Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Reduce length of stay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

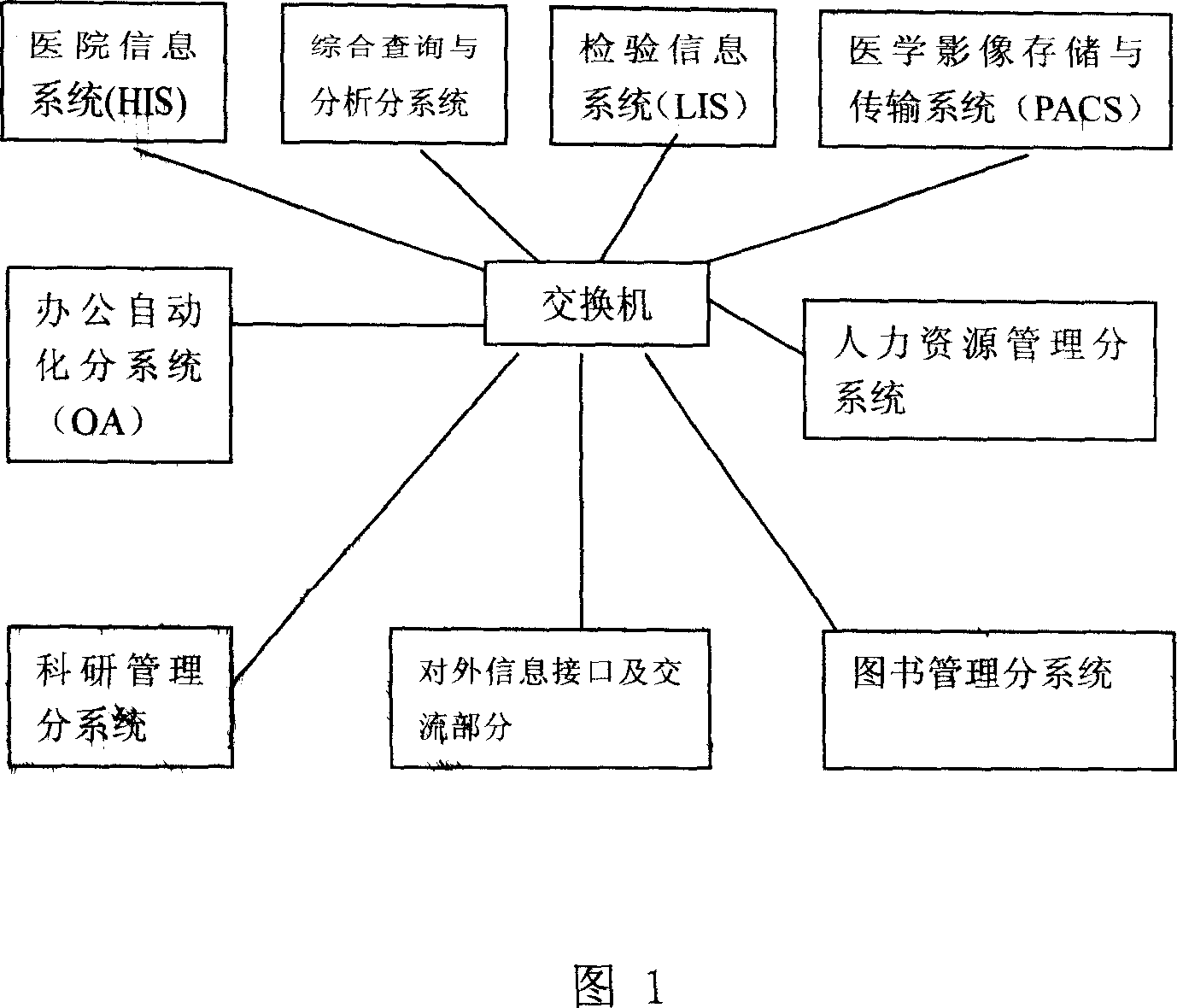

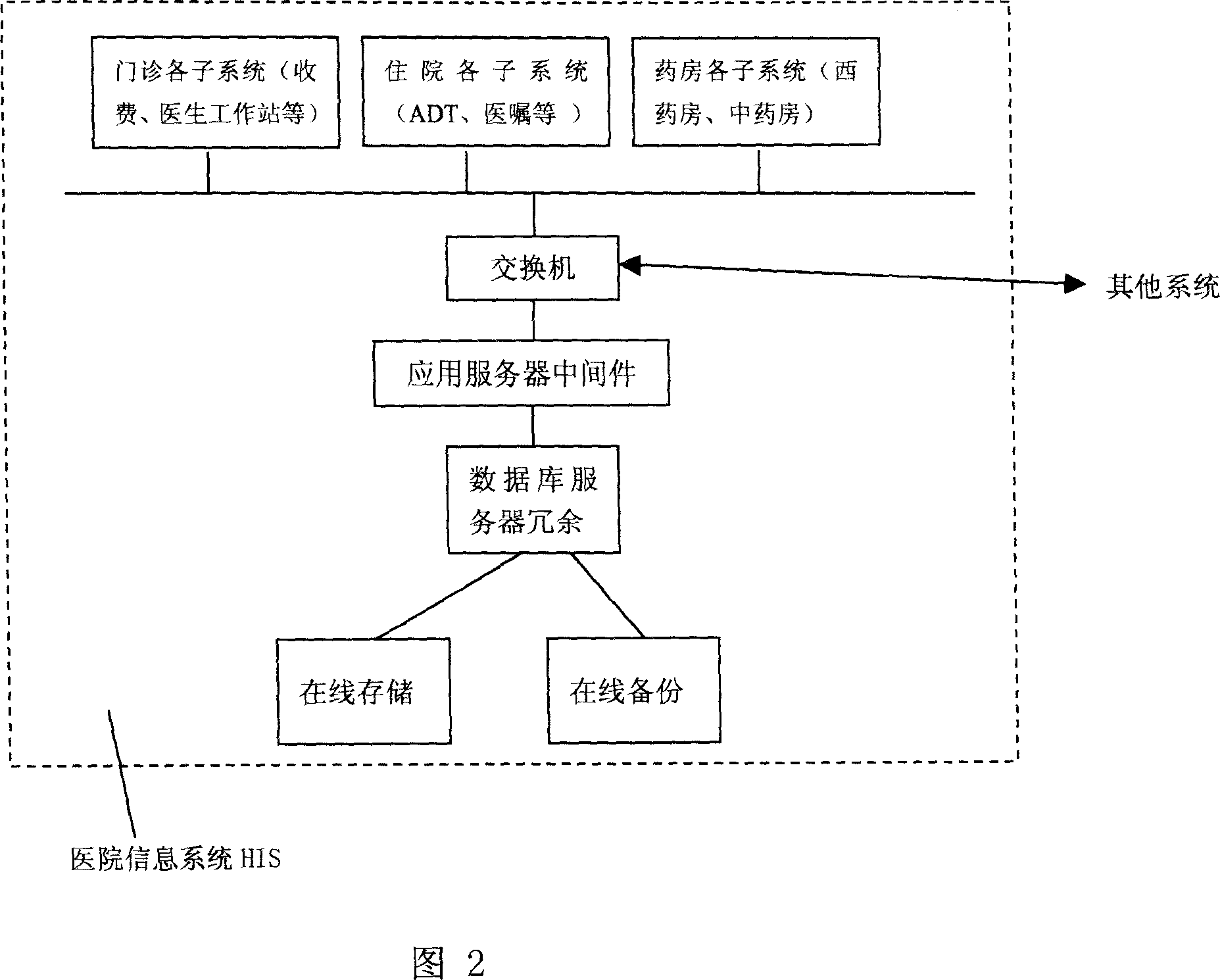

Hospital information system

InactiveCN101021912AImprove performanceImprove reliabilityOffice automationResourcesInformation transmissionSystems design

This invention discloses a hospital information system including HIS, PACS and LIS, in which, all the systems are connected by exchanges to realize information transmission and exchange.

Owner:ZHONG SHAN PEOPLES HOSPITAL

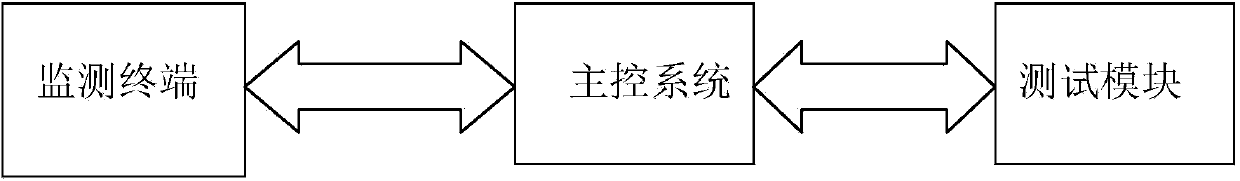

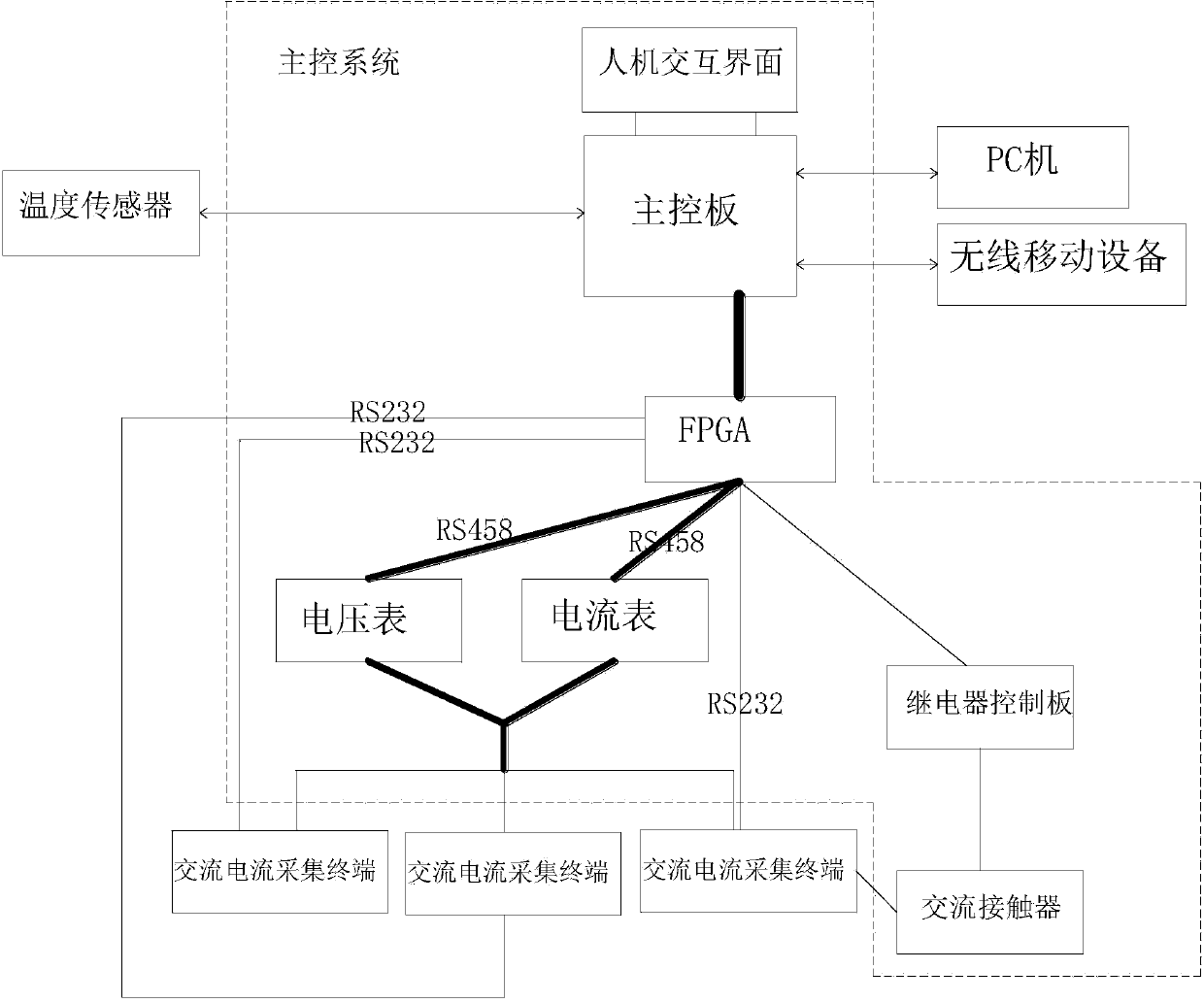

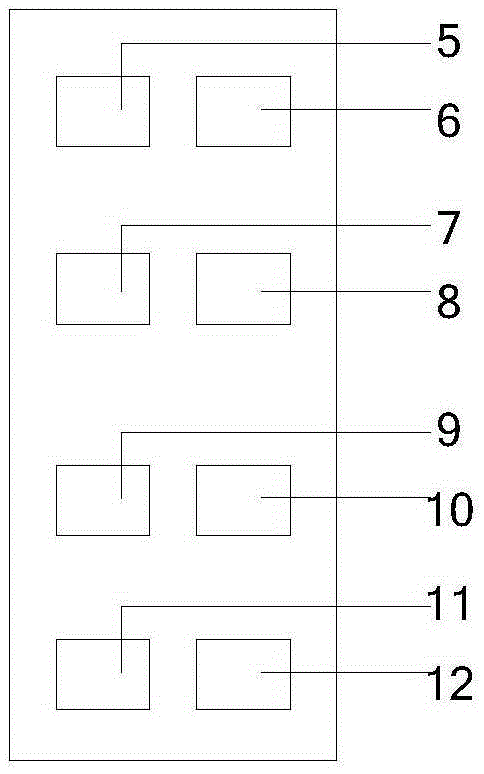

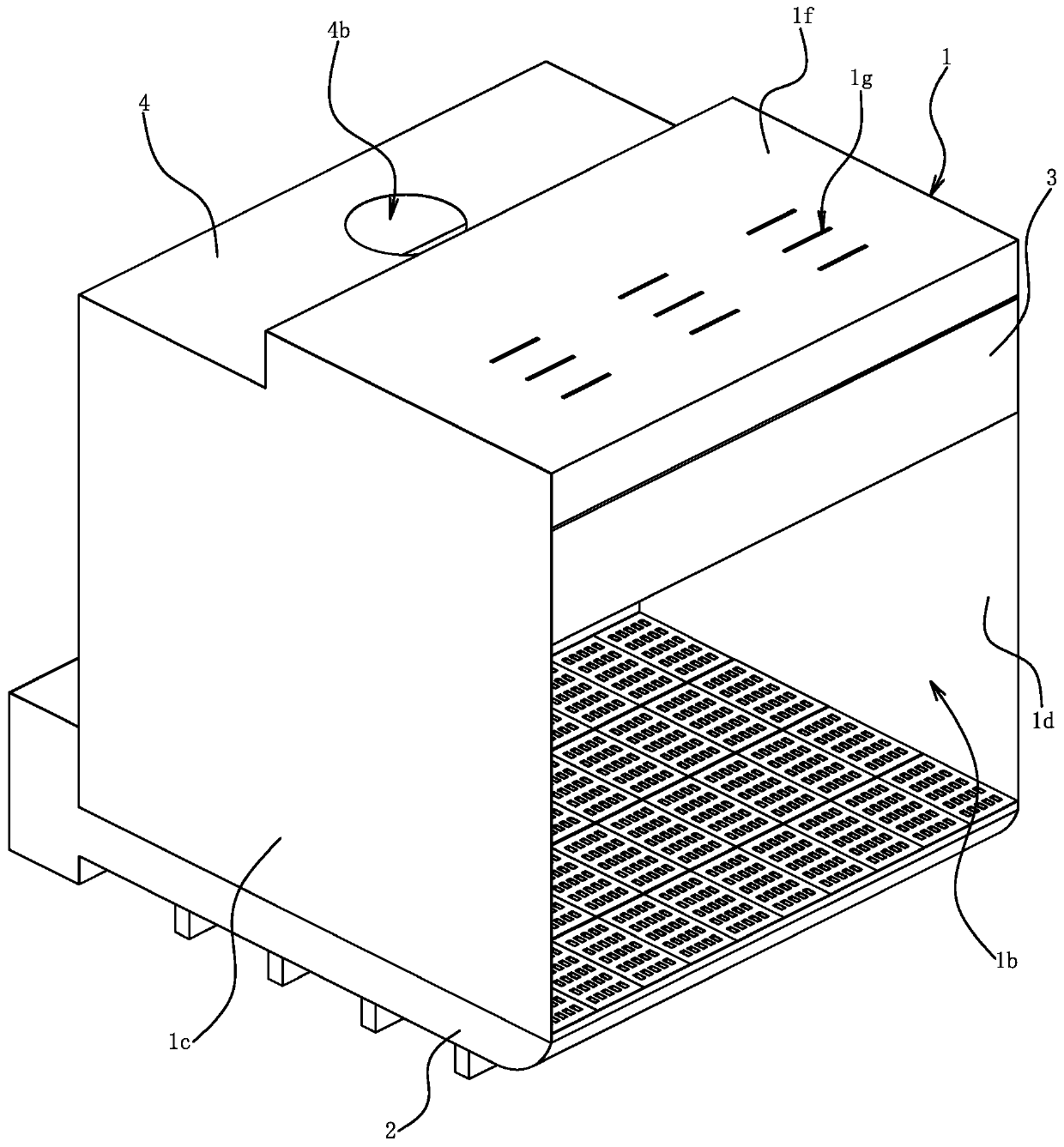

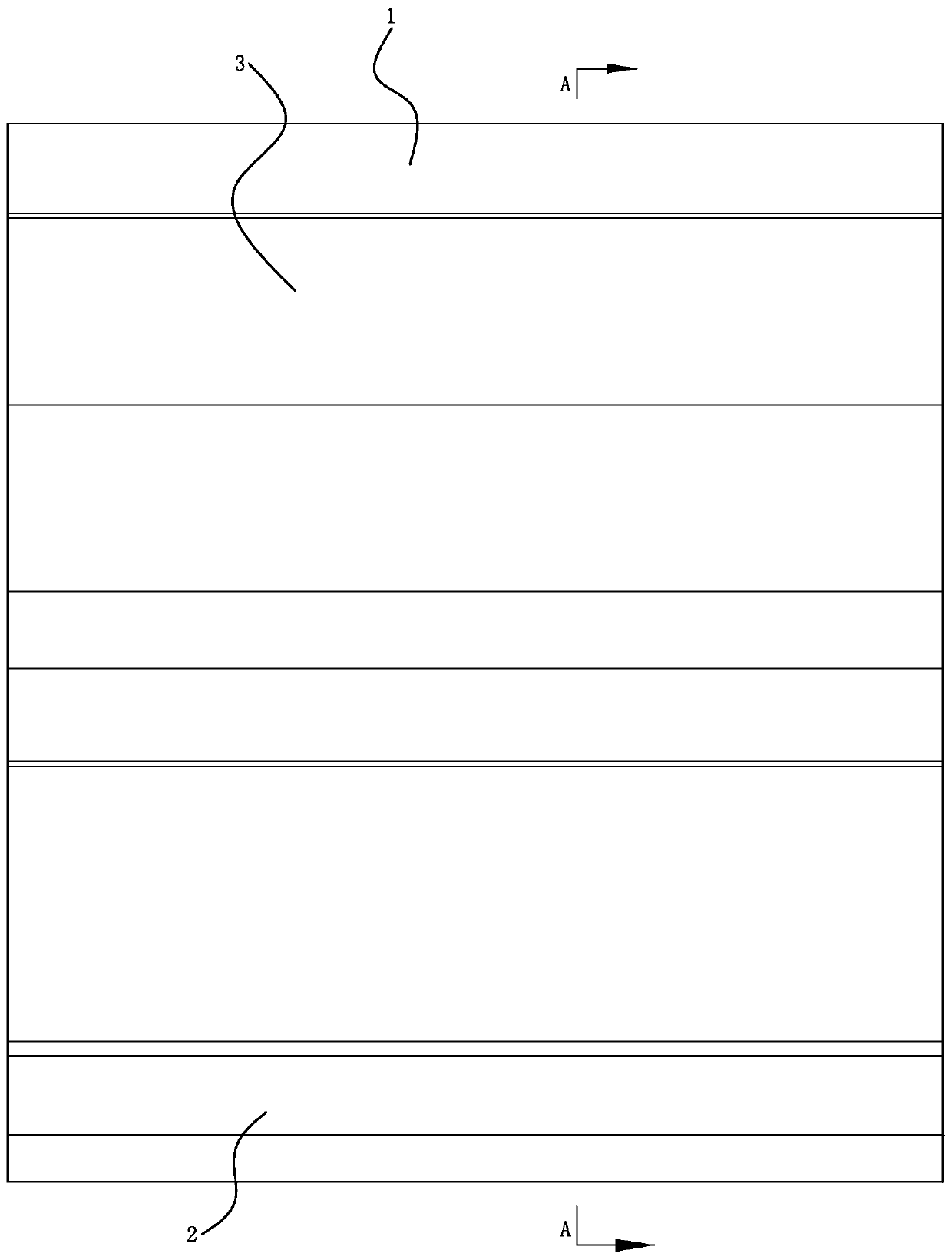

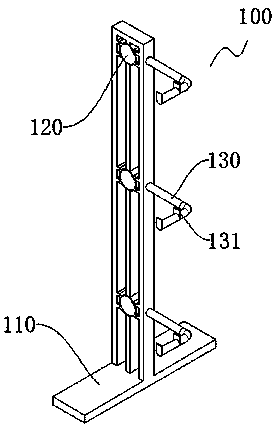

Aging test equipment for electronic products

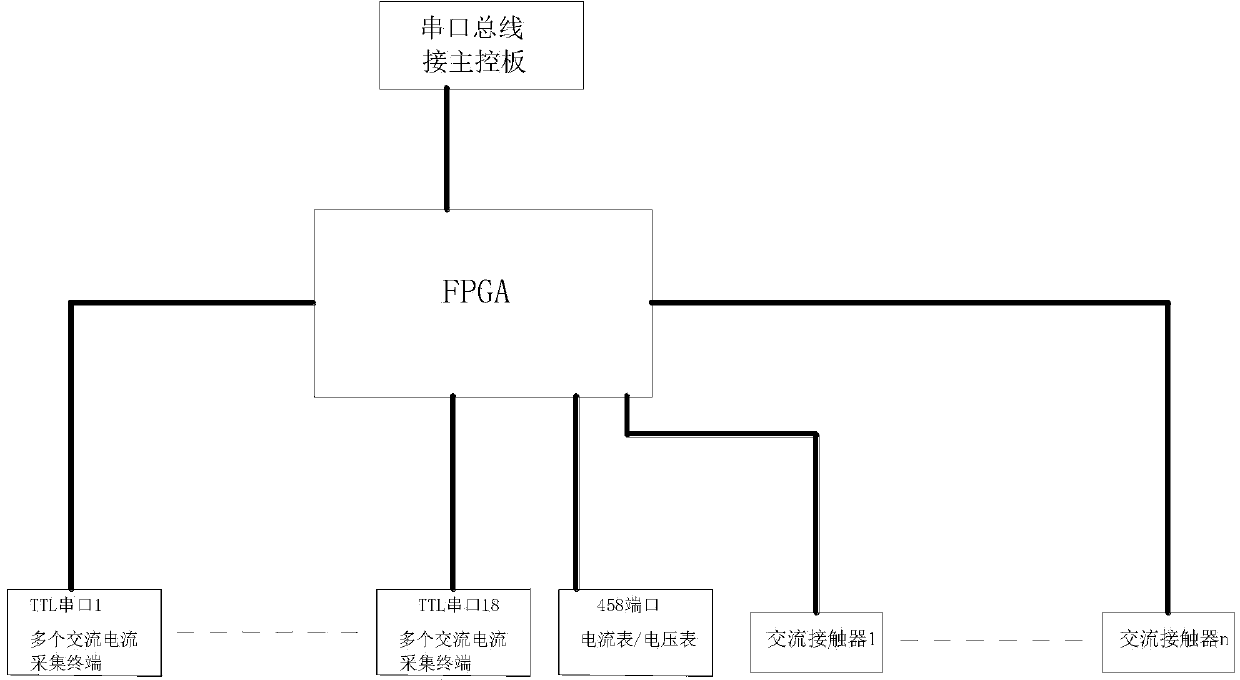

The invention particularly relates to aging test equipment for electronic products. The aging test equipment comprises a test module, a main control system and a monitoring terminal. The test module is in signal connection with the main control system, the main control system is connected with the monitoring terminal, the test module comprises a plurality of alternating-current acquisition terminals, and the main control system comprises a service processing module. The service processing module comprises a main control panel, an FPGA, an ampere meter, a voltmeter and a switch module, wherein the FPGA is respectively and electrically connected with the ampere meter and the voltmeter through ports 458, the FPGA is electrically connected with the alternating-current acquisition terminals which are grouped and combined into a bus and are connected with the ampere meter and the voltmeter respectively, and the FPGA is connected with the main control panel through a serial port bus. The aging test equipment for the electronic products can adapt to the electronic products of different kinds and different powers, can test the electronic products uniformly in batch on a large scale, is high in aging test efficiency and can meet the industrialization demands.

