Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "3-hydroxypropionaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyhydroxyalkanoate production from polyols

InactiveUS20050239179A1Promote recoveryProduct can be usedBacteriaMicroorganism based processes3-Hydroxypropionic acidPropanoic acid

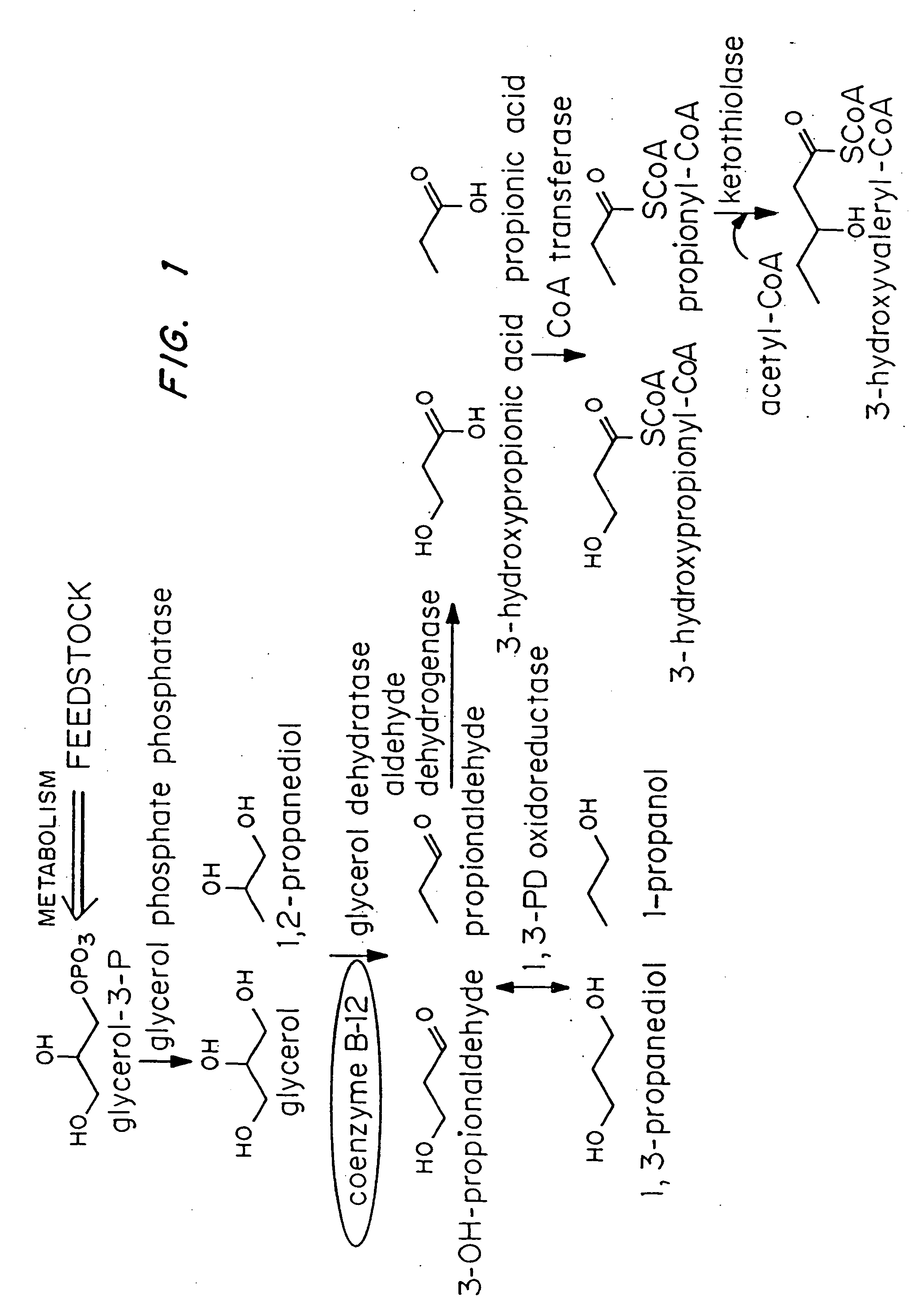

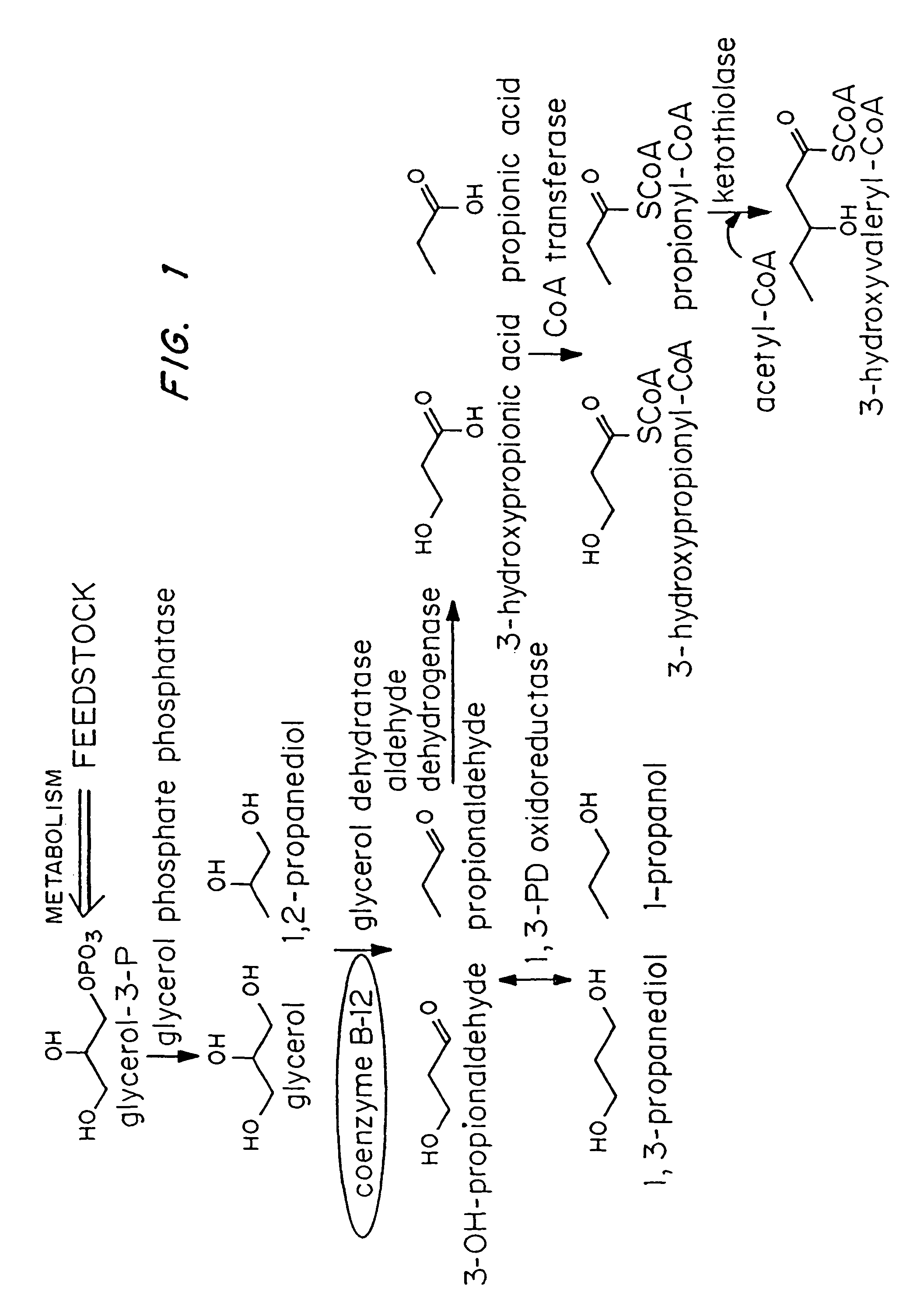

Organisms are provided which express enzymes such as glycerol dehydratase, diol dehydratase, acyl-CoA transferase, acyl-CoA synthetase β-ketothiolase, acetoacetyl-CoA reductase, PHA synthase, glycerol-3-phosphate dehydrogenase and glycerol-3-phosphatase, which are useful for the production of PHAs. In some cases one or more of these genes are native to the host organism and the remainder are provided from transgenes. These organisms produce poly (3-hydroxyalkanoate) homopolymers or co-polymers incorporating 3-hydroxypropionate or 3-hydroxyvalerate monomers wherein the 3-hydroxypropionate and 3-hydroxyvalreate units are derived from the enzyme catalysed conversion of diols. Suitable diols that can be used include 1,2-propanediol, 1,3 propanediol and glycerol. Biochemical pathways for obtaining the glycerol from normal cellular metabolites are also described. The PHA polymers are readily recovered and industrially useful as polymers or as starting materials for a range of chemical intermediates including 1,3-propanediol, 3-hydroxypropionaldehyde, acrylics, malonic acid, esters and amines.

