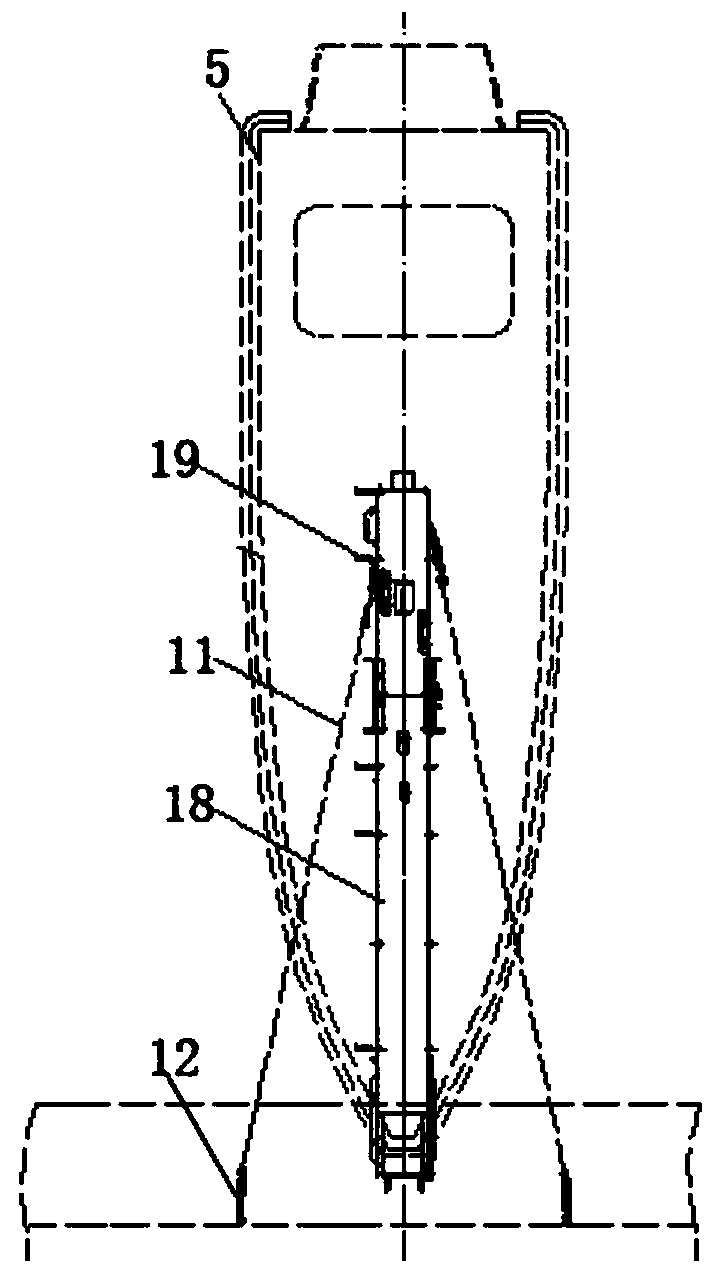

Long-span embarkation device for large ship

ActiveCN111572719AImprove convenienceReasonable designCargo handling apparatusPassenger handling apparatusLong spanMechanical engineering

The invention provides a long-span embarkation device for a large ship. The device comprises an embarkation platform, a platform hoisting mechanism, a platform locking mechanism and a platform positioning mechanism. An inner side end of the embarkation platform is hinged to a ship body and is installed corresponding to a low-layer deck, a rope ladder is tied and fixed to the embarkation platform,the platform hoisting mechanism is used for folding and unfolding the embarkation platform, the platform locking mechanism is used for unfolding and positioning the embarkation platform, and the platform positioning mechanism keeps the unfolding state of the embarkation platform to be stable. During use, a long span can be achieved, embarkation positions are more reasonably selected in an aspect of ship arrangement, and problems that personnel cannot easily reach embarkation positions, single person sequential embarkation efficiency is low and so on are solved.

Owner:CHINA SHIP DEV & DESIGN CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com