Owner:松阳西屏永新机械厂

Efficient multicast forward method based on sliding window in share memory switching structure

InactiveCN101188556AReduce forwarding spanReduce length of stayError prevention/detection by using return channelData switching networksSlide windowWindow Width

The invention belongs to a front end switching technology of an Ethernet switching system, in particular relates to a high-efficiency group-broadcasting repeat method based on a sliding window in a shared storage switching structure. The method adopts an optimization way outputting the sliding window and no longer uses a strict FIFO-type cell to make a repeat, but selects a suitable cell to make the repeat in a certain range (window width). The repeat way obviously decreases the repeat span of a group-broadcasting cell, thereby decreasing the stay time of the group-broadcasting cell in a shared storage area. The method has two most direct advantages that the method increases the synchronous level of the group-broadcasting cell repeat at every goal port, and lowers the consumption to a shared storage room. An analogue result shows that selecting the suitable window width can effectively increase the performances of the system at the two fields, but excessively widening the window width can not limitlessly increase the performances of the system, on the contrary, can increase the count complication.

Owner:WUHAN FIBERHOME NETWORKS

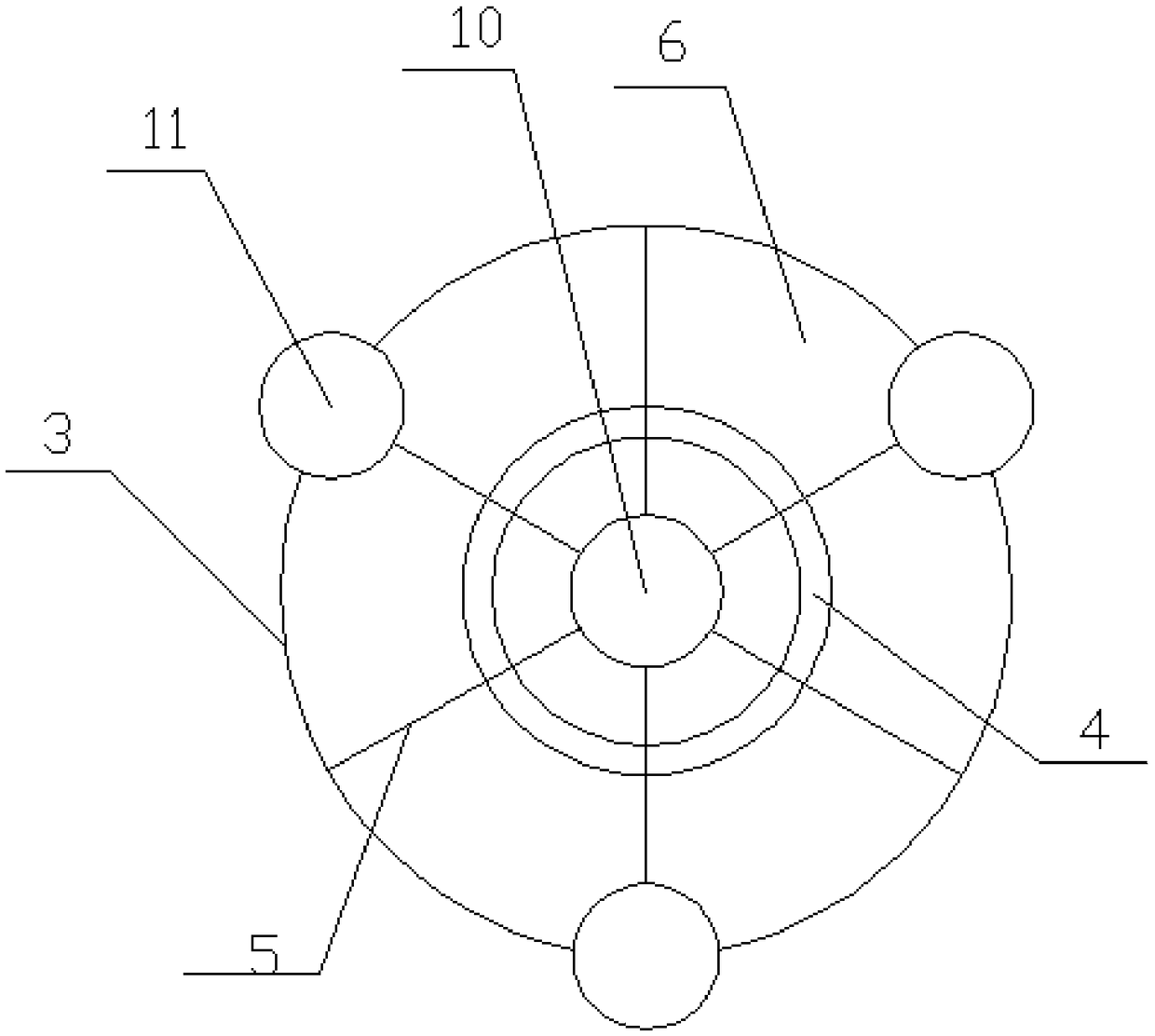

Connecting rod monitoring network and method for Beidou positioning node displacement for slope

ActiveCN109470134AReduce length of stayForce measurementElectrical/magnetic solid deformation measurementSloping shouldersEngineering

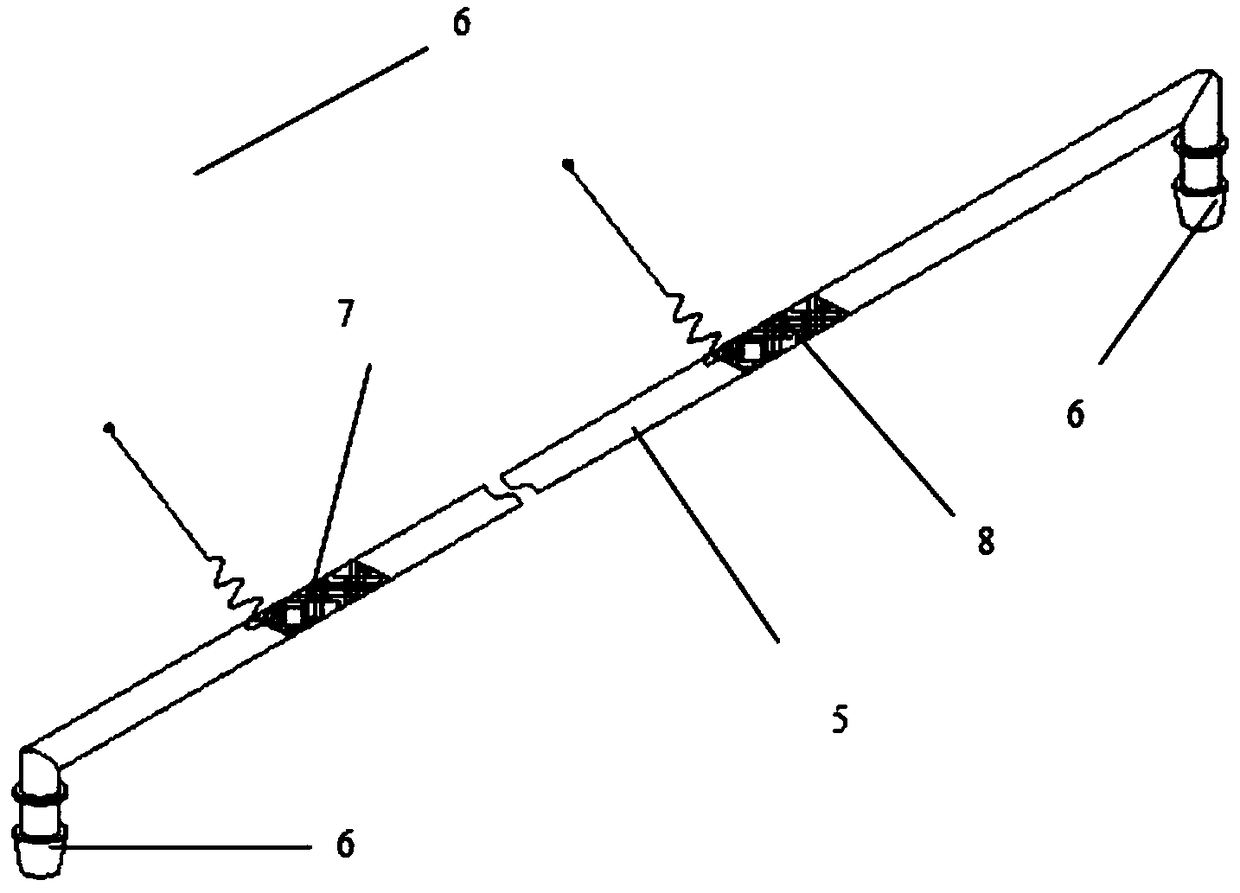

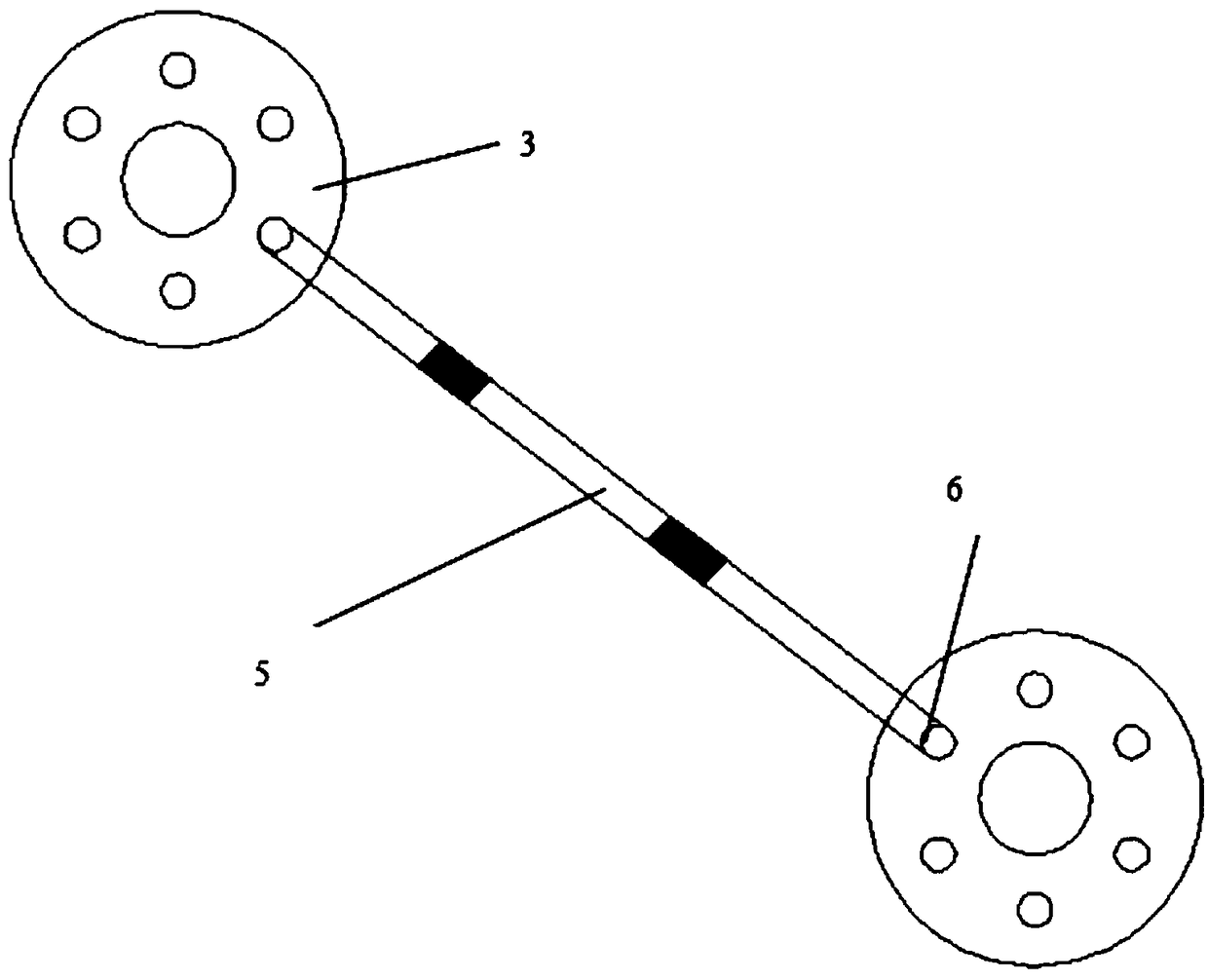

The invention provides a connecting rod monitoring network and method for Beidou positioning node displacement for a slope. The connecting rod monitoring network is composed of Beidou satellite positioning receiving nodes and stress strain monitoring connecting rods, wherein the Beidou satellite positioning receiving nodes mainly comprise Beidou satellite signal receiving modules and six-hole connecting rod connecting plates, and the rod bodies of the stress strain monitoring connecting rods are provided with tensile stress sensors and strain sensors. The Beidou satellite positioning receivingnodes are arranged on the slope surface or slope shoulder of the slope which need to be monitored, every adjacent two Beidou satellite positioning receiving nodes are connected through the corresponding stress strain monitoring connecting rod, and each Beidou satellite positioning receiving node can be connected with the other six nodes around the corresponding Beidou satellite positioning receiving node to form a group net on the monitored slope. The connecting rod monitoring network and method for the Beidou positioning node displacement for the slope have the advantages that an unattendedworking form is adopted, all data is transmitted wirelessly, and analysis can be carried out by receiving relevant data indoors regularly, so that the time for people to stay in a dangerous area in the field is shortened.

Owner:HOHAI UNIV

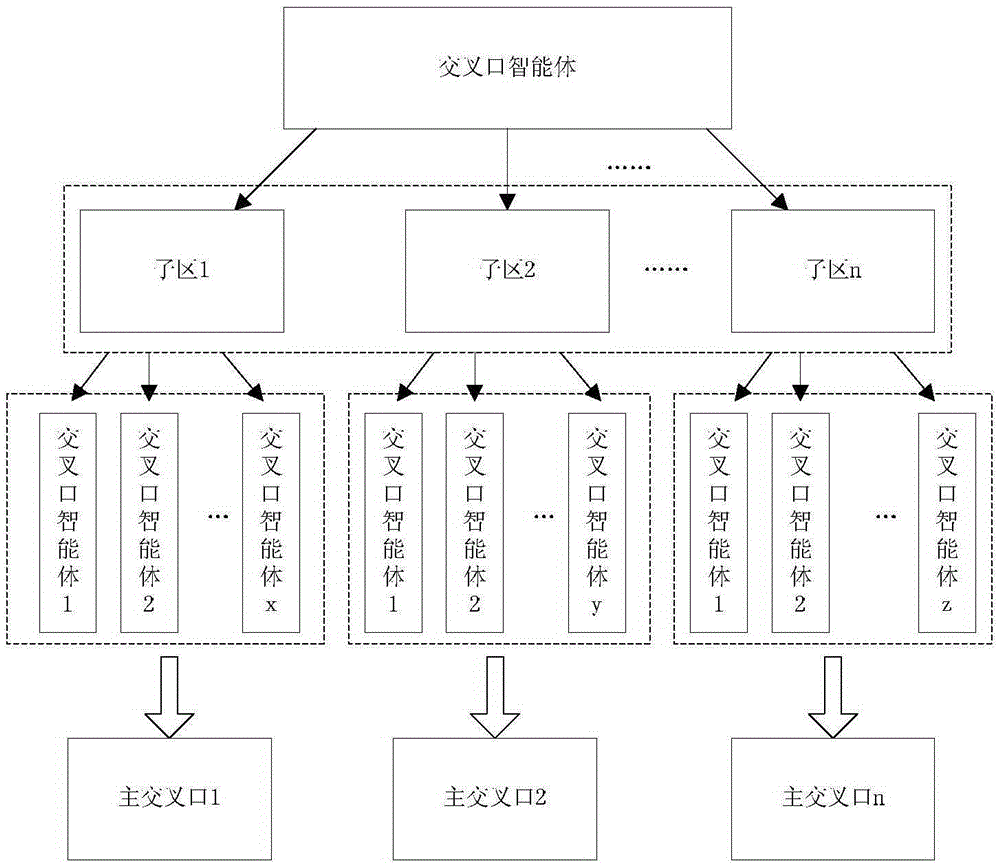

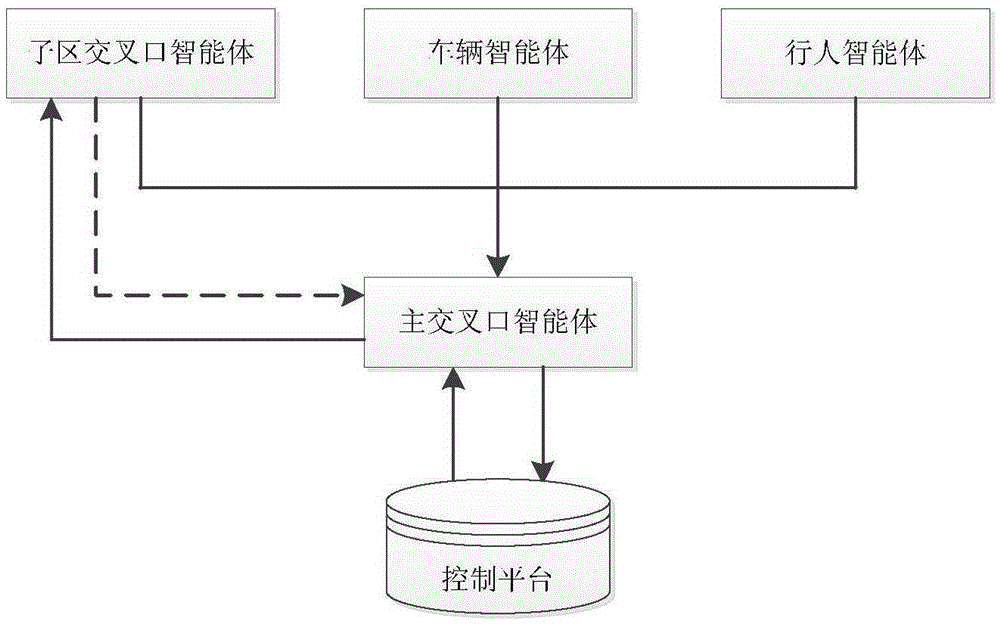

Urban road traffic network control method and system

InactiveCN105261222AReduce length of stayAvoid blockingRoad vehicles traffic controlRoad traffic controlTraffic network

The present invention provides an urban road traffic network control method and system. The urban road traffic network control method comprises: a. a control area is divided into a plurality of intersection subareas, an intersection of each subarea is respectively provided with an intersection agent used for detection and control of traffic information; b. correlations of the plurality of intersections are calculated in each subarea to determine an intersection agent having the highest correlation as a main agent of the subareas, and the main agent is used for gathering and uploading all the traffic information in the subarea; and c. the traffic is controlled and induced according to the gathered traffic information. According to the invention, intersections, road sections, vehicles and pedestrians are constructed to be agents, and the road traffic system is improved through the induction of travel behaviors of the vehicles and the pedestrians, so that the occurrence of the traffic jam may be avoided and the sojourn time of the vehicles on the road is reduced. Moreover, the traffic flow of each road section in the road network may be reasonably distributed, and the reliability and the stability of the road traffic network control may be ensured.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

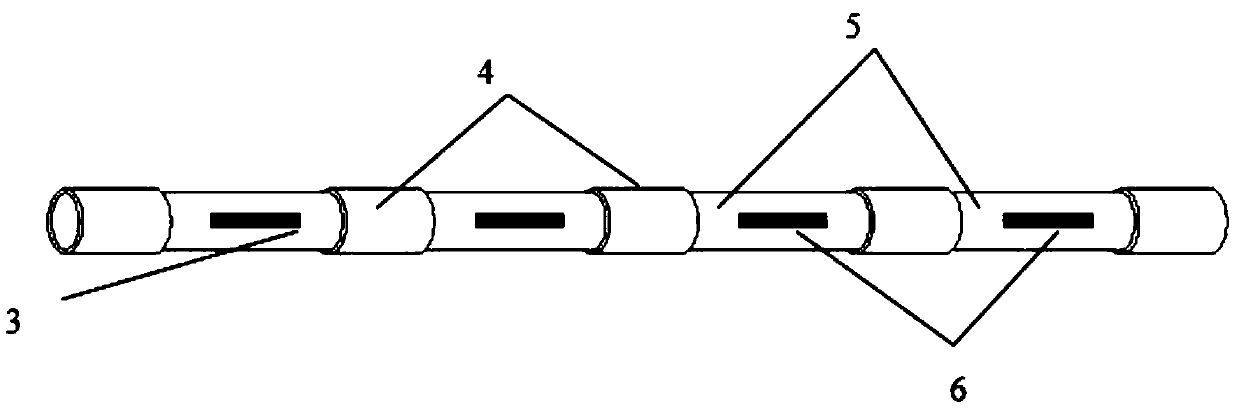

Multi-vector side slope monitoring anchor rod based on Big dipper location and monitoring method