Owner:CJ CHEILJEDANG CORP

Process for the biological production of 1,3-propanediol with high titer

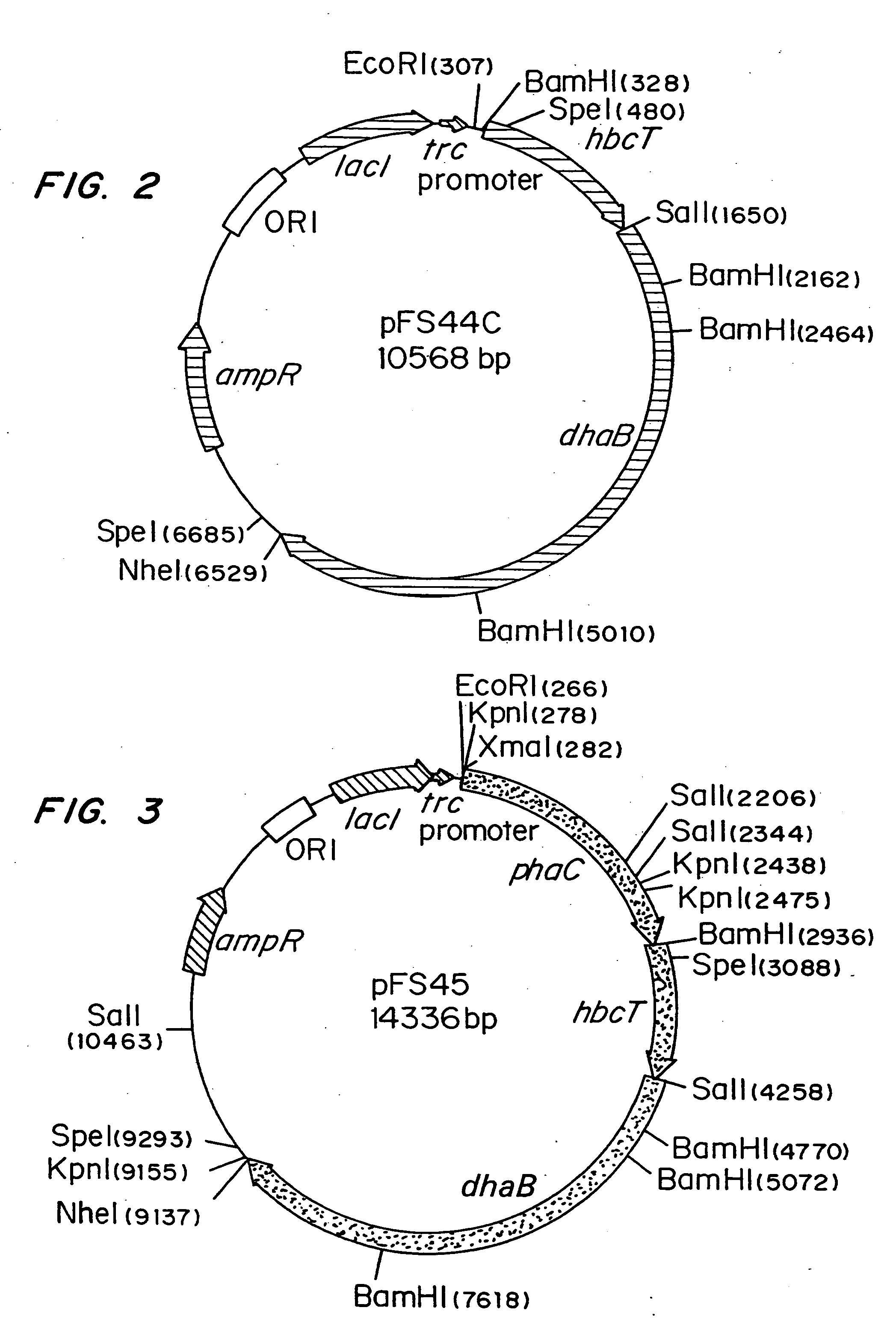

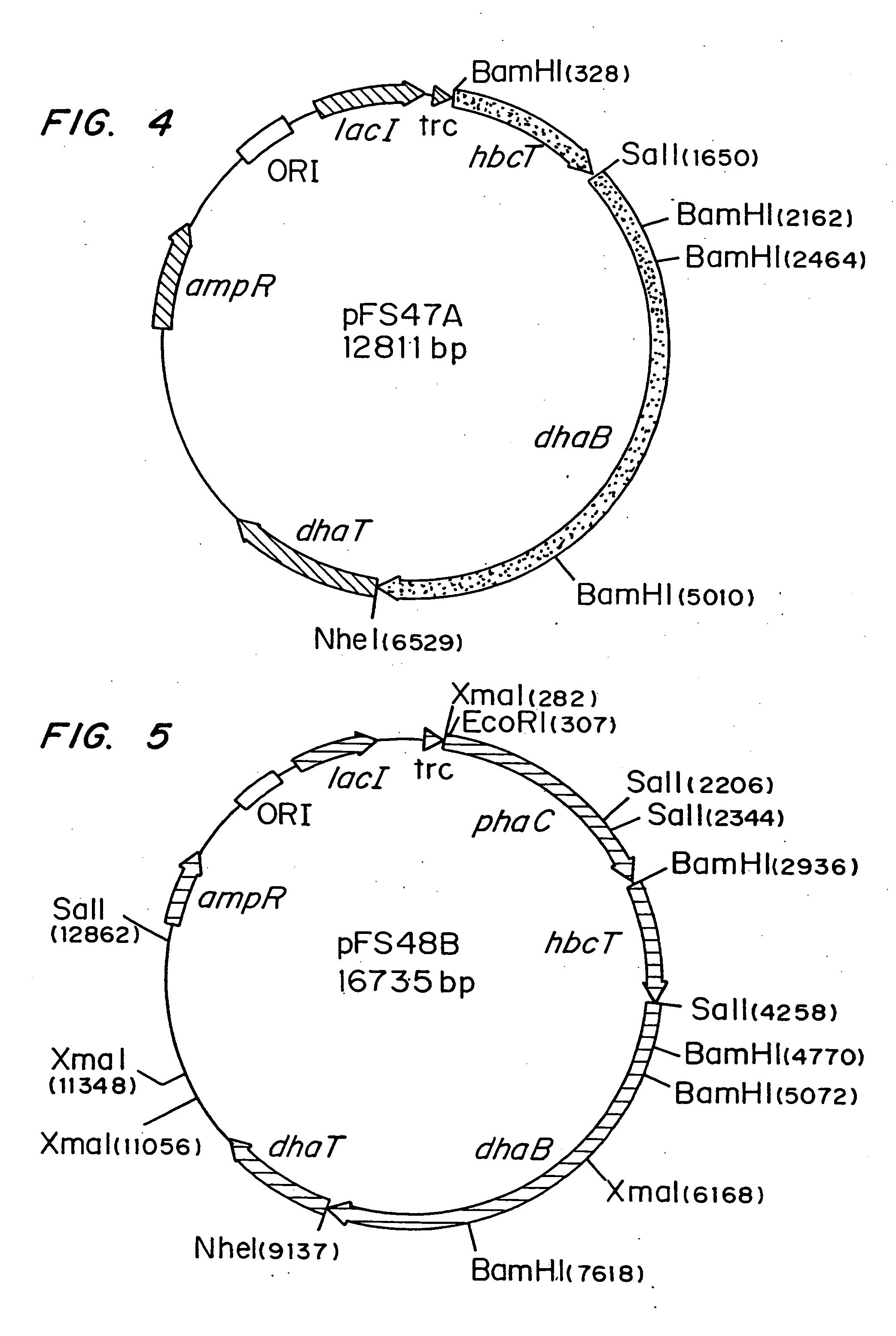

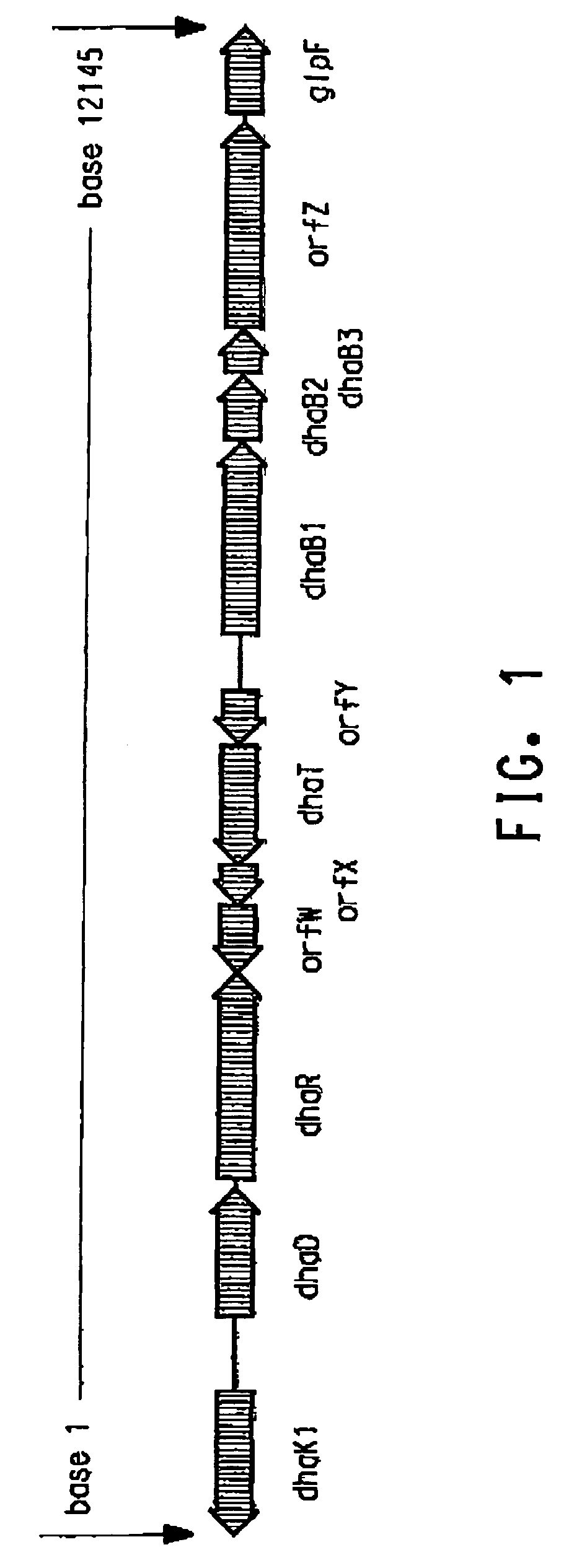

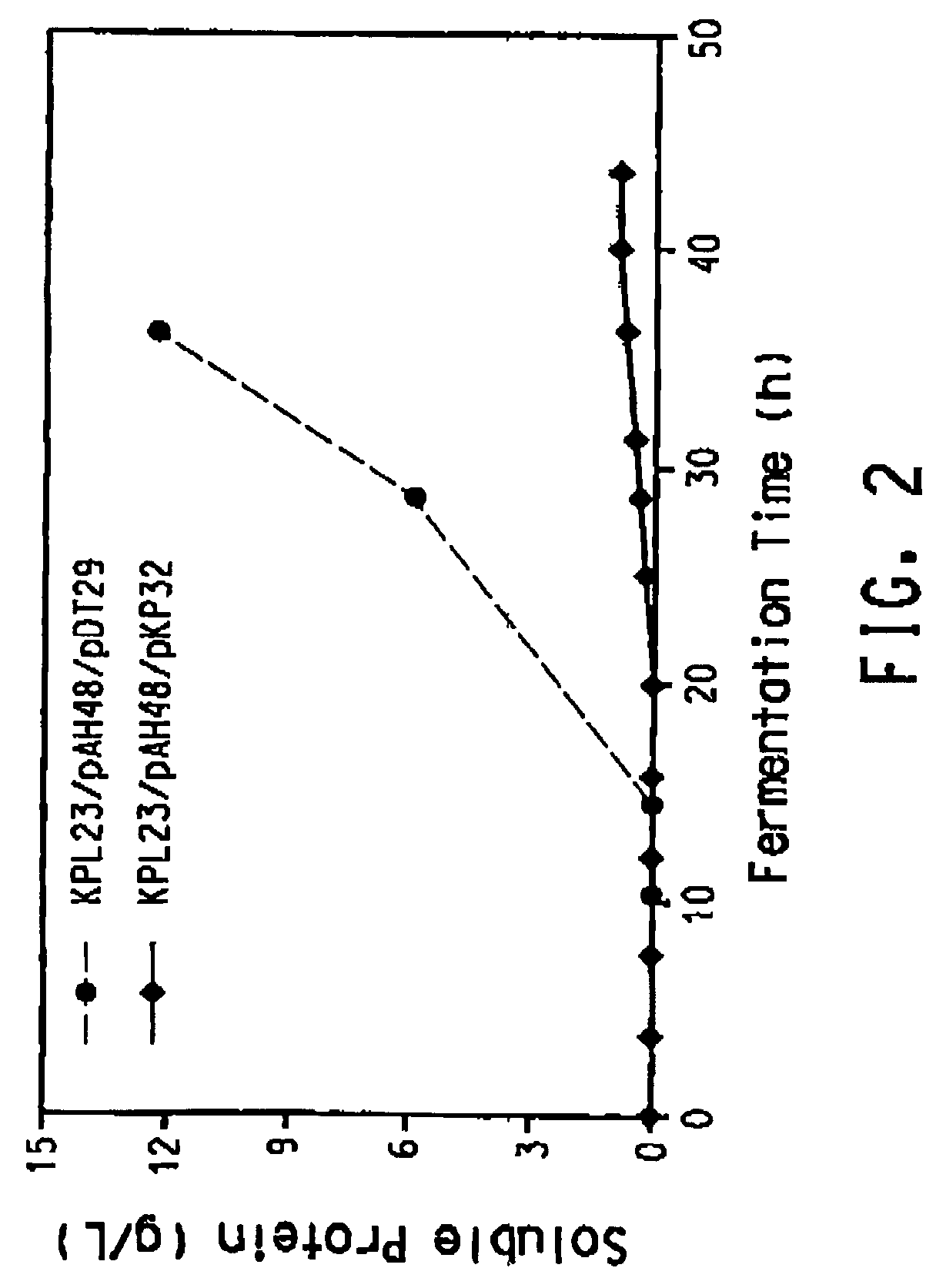

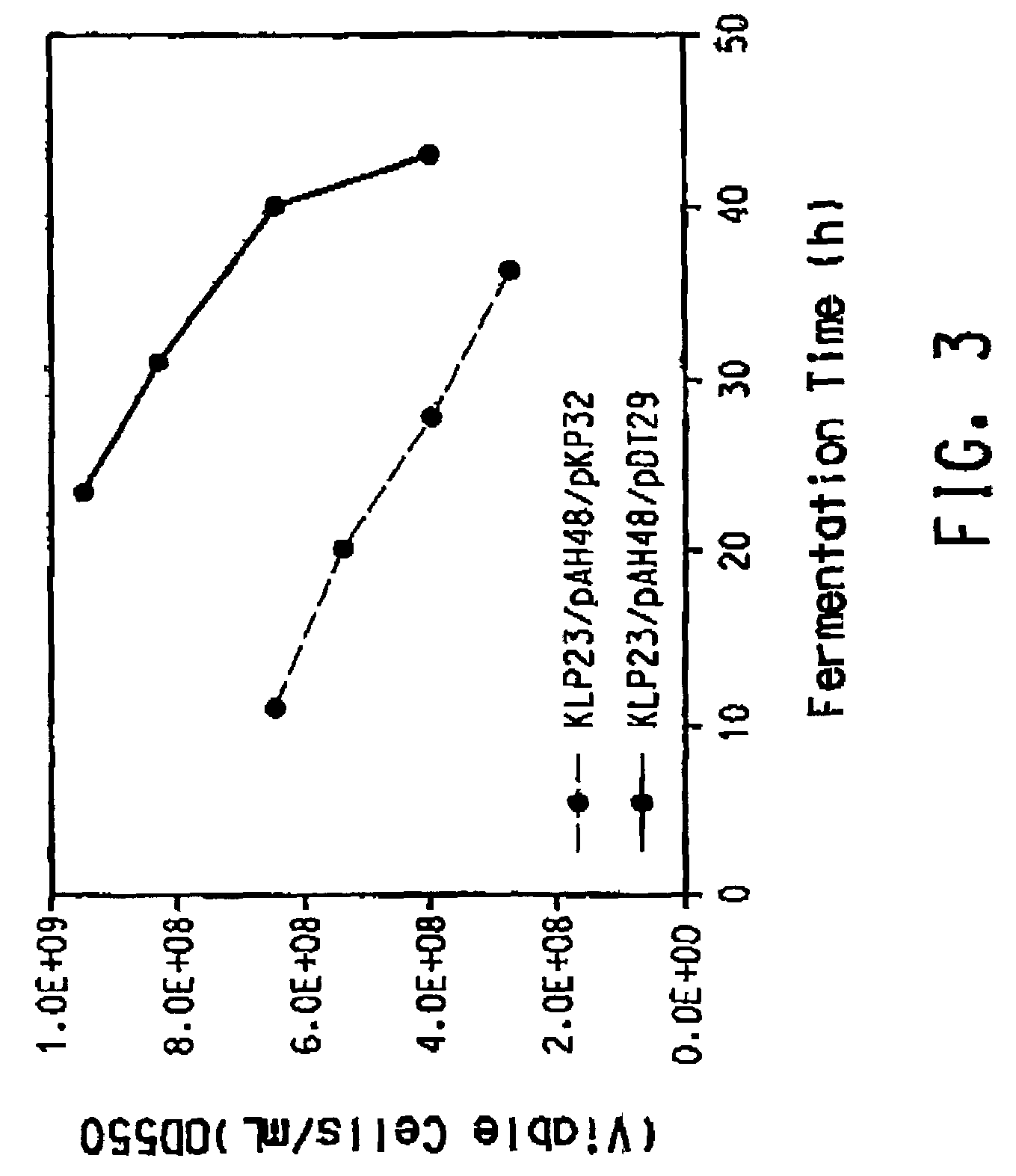

The present invention provides an improved method for the biological production of 1,3-propanediol from a fermentable carbon source in a single microorganism. In one aspect of the present invention, an improved process for the conversion of glucose to 1,3-propanediol is achieved by the use of an E. coli transformed with the Klebsiella pneumoniae dha regulon genes dhaR, orfY, dhaT, orfX, orfW, dhaB1, dhaB2, dhaB3, and orfZ, all these genes arranged in the same genetic organization as found in wild type Klebsiella pneumoniae. In another aspect of the present invention, an improved process for the production of 1,3-propanediol from glucose using a recombinant E. coli containing genes encoding a G3PDH, a G3P phosphatase, a dehydratase, and a dehydratase reactivation factor compared to an identical process using a recombinant E. coli containing genes encoding a G3PDH, a G3P phosphatase, a dehydratase, a dehydratase reactivation factor and a 1,3-propanediol oxidoreductase (dhaT). The dramatically improved process relies on the presence in E. coli of a gene encoding a non-specific catalytic activity sufficient to convert 3-hydroxypropionaldehyde to 1,3-propanediol.

Owner:DUPONT US HLDG LLC

Treatment of an aqueous mixture containing an alkylene oxide with an ion exchange resin

InactiveUS20060189833A1Organic compound preparationHydroxy compound preparationEthylene oxideIon exchange

A process for separating an alkylene oxide from an aqueous mixture is provided in which no detectable dioxane byproduct is formed. An aqueous mixture containing an alkylene oxide is contacted with a carboxylic acid ion exchange resin to separate the alkylene oxide from the aqueous mixture. The ion exchange capacity of the resin is regenerated with an acid wash at a temperature of at least 60° C., wherein regeneration of the resin does not result in the formation of dioxane in the spent acid wash. The process is particularly useful in purifying an aqueous 3-hydroxypropionaldehyde solution derived from an aqueous extraction of a hydroformylation reaction mixture containing ethylene oxide.

Owner:SHELL OIL CO

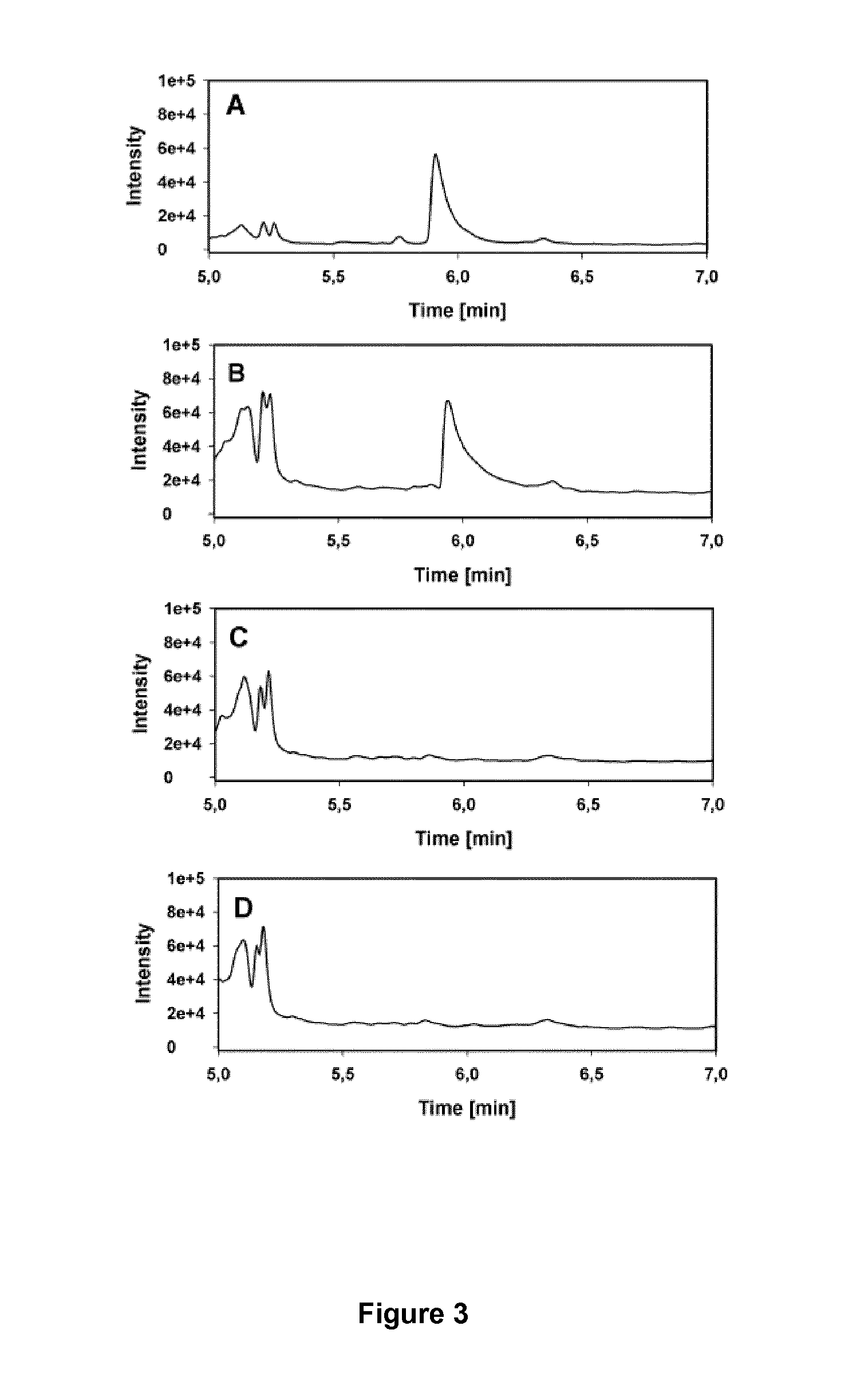

Hydrogenation catalyst and hydrogenation method

InactiveUS20060241325A1Preparation by oxo-reaction and reductionOrganic compound preparationPropynalRuthenium

The present invention provides a hydrogenation catalyst effective for hydrogenating 3-hydroxypropionaldehyde to 1,3-propanediol. The hydrogenation catalyst comprises an α-alumina support, nickel, ruthenium, and a promoter. The nickel is deposited on the α-alumina support, and the ruthenium and the promoter are deposited on the nickel and the α-alumina support. The α-alumina support comprises at least 92 wt. % of the catalyst, and the nickel comprises from 1 wt. % to 6 wt. % of the catalyst. The present invention also provides a process of hydrogenating 3-hydroxypropionaldehyde to 1,3-propanediol with the catalyst.

