Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Propanediol oxidoreductase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the biological production of 1,3-propanediol with high titer

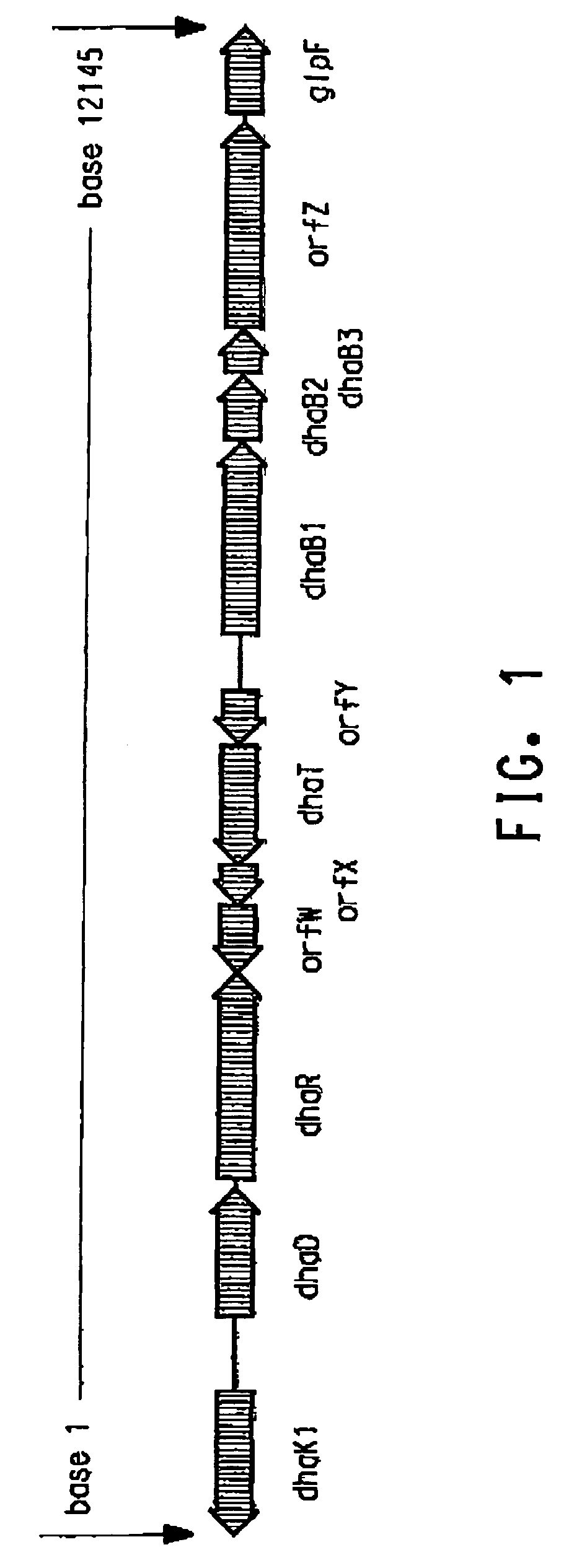

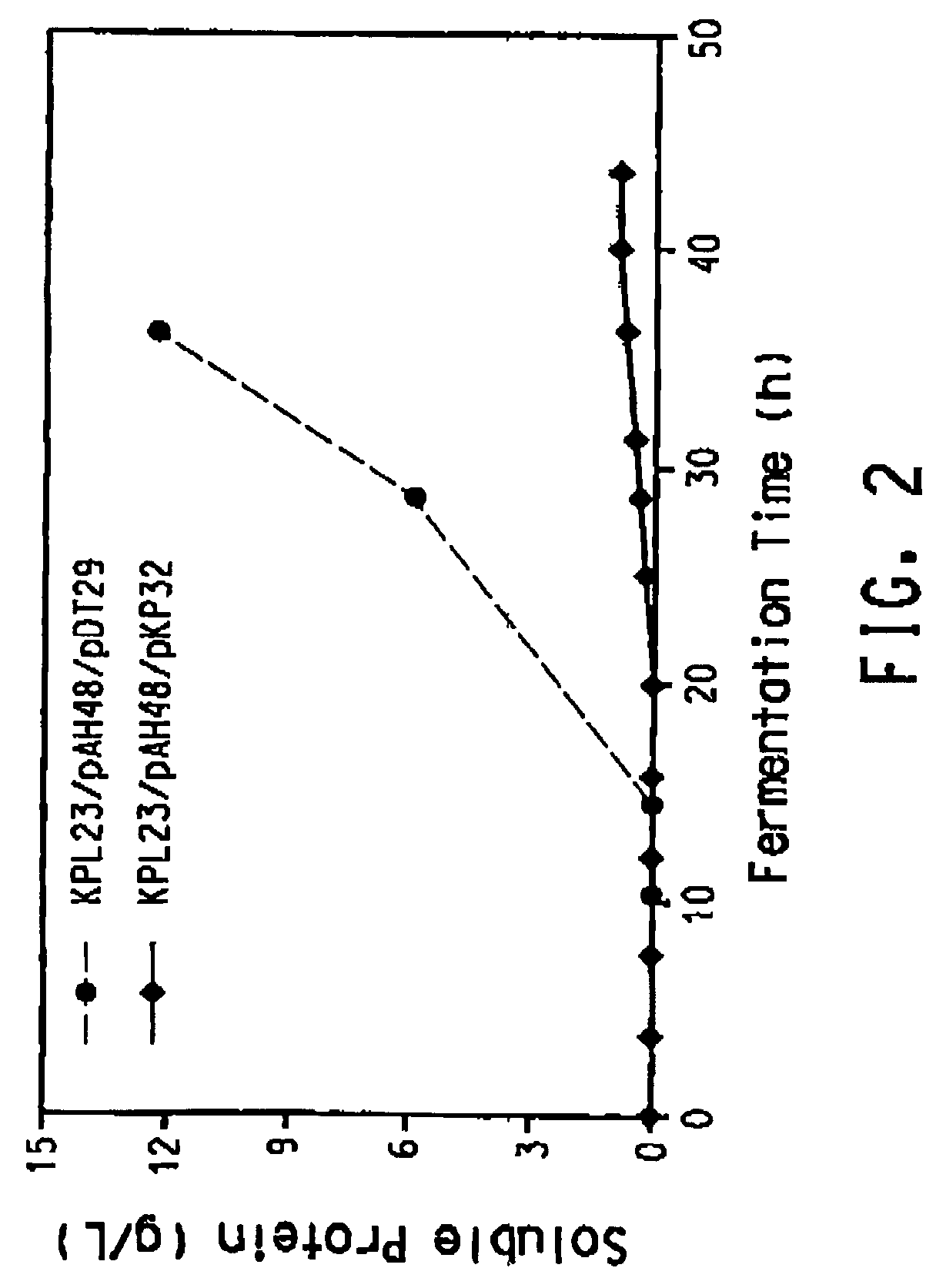

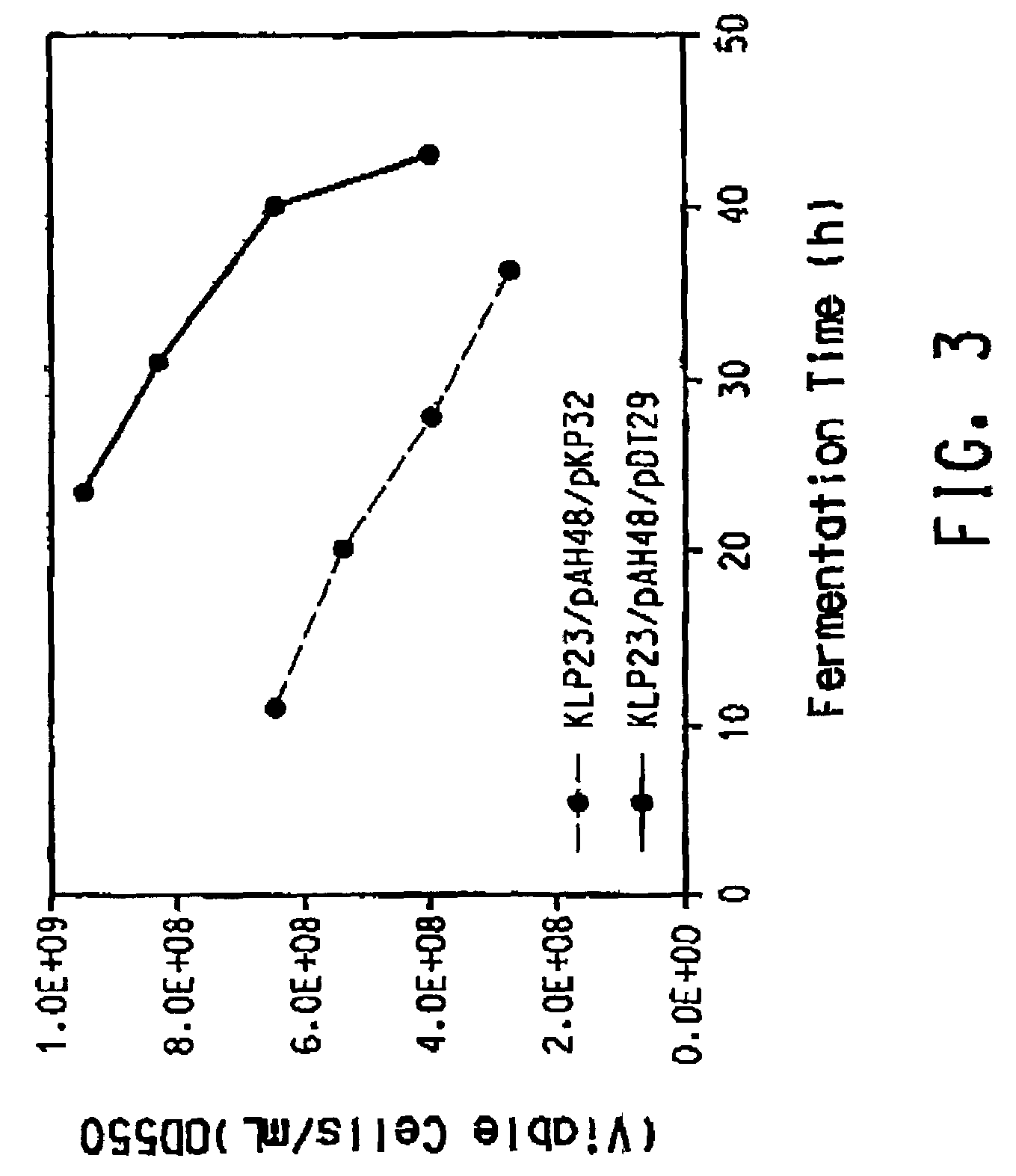

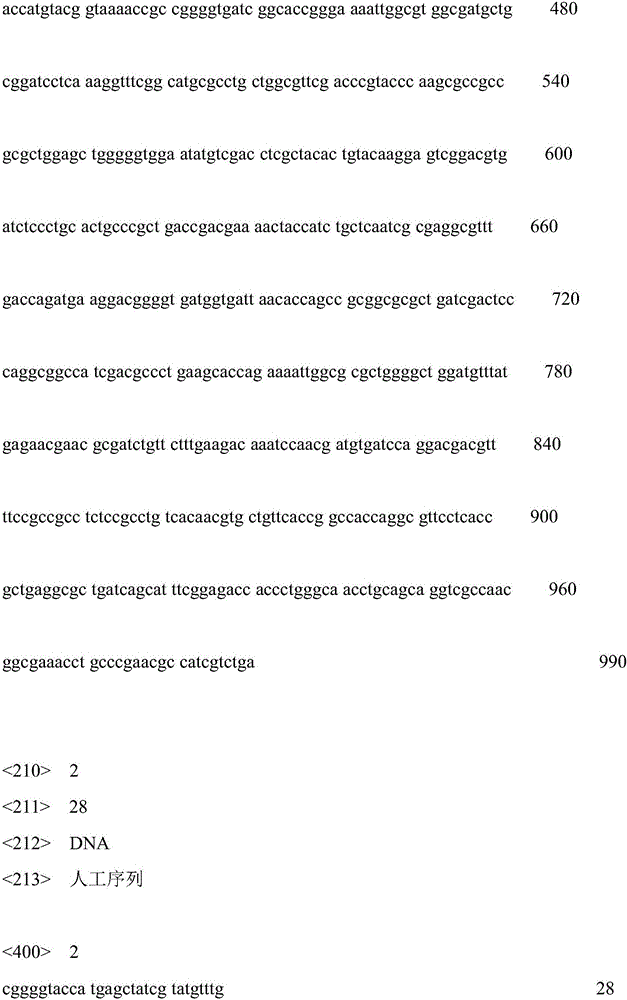

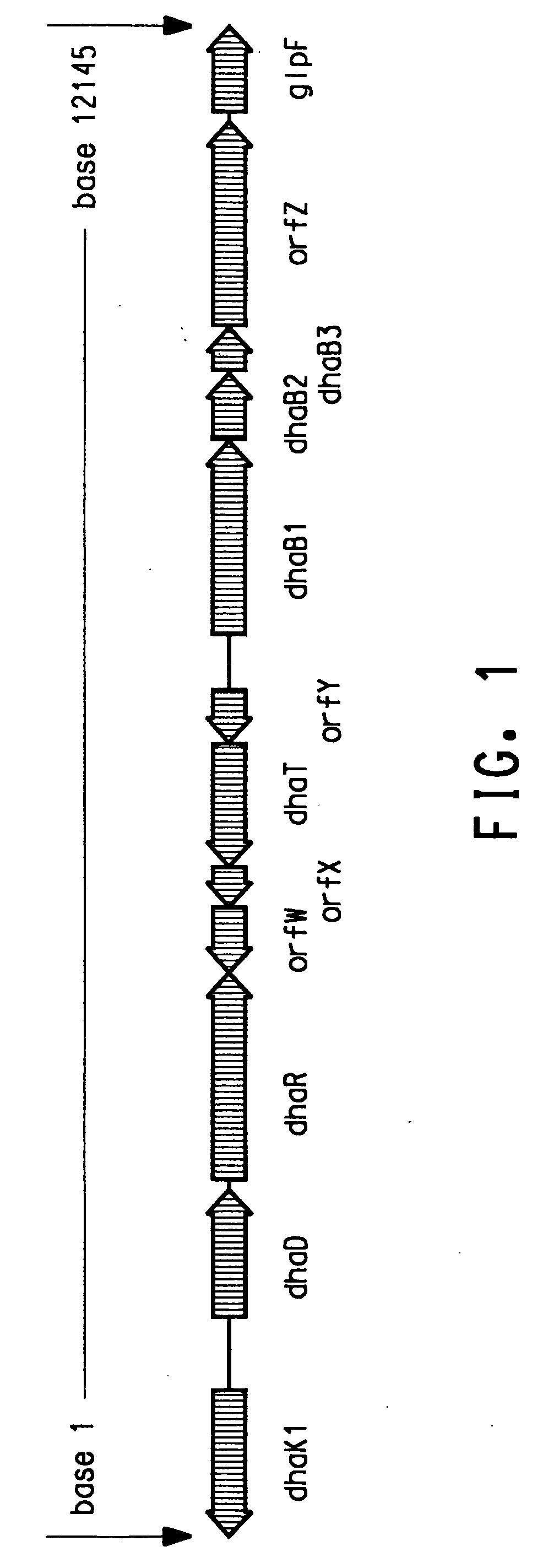