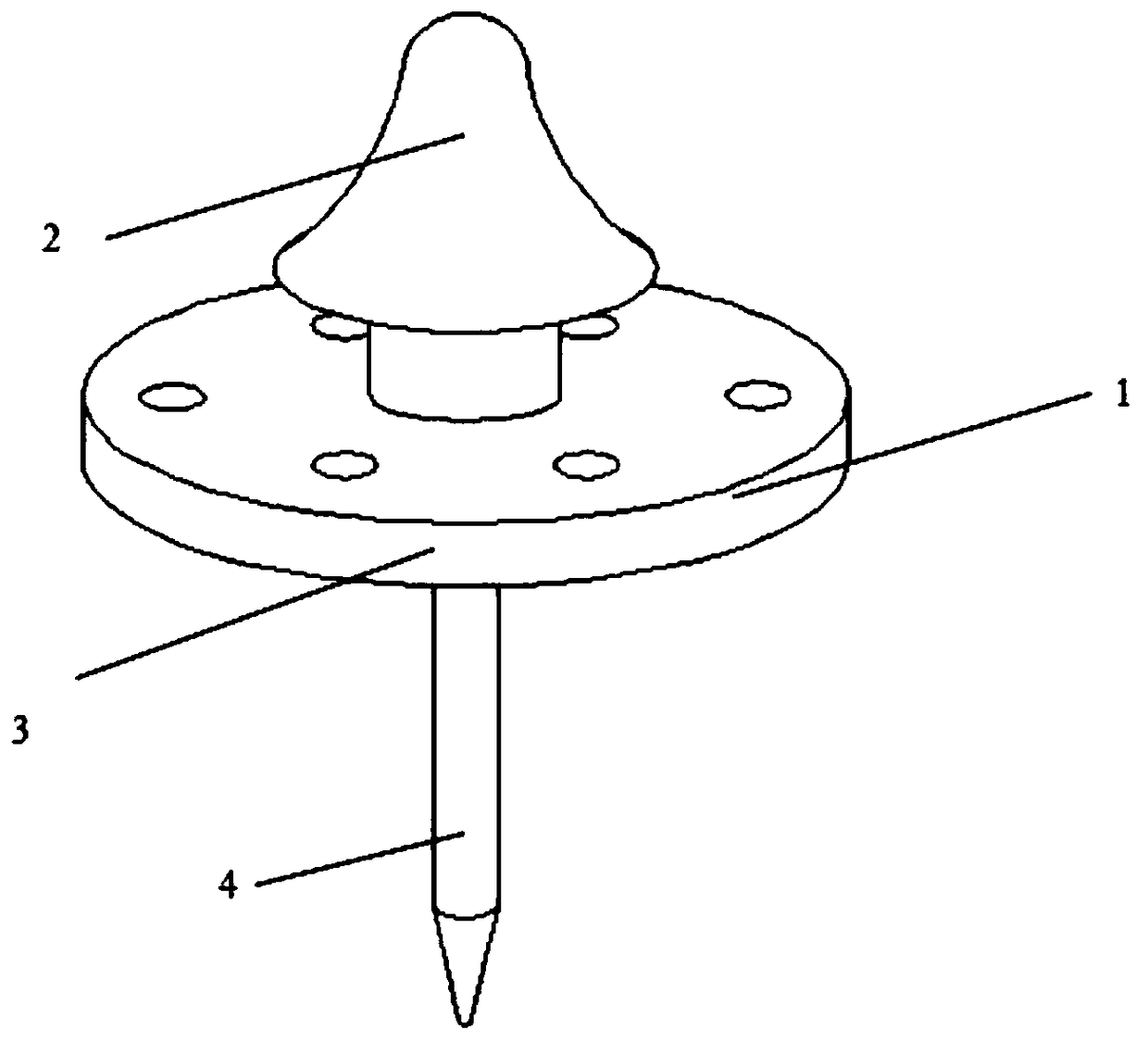

The invention provides a multi-vector side slope monitoring anchor rod based on Big dipper location and a monitoring method. The side slope monitoring anchor rod is formed by four parts including an end portion signal receiving and outputting device, a multi-section sensor inner core, a hydraulic three-tip anchor head and an outer cover protecting cylinder. The end portion signal receiving and outputting device mainly receives locating signals of the Big dipper. The multi-section sensor inner core is a core part and can be arranged into the side slope like the anchor rod, the multi-section sensor inner core and surrounding soil bodies or rock bodies are anchored in a multi-point manner through anchoring rings, an axial stress sensor, a torque sensor and an axial strain sensor are arrangedinside, and by means of a cable, convergence to the end portion signal receiving and output device. The hydraulic three-tip anchor head jacks the anchoring rings in the multi-section sensor inner coreout to expand, and anchoring with the surrounding soil bodies or surrounding rock is achieved. After hole forming, the multi-section sensor inner core is arranged in the outer cover protecting cylinder so as to be protected. According to the anchor rod, Big dipper location and navigation are adopted for initially monitoring the trend of occurrence of landslip, the exquisite sensor determines theposition of risk of landslip, and necessary data support is provided for early warning of landslip and treatment of project slipping resistance.

Owner:HOHAI UNIV

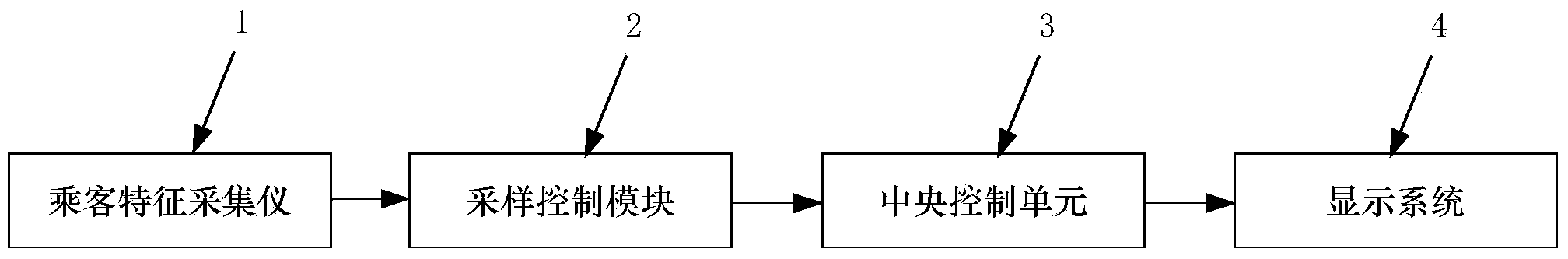

Boarding system based on passenger attributes

ActiveCN104077826AImprove boarding speedShorten boarding timeIndividual entry/exit registersComputer moduleSecurity check

The invention provides a boarding system based on passenger attributes, and belongs to the field of self-service boarding systems in airports. The boarding system comprises a passenger attribute acquirer, a sampling control module, a center control unit and a display system, wherein the passenger attribute acquirer acquires information of passengers and sends the information to the sampling control module; the sampling control module filters and processes the information, stores the processed information and sends available information into the center control unit; the center control unit determines a boarding sequence of the passengers passing through the security check by adopting a control program and an algorithm; the passengers who does not pass through the security check within half an hour ahead of the departure time of an airplane can board orderly according to the arrival sequence. Parts in the boarding system are common in the market; the system is low in development cost, and the boarding efficiency of the passengers can be effectively improved; the jam and the stagnation of the passengers in the boarding process and on the airplane can be reduced; the staying time of the airplane in the airport is shortened; and therefore, the flight times can be increased, and giant benefits are brought to a civil aviation system.

Owner:BEIHANG UNIV

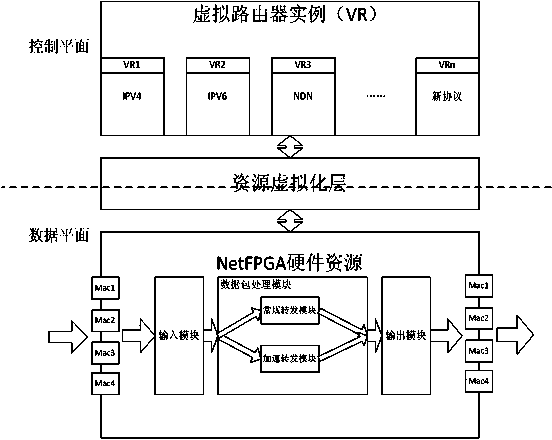

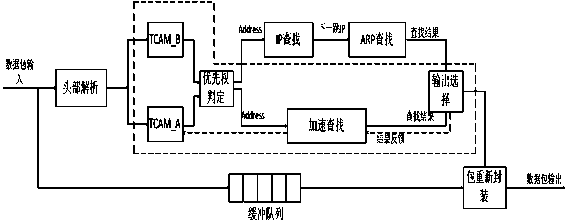

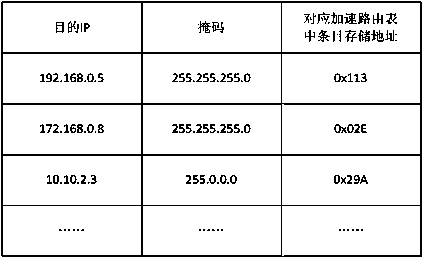

Accelerated data packet forwarding method and device based on NetFPGA (field programmable gate array) programmable virtual router

ActiveCN103856407ASolve insufficient capacityReduce lookupData switching networksRouting tableRoute search

The invention discloses an accelerated data packet forwarding method and an accelerated data packet forwarding device based on a NetFPGA (field programmable gate array) programmable virtual router. A local accelerated forwarding module is designed on a data forwarding plane, and the local accelerated forwarding module and the original conventional forwarding module form a double-engine structure; two search lines are switched through a priority selection module to form a complementary search structure. Items in an accelerated route table have life cycles; data in the table can be regularly updated through a regular updating mechanism. Due to the design of the accelerated forwarding module, the programmable virtual router can shorten the search process data packets, reduce the search times for the route table, relieve the route search burden and fulfill the aim of accelerating data packet forwarding in a procedure of processing the data packets.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

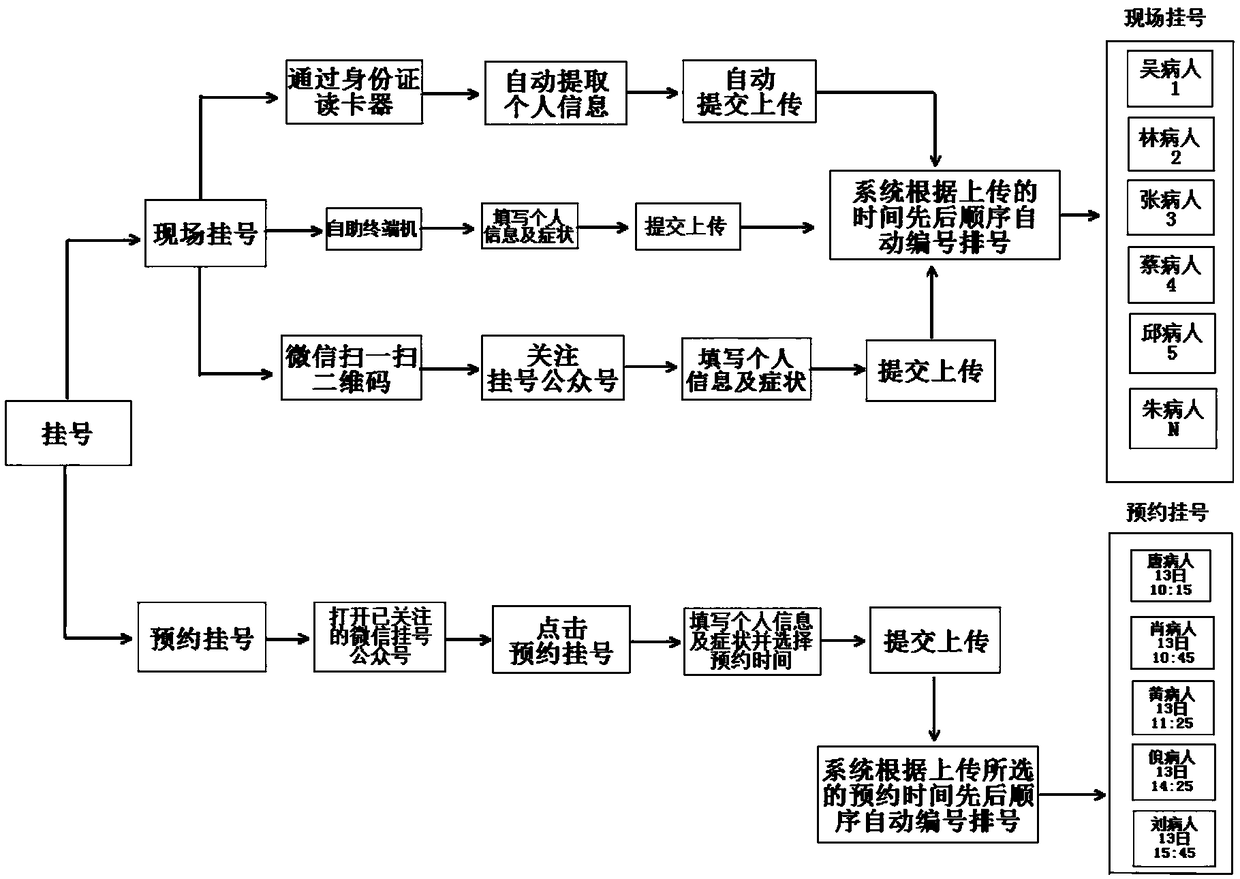

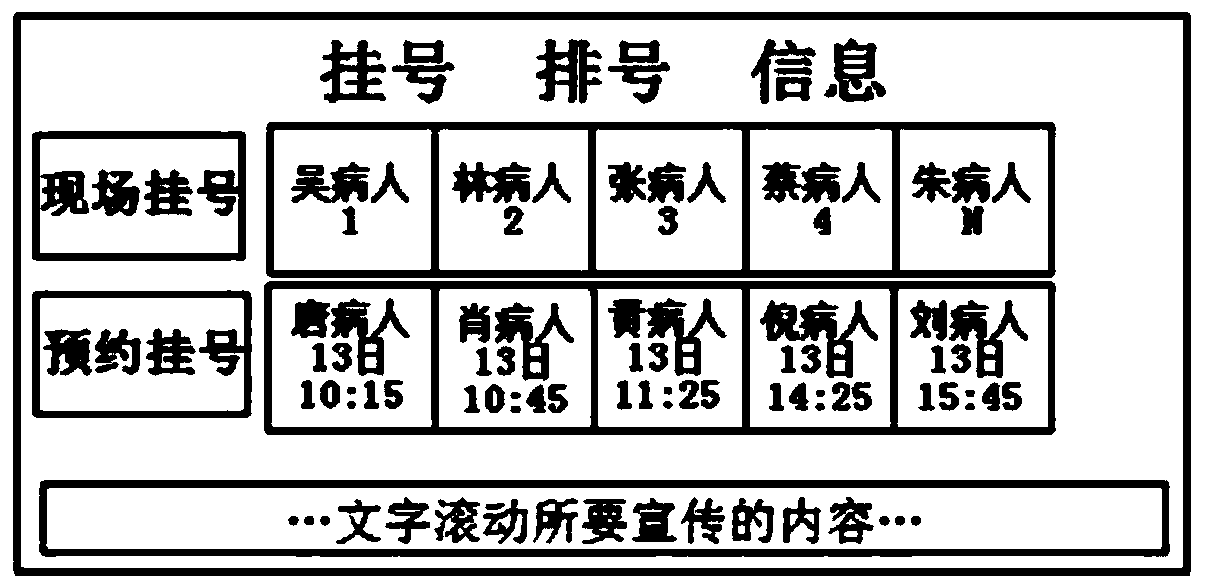

Intelligent registering and queuing synchronous system

InactiveCN108629881AReduce length of stayArrangement of medical treatment in a standardized and orderly mannerHealthcare managementReservationsComputer hardwareOffice systems

The invention discloses an intelligent registering and queuing synchronous system which comprises a registering terminal, a signal transmission end and a doctor attendance information terminal. The registering terminal comprises an on-site registering module and a reservation registering module, the signal transmission end comprises an information uploading end and an information processing end, and the doctor attendance information terminal comprises a terminal display screen and the left side of a main interface of a Yiyisheng outpatient service cloud office system. Registration can be realized through on-site registration and reserved registration, on-site registration includes ID card reading, self-help terminal filling-out and Wechat two-dimensional code scanning, registration by using ID cards is more suitable for the aged, the self-help terminal is suitable for people without carrying own mobile phones and ID cards, and Wechat two-dimensional code scanning is suitable for youngpeople carrying their ID cards. On the other side, reserved registration can realize advanced reservation, so that time waste caused by queuing is avoided.

Owner:深圳医翼升网络科技有限公司

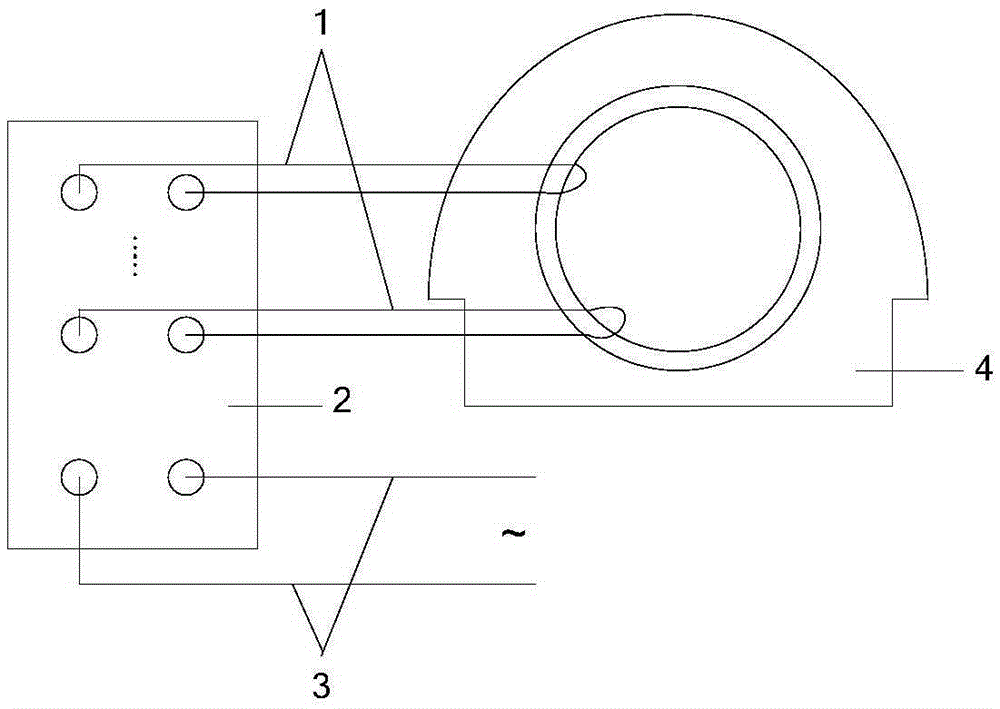

Electric generator iron loss test apparatus and experimental method

InactiveCN105259424ASpeed up test wiringTest securityResistance/reactance/impedenceDynamo-electric machine testingExperimental methodsSwitchgear

The invention discloses an electric generator iron loss test apparatus and an experimental method. According to the invention, one end of a grouping test cable is connected directly with a switchgear, the other end is wounded onto an iron core of an electric generator for a set number of turns and then connected to the switchgear, and the switchgear is connected with a power supply through a power supply cable; the grouping test cable comprises a plurality of groups of test cables of different number and length. The invention has the beneficial effects of being capable of greatly accelerating the test connection link, ensuring a safe and reliable test, meanwhile greatly reducing work hours and improving work efficiency.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

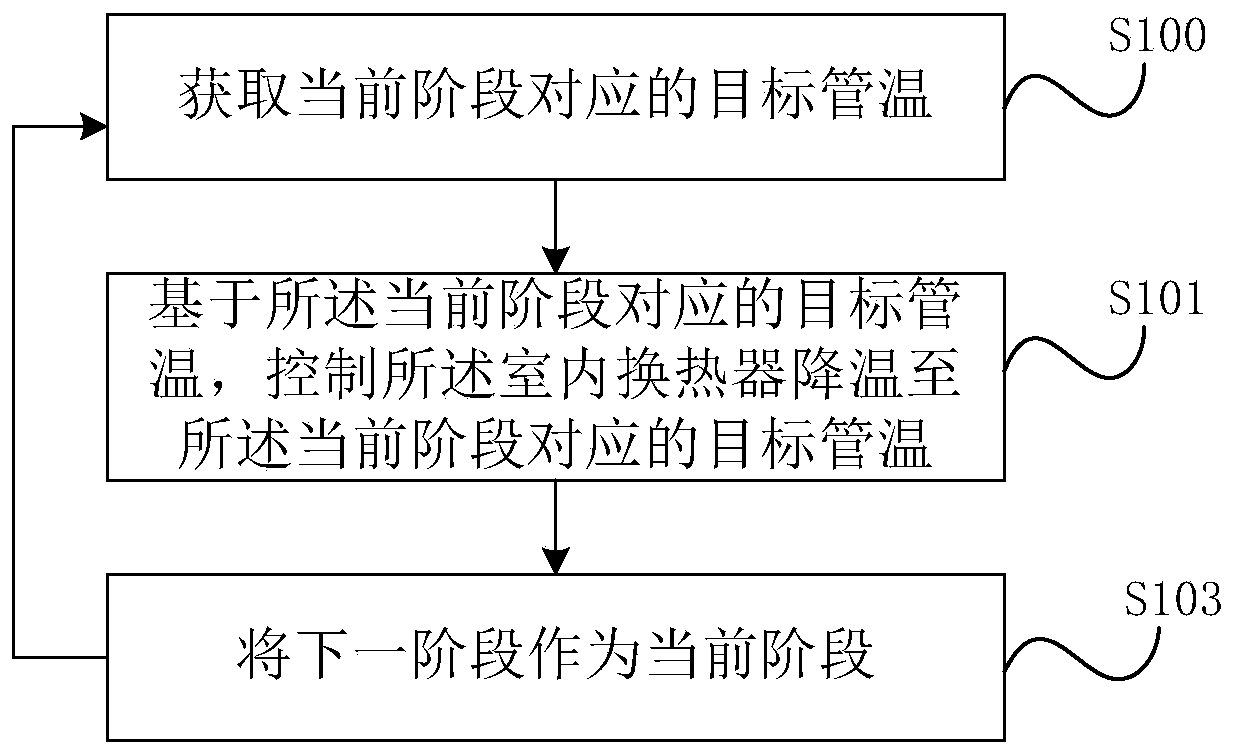

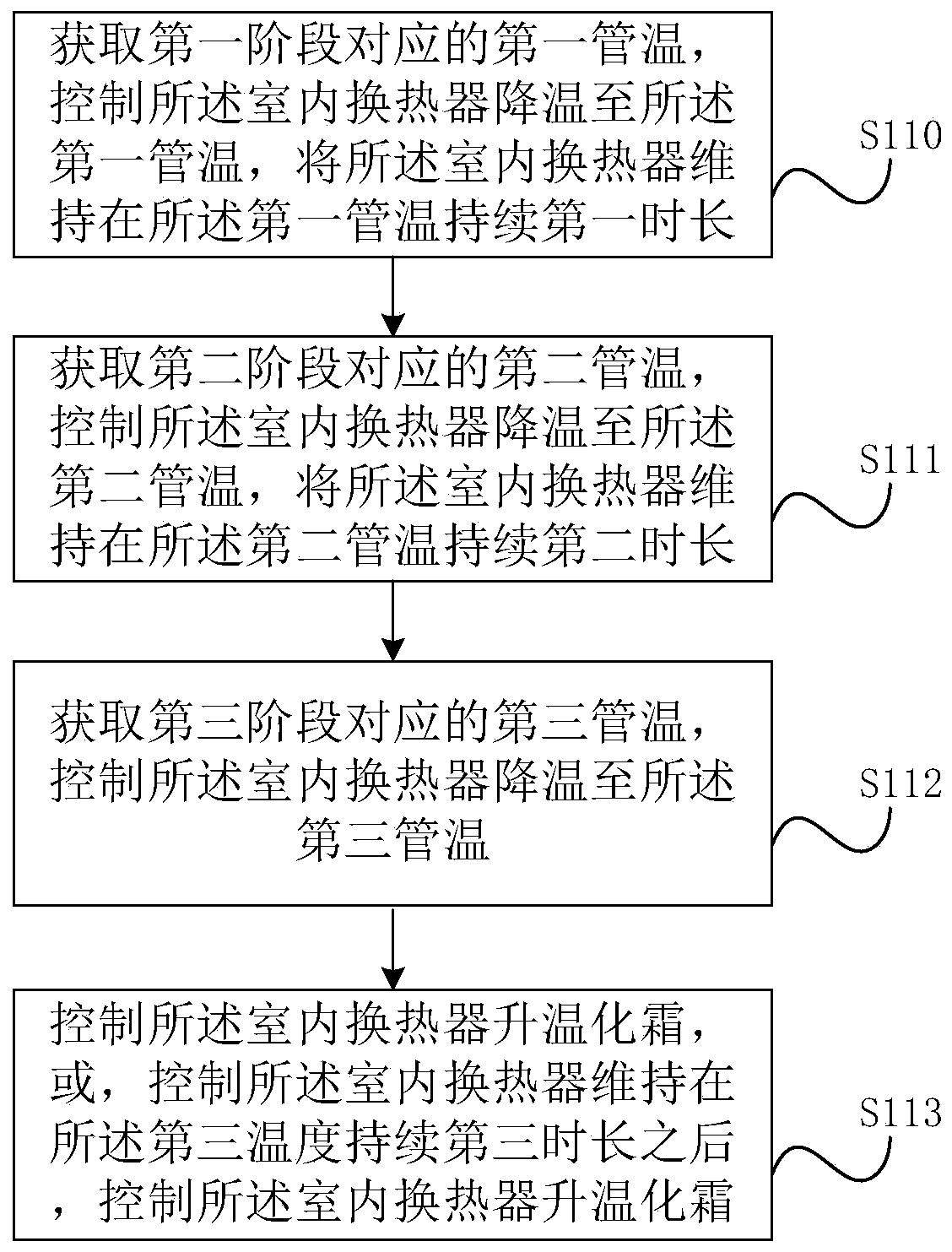

Air conditioner self-cleaning control method and device, air conditioner and storage medium

ActiveCN111442463ATube temperature dropTarget tube temperature dropMechanical apparatusNoise suppressionProcess engineeringControl room

The invention provides an air conditioner self-cleaning control method and device, an air conditioner and a storage medium. The air conditioner self-cleaning control method comprises the step that when the air conditioner is in a self-cleaning mode, an indoor heat exchanger is controlled to cool and frost stage by stage, wherein the operation of controlling the indoor heat exchanger to cool and frost stage by stage comprises the steps that target tube temperatures corresponding to all the stages are acquired sequentially, and the indoor heat exchanger is controlled to cool based on the targettube temperatures corresponding to all the stages. Through the method, cooling speed of the indoor heat exchanger can be reduced, and noise generated in the frosting process can be lowered.