Owner:SHELL OIL CO

Method for preparing 1,3-propylene glycol by 3-hydroxypropionaldehyde hydrogenation

InactiveCN1428322AHigh activityFacilitated DiffusionPreparation by oxygen reductionHydrogen pressureGas pressure

The method for preparing 1,3-propylene glycol by means of hydrogenation of 3-hydroxy-propionaldehyde is characterized by that the weight percentage concentration of raw material 3-hydroxy-propionaldehyde aqueous solution is 10-20%, in the presence of catalyst two-stage hydrogenation process can be adopted to obtain 1,3-propylene glycol, in which the first stage hydrogenation temp. is 25-60 deg.C, second stage hydrogenation temp. is 110-130 deg.C, hydrogen gas pressure of two-stage hydrogenation is 4.0-7.0 MPa, and its space velocity is 0.1-5 hr (-1), and the active component of the catalyst is Ni-A, in which A is any one of Cr, Zn, Mo or Fe, and its carrier is molecular sieve containing Al2O3 or SiO2 or containing both them simultaneously, and the weight percetnage content of the actigve component of the catalyst is 30-60%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Method For Producing 3-Hydroxypropionaldehyde

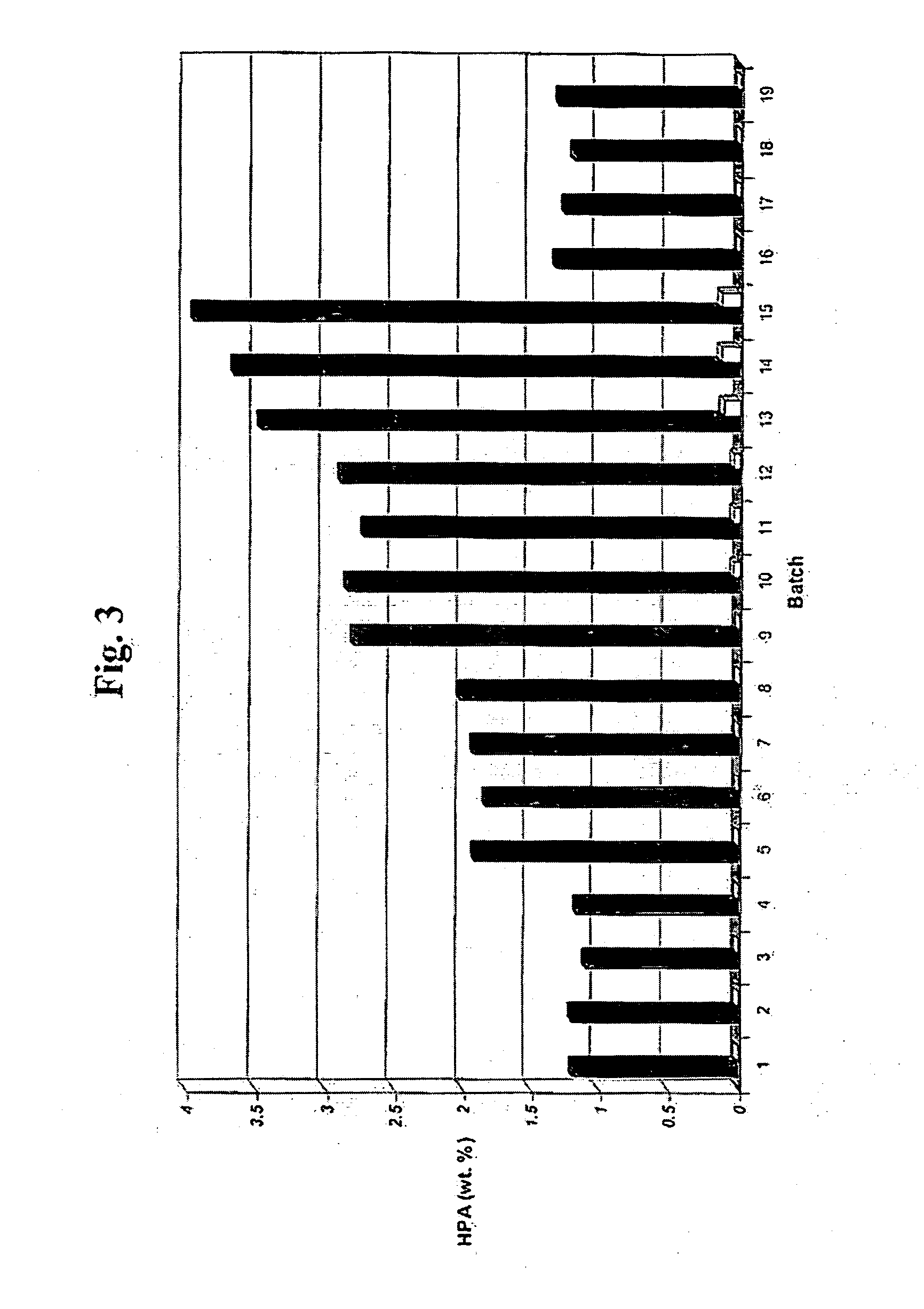

InactiveUS20080131945A1High conversion ratioHigh yieldOrganic compound preparationOrganic chemistry methodsGlycerolDiol Dehydratase

A method for producing 3-hydroxypropionaldehyde from glycerin in high conversion ratio is provided. The method is characterized by comprising a step of dehydrating glycerin using a microbial cell and / or a treated microbial cell containing diol dehydratase and / or glycerol dehydratase, and optionally diol dehydratase reactivating factor and / or glycerol dehydratase reactivating factor, under conditions so as to give a value (X / Y2) calculated by dividing a catalytic amount [X (U / g glycerin)] of diol dehydratase and / or glycerol dehydratase by square of glycerin concentration [Y (g / 100 ml)] within a range of 10 to 8,000, to produce 3-hydroxypropionaldehyde.

Owner:NIPPON SHOKUBAI CO LTD

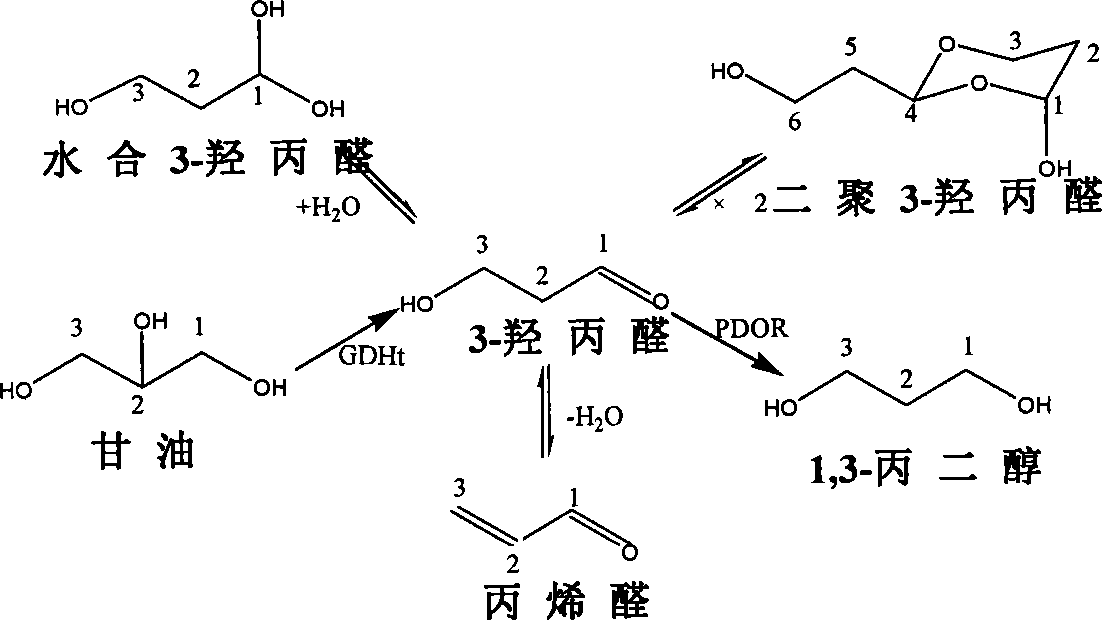

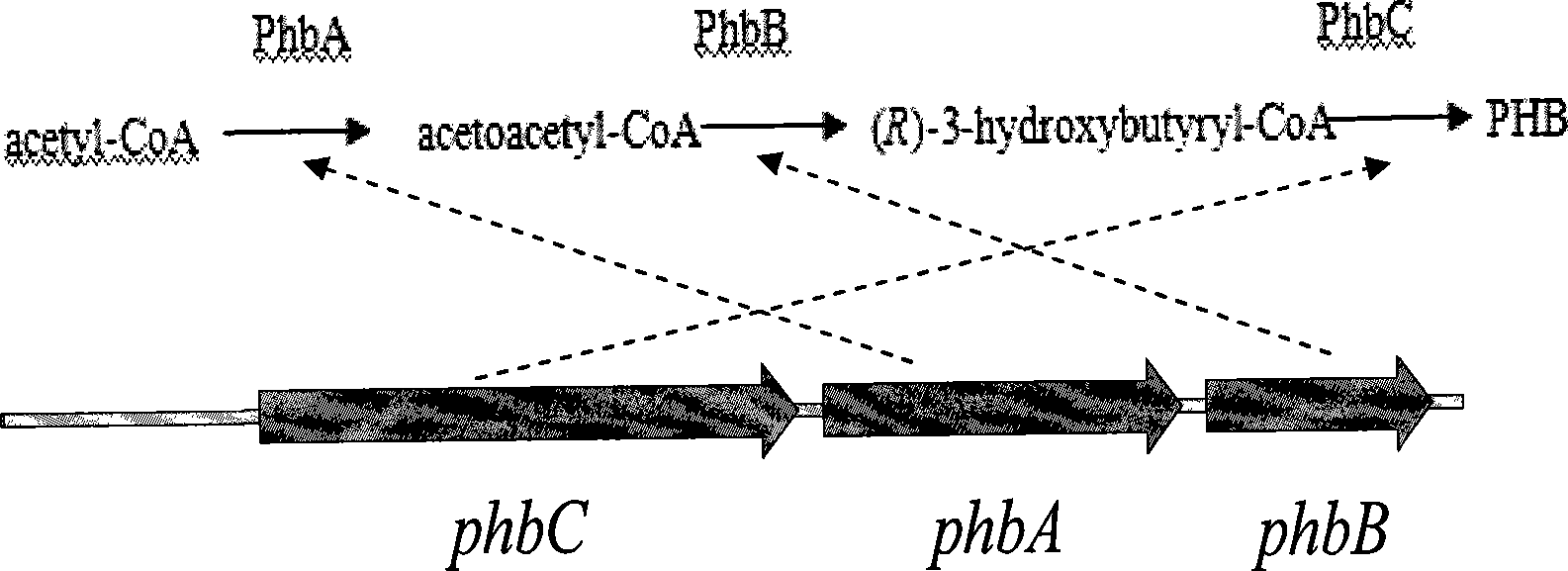

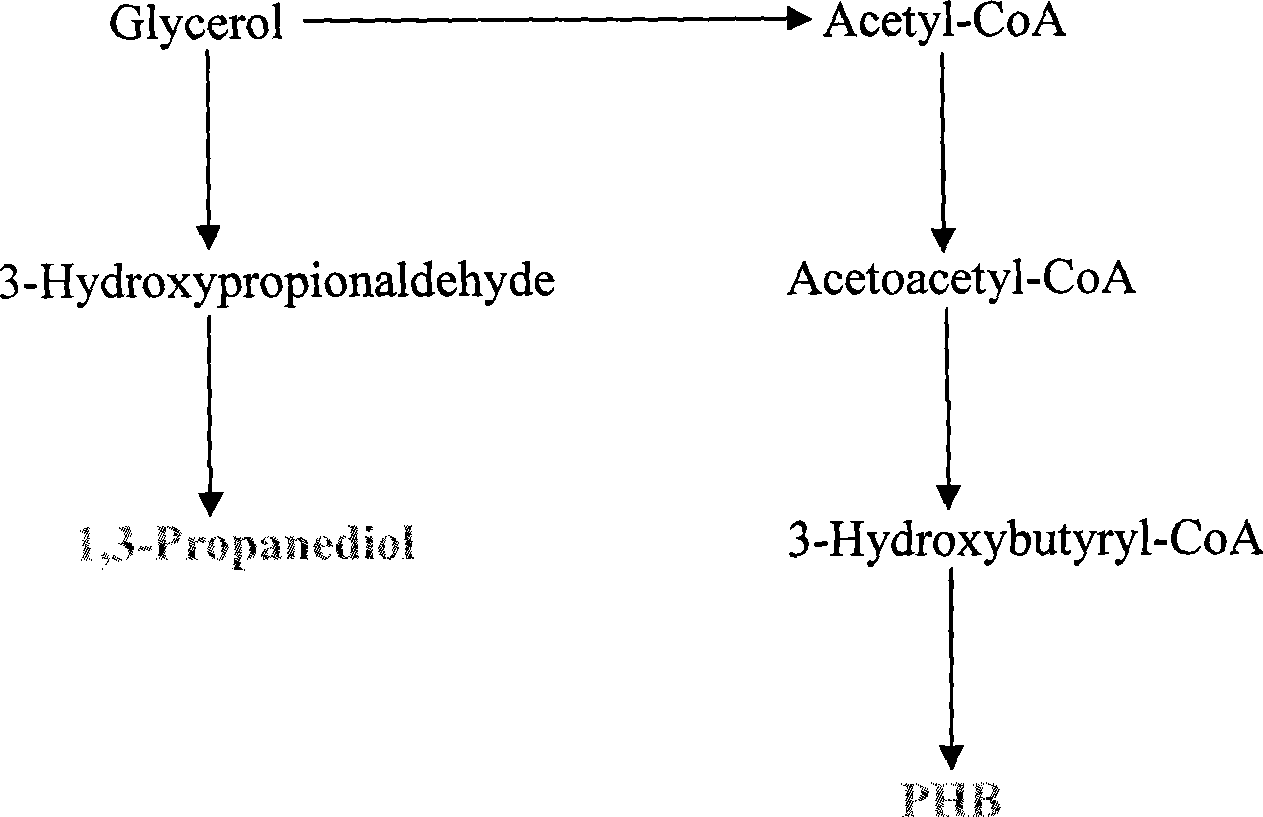

Method for constructing genetic engineering bacteria and enhancing stress resistance of 1,3-propanediol producing strain

InactiveCN101381696AImprove stress resistanceIncrease added valueBacteriaBiofuelsHigh concentrationGlycerol

The invention provides a method for constructing a gene engineering strain to enhance the resistance of a 1, 3-propanediol (PDO) production strain, which belongs to the technical field of biochemical engineering and comprises the step of: introducing Beta-ketothiolase PhbA, NADPH-dependent acetoacetyl CoA, PhbB and polyhydroxyalkanoates synthases, PhbC gene to a wild bacteria which can produce PDO to accumulate high concentration of PHB while the bacterial strain produces PDO so as obviously improve the tolerance of the bacterial strain to glycerol and 3-hydroxypropionaldehyde; the method can also be used to co-produce PHB and PDO. The method has the advantages that the constructed gene engineering strain improves the resistance of the bacterial strain to the high concentration of glycedrol and the intermediate product 3-hydroxypropionaldehyde and reduces the abnormal fermentation in industrial production; in addition, high concentration of PHB can be accumulated while PDO is produced, and PHB can be used as a separated product, thereby promoting the added valve of products and the utilization rate of materials and reducing the production cost.