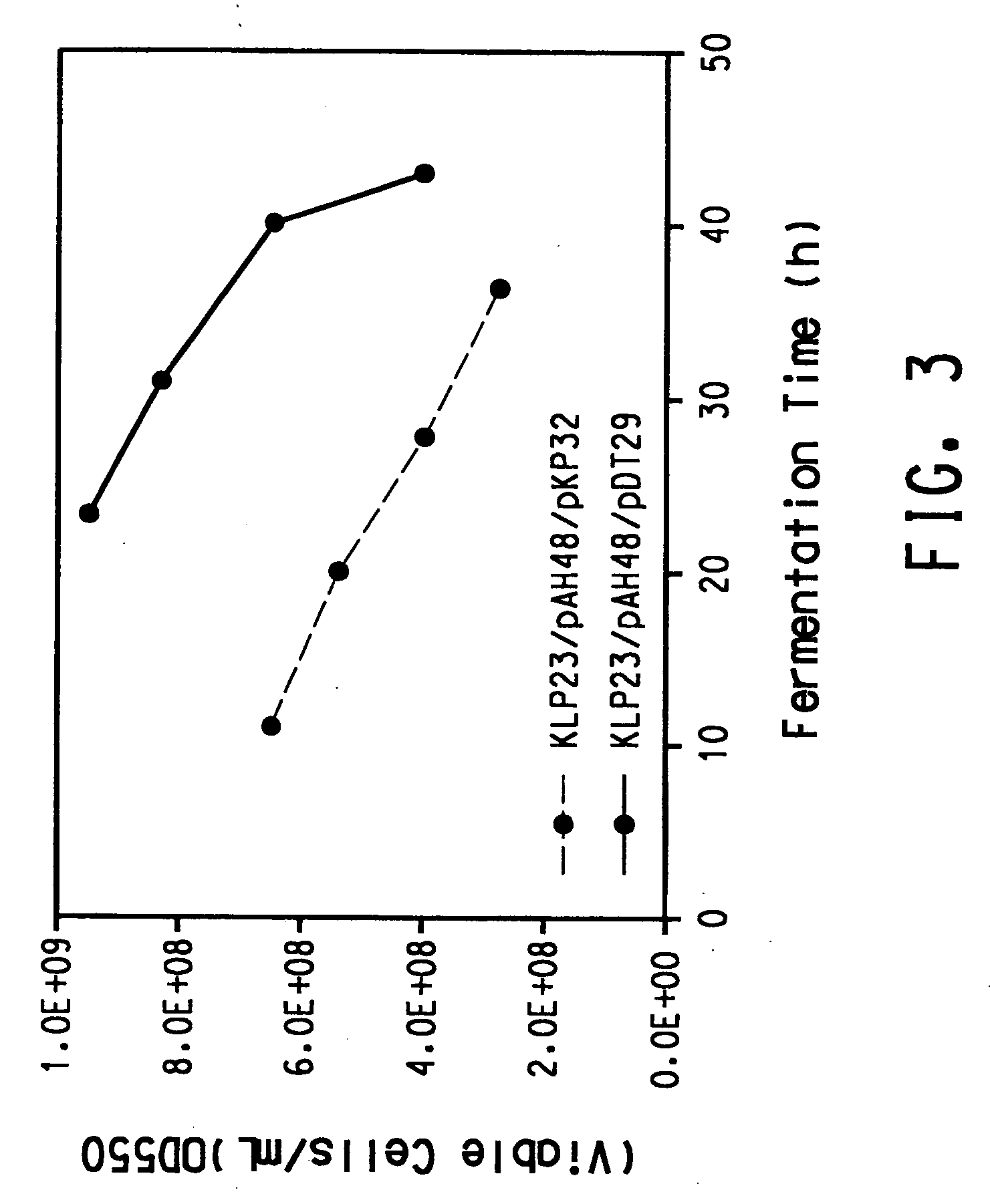

The present invention provides an improved method for the biological production of 1,3-propanediol from a fermentable carbon source in a single microorganism. In one aspect of the present invention, an improved process for the conversion of glucose to 1,3-propanediol is achieved by the use of an E. coli transformed with the Klebsiella pneumoniae dha regulon genes dhaR, orfY, dhaT, orfX, orfW, dhaB1, dhaB2, dhaB3, and orfZ, all these genes arranged in the same genetic organization as found in wild type Klebsiella pneumoniae. In another aspect of the present invention, an improved process for the production of 1,3-propanediol from glucose using a recombinant E. coli containing genes encoding a G3PDH, a G3P phosphatase, a dehydratase, and a dehydratase reactivation factor compared to an identical process using a recombinant E. coli containing genes encoding a G3PDH, a G3P phosphatase, a dehydratase, a dehydratase reactivation factor and a 1,3-propanediol oxidoreductase (dhaT). The dramatically improved process relies on the presence in E. coli of a gene encoding a non-specific catalytic activity sufficient to convert 3-hydroxypropionaldehyde to 1,3-propanediol.