Owner:NINGBO AUX ELECTRIC +1

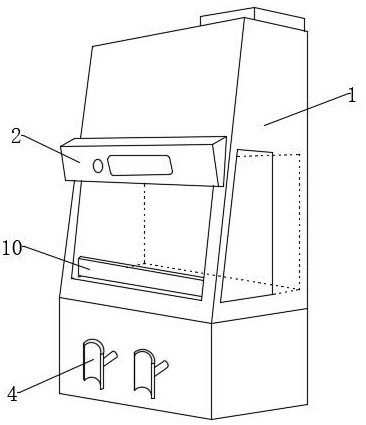

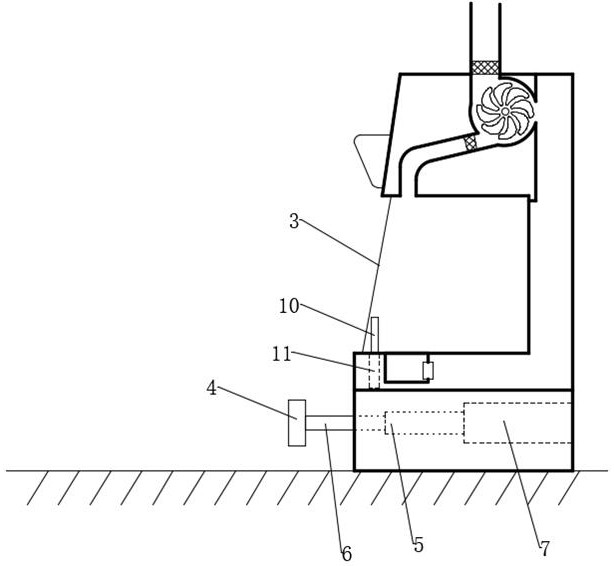

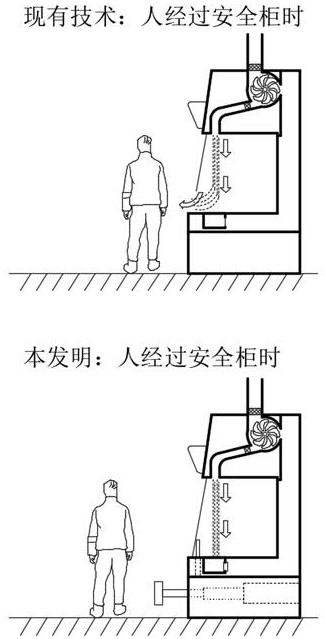

High-safety biological safety cabinet and use method thereof

ActiveCN113368908AHas double protectionNo leakageEnclosures/chambersStructural engineeringMechanical engineering

Owner:南通江涌投资开发有限公司

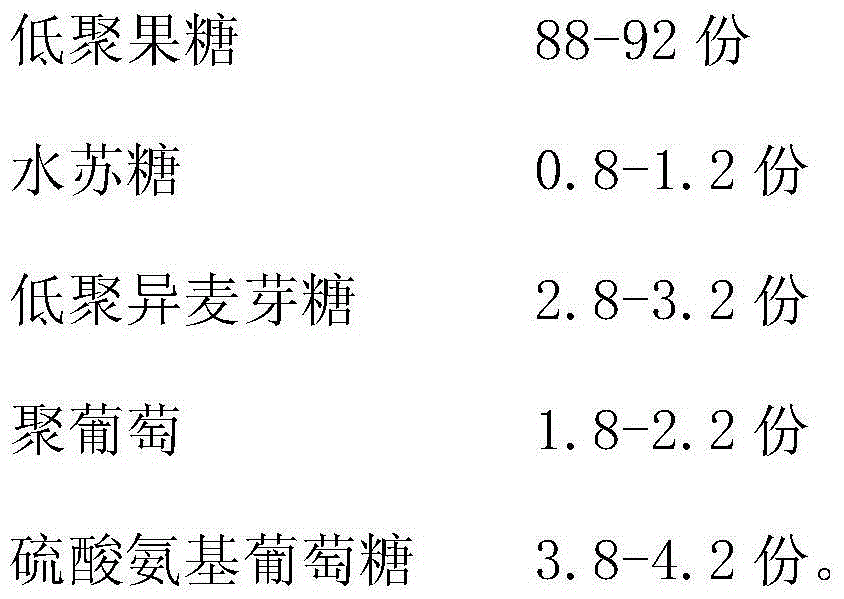

Prebiotics composition

InactiveCN104824511AReduce symptoms of constipationReduce length of stayFood preparationGlucosamine SulfatePolydextrose

The invention relates to a prebiotics composition which contains fructo-oligosaccharide, stachyose, xylooligosaccharide, polydextrose and glucosamine sulfate. The composition can be prepared into foods or health-care foods suitable for being taken. Experiments confirm that the prebiotics composition plays the role of enhancing the immunity.

Owner:张利民

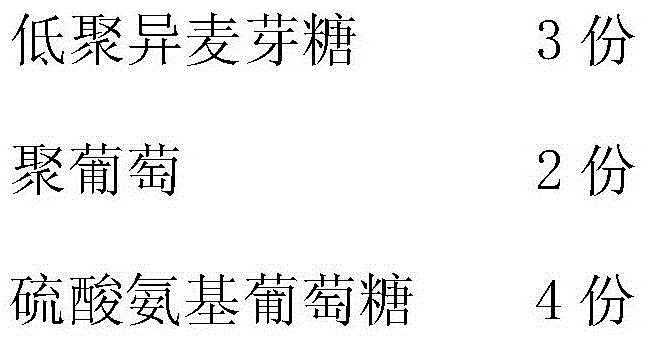

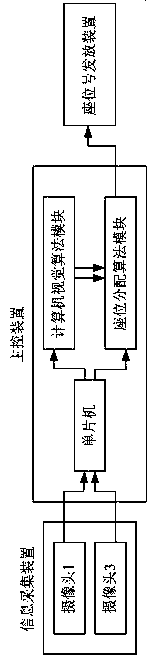

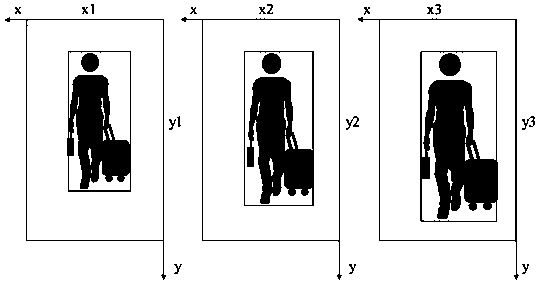

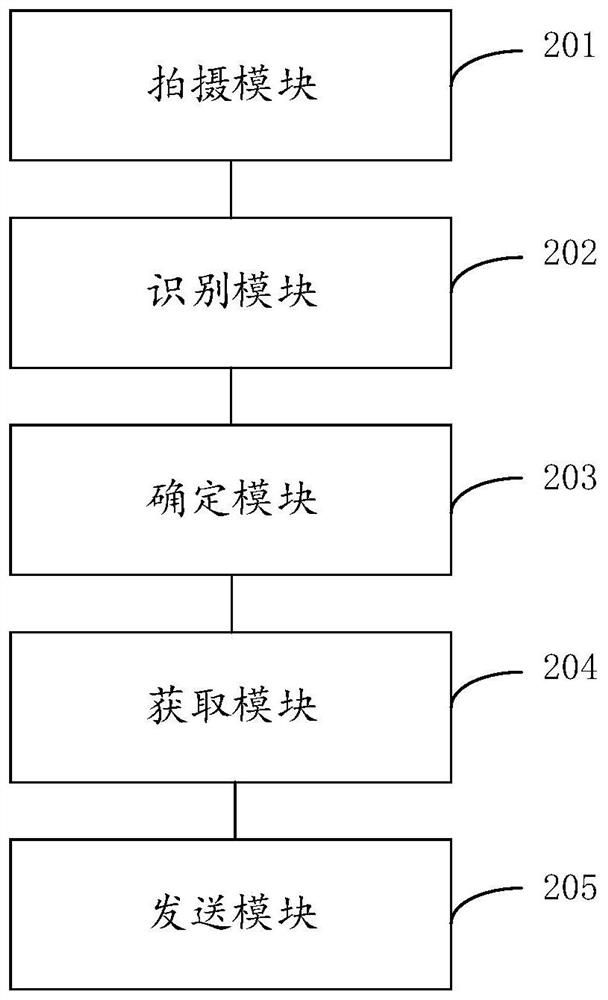

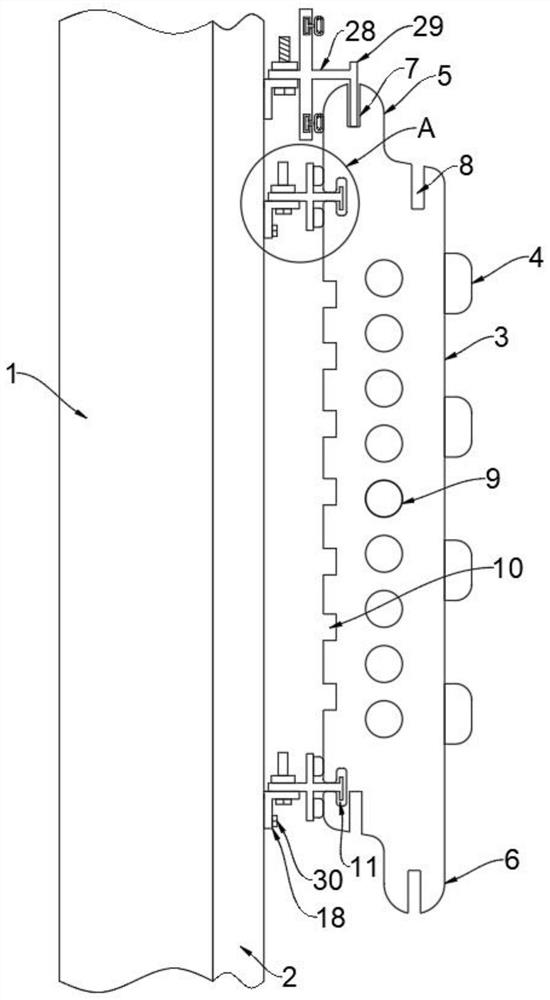

Dynamic boarding method based on passengers and baggage

InactiveCN108470393AImprove traffic efficiencyReduce length of stayLottery apparatusIndividual entry/exit registersEconomic benefitsSimulation

The invention discloses a dynamic boarding method based on passengers and baggage. According to the method, a dynamic boarding system is firstly constructed, an information collecting device of the system collects passenger image information, a computer visual algorithm module of a main control device calculates passenger agility degree coefficient alpha and baggage coefficient beta, and a seat allocation algorithm module of the main control device performs seat allocation based on the situation of group passengers and reserved seats; a seat number issuing device issues a seat number to each passenger at a boarding gate based on the obtained seat number. The dynamic boarding method designs a new seat allocation algorithm, solves the actual execution problem of boarding, increases the dynamic boarding method, improves the passenger passing efficiency at the boarding gate, and shortens the sojourn time of an aircraft at an airport, thereby bringing huge economic benefits to airlines.

Owner:CIVIL AVIATION UNIV OF CHINA

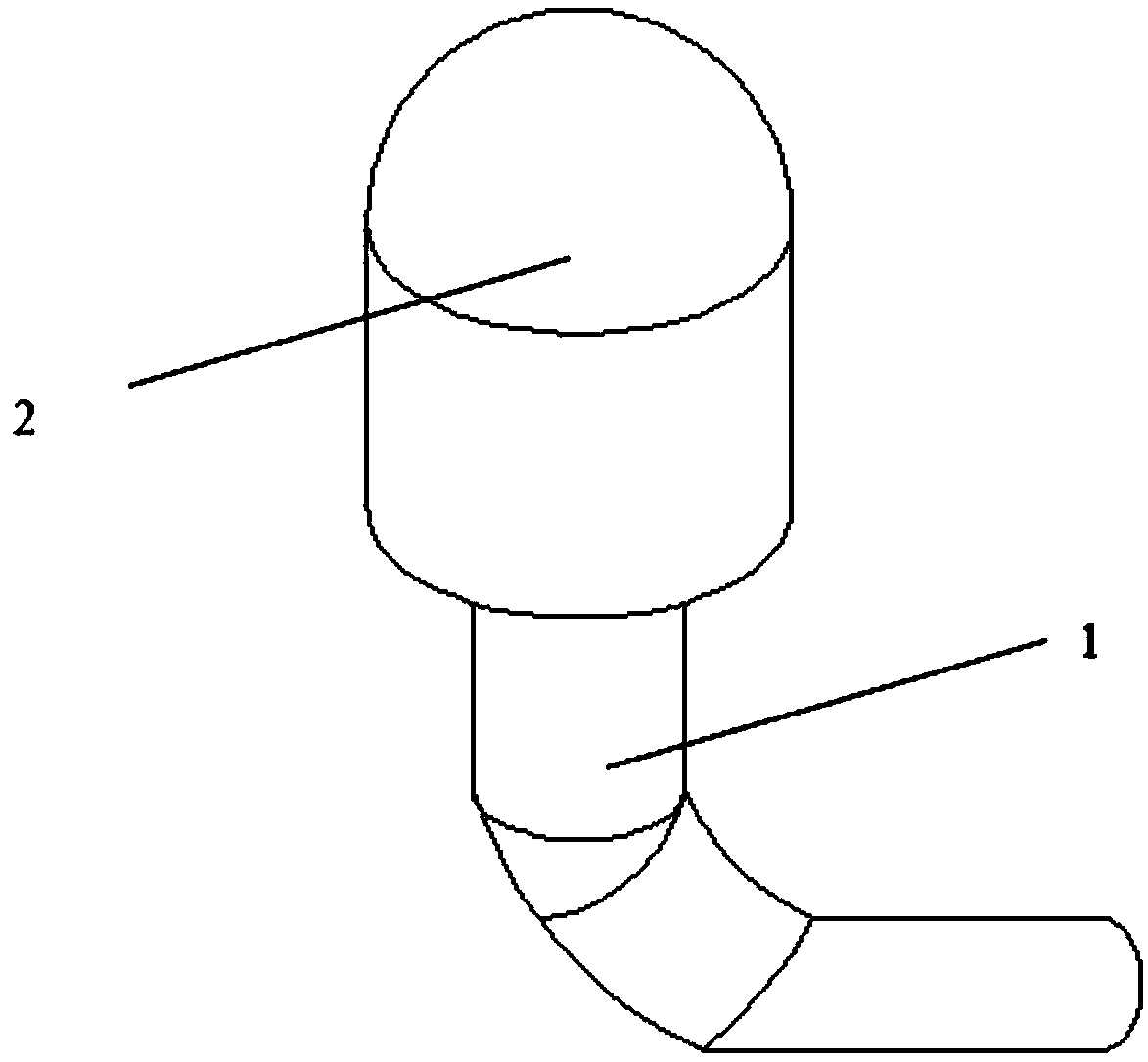

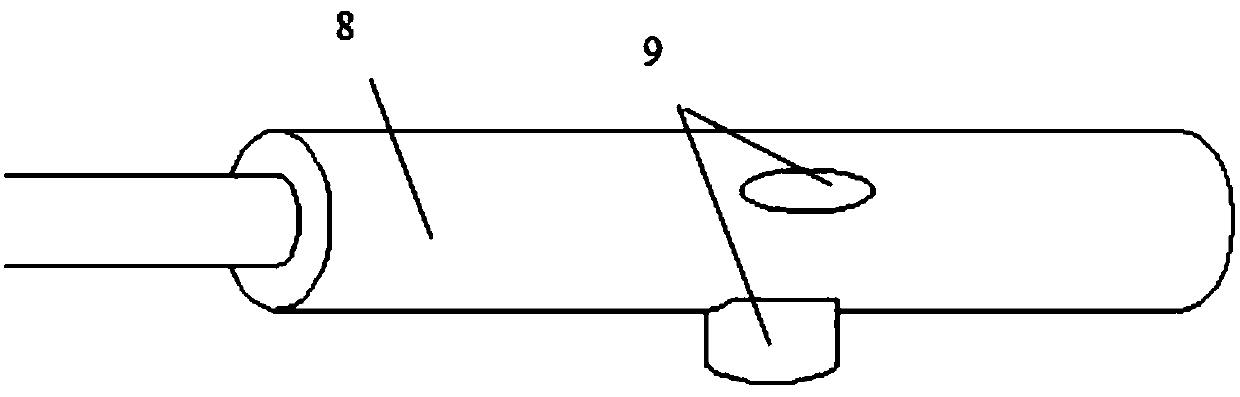

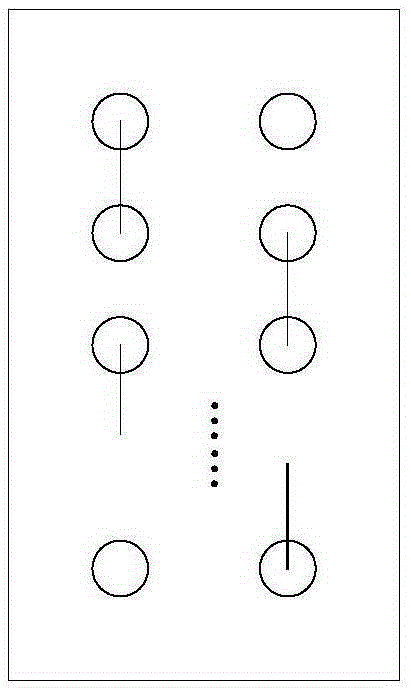

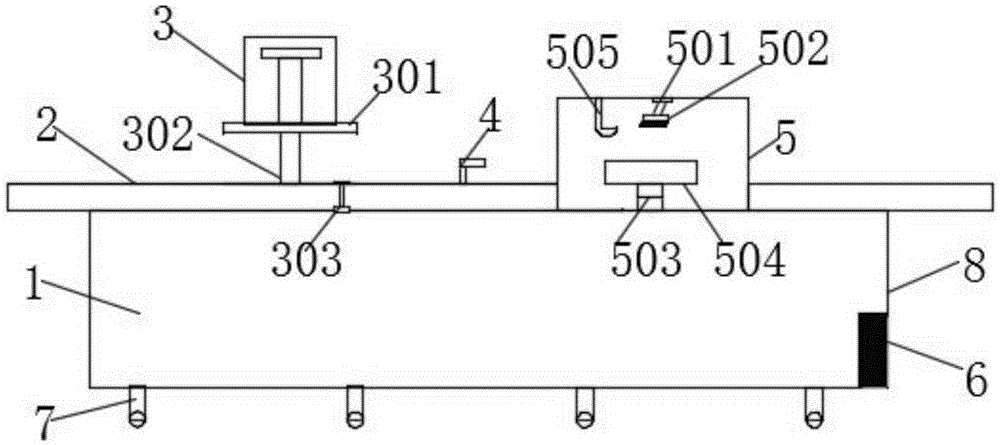

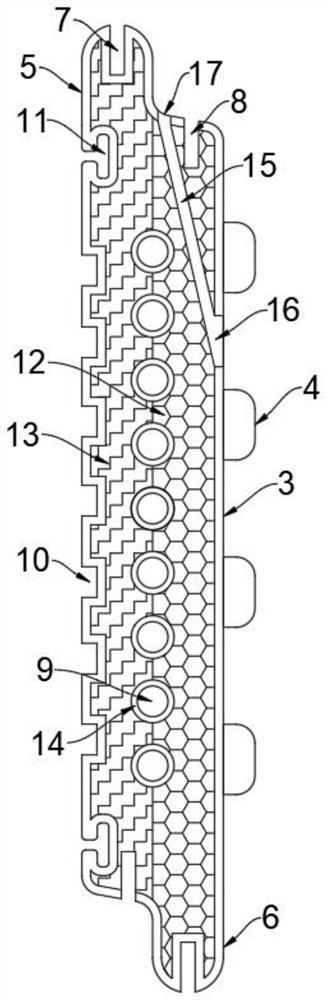

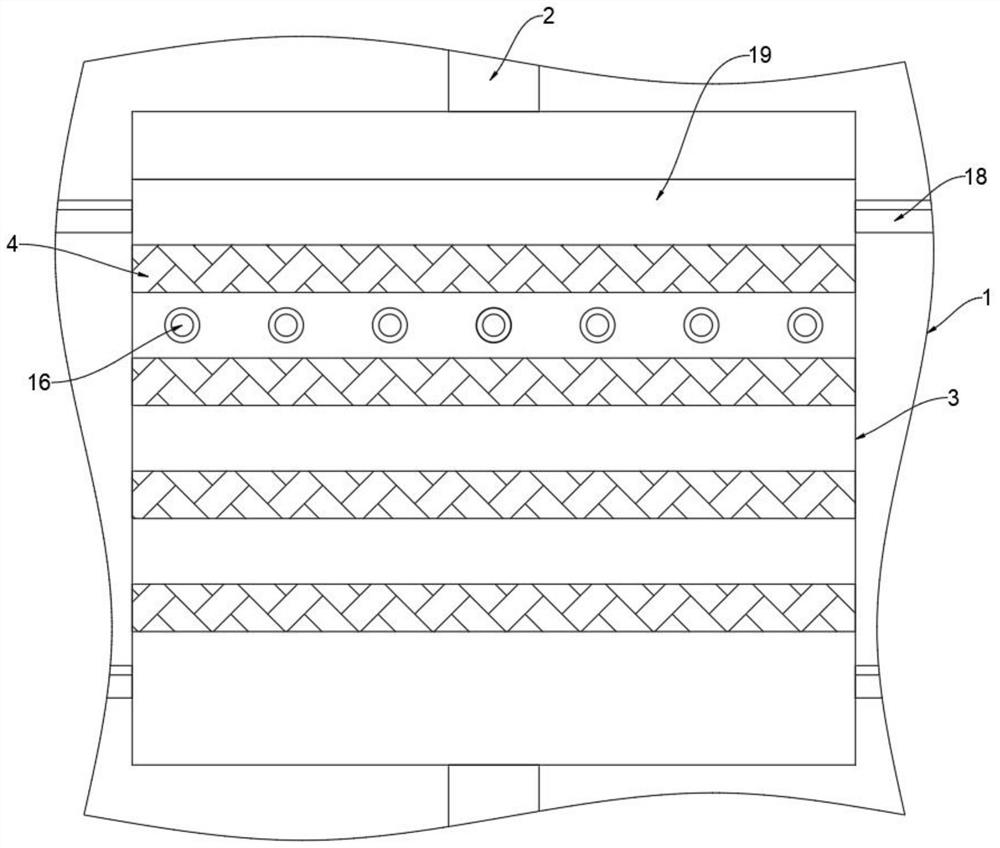

Equipment for uniformly injecting glue into battery

ActiveCN105789649AAvoid drippingReduce length of stayPrimary cell manufactureCell sealing materialsInjectorEngineering