Owner:TSINGHUA UNIV

Polyhydroxyalkanoate production from polyols

Organisms are provided which express enzymes such as glycerol dehydratase, diol dehydratase, acyl-CoA transferase, acyl-CoA synthetase β-ketothiolase, acetoacetyl-CoA reductase, PHA synthase, glycerol-3-phosphate dehydrogenase and glycerol-3-phosphatase, which are useful for the production of PHAs. In some cases one or more of these genes are native to the host organism and the remainder are provided from transgenes. These organisms produce poly (3-hydroxyalkanoate) homopolymers or co-polymers incorporating 3-hydroxypropionate or 3-hydroxyvalerate monomers wherein the 3-hydroxypropionate and 3-hydroxyvalerate units are derived from the enzyme catalysed conversion of diols. Suitable diols that can be used include 1,2-propanediol, 1,3 propanediol and glycerol. Biochemical pathways for obtaining the glycerol from normal cellular metabolites are also described. The PHA polymers are readily recovered and industrially useful as polymers or as starting materials for a range of chemical intermediates including 1,3-propanediol, 3-hydroxypropionaldehyde, acrylics, malonic acid, esters and amines.

Owner:CJ CHEILJEDANG CORP

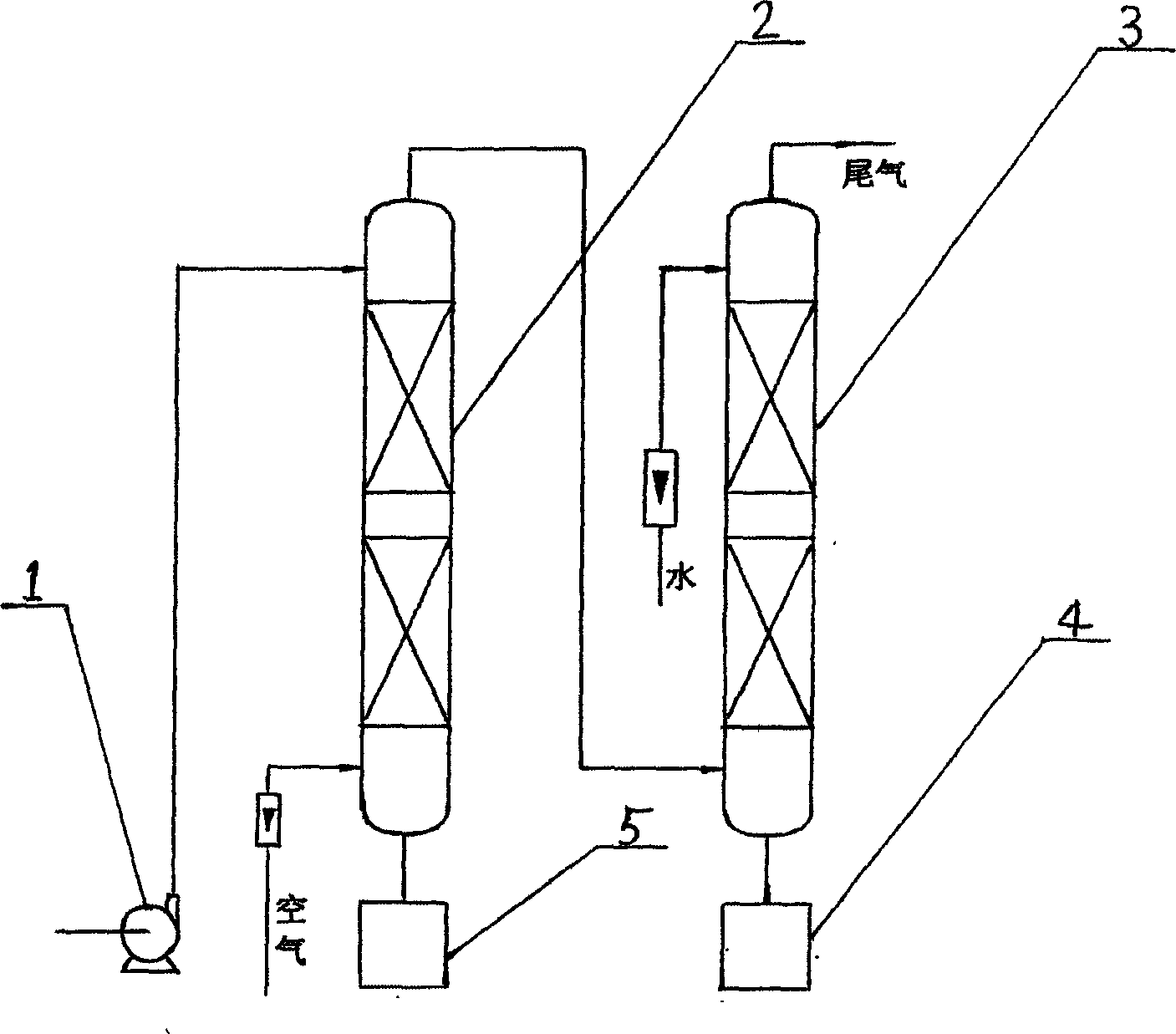

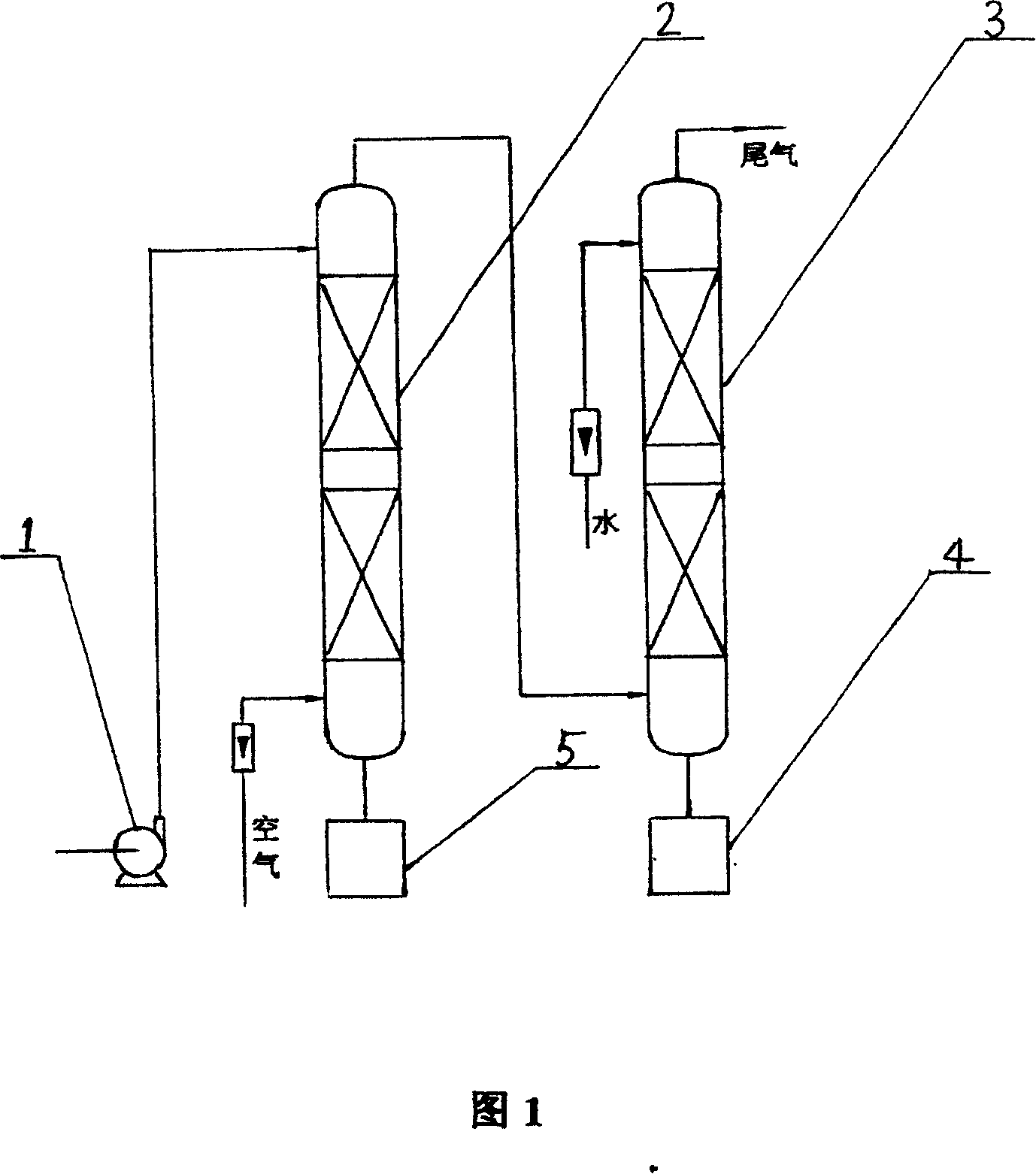

Method for separating and reclaiming acrolein

ActiveCN1803750ASeparation and recovery methods are easy to implementLower operating temperatureCarbonyl compound separation/purificationHydration reactionRecovery method

The provided separate and recovery method for non-reacted acrolein in preparation process of 3-hydroxypropionaldehyde comprises: leading gas into the tower bottom for gas stripping the acrolein from reaction product and absorb it in absorption tower with water. This invention has high recovery and prepares the material with the absorbed liquid for acrolein hydration reaction.