Owner:DUPONT US HLDG LLC

Method for the production of 1,3-propanediol by recombinant organisms comprising genes for coenzyme B12 synthesis

Recombinant organisms are provided comprising genes encoding aquacobalamin reductase, cob(II)alamin reductase, cob(I)alamin adenosyltransferase, glycerol dehydratase and 1,3-propanediol oxidoreductase activities useful for the production of 1,3-propanediol from a variety of carbon substrates. More specifically the following nucleotide sequences are provided: btuR, encoding the E. coli cob(I)alamin adenosyltransferase enzyme; cobA, encoding the Salmonella typhimurium cob(I)alamin adenosyltransferase enzyme; cobO, encoding the Pseudomonas denitrificans cob(I)alamin adenosyltransferase enzyme; dhaB1, encoding the α subunit of the Klebsiella glycerol dehydratase enzyme; dhaB2, encoding the β subunit of the Klebsiella glycerol dehydratase enzyme; dhaB3, encoding the γ subunit of the Klebsiella glycerol dehydratase enzyme; dhaT, encoding Klebsiella oxidoreductase enzyme; the yciK gene isolated from E. coli; the glucose isomerase promoter sequence from Streptomyces; and the N-terminal amino acid sequence for cob(II)alamin reductase from Pseudomonas denitrificans.