The invention relates to equipment for uniformly injecting glue into a battery. The equipment comprises a bearing platform, a plurality of glue injecting components, a tank and an incoming material component, wherein the plurality of glue injecting components are arranged in parallel at equal intervals; the tank is used for storing glue; the incoming material component carries a plurality of battery steel shells; the glue injecting components vertically correspond to glue injecting openings of the battery steel shells; each of the glue injecting components comprise a power part, a pressing plate, a discharge rod, a glue injecting bucket and a material guide column; the pressing plates are arranged on top rods of the power parts; the discharge rods are arranged on the pressing plates; the material guide columns are arranged at the end parts of the discharge rods in a sleeving manner; the discharge rods can slide upwards and downwards relative to the inner walls of the material guide columns; the material guide columns are fixed on the glue injecting buckets; a semicircular material guide hole is formed in the end part of each discharge rod; a discharge hole is formed in each material guide column. By adopting the equipment, the problems that in the battery glue injecting process, the sealing property of a battery can be affected as the flowability is poorer as glue can be relatively greatly affected by the external environment, the glue injecting process is slow, the glue cannot be uniformly injected and distributed, and an injector can be easily blocked, are overcome.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

Full-automatic paper box forming machine

InactiveCN105252817AReduce length of stayImprove work efficiencyBox making operationsPaper-makingEngineeringMechanical engineering

The invention discloses a full-automatic paper box forming machine. The full-automatic paper box forming machine comprises a transmission mechanism, a primary forming mechanism and a gluing and forming mechanism, wherein the primary forming mechanism comprises a first telescopic rod and a first die; the first die is fastened to the bottom of a housing of the primary forming mechanism; the upper section of the first telescopic rod is fixed to the rear side of the housing of the primary forming mechanism; a paper skipping mechanism is arranged between the primary forming mechanism and the gluing and forming mechanism; the gluing and forming mechanism comprises a second telescopic rod; a second die is fastened to the tail end of the second telescopic rod; a gluing brush is arranged on the upper side of the second die. The full-automatic paper box forming machine is provided with the gluing brush and the second die, so that paper boxes can be glued and formed in the same mechanism in a short time, the dwell time of the glue in the air is reduced, the paper boxes are relatively firm, the manufacturing time is reduced, and the working efficiency of the machine is improved.

Owner:RUIAN ZHONGFA MACHINERY CO LTD

Black-bone silky fowl breeding method capable of improving delicious degree of chickens

InactiveCN109006685AReduce length of stayPromote growthAnimal housingCultivating equipmentsFowlFruit tree

The invention discloses a black-bone silky fowl breeding method capable of improving the delicious degree of chickens, and relates to the field of broiler chicken breeding. The black-bone silky fowl breeding method comprises henhouse building, chick selection, breeding management and transfer control. Henhouse building includes steps: building a main henhouse in a place center; building a water tank surrounding the main henhouse; planting herbage and fruit trees surrounding the main henhouse; building a fence at the periphery of the main henhouse to limit the size of a place; and building grids between the fence and the main henhouse, and dividing the place into six equal free-range areas; and building auxiliary henhouses on the grids. Breeding management comprises cleaning and ventilationof the henhouse, disease control, and breeding of chicks, baby chicks and grown chicks. According to the method, the operation is simple, and the healthy growth of black-bone silky fowls can be effectively guaranteed.

Owner:盐津吉瑞农业有限责任公司

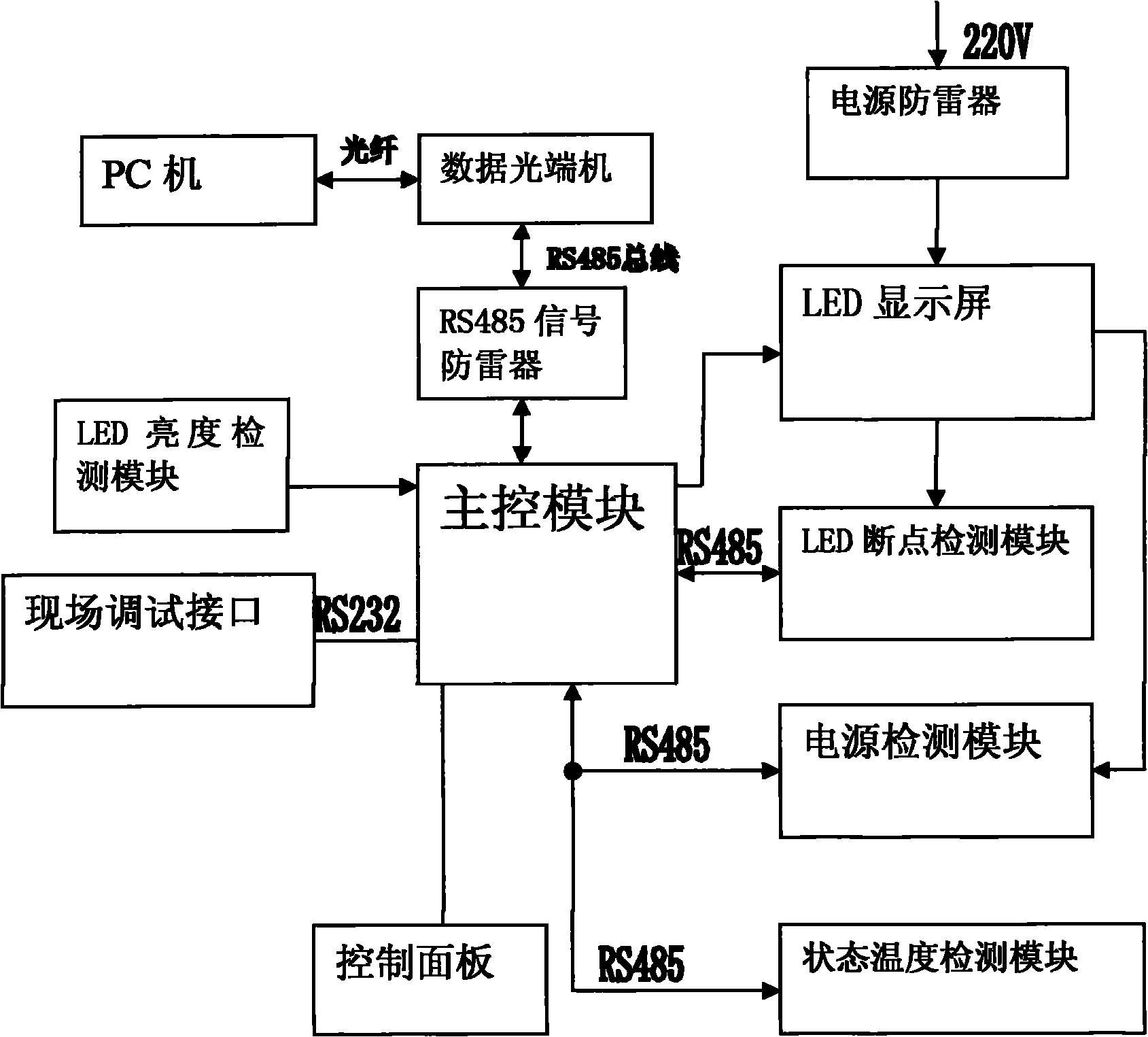

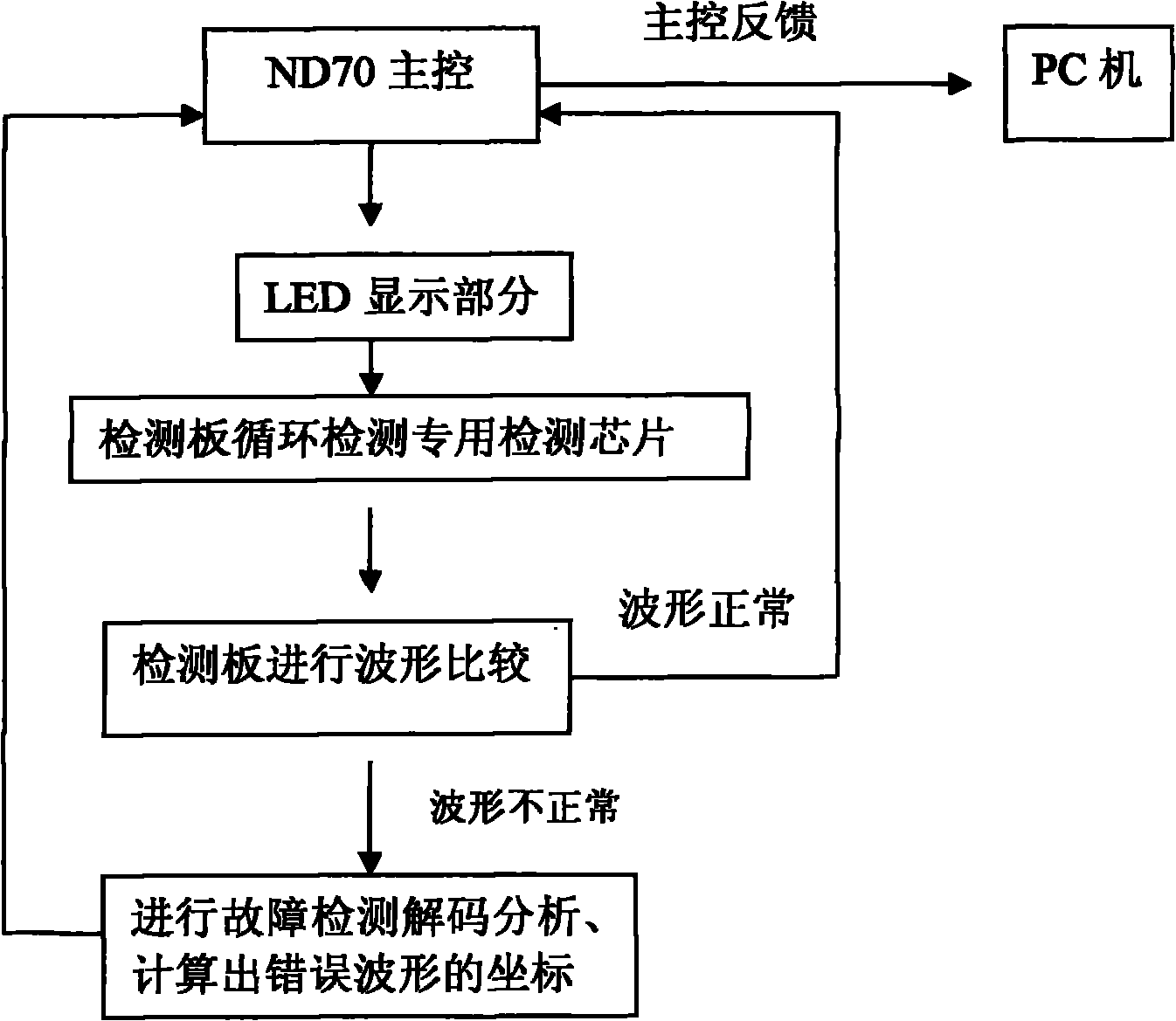

Urban intelligent traffic guide display

InactiveCN102147975AGuaranteed unobstructedReduce length of stayArrangements for variable traffic instructionsIdentification meansIntelligent transportLightning arrester

The invention discloses an urban intelligent traffic guide display, which is characterized in that: a light-emitting diode (LED) display module is connected with a master control module; the LED display module is connected with an LED breakpoint detection module and a power supply detection module respectively; the LED breakpoint detection module, the power supply detection module and the state and temperature detection module are connected to the master control module via a RS485 bus; the master control module is connected with a RS485 signal lightning arrester which is connected with data lightware terminal equipment; the data lightware terminal equipment is connected with a personal computer (PC) via an optical fiber; the LED luminance detection module is connected with the master control model; an on-site debugging interface is connected with the master control module via a RS232; and the control penal is connected with the master control module. The urban intelligent traffic guide display has the functions of local / remote control, power supply detection, breakpoint detection, LED luminance adjustment detection, case state detection, case temperature detection, lightning protection and the like and has the advantages of simple and practical circuit design, low power consumption, stable working performance and the like.

Owner:FUSHUN OPTOELECTRONICS TECH

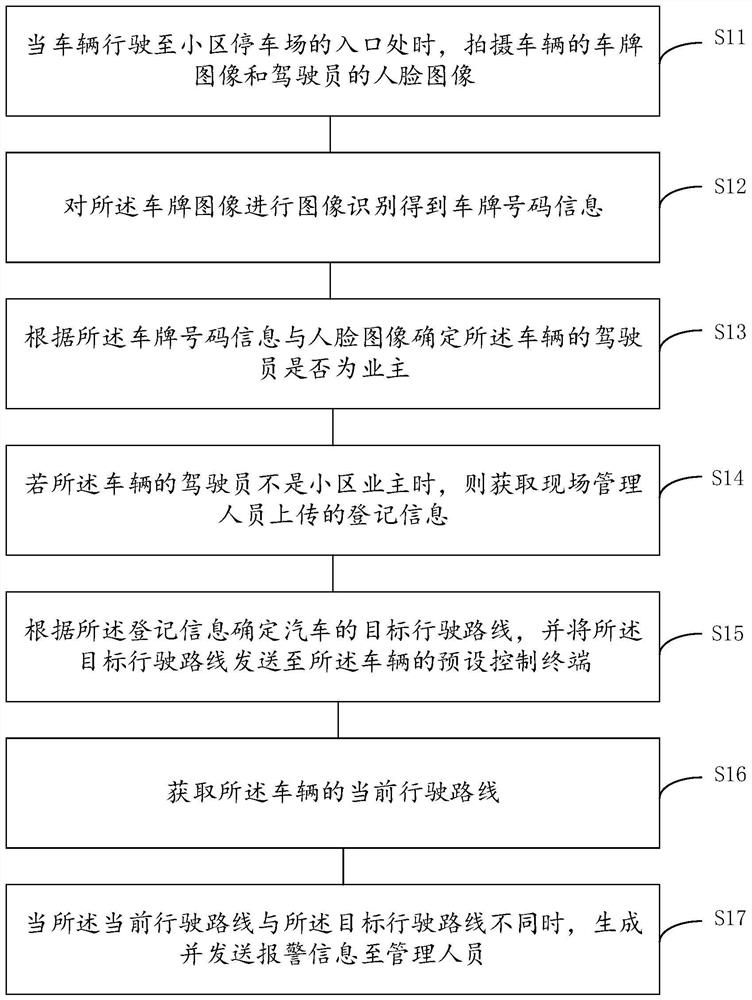

Parking lot management method and device

ActiveCN112820137AReduce cloggingReduce length of stayTicket-issuing apparatusIndication of parksing free spacesDriver/operatorParking space

The invention discloses a parking lot management method and device. The method is suitable for a management system with cameras at the exit and entrance of a community parking lot, and the method comprises the steps: shooting a license plate image of a vehicle and a face image of a driver when the vehicle is driven to the entrance of the community parking lot; performing image recognition on the license plate image to obtain license plate number information; determining whether a driver of the vehicle is an owner or not according to the license plate number information and the face image; if the driver of the vehicle is not the owner of the community, acquiring registration information uploaded by a field manager; and determining a target driving route of the vehicle according to the registration information, and sending the target driving route to a preset control terminal of the vehicle so as to prompt a driver to drive to a target area according to the target driving route displayed by the preset control terminal of the vehicle. The detection efficiency can be improved, and the probability that the parking lot is blocked and the parking space is occupied maliciously can be reduced.