Owner:SHANGHAI HUAYI NEW MATERIAL

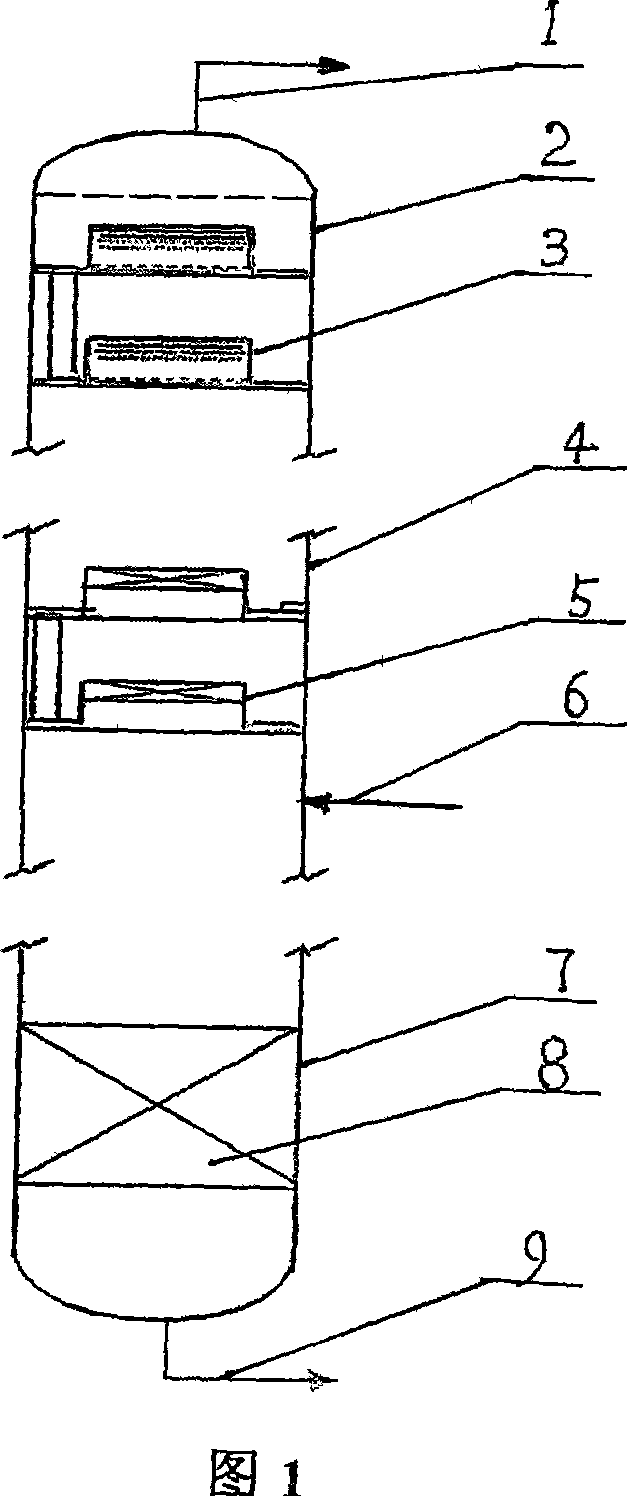

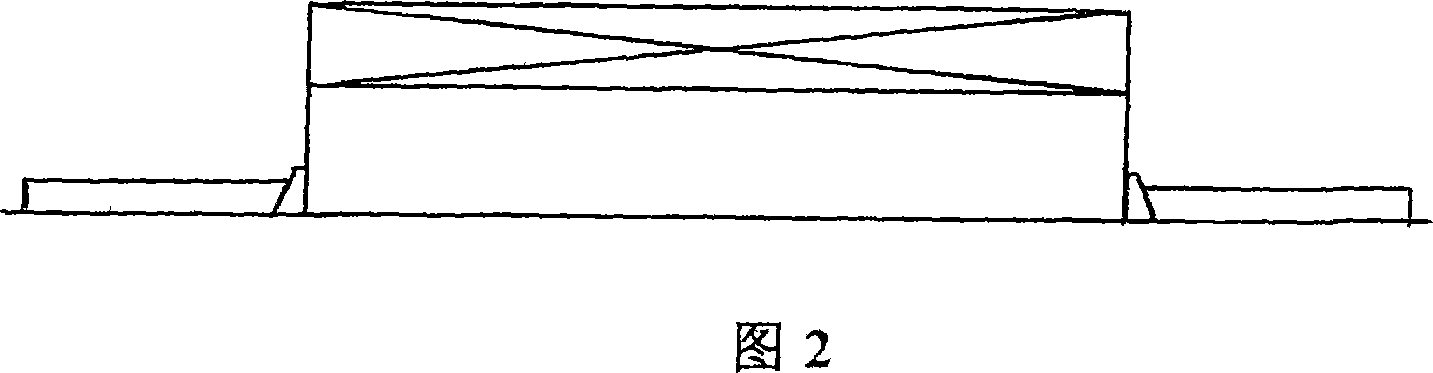

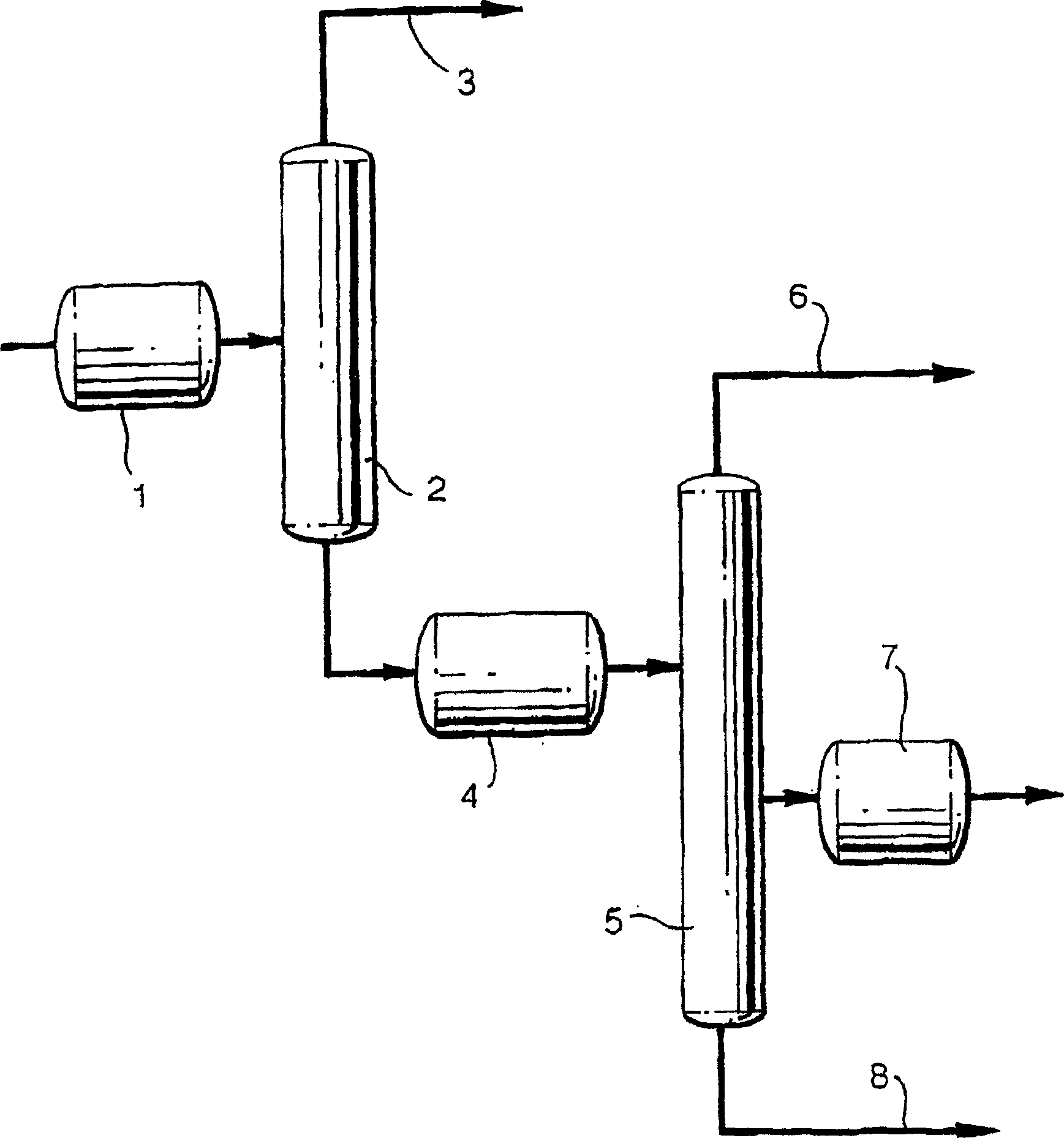

Fractionating tower for separating acrylic aldehyde from 3-hydroxypropionaldehyde solution

ActiveCN101033180AEasy to cleanSpeed up contactCarbonyl compound separation/purificationEngineeringTower

This invention provides a rectifying tower for separating and hydrate acrolein to prepare non-reacted acrolein in a 3-lactic aldehyde reacted product, the top of the tower applies a new vertical seeve plate and the lower part applies a parallel flow jet filling tower plate and the rectifying section applies structured packing, which can increase the separation ability of towers to reduce pressure drop of the tower and operation temperature, reduce aggregation trend and reduction and aggregation trend of 3-hydroxide propaldehyde so as to reduce the loss of acrolein in the top tower.

Owner:SHANGHAI HUAYI NEW MATERIAL

Method for removing micro aldehyde group from 1,3-propylene glycol

ActiveCN1803744ALow costGood dealdehyde effectPhysical/chemical process catalystsHydroxy compound separation/purificationHydrogenation reactionPropynal

The related stripping method for trace-amount aldehydo in 1, 3-dihydroxypropane comprises: adding proper solid super acidic catalyst of SO42- / MxOy into the 1, 3-dihydroxypropane solution with micro impurity dewatered and condensed from hydrogenation reaction production of 3-hydroxypropionaldehyde for dealdehydation treatment at given temperature; rectifying the solution under vacuum to obtain polymer-grade product that has 1, 3-dihydroxypropane content more than 99.7% and aldehyde content less than 10ppm and fit to material quality request for PTT.

Owner:SHANGHAI HUAYI NEW MATERIAL

Hydrogenation catalyst and hydrogenation method

InactiveUS7335800B2Preparation by oxo-reaction and reductionOrganic compound preparationPropynalRuthenium

The present invention provides a hydrogenation catalyst effective for hydrogenating 3-hydroxypropionaldehyde to 1,3-propanediol. The hydrogenation catalyst comprises an α-alumina support, nickel, ruthenium, and a promoter. The nickel is deposited on the α-alumina support, and the ruthenium and the promoter are deposited on the nickel and the α-alumina support. The α-alumina support comprises at least 92 wt. % of the catalyst, and the nickel comprises from 1 wt. % to 6 wt. % of the catalyst. The present invention also provides a process of hydrogenating 3-hydroxypropionaldehyde to 1,3-propanediol with the catalyst.

Owner:SHELL OIL CO

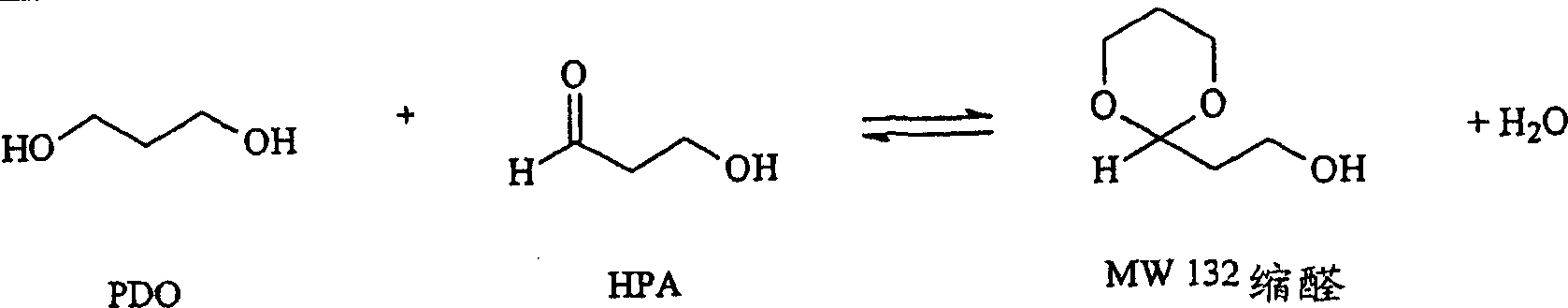

Removal of impurities formed during the production of 1,3-propanediol

InactiveCN1708467AOrganic compound preparationHydroxy compound preparationPropylene glycol preparationDistillation

Owner:SHELL INT RES MAATSCHAPPIJ BV

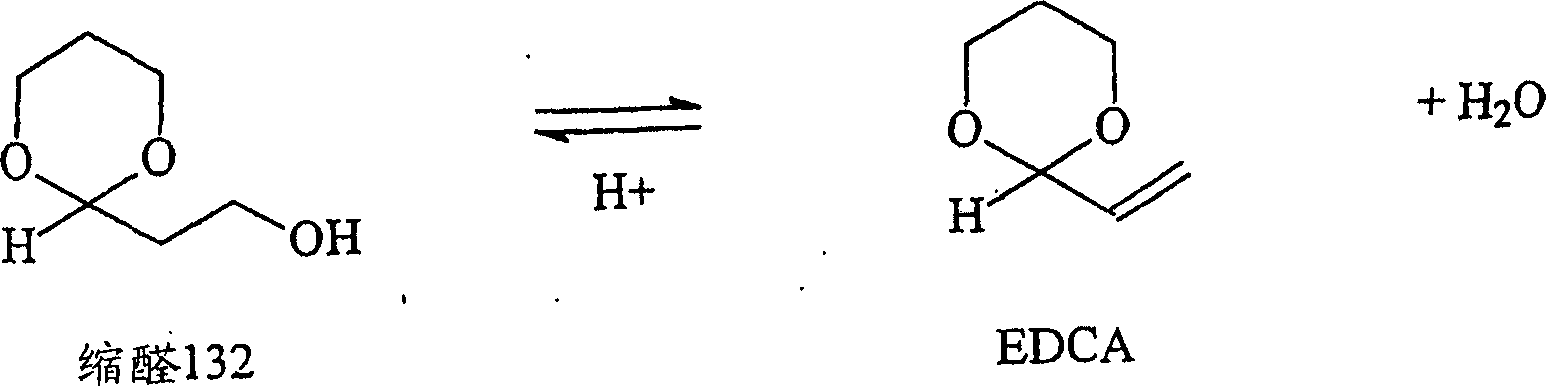

Aldehyde dehydrogenase gene, vector, engineering bacteria and application thereof

The invention provides an aldehyde dehydrogenase gene derived from saccharomyces cerevisiae strains, a recombination expression vector, engineering bacteria thereof, and applications thereof in preparing the recombination aldehyde dehydrogenase. The invention provides an aldehyde dehydrogenase gene nucleotide sequence derived from the saccharomyces cerevisiae strains, connects and constructs the gene and the expression vector into an expression recombination plasmid pET28b-aldH containing the gene, and transforms the expression recombination plasmid pET28b-aldH to colibacillus BL21 to obtain the recombination colibacillus BL21 / pET28b-aldH containing the expression recombination plasmid pET28b-aldH; and the recombination colibacillus constructed by the invention can be applied to carry out biocatalysis and transformation, thus acetaldehyde, propionaldehyde or 3-hydroxypropionaldehyde are transformed into corresponding acetic acid, propionic acid or 3-hydroxypropionic acid.

Owner:ZHEJIANG UNIV OF TECH

Process for the biological production of 1,3-propanediol with high titer

The present invention provides an improved method for the biological production of 1,3-propanediol from a fermentable carbon source in a single microorganism. In one aspect of the present invention, an improved process for the conversion of glucose to 1,3-propanediol is achieved by the use of an E. coli transformed with the Klebsiella pneumoniae dha regulon genes dhaR, orfY, dhaT, orfX, orfW, dhaB1, dhaB2, dhaB3, and orfZ, all these genes arranged in the same genetic organization as found in wild type Klebsiella pneumoniae. In another aspect of the present invention, an improved process for the production of 1,3-propanediol from glucose using a recombinant E. coli containing genes encoding a G3PDH, a G3P phosphatase, a dehydratase, and a dehydratase reactivation factor compared to an identical process using a recombinant E. coli containing genes encoding a G3PDH, a G3P phosphatase, a dehydratase, a dehydratase reactivation factor and a 1,3-propanediol oxidoreductase (dhaT). The dramatically improved process relies on the presence in E. coli of a gene encoding a non-specific catalytic activity sufficient to convert 3-hydroxypropionaldehyde to 1,3-propanediol.

Owner:DUPONT US HLDG LLC

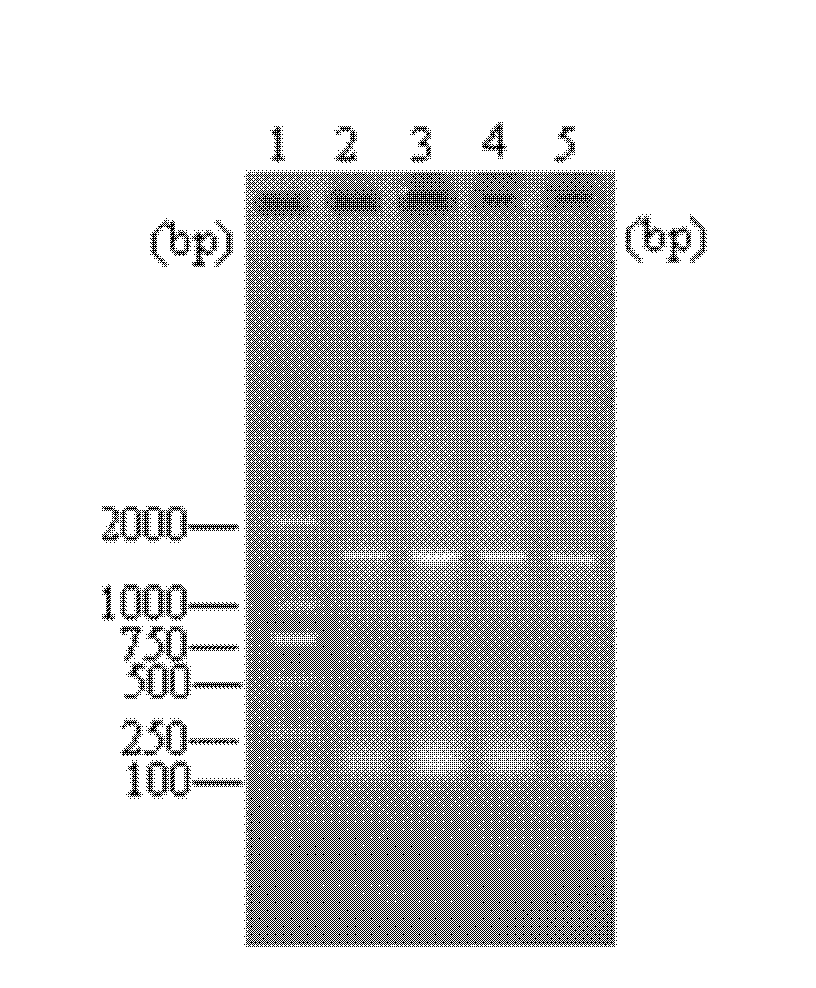

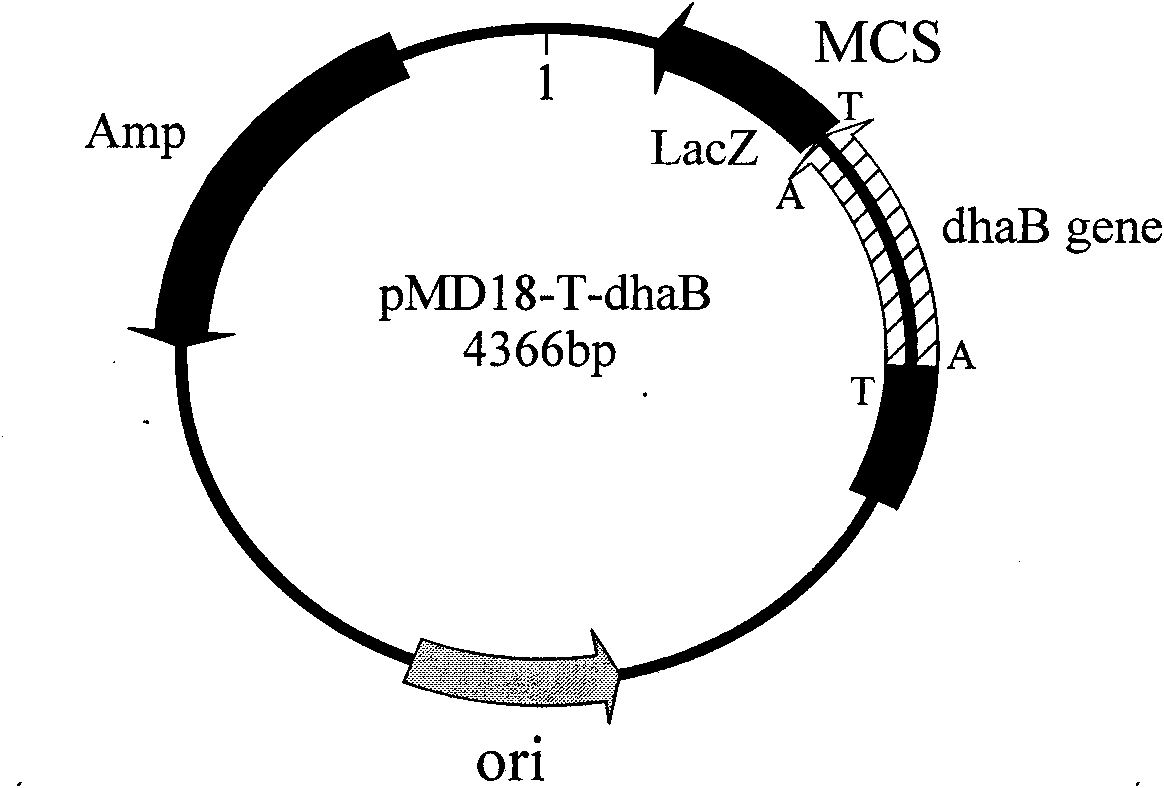

Glycerol dehydratase gene, vector, engineering bacteria and application thereof

The invention provides a glycerol dehydratase gene for coding glycerol dehydratase, a recombinant vector containing the gene, a recombinant gene engineering bacteria obtained by the transformation ofthe recombinant vector and an application thereof for preparing the recombinant glycerol dehydratase. The glycerol dehydratase gene can obtain an intracellular expression recombinant plasmid or a secretory expression recombinant plasmid by connection and construction with an expression vector, then the intracellular expression recombinant plasmid or the secretory expression recombinant plasmid isrespectively and correspondingly transformed to an escherichia coli strain and obtains the recombinant escherichia coli which contains recombinant glycerol dehydratase, and can recombine the escherichia coli to carry out biocatalysis and transformation for an enzyme source. As an enzyme for transformation, the recombinant glycerol dehydratase can respectively adopt glycerol, 1, 2-propylene glycolor alcohol as primer and carry out transformation reaction so as to prepare corresponding 3-hydroxypropionaldehyde, propionaldehyde or aldehyde and the like.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of 1,3-propylene glycol