Owner:EI DU PONT DE NEMOURS & CO

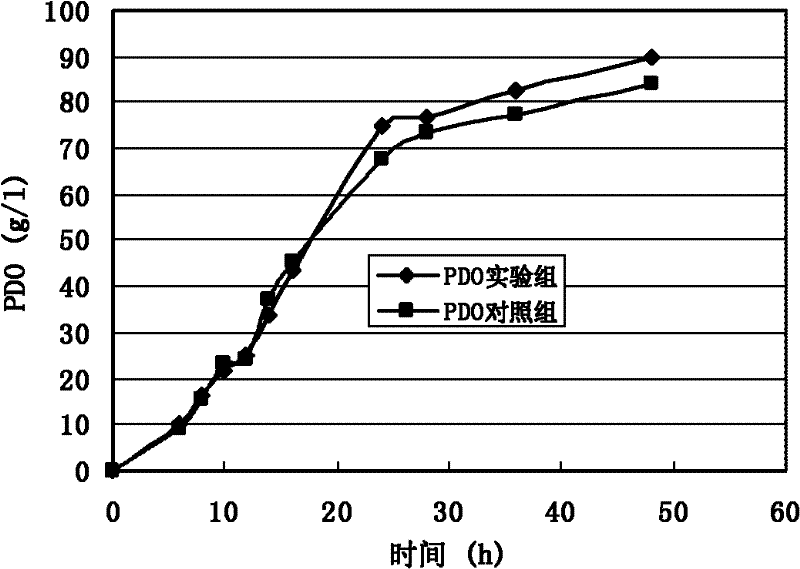

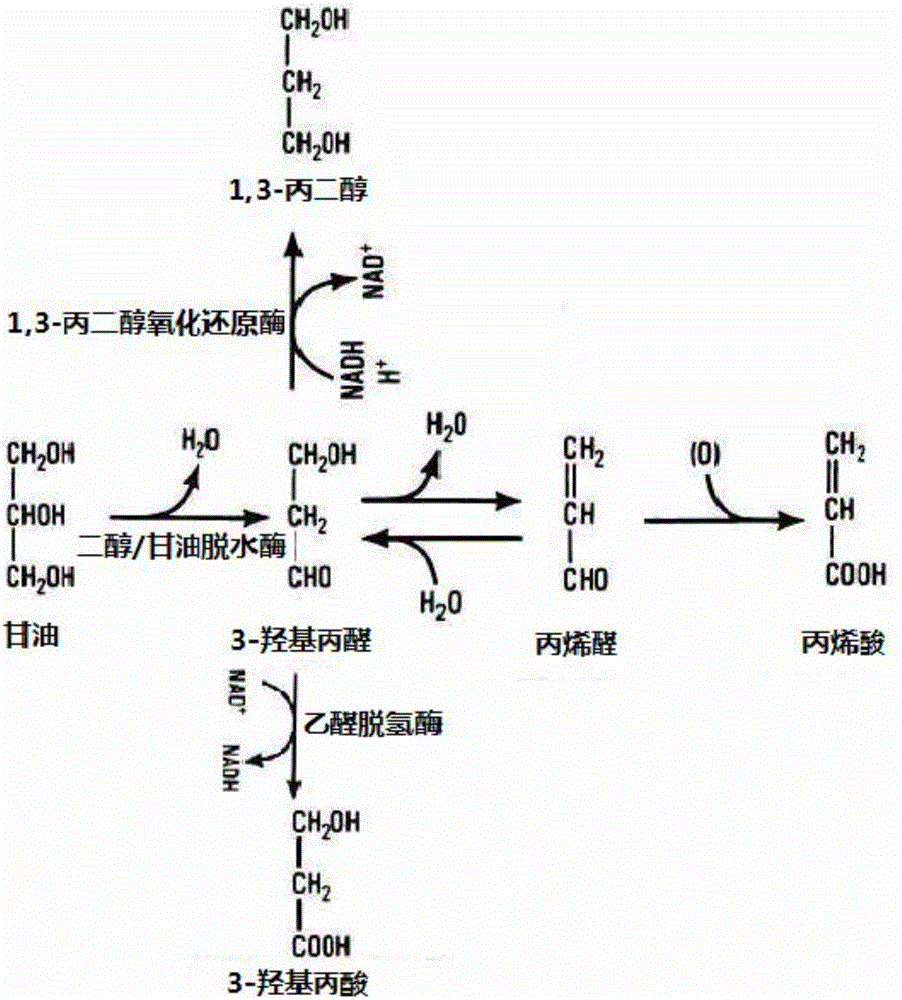

Method for improving glycerol microbial fermentation production of 1,3-propanediol by constructing gene engineering bacterium

ActiveCN102199570APromote conversionPromote circulationBacteriaMicroorganism based processesBiotechnologyTricarboxylic acid

The invention provides a method for improving the microbial production of 1,3-propanediol by constructing a gene engineering bacterium. The method comprises the following steps: constructing an expression vector with the inserted malic enzyme gene; delivering the expression vector in host bacteria generating 1,3-propanediol; adding an inducer to induce the overexpression of the malic enzyme gene in the fermentation and culture process; and adopting the aerobic fermentation means and performing the fed batch of substrate glycerol to produce 1,3-propanediol. The method is characterized in that the constructed gene engineering bacterium can express more malic enzyme than the original strain in the fermentation process, thus the convertion from pyruvic acid to malic acid can be promoted, the circulation of tricarboxylic acid can be promoted, the bacterium can generate more nicotinamide adenine dinueleotide (NADH) and energy (ATP), the activity of 1,3-propanediol oxidation-reduction enzymein the bacterium and the glycerol conversion rate can be increased. The invention has the following advantages: the substrate glycerol utilization rate of the producing bacterium can be increased, the concentration and production strength of the fermented 1,3-propanediol can be obviously increased, the yield of 1,3-propanediol can be increased and the production cost can be reduced.