Owner:金茂智慧科技(广州)有限公司

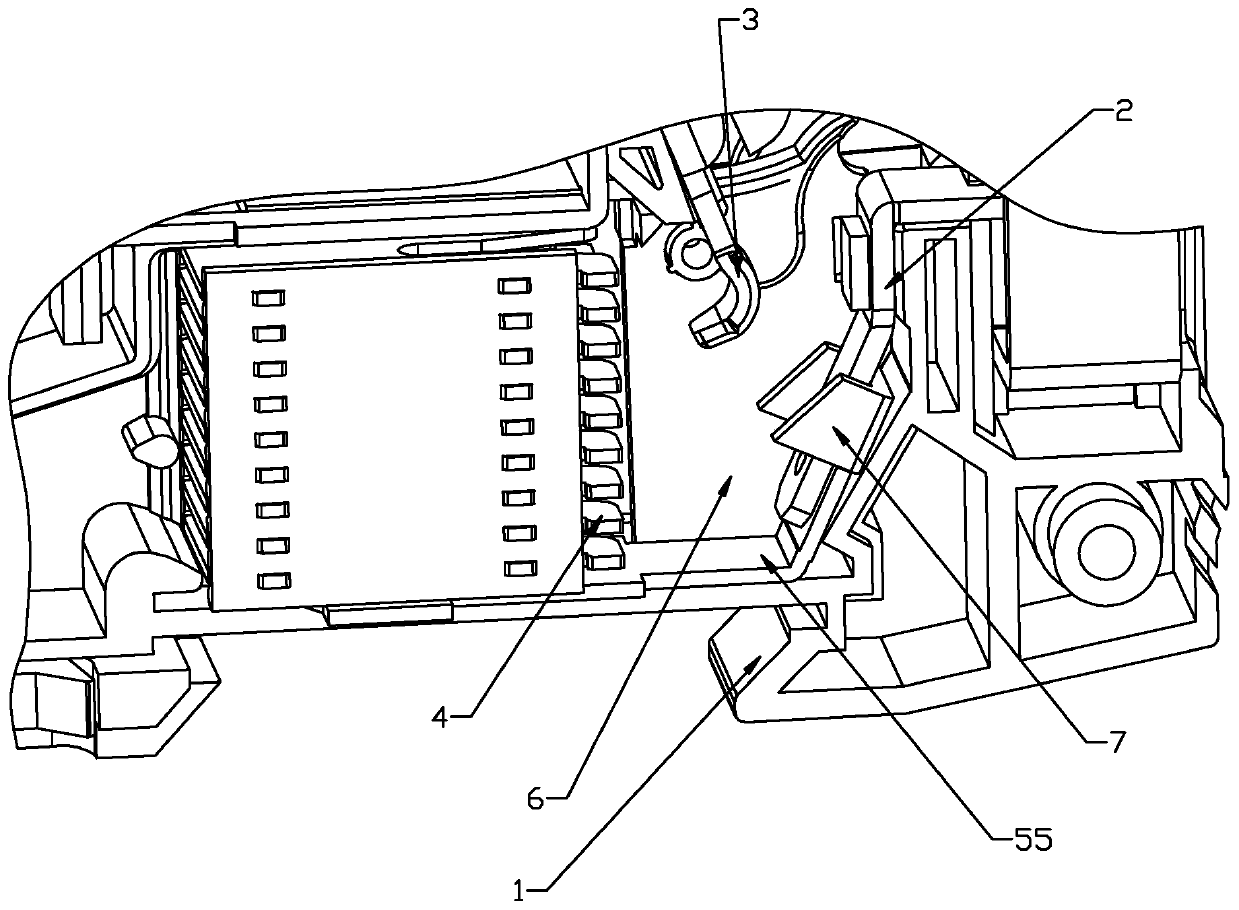

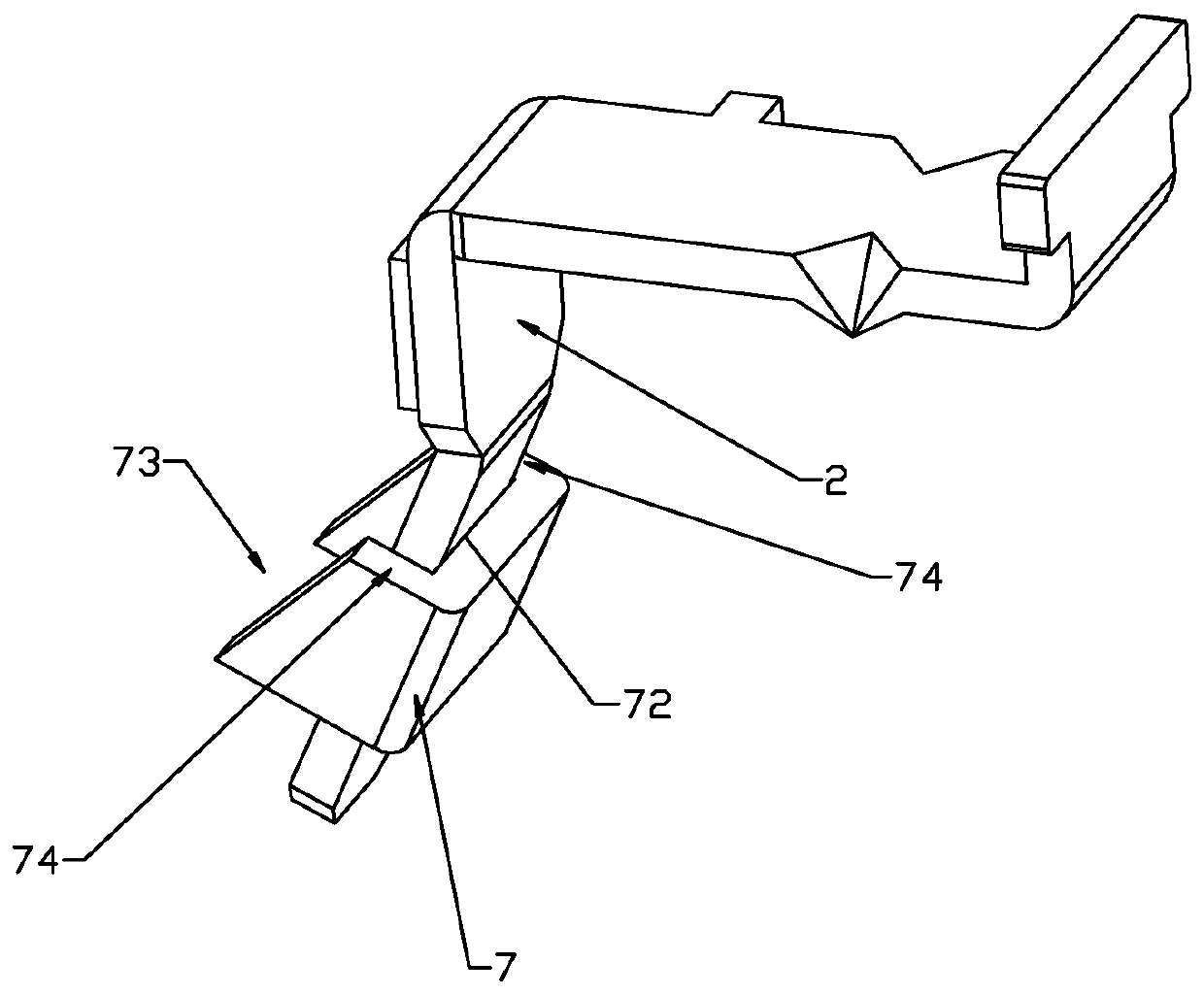

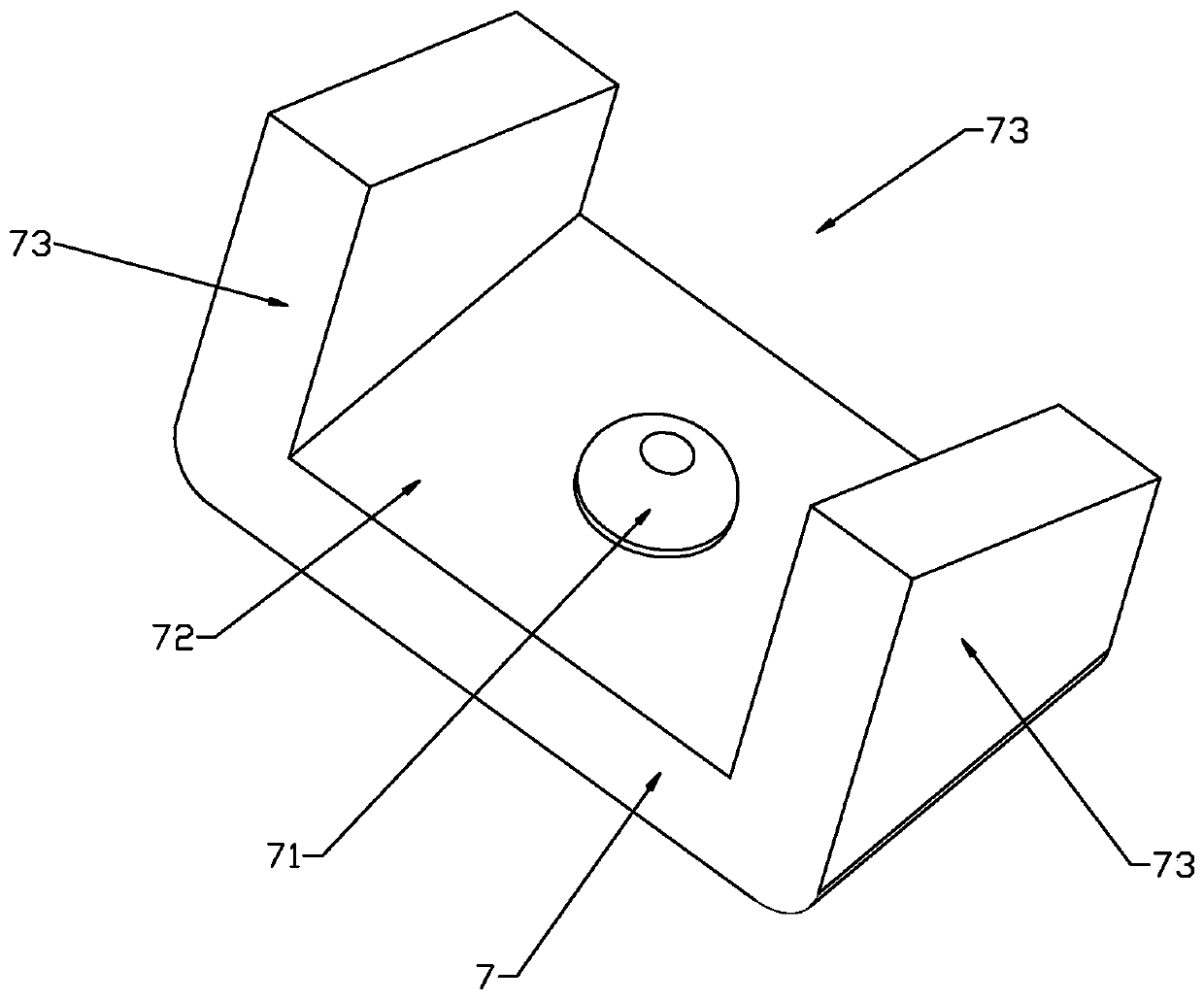

Arc extinguishing device of circuit breaker

PendingCN109755079AReduce length of stayAvoid damageCircuit-breaking switch detailsCurrent loadEngineering

The invention relates to an arc extinguishing device of a circuit breaker. The arc extinguishing device comprises a circuit breaker shell, and a static contact piece, a movable contact piece, an arc extinguishing grid piece and an arc striking piece which are arranged in the circuit breaker shell; an arc extinguishing chamber is arranged at the breaking position, close to the static contact pieceand the movable contact piece, of the circuit breaker shell; the arc extinguishing grid piece and the arc striking piece are located in the arc extinguishing chamber; one end of the arc striking pieceabuts against the static contact piece or abuts against the movable contact piece when the movable contact piece and the static contact piece are disconnected, and the other end of the arc striking piece extends to the arc extinguishing grid piece; the arc extinguishing device is characterized by further comprising an arc pushing piece, wherein the arc pushing piece forms a magnetic field facingthe arc extinguishing grid piece, and the magnetic field pushes the arc to the direction of the arc extinguishing grid piece when the static contact piece and the movable contact piece are disconnected to generate arc. By adoption of the scheme, the invention provides the arc extinguishing device of the circuit breaker capable of enhancing the breaking capacity by increasing the arc striking efficiency, so that the circuit breaker can meet the requirements of high-current loads.

Owner:WENZHOU NEW BLUD SKY ELECRICIAL

Sealed type polishing and sanding room

PendingCN110774146ALow manufacturing costLow maintenance costUsing liquid separation agentGrinding machinesWorking environment

The invention provides a sealed type polishing and sanding room, belongs to the technical field of operation, and solves the problem that the front side of an existing sanding room is open and part ofdust is diffused from the opening. The sealed type polishing and sanding room comprises a sanding room body with a sanding chamber, the front side of the sanding chamber is an entrance, and the sanding room body comprises a left side wall, a right side wall, a rear side wall and a top plate; the sealed type polishing and sanding room further comprises a base placed on the ground and an entrance and exit door mounted on the sanding room body; the bottom surface of the sanding chamber is covered with the base, a dust collecting cavity is formed in the base, multiple small dust inlet openings enabling the sanding chamber and the dust collecting cavity to communicate are formed in the top wall of the dust collecting cavity, and a dust outlet communicating with the dust collecting cavity is formed in the wall of the base; the entrance and exit door is located at the entrance and enables the entrance to be in an open state or a closed state; and an air inlet is formed in the top plate. Thesealed type polishing and sanding room has high dust collecting efficiency and lower use and maintenance costs, and the working environment of a sanding worker is more comfortable.

Owner:安徽正义研磨环保科技有限公司

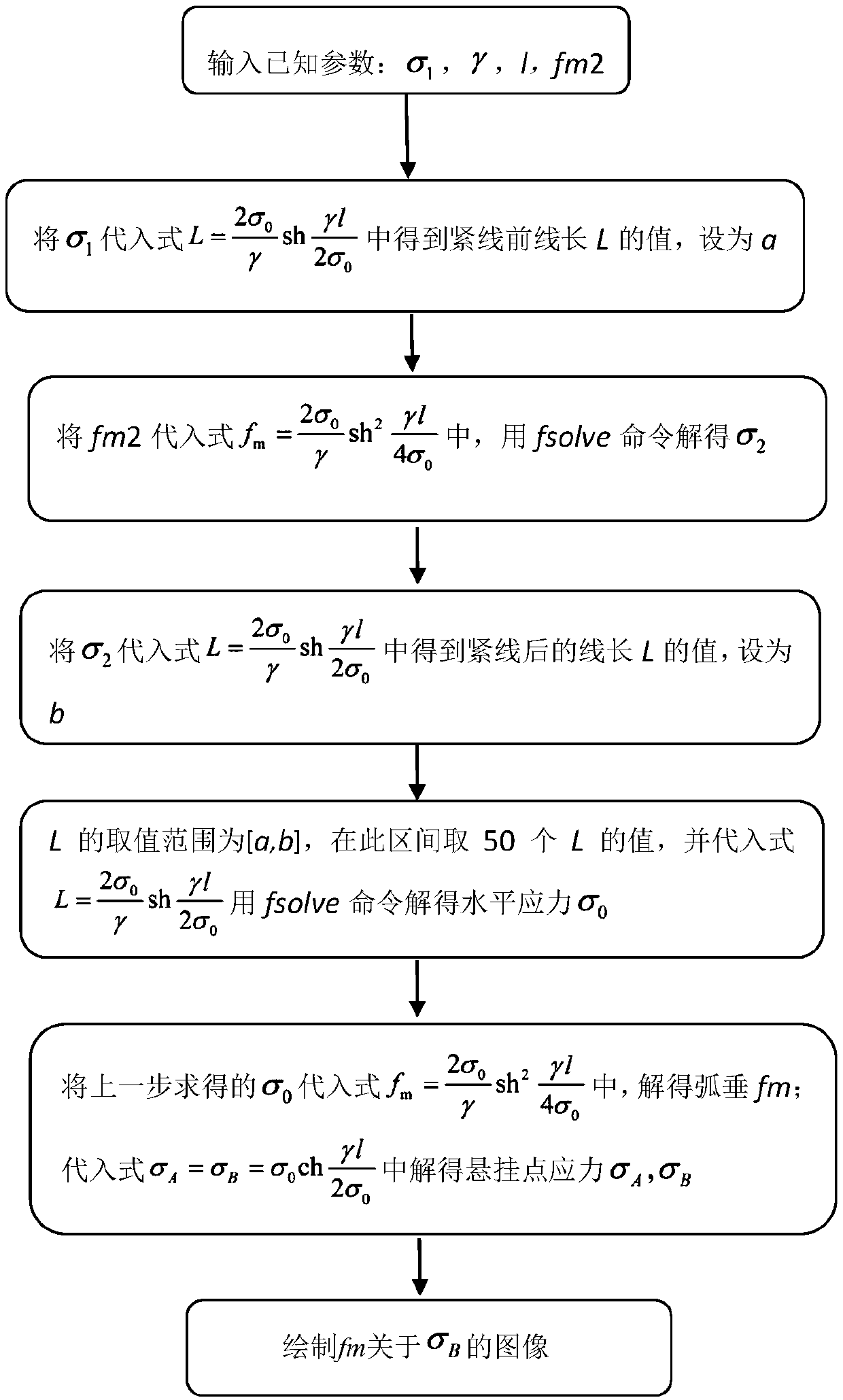

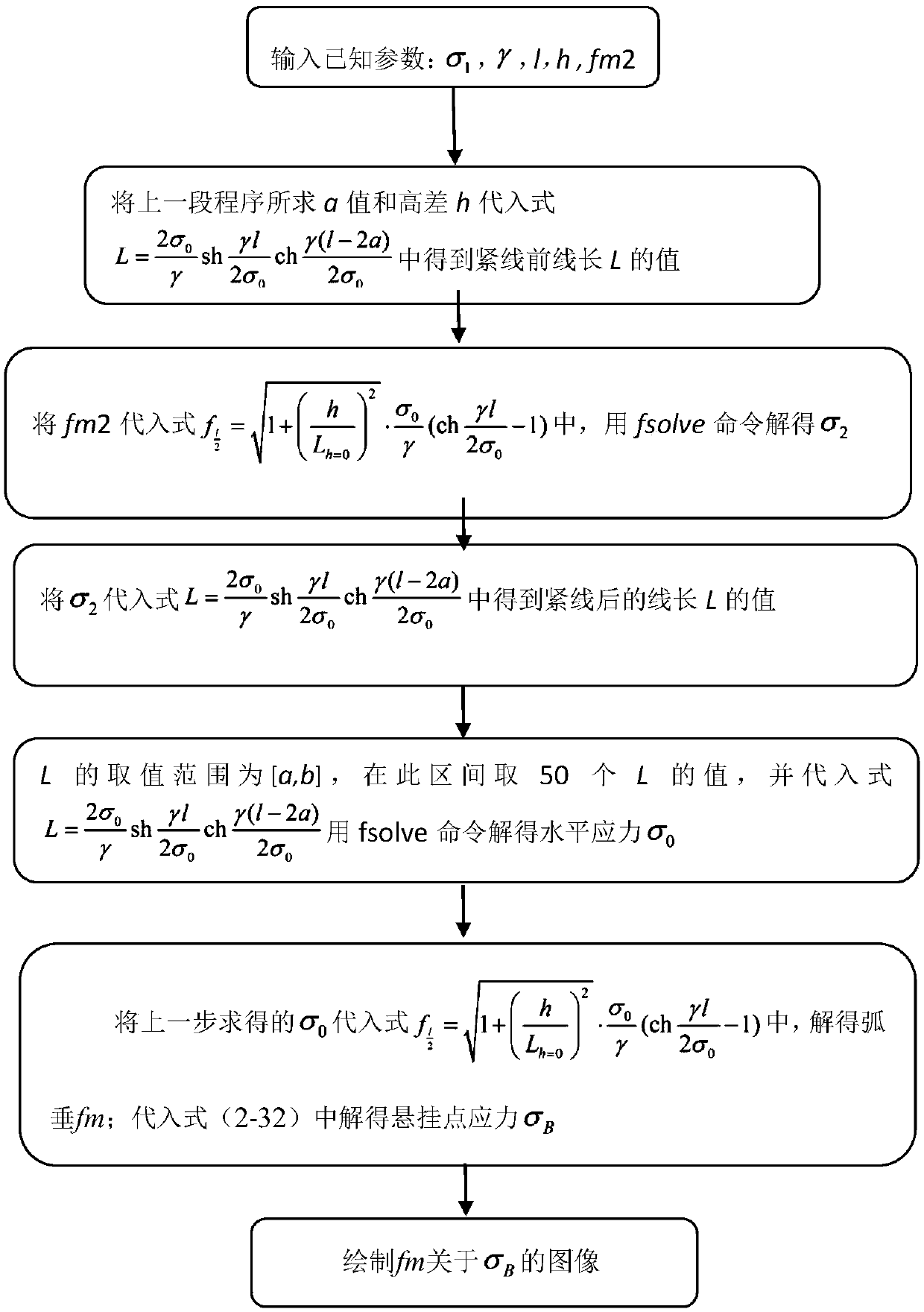

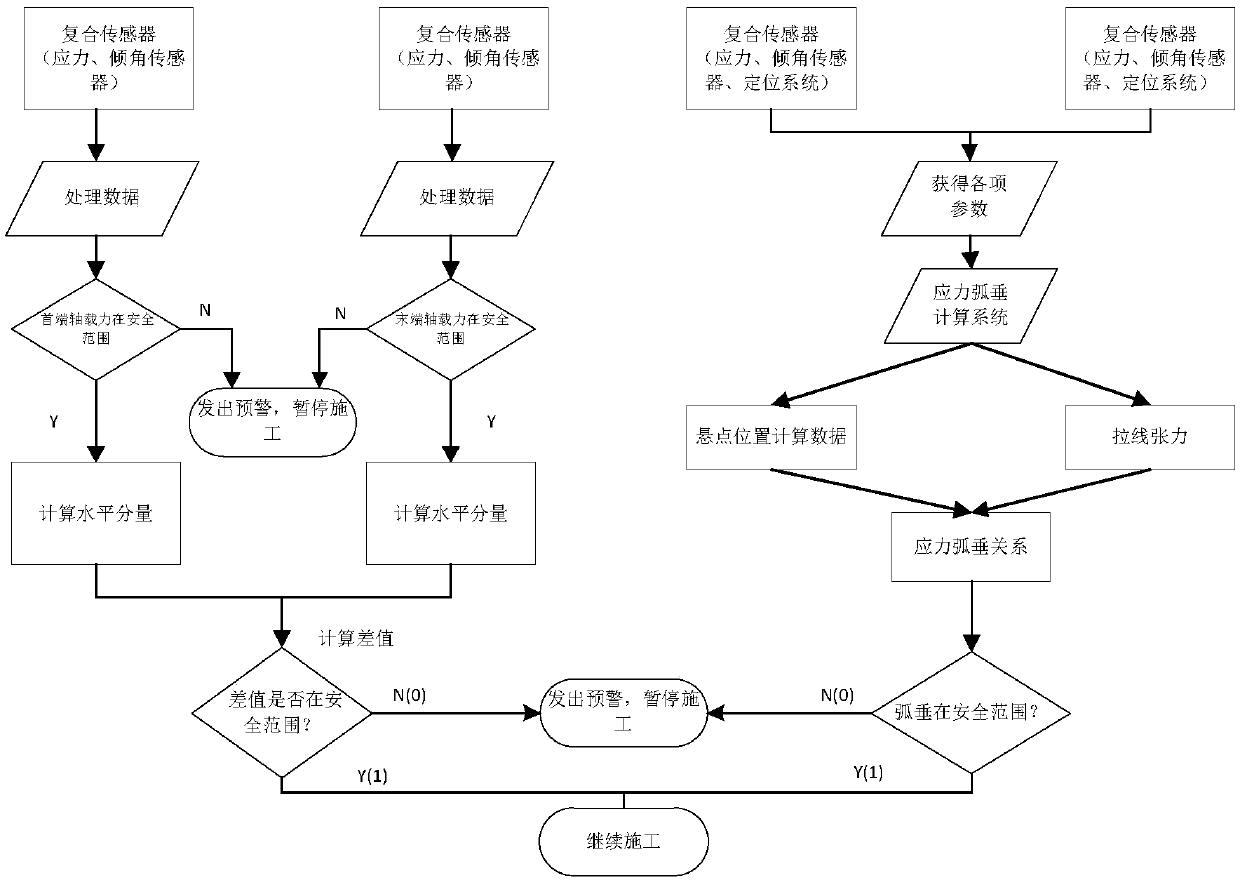

High-voltage power transmission line construction stringing early warning method based on precise positioning

InactiveCN109580067ASave human effortReduce length of stayTension measurementPrecise Point PositioningHigh pressure

The invention relates to a high-voltage power transmission line construction stringing early warning method based on precise positioning, in particular to a method for giving an early warning signal when the real-time sag in the extra-high-voltage wiring construction stringing operation process exceeds a safety value range. A set of high-voltage power transmission line stringing early warning method is designed on the basis of a stress sag curve. In the method, a tension sensor is used for monitoring the conducting wire stress in the wire drawing process; the real-time conducting wire sag in the wire pulling process is analyzed through a stress sag relationship curve; the safety judgement is made through the comparison with the sag safety value given by relevant regulation requirements; and early warning signals are given out under the condition that the real-time sag exceeds the safety value range. Meanwhile, sensors arranged at the head and tail ends of the system can transmit real-time axial tension data to an upper computer; differences between the two tension data horizontal components are calculated; and an early warning signal can also be given out if the condition that tension change differences at the two ends are great is found.

Owner:国网湖北省电力有限公司中超建设管理公司 +1

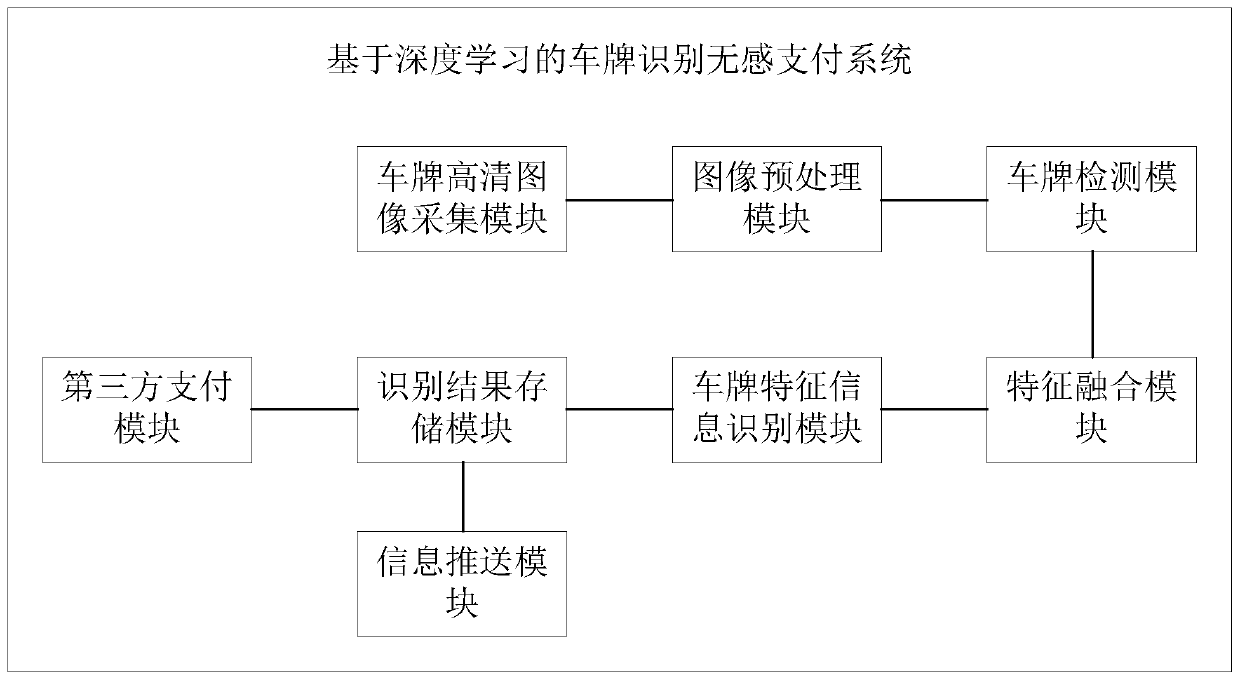

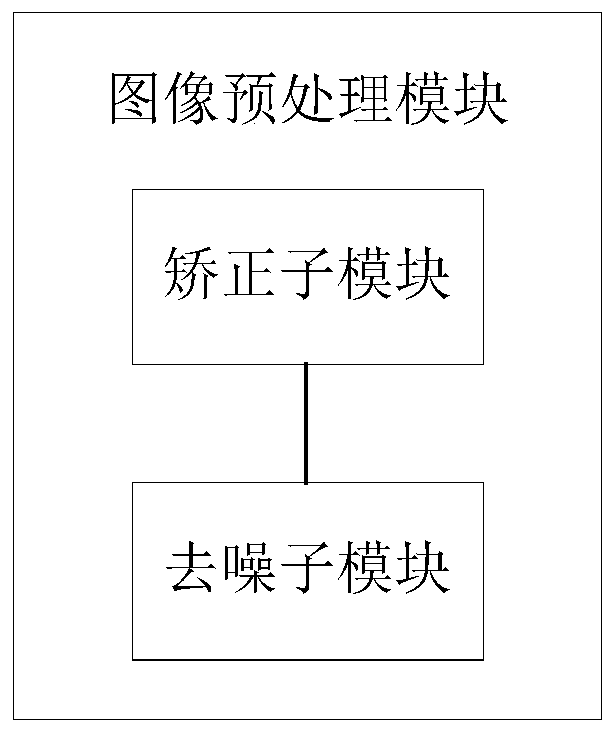

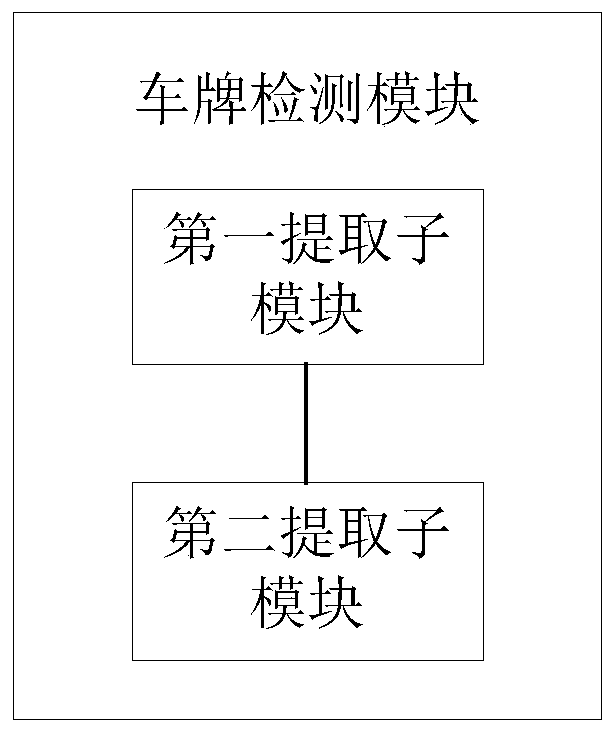

License plate recognition non-inductive payment system based on deep learning

ActiveCN110598704AReduce length of stayImprove recognition accuracyCharacter and pattern recognitionPayment architecturePattern recognitionThird-Party Payments

The invention discloses a license plate recognition non-inductive payment system based on deep learning, and the system is used for recognizing a license plate through a preset neural network and carrying out the non-inductive payment through combining with a third-party payment system, improves the recognition accuracy, and reduces the parking time of a vehicle. The system comprises a license plate high-definition image acquisition module, an image preprocessing module, a license plate detection module, a feature fusion module, a license plate feature information identification module, an identification result storage module, a third-party payment module and an information pushing module. The license plate high-definition image acquisition module is used for acquiring an original licenseplate image acquired by the high-definition camera at a road gate or a vehicle management entrance / exit; the image preprocessing module is used for screening out a target license plate image meeting requirements from the original license plate images; the license plate detection module is used for extracting a color feature image and a character feature image of the target license plate image; andthe feature fusion module is used for fusing the color feature image and the character feature image into a feature information image of the target license plate.

