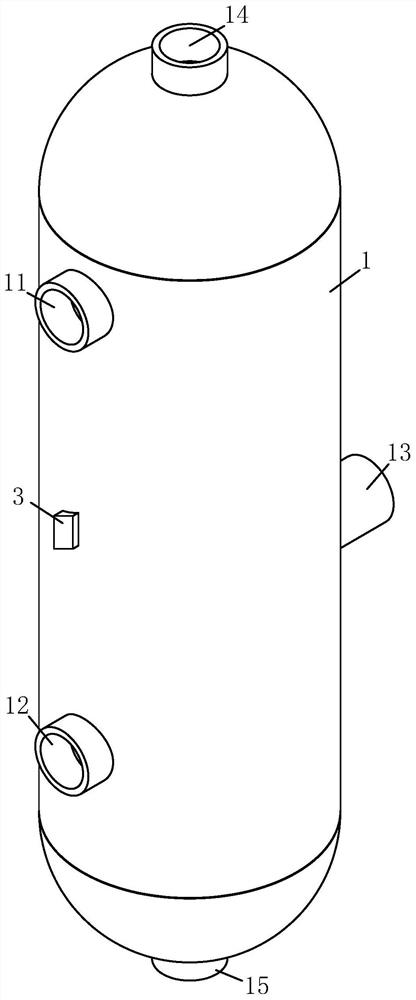

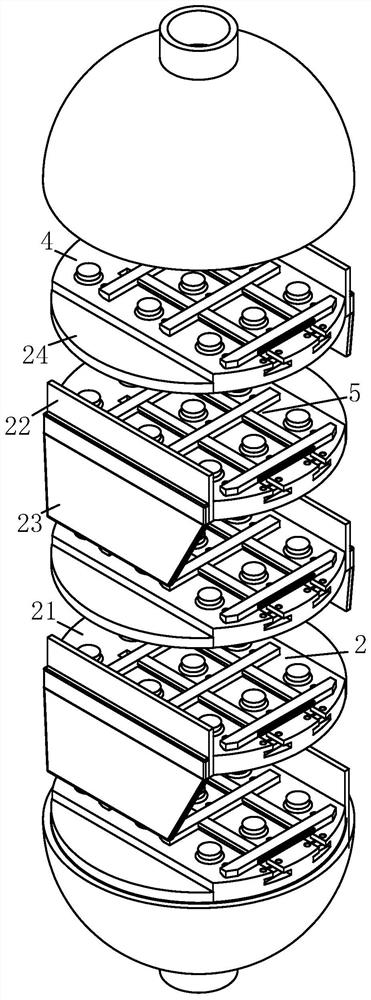

Plate-type packed rectifying tower

A technology of plate packing and rectification tower, which is applied in the direction of fractionation, etc., can solve the problems of insufficient gas pressure of rectification tower, insufficient gas-liquid contact, and affect production efficiency, so as to improve plate efficiency, increase gas-liquid contact, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

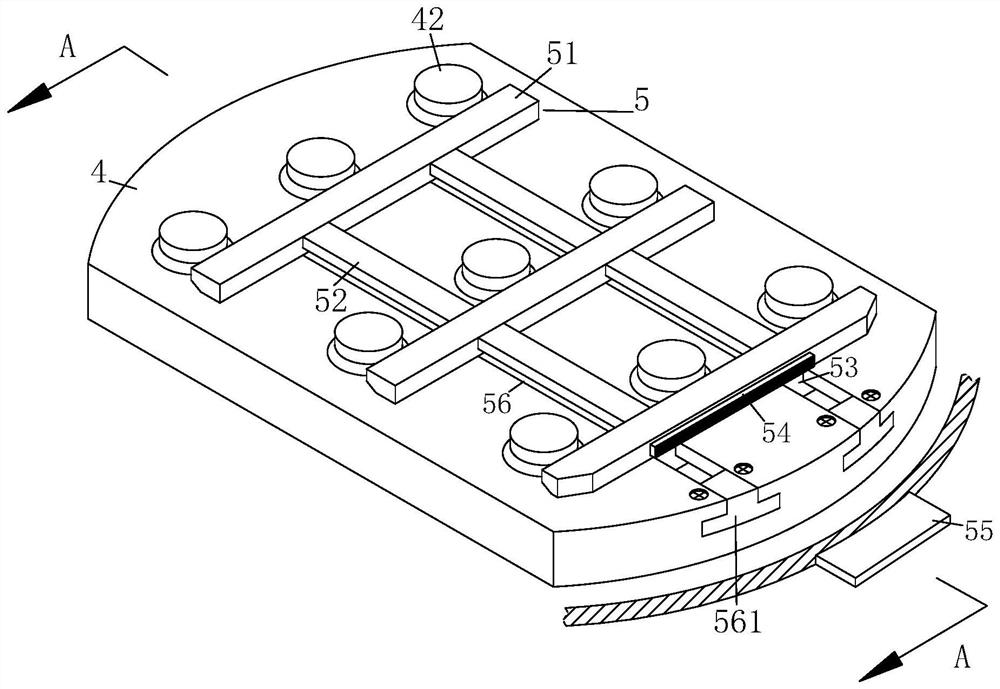

[0032] As an embodiment of the present invention, the ventilation groove 421 is tapered, the diameter of the opening of the ventilation groove 421 gradually decreases toward the upper end of the floating block 42 , and there is a gap between the top of the ventilation groove 421 and the upper end of the floating block 42 . During work, when the gas moves upwards along the ventilation groove 421, because the opening of the ventilation groove 421 is gradually reduced, the gas pressure is continuously increased, so that the liquid is not easy to leak from the auxiliary hole 212; The gap makes the auxiliary hole 212 in a sealed state before the floating block 42 is lifted, that is, when the rectification tower is working normally, and the liquid cannot leak from the auxiliary hole 212, which reduces the leakage phenomenon and ensures the safety of the auxiliary hole 212. Adjustability.

[0033] As an embodiment of the present invention, the upper end of the floating block 42 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com