Owner:TSINGHUA UNIV

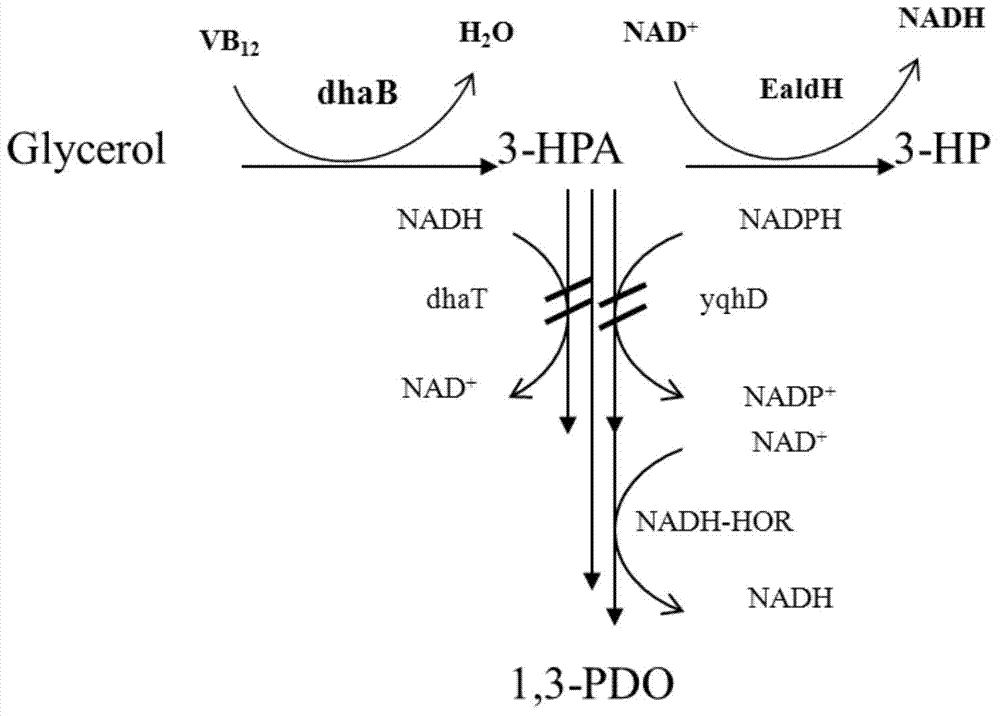

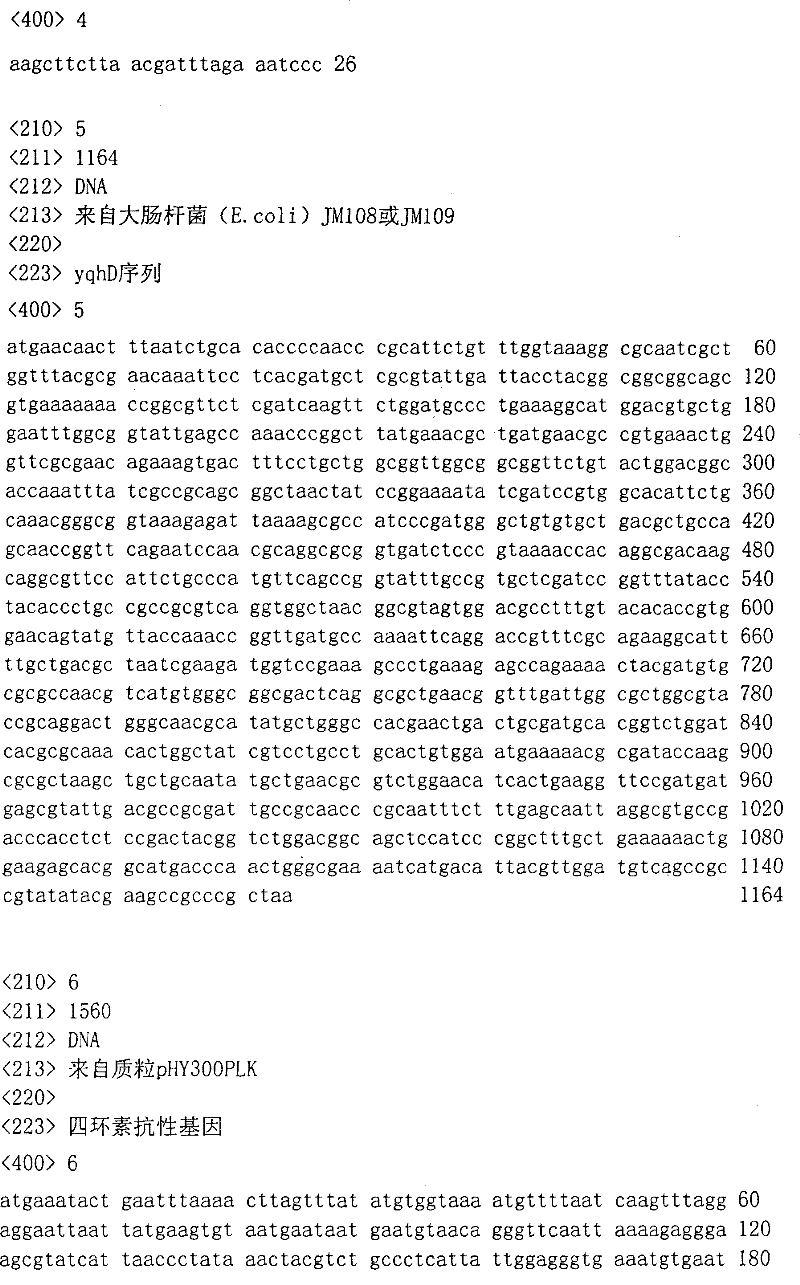

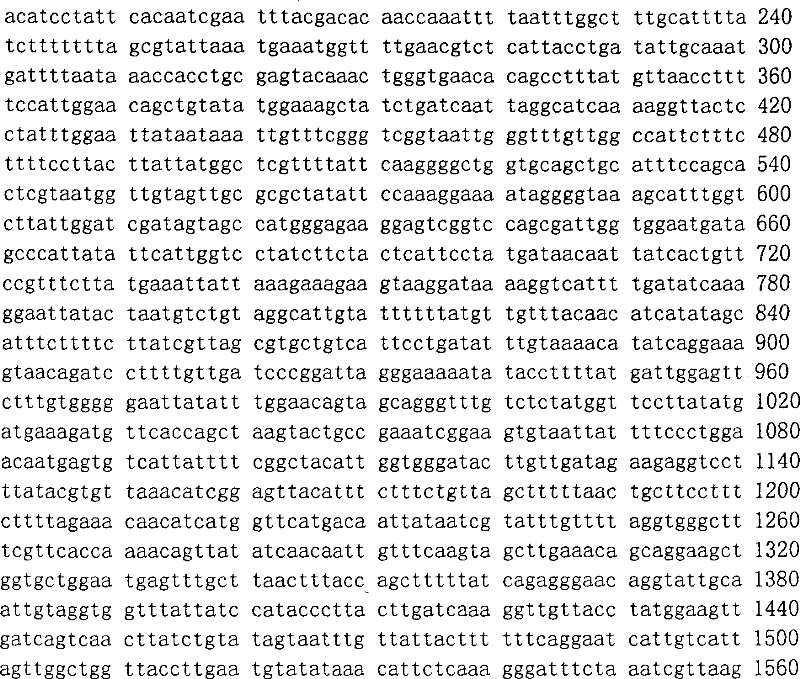

Gene engineering bacterium for producing 1,3-propanediol and its preparation method and application