InactiveCN108358750AReduce hot spot temperatureReduced acetal impurity contentOrganic compound preparationHydroxy compound preparationHydrogenation reactionAqueous solution

The invention provides a preparation method of 1,3-propylene glycol. The preparation method comprises the following steps: providing an aqueous solution of 3-hydroxypropionaldehyde with the mass concentration of 8 to 13 percent; mixing hydrogen and the aqueous solution of 3-hydroxypropionaldehyde, and successively performing the one-stage hydrogenation reaction and two-stage hydrogenation reactionto obtain a two-stage hydrogenated product; and circulating a part of the two-stage hydrogenated product to the one-stage hydrogenation reaction. According to the preparation method of 1,3-propyleneglycol, part of the two-stage hydrogenated product is circulated to the one-stage hydrogenation reaction to absorb the reaction heat, so that the hot-spot temperature of the first hydrogenation reaction can be reduced, the content of acetal impurities in the product can be effectively reduced, and the selectivity of the hydrogenation reaction can be improved.

Owner:王鹏飞

Catalyst for preparing hydroxyl-terminated aldehyde through hydroformylation of epoxyalkane, and preparation method and application thereof

InactiveCN106861759AHigh activityImprove conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsCobaltOrganic chemistry

The invention discloses a catalyst for preparing hydroxyl-terminated aldehyde through hydroformylation of epoxyalkane, and a preparation method and application thereof. According to the preparation method, a cobalt precursor reacts with synthetic gas under the action of a sulfur-containing auxiliary agent so as to obtain a crude catalyst product. The catalyst provided by the invention is applied to preparation of hydroxyl-terminated aldehyde through hydroformylation of epoxyalkane and can inhibit yield reduction caused by hydrogenation of aldehyde, so heavy components by-produced in aldol condensation are reduced, and selectivity of 3-hydroxypropionaldehyde.

Owner:SHANGHAI HUAYI ENERGY CHEM

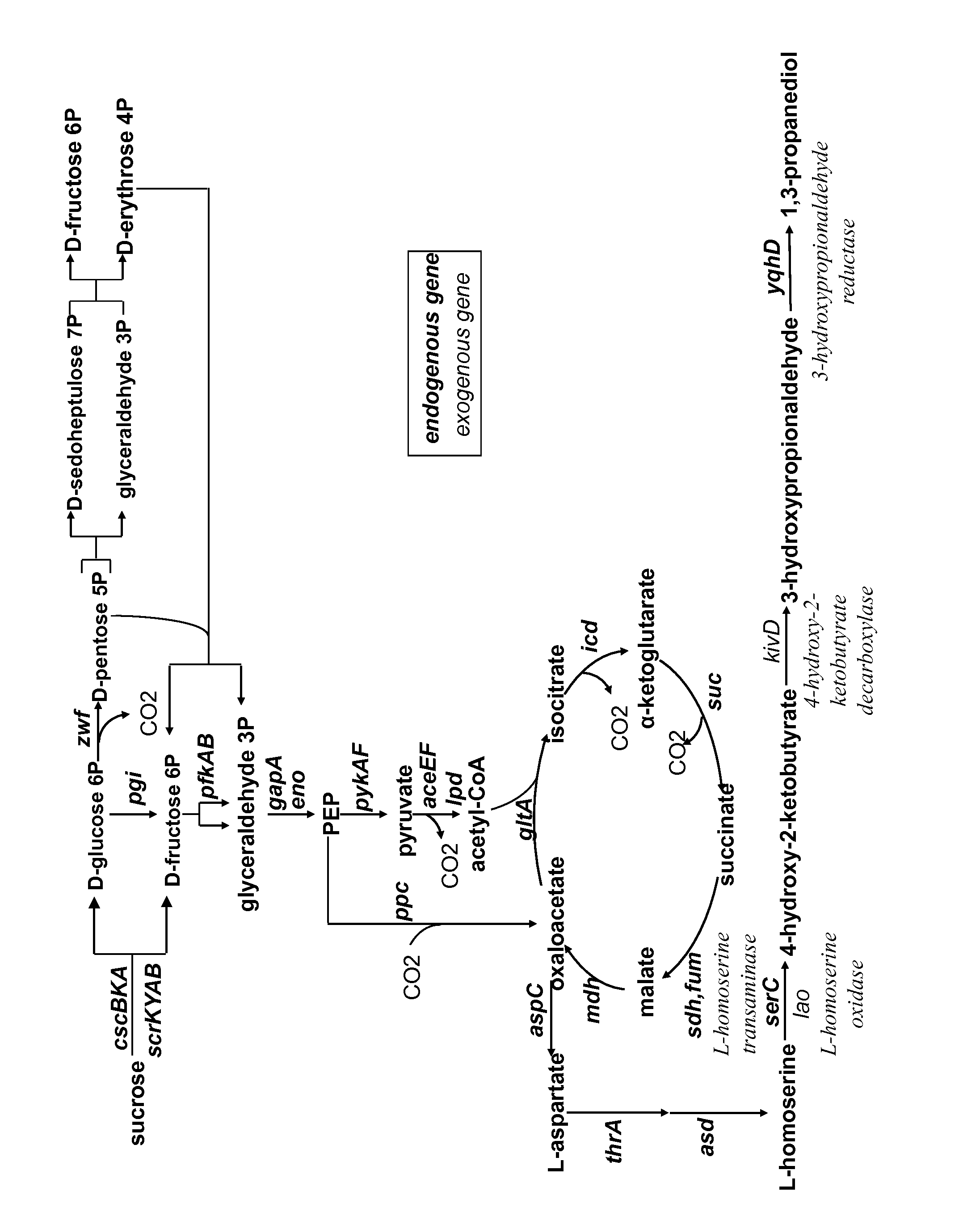

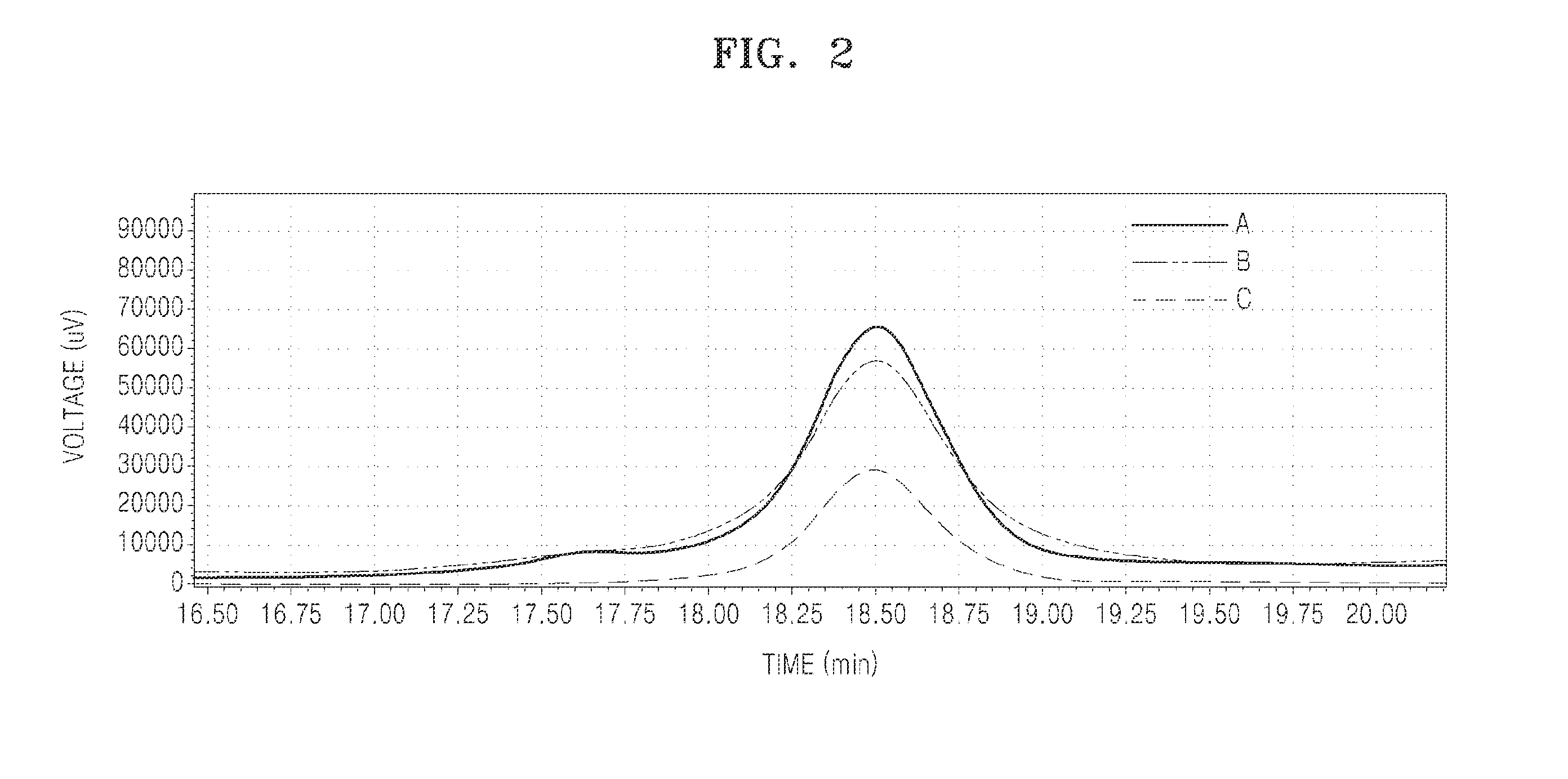

Method for the preparation of 1,3-propanediol from sucrose

A microorganism genetically modified for the bioproduction of 1,3-propanediol from sucrose, wherein the microorganism includes:a two-step metabolic pathway for the production of 1,3-propanediol, including a first step of decarboxylation of 4-hydroxy-2-ketobutyrate with an enzyme having a 2-keto acid decarboxylase activity, and a second step of reduction of the obtained 3-hydroxypropionaldehyde with an enzyme having hydroxy aldehyde reductase activity, andgenes enabling the microorganism to utilize sucrose as sole carbon source.A method for the biological preparation of 1,3-propanediol by fermentation, including cultivating said microorganism genetically modified, wherein the culture is performed in an appropriate medium including a source of sucrose, and recovering the 1,3-propanediol being produced.