Owner:中电万维信息技术有限责任公司

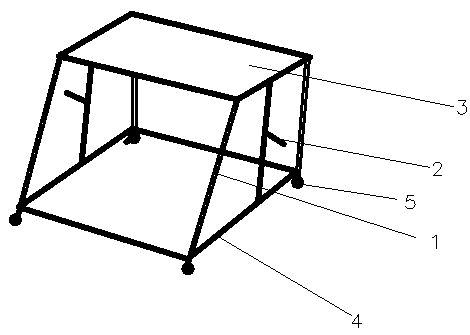

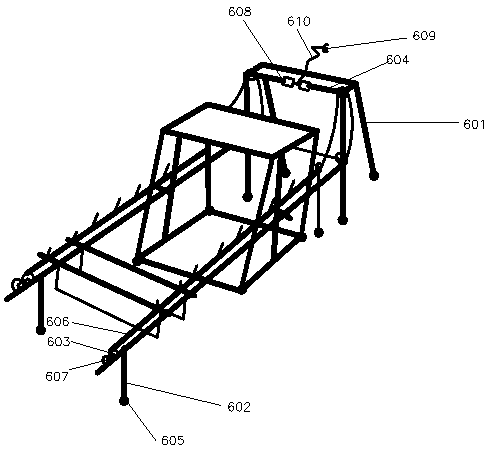

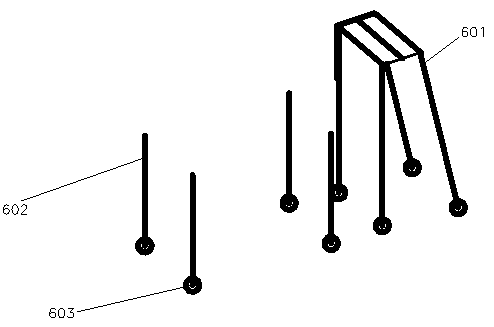

Tobacco leaf baking loading and unloading device and using method thereof

InactiveCN109436672AEasy balance settingPrevent slippingTobacco preparationConveyorsEconomic benefitsEngineering

The invention relates to the technical field of tobacco leaf baking equipment, in particular to a tobacco leaf baking loading and unloading device and a using method thereof. The device comprises telescopic rods, a handle, a panel, a fixing rod, universal wheels and a conveying device, the telescopic rods are connected with the panel and the fixing rod, the handle is located in the middle of the two middle telescopic rods, the universal wheels are located at the bottoms of the telescopic rods, and the conveying device is connected with the telescopic rods. According to the tobacco leaf bakingloading and unloading device, the structure is simple, the use is convenient, the device can be used for both baking loading and baking unloading, the number of tobacco growers and the staying time ofthe tobacco growers in a high-temperature baking house can be effectively reduced, the physical and psychological health of the tobacco growers is facilitated, the labor cost is saved, the working efficiency of the baking loading is improved, the tobacco leaf breaking rate is reduced, the economic benefits are increased, the safety hazard of an upper rod on the upper layer can be eliminated through the design of a platform, and the labor risk is reduced.

Owner:河南电翼电力科技有限公司

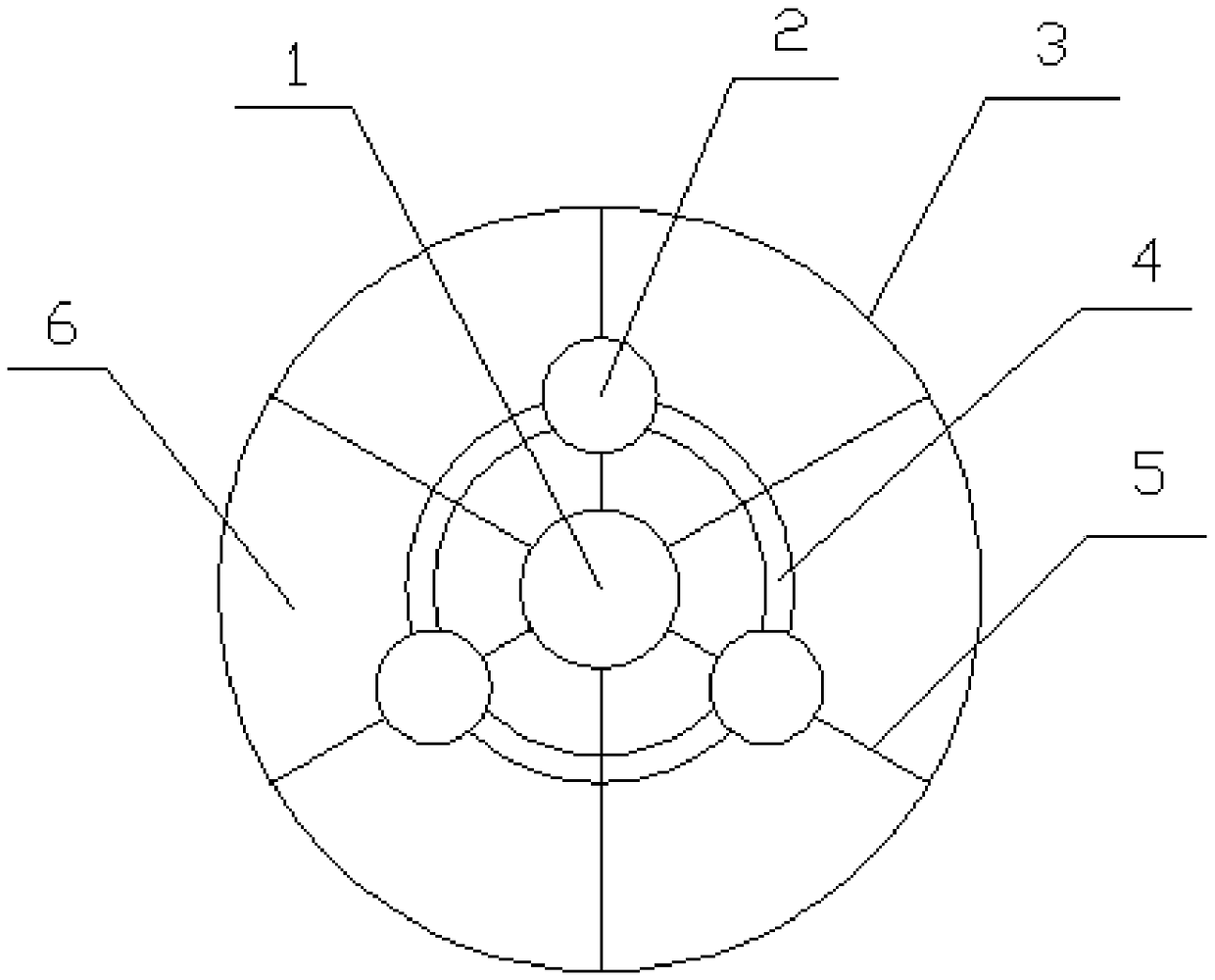

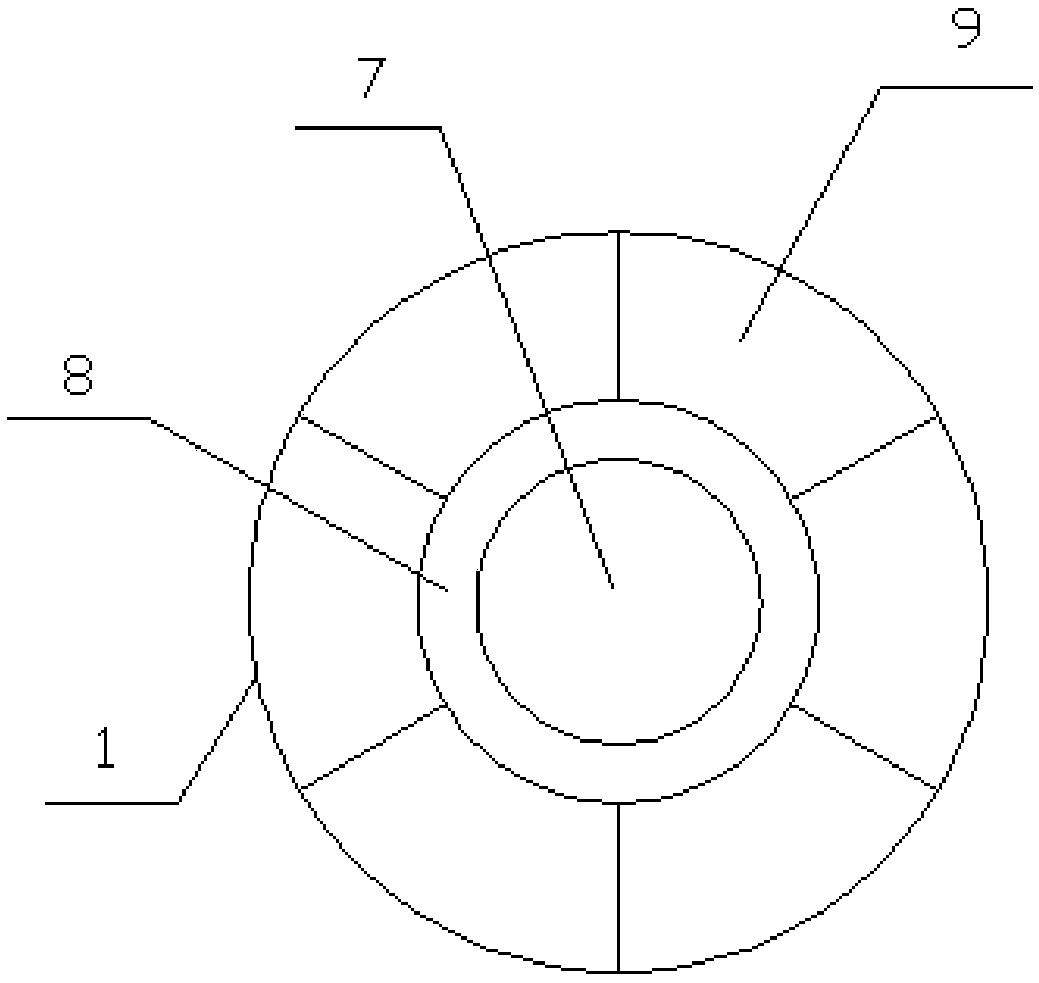

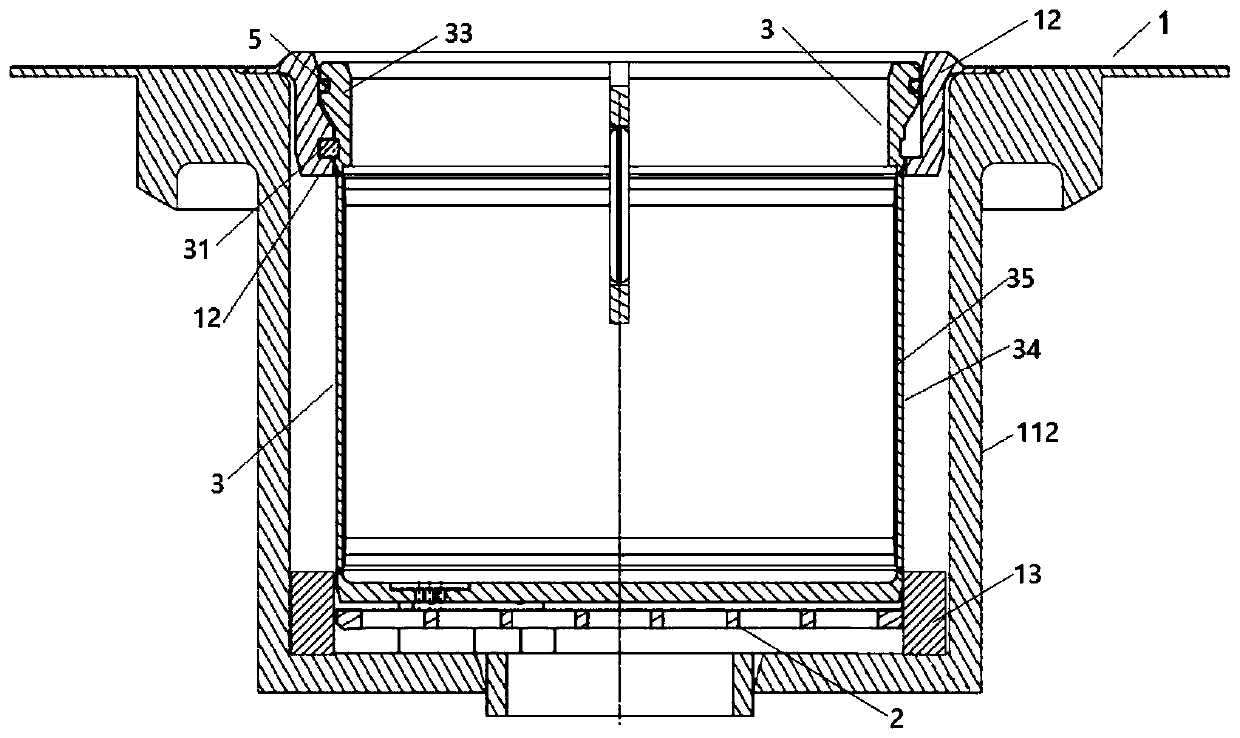

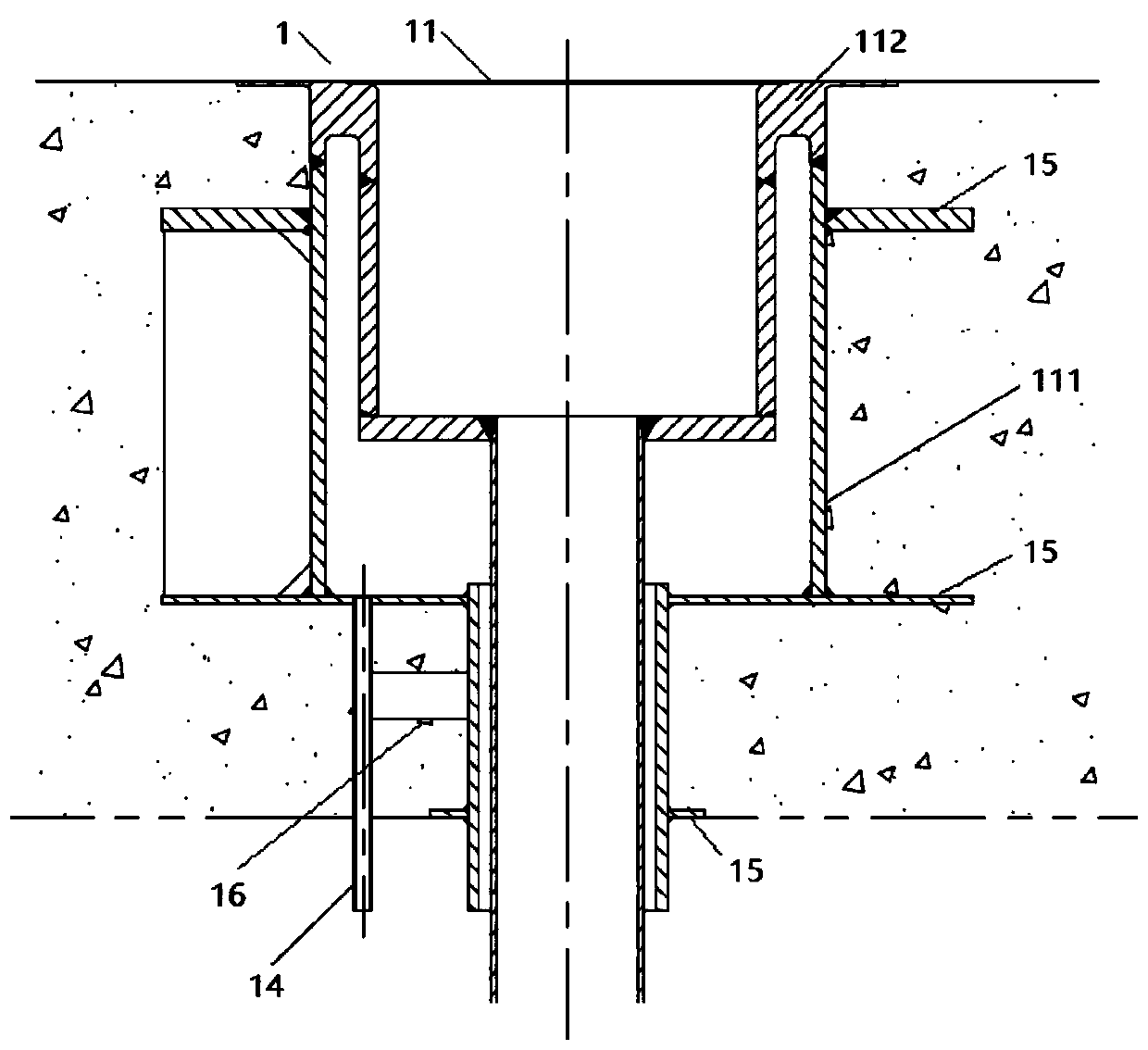

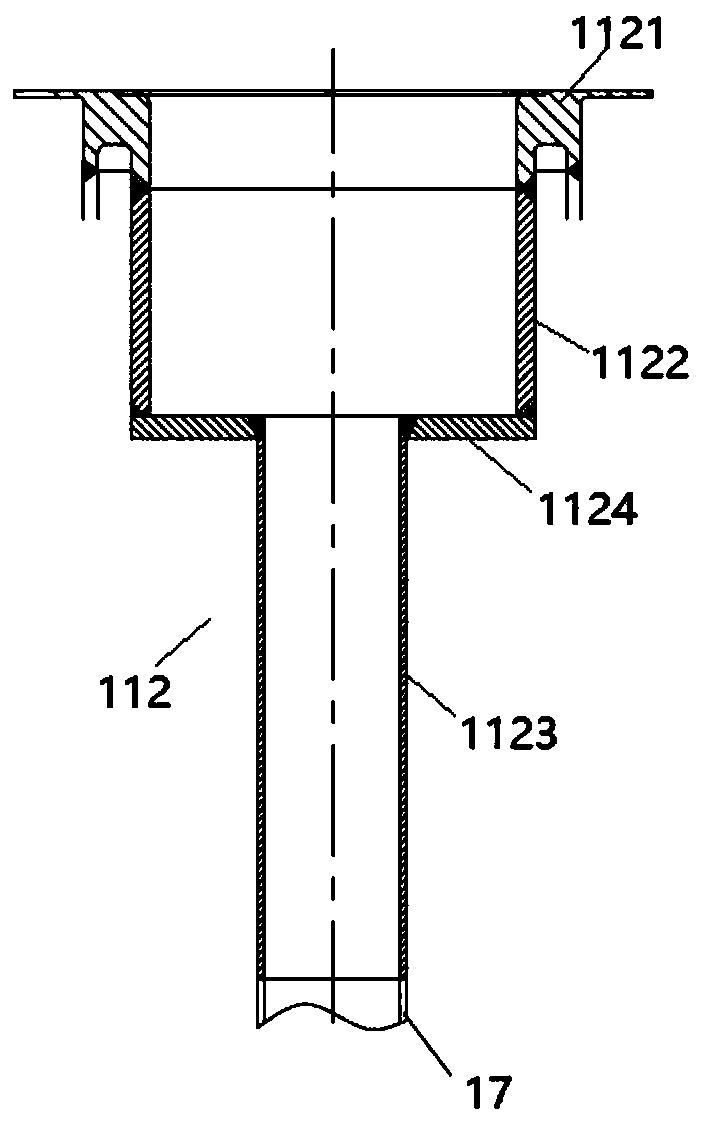

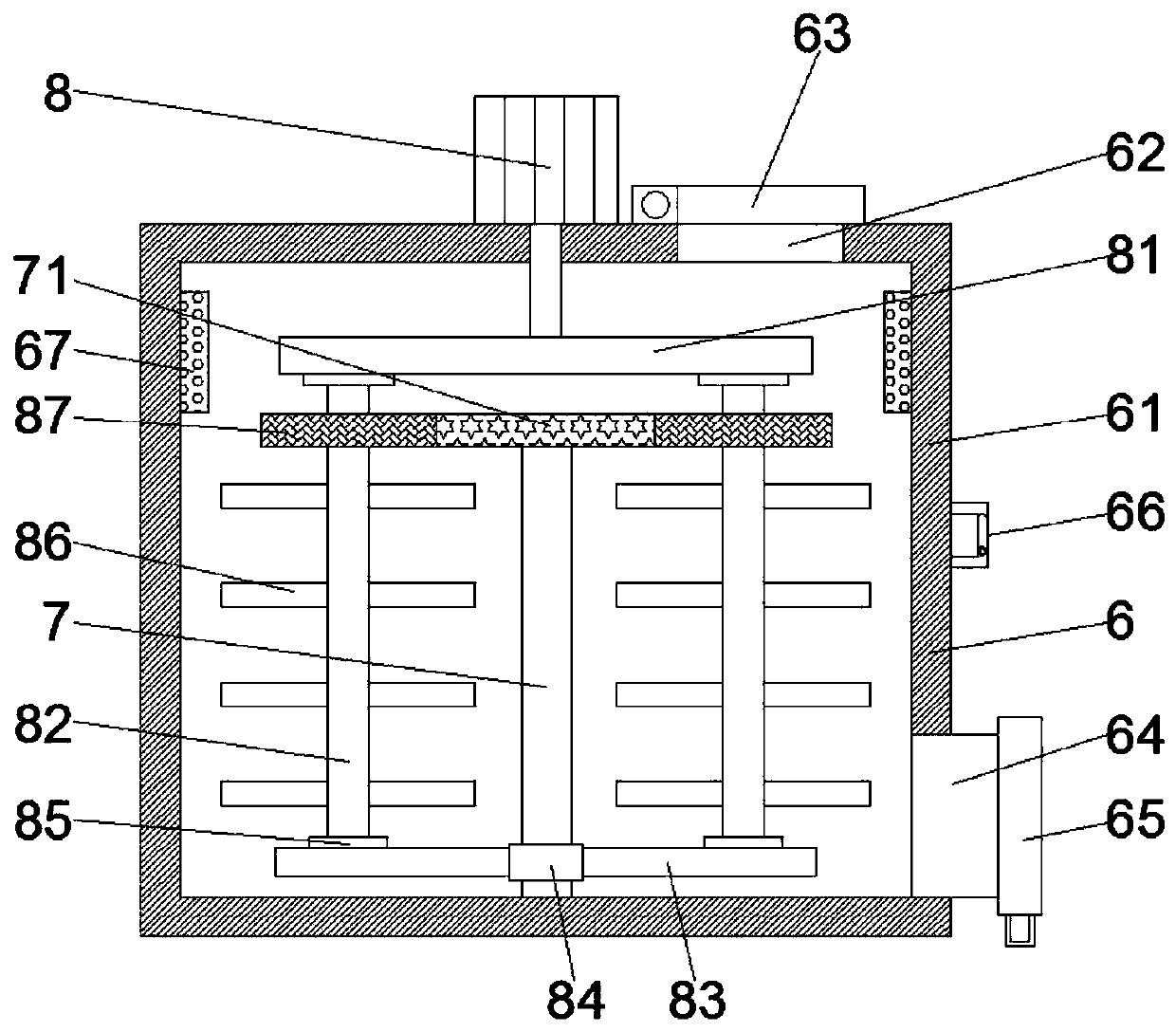

Nuclear power station pool filter screen and disassembly method thereof

ActiveCN110327683ASolve the rotation problemResolve filedNuclear energy generationReactor fuel elementsNuclear powerEngineering

The invention provides a nuclear power plant pool filter screen and a disassembly method thereof, belonging to the technical field of nuclear power plant equipment. The filter screen comprises a sleeve assembly, a coarse filter screen, a fine filter screen and a rope assembly. The sleeve assembly is arranged at the bottom of a water pool and is communicated with a replacement material water tank in a containment vessel. The coarse filter screen is arranged at the bottom of the sleeve assembly. The fine filter screen is arranged on the top of the sleeve assembly and is rotationally clamped andconnected with the sleeve assembly; one end of the rope assembly is connected with the fine filter screen, and the other end of the rope assembly is placed on a top operating platform of the nuclear power plant water pool, and is used for rotating and loosening the clamping connection between the fine filter screen and the sleeve assembly after applying of a force, and taking the fine filter screen out from the water pool. When in use, the rotation and lifting of the fine filter screen can be skillfully solved by directly operating the rope assembly on the top operating platform, thus avoidingthe scheme of using an operating rod, a replacing basket and a transferring trolley, saving time and simultaneously reducing the staying time of personnel in a radiation area.

Owner:中广核工程有限公司 +3

Multifunctional fire-fighting truck for fire-fighting facility engineering

The invention relates to the technical field of fire-fighting trucks, and discloses a multifunctional fire-fighting truck for fire-fighting facility engineering. The multifunctional fire-fighting truck comprises a main frame, a gear motor and a belt; the main frame comprises a T-shaped frame; the T-shaped frame comprises a transverse frame and a vertical frame and is inverted; mounting rings are evenly mounted on a frame body of the vertical frame of the T-shaped frame; lapping rods are arranged in front of the mounting rings; drivers are mounted in inner cavities of the mounting rings; and winding devices are mounted on the left sides of the drivers. The purpose of winding immediately after inserting can be achieved, mounting or dismounting of fire hoses is facilitated, the truck is easyto operate and relatively time-saving and labor-saving, the staying time of the fire-fighting truck on the fire rescue site is shortened, the fire-fighting truck can leave the site relatively quickly,and the site traffic order can be restored.

Owner:安徽明泽建设有限公司

Large-span multi-curved-surface ceramic plate curtain wall structure and construction method thereof

InactiveCN112647629AImprove drainage capacityExtended service lifeWallsHeat proofingEngineeringMechanical engineering

The invention discloses a large-span multi-curved-surface ceramic plate curtain wall structure and a construction method thereof, and relates to the technical field of ceramic plate curtain walls. The large-span multi-curved-surface ceramic plate curtain wall structure aims to solve the problem of short service life caused by poor drainage performance of an existing ceramic plate curtain wall. A vertical keel is arranged on one side of a wall body, the vertical keel is fixedly connected with the wall body, a transverse keel is arranged on one side of the vertical keel, a first bolt is arranged on one side of the transverse keel, the transverse keel is in threaded connection with the vertical keel through the first bolt, a ceramic plate body is arranged on one side of the transverse keel, a fixed sliding groove is formed in one side of the ceramic plate body, the fixed sliding groove and the ceramic plate body are of an integrated structure, a first ceramic plate hanging piece is arranged between the transverse keel and the ceramic plate body, a second bolt is arranged at one end of the first ceramic plate hanging piece, a fixed sliding block is arranged at the other end of the first ceramic plate hanging piece, a first connector is arranged at the upper end of the ceramic plate body, and a second connector is arranged at the lower end of the ceramic plate body.

Owner:ANYI BUILDING GROUP

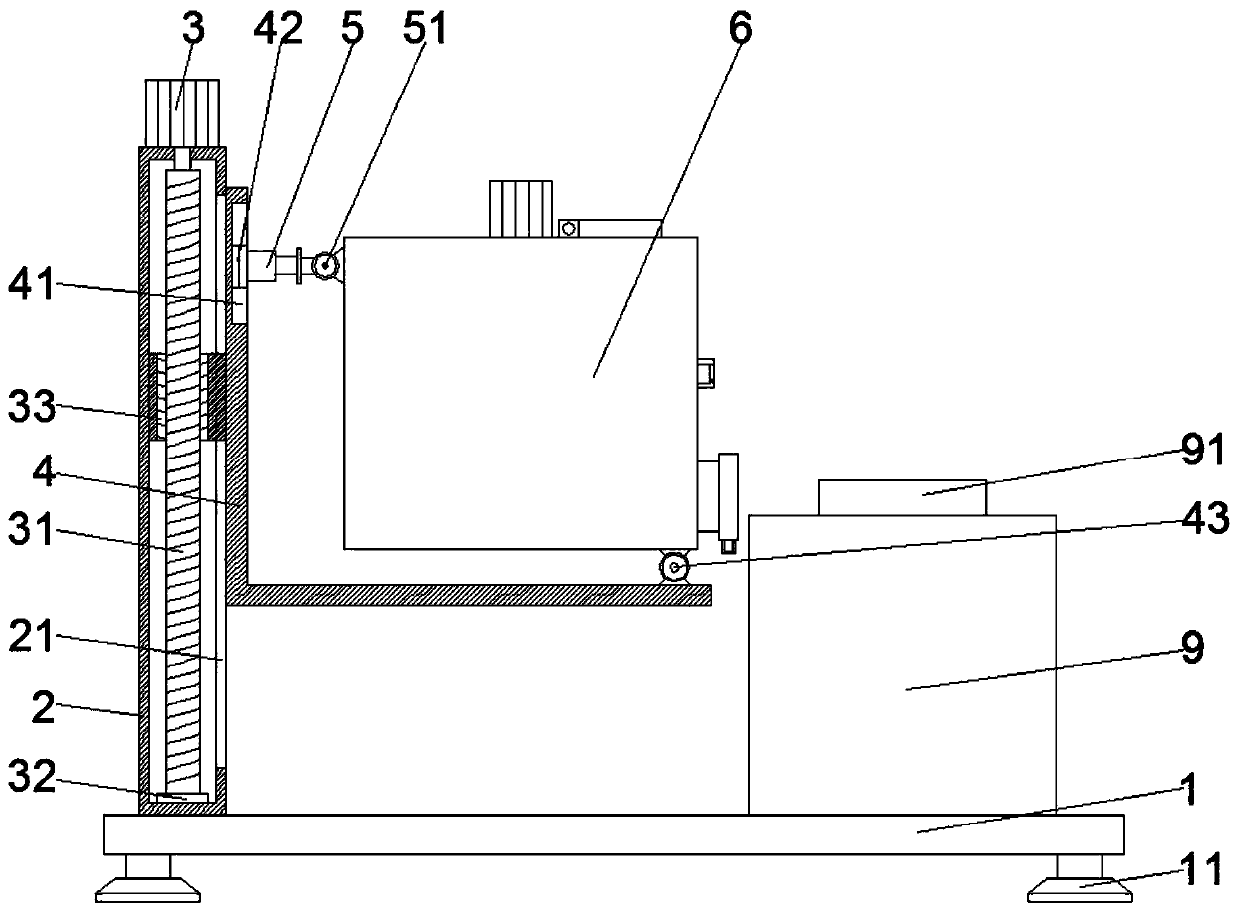

Flue gas desulfurization gypsum drying and calcining equipment

The invention discloses flue gas desulfurization gypsum drying and calcining equipment. The flue gas desulfurization gypsum drying and calcining equipment comprises a base and supporting legs. A standcolumn is installed on the left part of the upper end of the base, a sliding groove is vertically formed in the right end of the stand column, and a threaded rod is vertically installed in the standcolumn. The lower end of the threaded rod is rotatably connected into the bottom of the stand column, a first motor is installed at the upper end of the stand column, and the lower end of the first motor penetrates through the upper end of the stand column to be fixedly connected with the upper end of the threaded rod. An inner threaded block is arranged on the outer surface of the threaded rod ina sleeving mode, a L-shaped supporting plate is installed at the right end of the inner threaded block, a drying device is arranged at the upper end of the L-shaped supporting plate, a first rotatingshaft is arranged on the right part of the lower end of the drying device, a groove is vertically formed in the upper part of the right end of the L-shaped supporting plate, and a sliding block is arranged in the groove. An electric pushing rod is installed at the right end of the sliding block, and a second rotating shaft is installed at the right end of the electric pushing rod. According to the flue gas desulfurization gypsum drying and calcining equipment, flue gas desulfurization gypsum accumulated in the interior can be turned out and quickly dried, the drying efficiency is increased, meanwhile, the time that the dried flue gas desulfurization gypsum stays outside is reduced, so that the flue gas desulfurization gypsum still retains a certain temperature after entering a calcining device, and the calcining efficiency is improved.

Owner:邵阳金拓科技开发有限公司

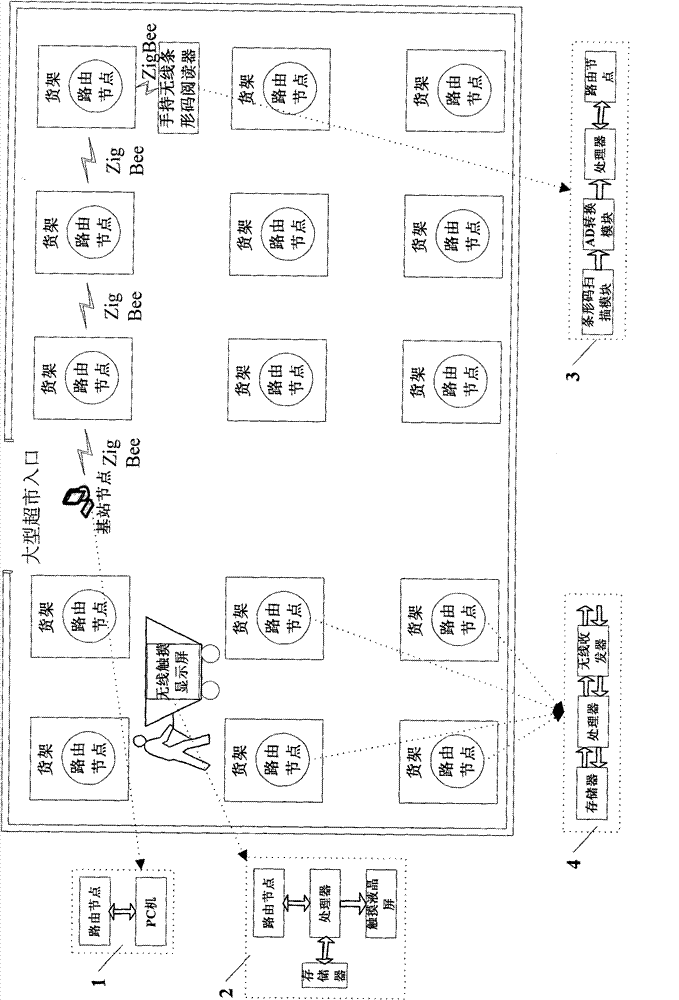

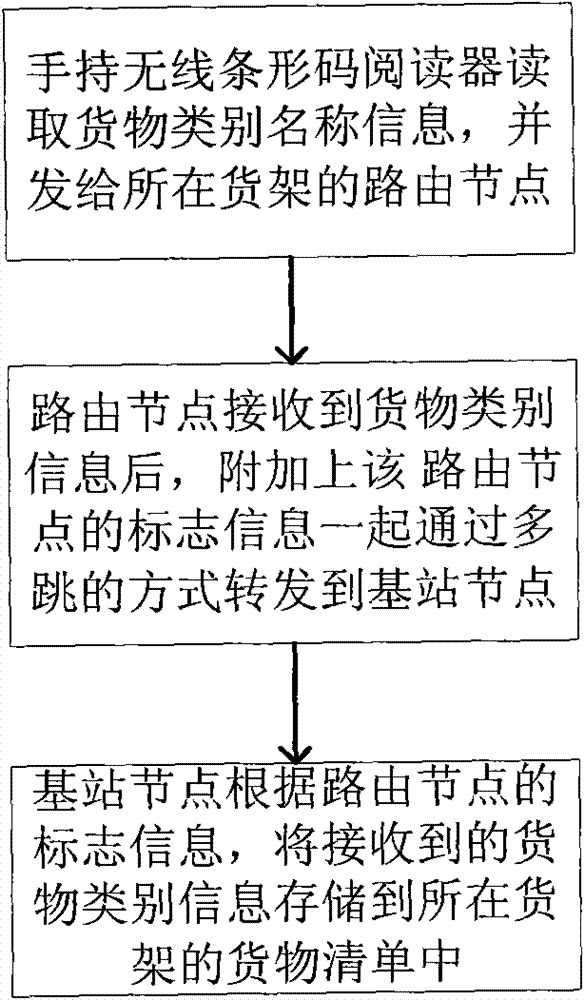

Supermarket shopping guiding and advertising system and control method based on wireless sensor network

InactiveCN101854384BConvenient shoppingGood serviceNetwork topologiesAdvertisingWireless mesh networkBarcode reader

The invention relates to a supermarket shopping guiding and advertising system and a control method based on a wireless sensor network; the system is characterized by comprising the wireless sensor network consisting of a base station node, a wireless touch display screen, a handheld wireless barcode reader and a wireless sensor network supporting platform; the handheld wireless barcode reader isconnected with the wireless sensor network supporting platform in a wireless communication way, and is used for reading barcodes on goods and collecting the category name information of the goods in a supermarket; the wireless sensor network supporting platform comprises the wireless sensor network consisting of all routing nodes which are deployed on all shelves of the supermarket; the base station node is connected with the wireless sensor network supporting platform in the wireless communication way, is used for saving the information forwarded by the wireless sensor network supporting platform, and interacts information with the wireless touch display screen; and the wireless touch display screen is connected with the base station node in the communication way, and is used for interacting information with the base station node. The invention can effectively guide a shopper to shop, and simultaneously play advertisements more purposefully.

Owner:ZHEJIANG UNIV CITY COLLEGE

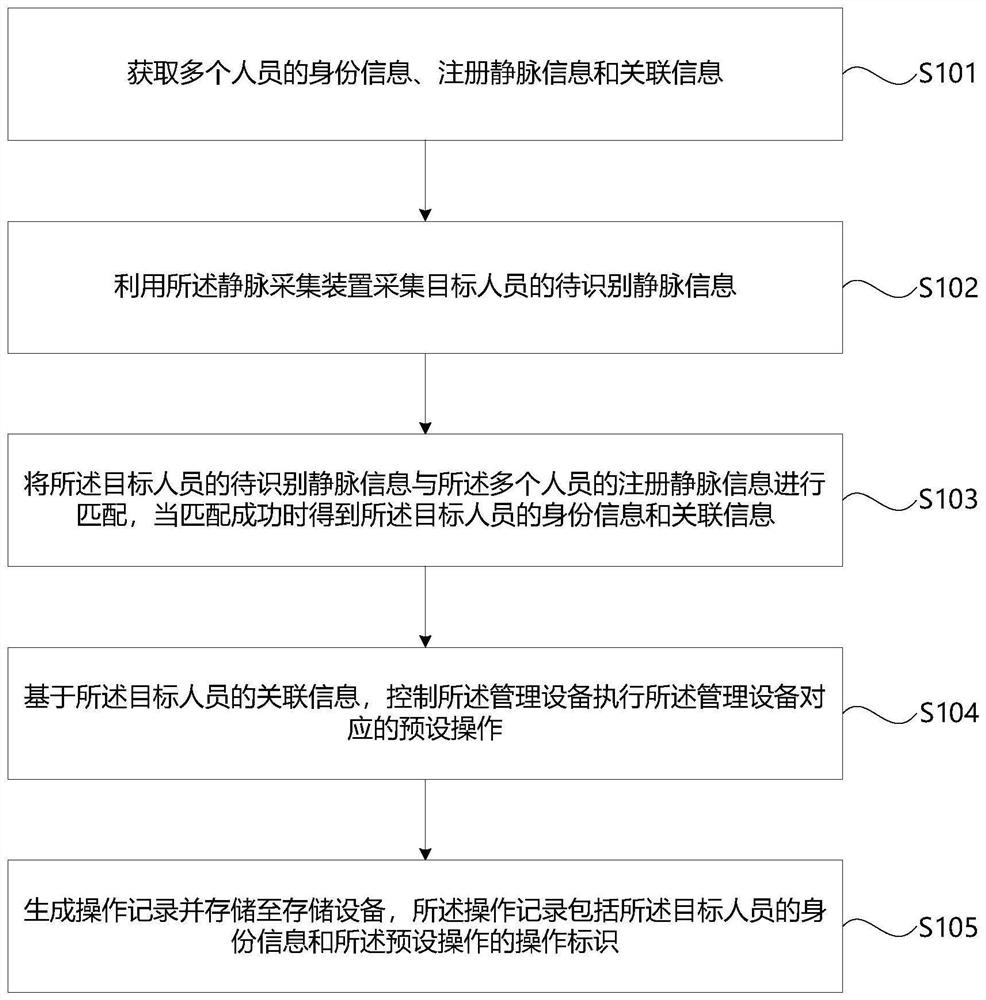

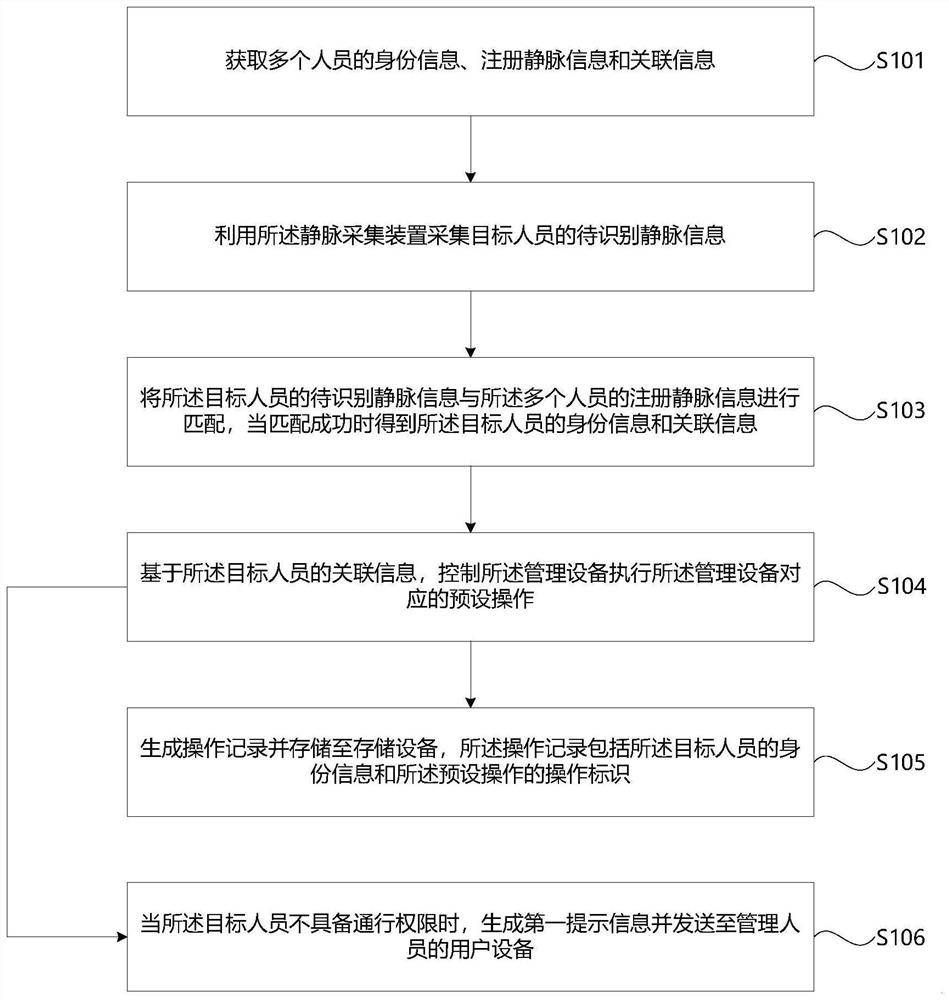

Strong security place management method based on vein recognition and related device

PendingCN113888780AImprove identification efficiencyReduce length of stayCharacter and pattern recognitionIndividual entry/exit registersVeinInformation control

The invention provides a strong security place management method based on vein recognition and a related device. The method comprises the following steps: acquiring identity information, registered vein information and associated information of a plurality of persons; acquiring to-be-recognized vein information of a target person by using a vein acquisition device; matching the to-be-recognized vein information of the target person with the registered vein information of the multiple persons, and when matching succeeds, obtaining identity information and associated information of the target person; and based on the associated information of the target person, controlling a management device to execute a preset operation corresponding to the management device, and generating an operation record and storing the operation record in the storage device. A vein recognition technology is used for recognizing the identity of a user, equipment is controlled to execute preset operation corresponding to the equipment, operation records are generated and stored, and the problem that behavior records of the user in a strong security place are not easy to count is solved.

Owner:DEEPBLUE SHENGSHI TECH SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com