Owner:METABOLIC EXPLORER

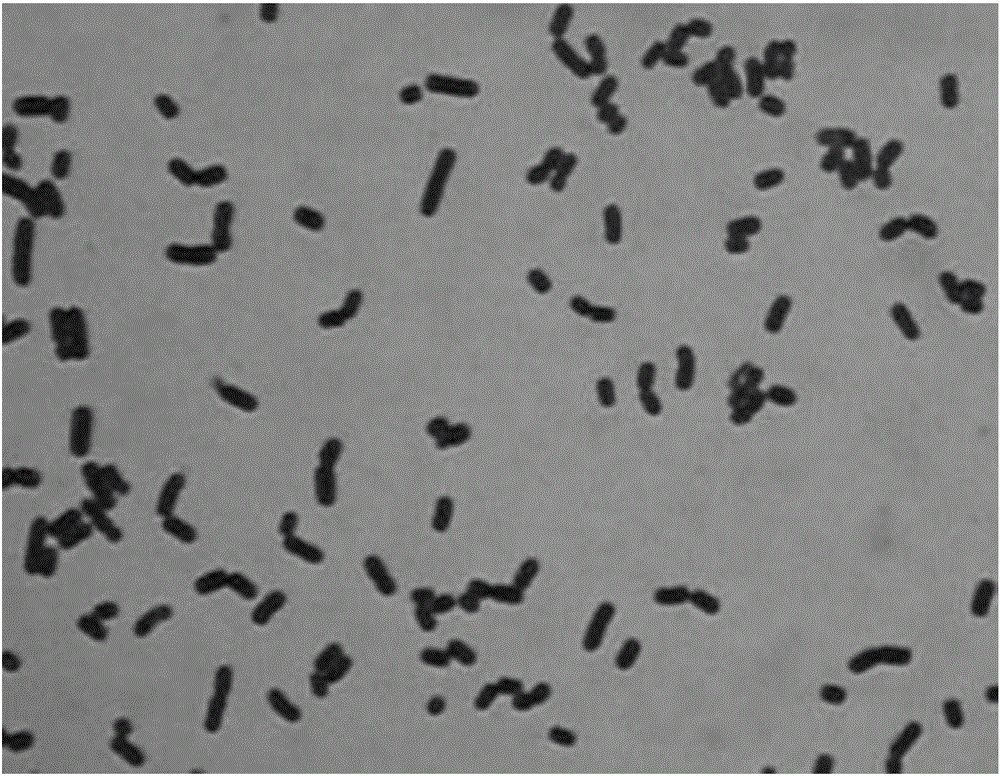

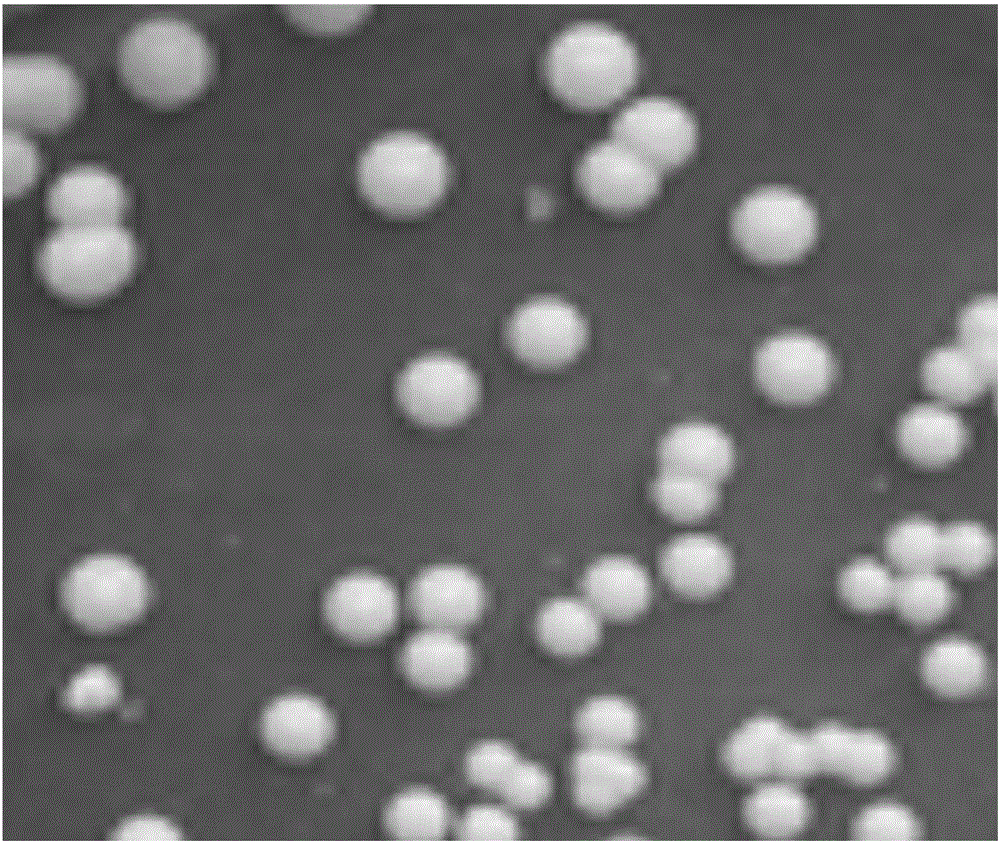

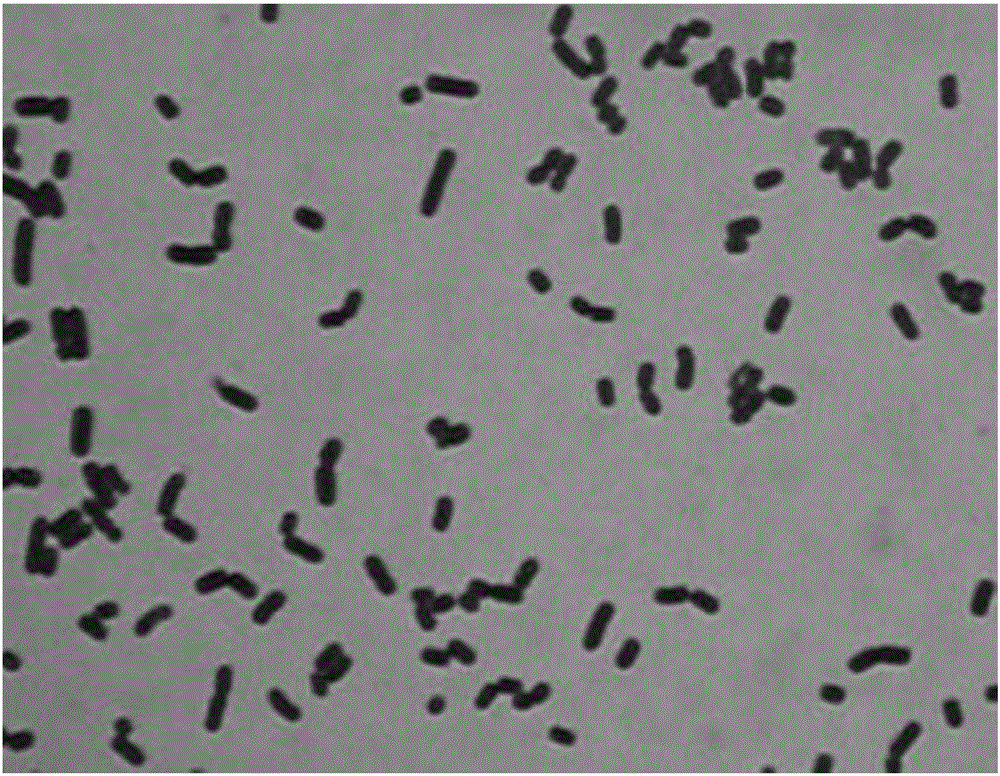

High-producing 3-hydroxypropionaldehyde strain and application thereof to prevention and treatment of oral cavity infection of mammals

InactiveCN105087434AQuick collectionLess likely to cause deathAntibacterial agentsAntimycoticsSide effectMammal

The invention discloses a high-producing 3-hydroxypropionaldehyde strain and application thereof to prevention and treatment of oral cavity infection of mammals, and relates to a microorganism and a composition thereof, in particular to a microorganism and a composition thereof for prevention and treatment of oral cavity infection of the mammals. Further, the invention aims to provide lactobacillus reuteri short in growth cycle and high in probiotics and application of the lactobacillus reuteri to prevention and treatment of oral cavity infection of the mammals. The high-producing 3-hydroxypropionaldehyde strain refers to the lactobacillus reuteri RS01 and is preserved with the preservation number CGMCC No.9971 in China General Microbiological Culture Collection Center on November 14th, 2014. The high-producing 3-hydroxypropionaldehyde strain has the advantages that the high-producing 3-hydroxypropionaldehyde strain is cultured easily and high in target product yield, and fermentation liquor of the high-producing 3-hydroxypropionaldehyde strain is safe and free of toxic and side effects and has broad-spectrum antibacterial effect. The high-producing 3-hydroxypropionaldehyde strain is applied to the field of prevention and treatment of oral cavity infection of the mammals.

Owner:吴前进

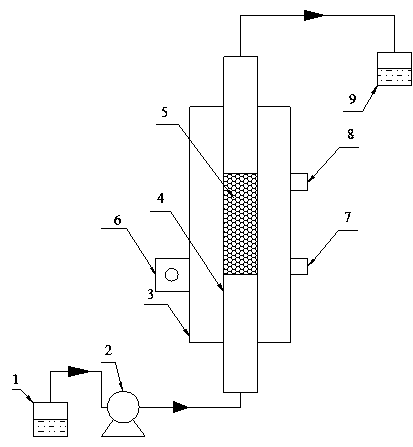

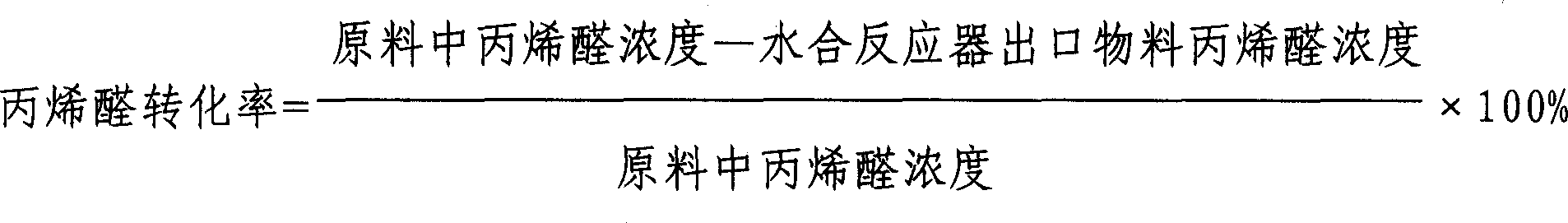

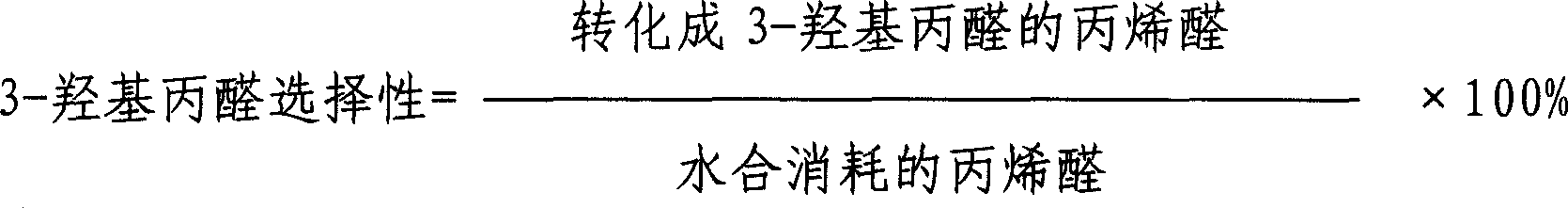

Method for preparing 3-hydroxypropionaldehyde through hydration of acrolein

PendingCN109134224APromotes hydrationAvoid PolymerizationOrganic compound preparationCarbonyl compound preparationHydration reactionMicrowave cavity

The invention discloses a method for preparing 3-hydroxypropionaldehyde through hydration of acrolein. The method comprises the following steps: conducting the reaction in a hydration reaction device,enabling an acrolein aqueous solution to enter a fixed bed reactor, and enabling the acrolein to have a continuous catalytic hydration reaction on a catalyst bed layer of the fixed bed reactor underthe action of microwaves to obtain the 3-hydroxypropionaldehyde, wherein the hydration reaction device comprises a microwave cavity body, the fixed bed reactor and the catalyst bed layer, the fixed bed reactor is internally provided with the catalyst bed layer, the fixed bed reactor is arranged in the microwave cavity body, and the microwave cavity body is connected with a microwave generation device. The microwave heating is used to evenly heat the material rapidly, the reaction speed is accelerated, the reaction time is shortened, the production efficiency is improved, the operation of the reaction process is simple, and the device can continuously stably operate for a long term.

Owner:ZHEJIANG UNIV OF TECH

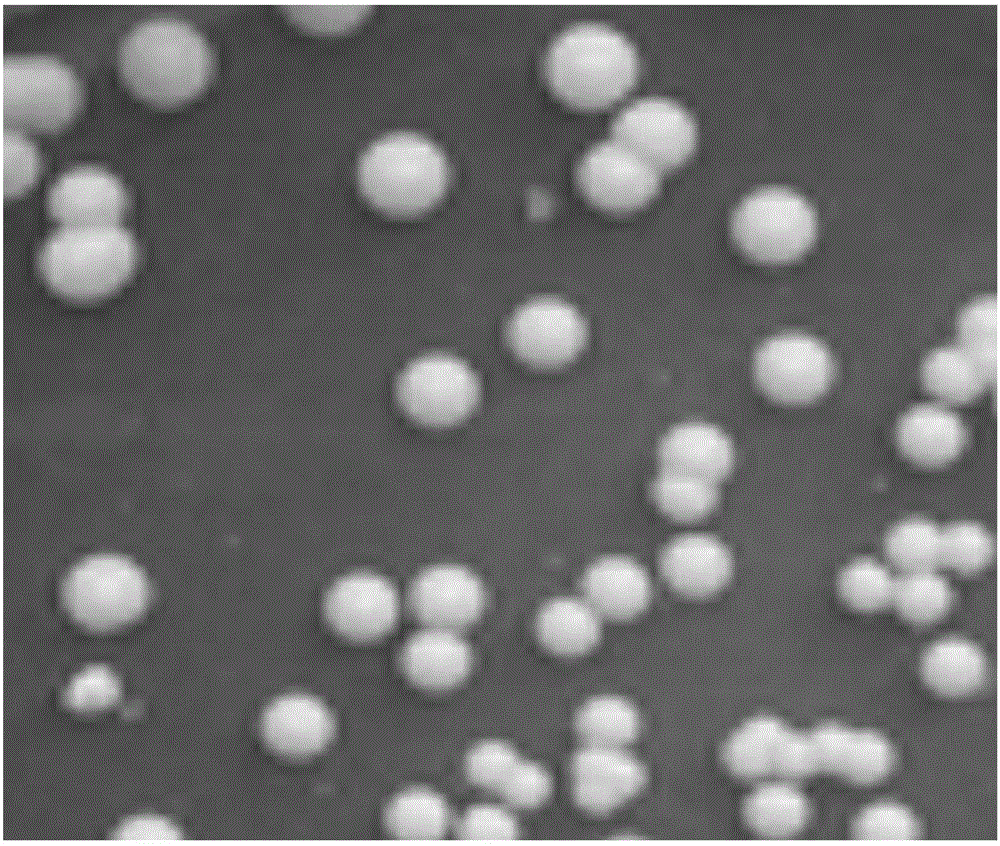

Catalyst and preparation method thereof and method for preparing 3-hydroxypropionaldehyde

ActiveCN108325560AAvoid inactivation3-HPA has good water solubilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydration reactionOil water

The invention relates to a catalyst and a preparation method thereof, and a method for preparing 3-hydroxypropionaldehyde. The catalyst has the excellent hydrophobicity, can be dissolved in a non-polar solvent and cannot be dissolved in water. The catalyst is suitable for catalyzing a hydration reaction of acrolein to prepare 3-hydroxypropionaldehyde. When an oil-water two-phase technology is usedfor preparing 3-hydroxypropionaldehyde, the catalyst cyclic utilization degree is effectively improved, the loss of the catalyst is reduced, the single-way conversion rate of acrolein of the technology is high, the technological process is easy to control, and the problems that an acrolein hydrated solid catalyst is unstable and prone to losing activity, and a water soluble catalyst is not easy to separate are effectively solved.

Owner:WANHUA CHEM GRP CO LTD

Method for preparing 3-hydroxypropionaldehyde by acrylaldehyde hydration

InactiveCN1580024AOrganic compound preparationCarbonyl compound preparationHydration reactionReaction temperature

The invention refers to a method of mading 3-hydroxy propionaldehyde from acraldehyde through hydration. We mix the acraldehyde with the water to get the acraldehyde solution. The thickness of the acraldehyde is between 8wt% and 25wt%. The acraldehyde solution passes through the static bde of catalys to hydrate at the reaction temperature of between 40deg.C and 80deg.C and at the speed in the liquid of 3hr-1 and 10 hr-1. The hydration reaction happens in the condition of carbon dioxide gas, with the branch pressure of the carbon dioxide gas between 0.01MPa and 1.5MPa, and the rest is inert gases. That the hydration reaction happens in the condition of carbon dioxide gas can effectively prevent the self polymerization of the acraldehyde. Compared with the now-existing technoloty of adding organic material as the inhibitor, the whole technology is more simple and easier to operate. And the inhibitor chosen don't affect the production of the hydrating outcome.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

High-producing 3-hydroxypropionaldehyde strain and application thereof to prevention and treatment of digestive tract infection of mammals

InactiveCN105087433AQuick collectionLess likely to cause deathAntibacterial agentsAntimycoticsSide effectMammal

The invention discloses a high-producing 3-hydroxypropionaldehyde strain and application thereof to prevention and treatment of digestive tract infection of mammals, and relates to a microorganism and a composition thereof, in particular to a microorganism and a composition thereof for prevention and treatment of digestive tract infection of the mammals. Further, the invention aims to provide lactobacillus reuteri short in growth cycle and high in probiotics and application of the lactobacillus reuteri to prevention and treatment of digestive tract infection of the mammals. The high-producing 3-hydroxypropionaldehyde strain refers to the lactobacillus reuteri RS01 and is preserved with the preservation number CGMCC No.9971 in China General Microbiological Culture Collection Center on November 14th, 2014. The high-producing 3-hydroxypropionaldehyde strain has the advantages that the high-producing 3-hydroxypropionaldehyde strain is cultured easily and high in target product yield, and fermentation liquor of the high-producing 3-hydroxypropionaldehyde strain is safe and free of toxic and side effects and has broad-spectrum antibacterial effect. The high-producing 3-hydroxypropionaldehyde strain is applied to the field of prevention and treatment of digestive tract infection of the mammals.

Owner:吴前进

Method for separating and reclaiming acrolein

ActiveCN100376531CSeparation and recovery methods are easy to implementLower operating temperatureCarbonyl compound separation/purificationHydration reactionRecovery method

The provided separate and recovery method for non-reacted acrolein in preparation process of 3-hydroxypropionaldehyde comprises: leading gas into the tower bottom for gas stripping the acrolein from reaction product and absorb it in absorption tower with water. This invention has high recovery and prepares the material with the absorbed liquid for acrolein hydration reaction.

Owner:SHANGHAI HUAYI NEW MATERIAL

Method used for co-production of 1,3-propanediol and 1,2-propanediol via hydrogenation of 3-hydroxypropionaldehyde aqueous solution

ActiveCN107353180ALarge specific surface areaHigh activityOrganic compound preparationHydroxy compound preparationHydrogenBULK ACTIVE INGREDIENT

The invention discloses a method used for co-production of 1,3-propanediol and 1,2-propanediol via hydrogenation of 3-hydroxypropionaldehyde aqueous solution. The method comprises following steps: the 3-hydroxypropionaldehyde aqueous solution is delivered into a reactor loaded with a catalyst, heating and pressurization are carried out, reaction is carried out for a certain period of time, and an obtained 1,3-propanediol product is subjected to refining. The 3-hydroxypropionaldehyde aqueous solution comprises effective ingredients 3-hydroxypropionaldehyde at a mass concentration of 5 to 70% and hydroxyacetone at a mass concentration of 0 to 30%; the molar of hydrogen to the effective ingredients is controlled to be 20-300:1; the mass space velocity of the effective ingredients to the catalyst is controlled to be 0.1-5.0h<-1>; Al2O3, TiO2, or SiO2-Al2O3 is taken as a carrier of the catalyst; and the catalyst comprises, by mass, 10 to 40% of a main active ingredient and 1 to 5% of an auxiliary active ingredient. The method is capable of realizing co-production of 1,3-propanediol and 1,2-propanediol via one step catalytic hydrogenation.

Owner:JIANGSU FEIXIANG CHEM

Microorganism having novel acrylic acid synthesis pathway having enhanced activity of coa acylating aldehyde dehydrogenase and method of producing acrylic acid using the same

A microorganism capable of producing acrylic acid, comprising a genetic modification that increases activity of CoA acylating aldehyde dehydrogenase (ALDH) catalyzing conversion of 3-hydroxypropionaldehyde (3-HPA) to 3-hydroxy propionyl-CoA (3-HP-CoA) and a genetic modification that increases activity of 3-HP-CoA dehydratase catalyzing conversion of 3-HP-CoA to acrylyl-CoA in the microorganism in comparison with a cell that is not genetically engineered; as well as a method of producing the microorganism, and a method of producing acrylic acid using the same.

Owner:SAMSUNG ELECTRONICS CO LTD

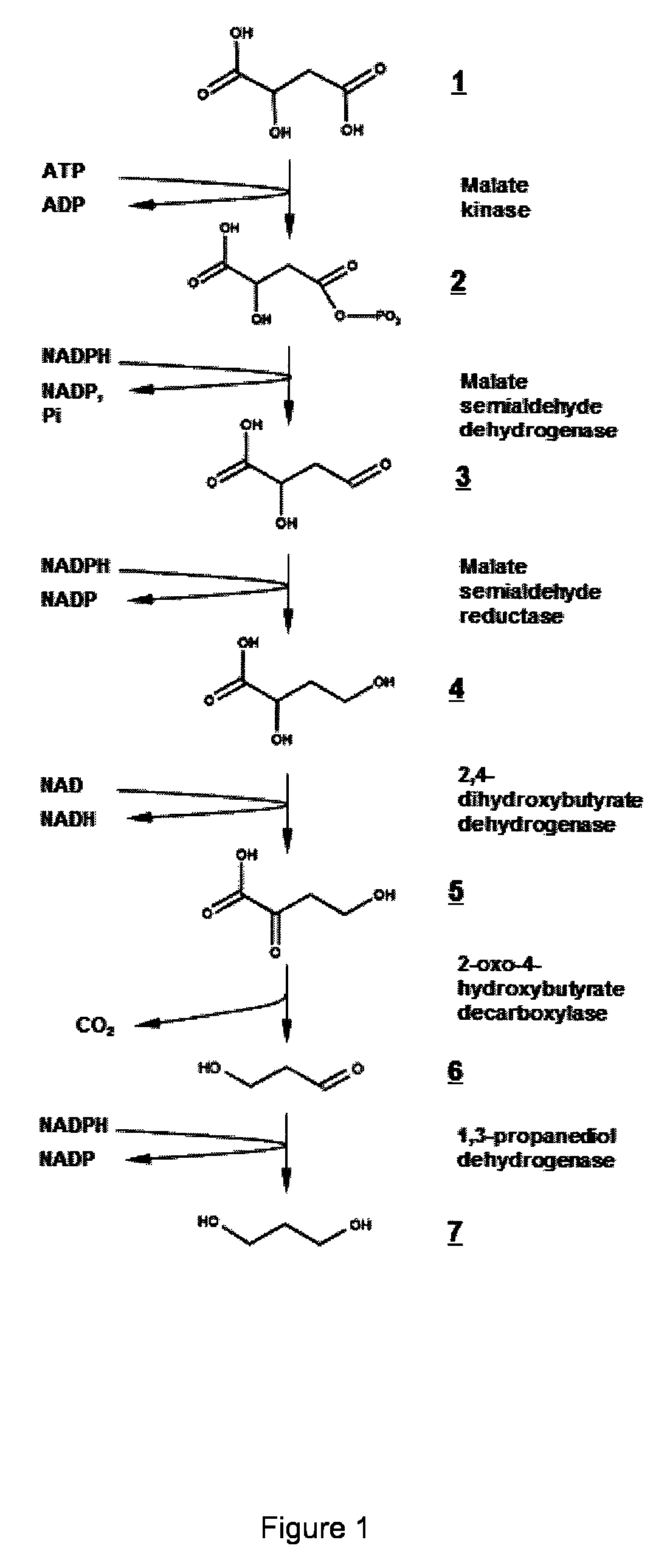

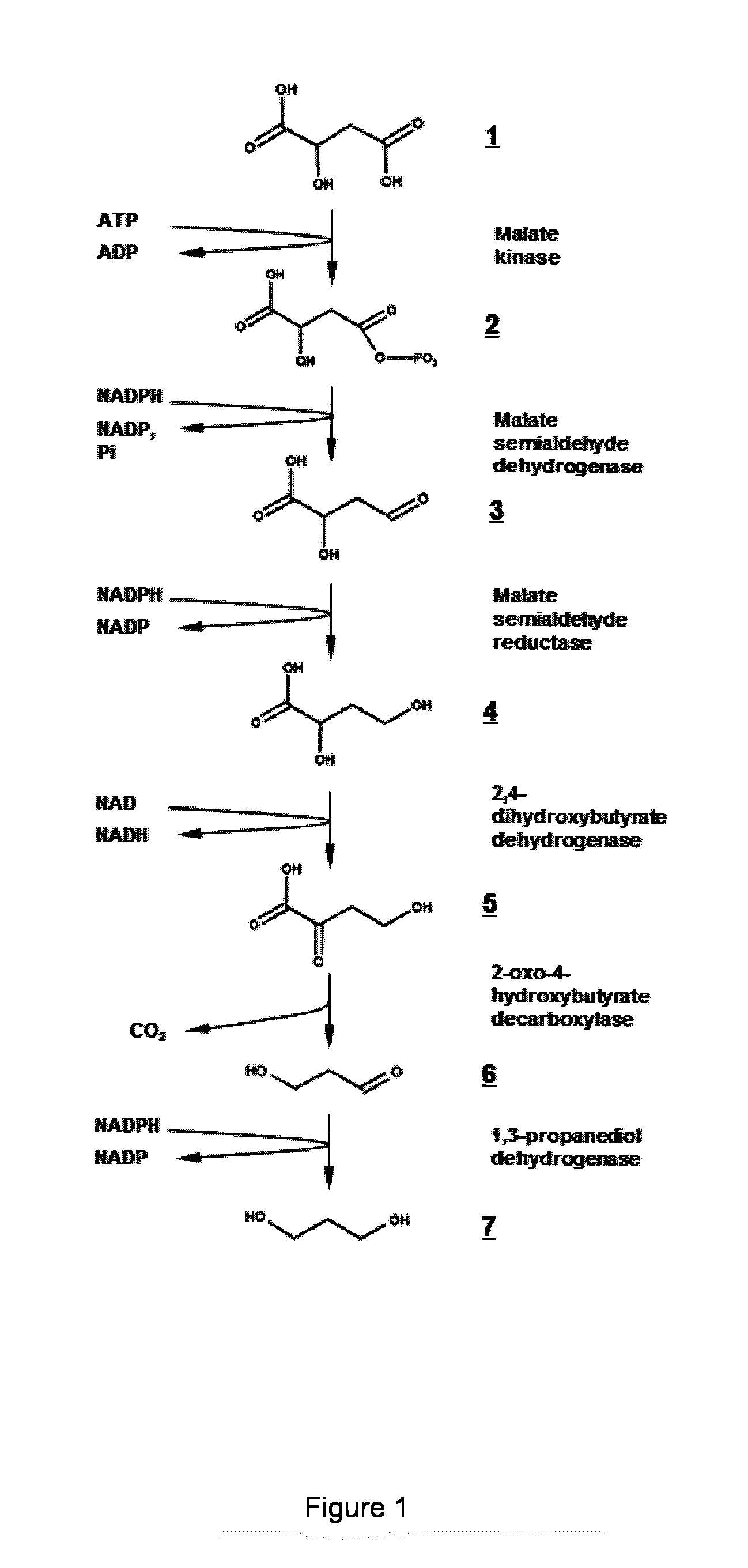

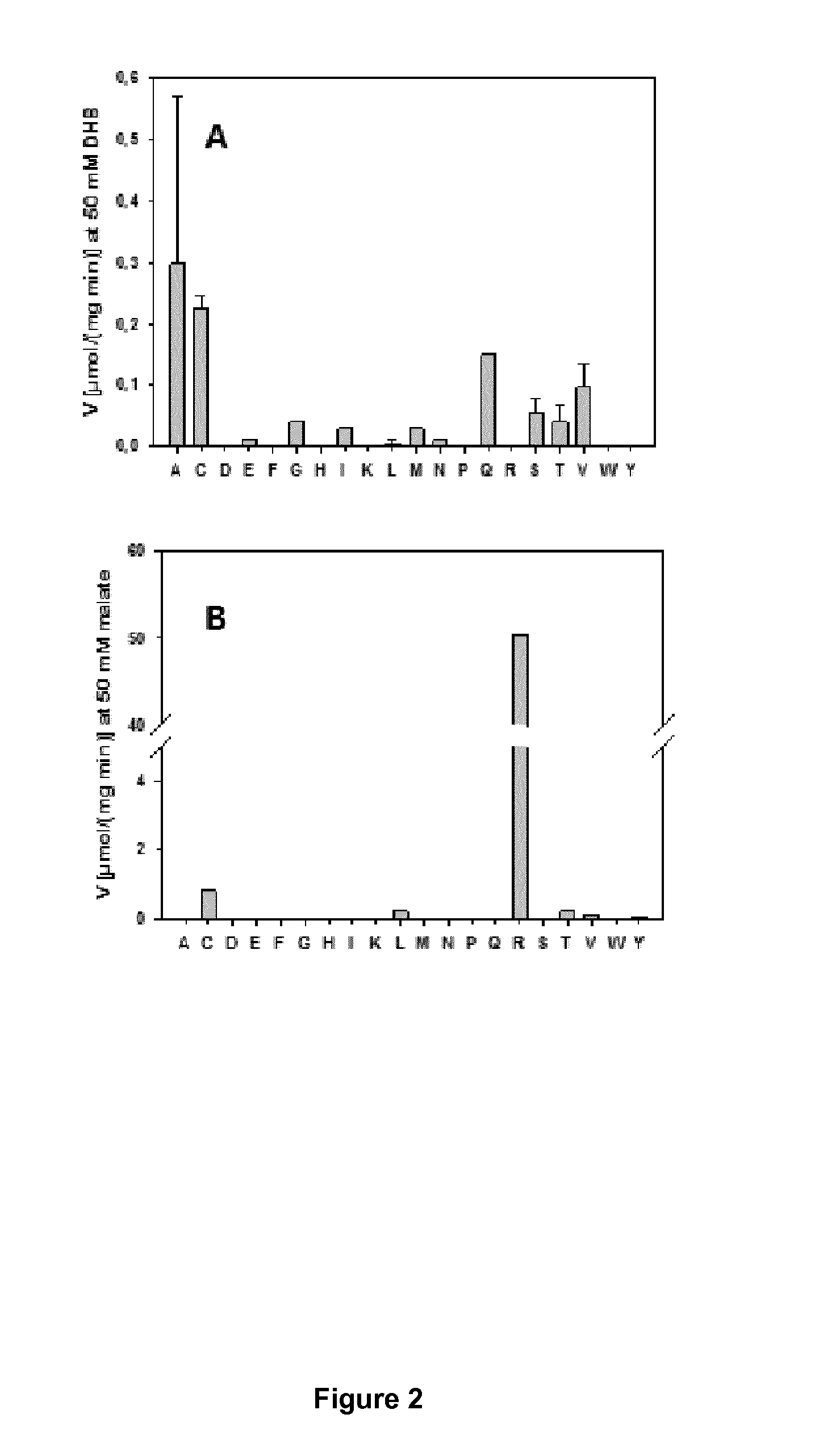

Microorganism modified for the production of 1,3-propanediol

The invention relates to a modified microorganism for the production of PDO from a carbon substrate wherein the microorganism includes a three-step metabolic pathway including a first step of conversion of 2,4-dihydroxybutyrate (DHB) to obtain 2-oxo-4-hydroxybutyrate (OHB) by an enzyme having 2,4-DHB dehydrogenase activity, a second step of decarboxylation of the OHB to obtain 3-hydroxypropionaldehyde by an enzyme having 2-oxo-4-hydroxybutyrate decarboxylase activity, and a third step of reduction of the obtained 3-hydroxypropionaldehyde to obtain PDO with an enzyme having 3-hydroxypropionaldehyde reductase activity and the genes enabling the microorganism for the synthesis of DHB.

Owner:INSTITUT NAT DES SCI APPLIQUEES INSA

Microorganism modified for the production of 1,3-propanediol

The invention relates to a modified microorganism for the production of PDO from a carbon substrate wherein the microorganism includes a three-step metabolic pathway including a first step of conversion of 2,4-dihydroxybutyrate (DHB) to obtain 2-oxo-4-hydroxybutyrate (OHB) by an enzyme having 2,4-DHB dehydrogenase activity, a second step of decarboxylation of the OHB to obtain 3-hydroxypropionaldehyde by an enzyme having 2-oxo-4-hydroxybutyrate decarboxylase activity, and a third step of reduction of the obtained 3-hydroxypropionaldehyde to obtain PDO with an enzyme having 3-hydroxypropionaldehyde reductase activity and the genes enabling the microorganism for the synthesis of DHB.

Owner:INSTITUT NAT DES SCI APPLIQUEES INSA

Method for preparing 1,3-propylene glycol by 3-hydroxypropionaldehyde hydrogenation

InactiveCN1184181CHigh activityFacilitated DiffusionPreparation by oxygen reductionHydrogen pressurePropanediol

The method for preparing 1,3-propylene glycol by means of hydrogenation of 3-hydroxy-propionaldehyde is characterized by that the weight percentage concentration of raw material 3-hydroxy-propionaldehyde aqueous solution is 10-20%, in the presence of catalyst two-stage hydrogenation process can be adopted to obtain 1,3-propylene glycol, in which the first stage hydrogenation temp. is 25-60 deg.C, second stage hydrogenation temp. is 110-130 deg.C, hydrogen gas pressure of two-stage hydrogenation is 4.0-7.0 MPa, and its space velocity is 0.1-5 hr (-1), and the active component of the catalyst is Ni-A, in which A is any one of Cr, Zn, Mo or Fe, and its carrier is molecular sieve containing Al2O3 or SiO2 or containing both them simultaneously, and the weight percetnage content of the actigve component of the catalyst is 30-60%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com