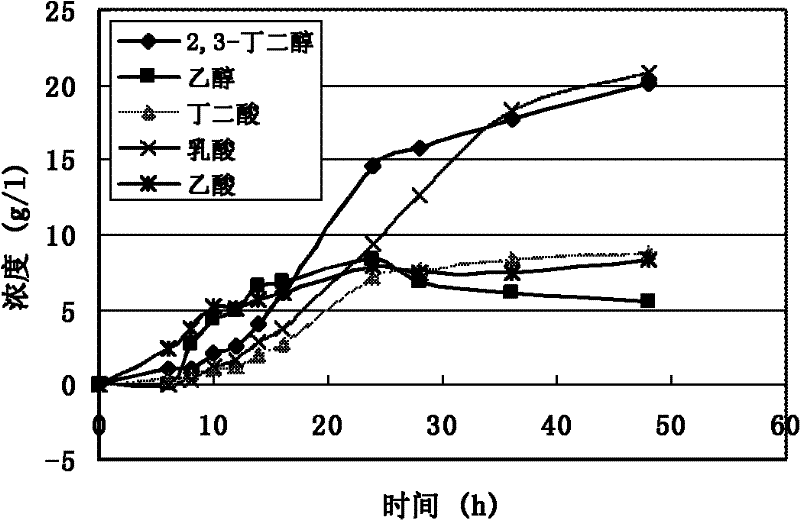

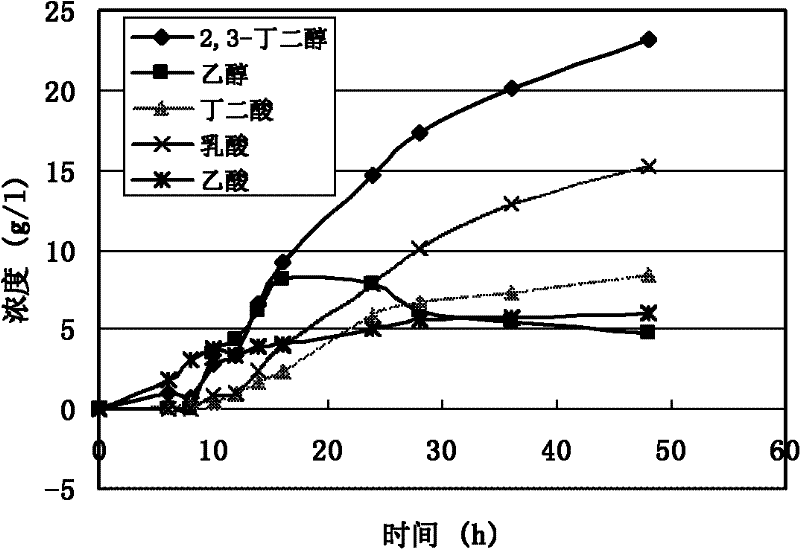

InactiveCN101260379AImprove stabilityHigh final concentrationBacteriaMicroorganism based processesIsozymeGlycerol

The invention belongs to the biochemical field and discloses a 1, 3-propylene glycol genetic engineering bacterium and a preparation method and application thereof. The strain is classified and named as Klebsiella pneumoniae ATCC 25955-pUC18-yqhD-Tet<R>, and is obtained by connection of a 3-propylene redoxase isozyme gene yqhD from Escherichia coli and a tetracycline resistant gene Tet<R> from a plasmid pHY300PLK, insertion of a carrier pUC18 and conversion of Klebsiella pneumoniae ATCC 25955. The bacterium can obviously improve the capacity for conversion of glycerol into 1, 3-propylene glycol, improve the utilization ability and the conversion rate of the substrate glycerol and the final concentration of the final offspring 1, 3-propylene glycol, simultaneously shorten the fermentation time, and is convenient for industrial production of the 1, 3-propylene glycol through the microbial fermentation method.

Owner:NANJING UNIV OF TECH

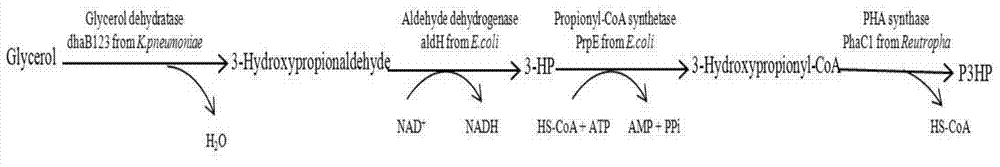

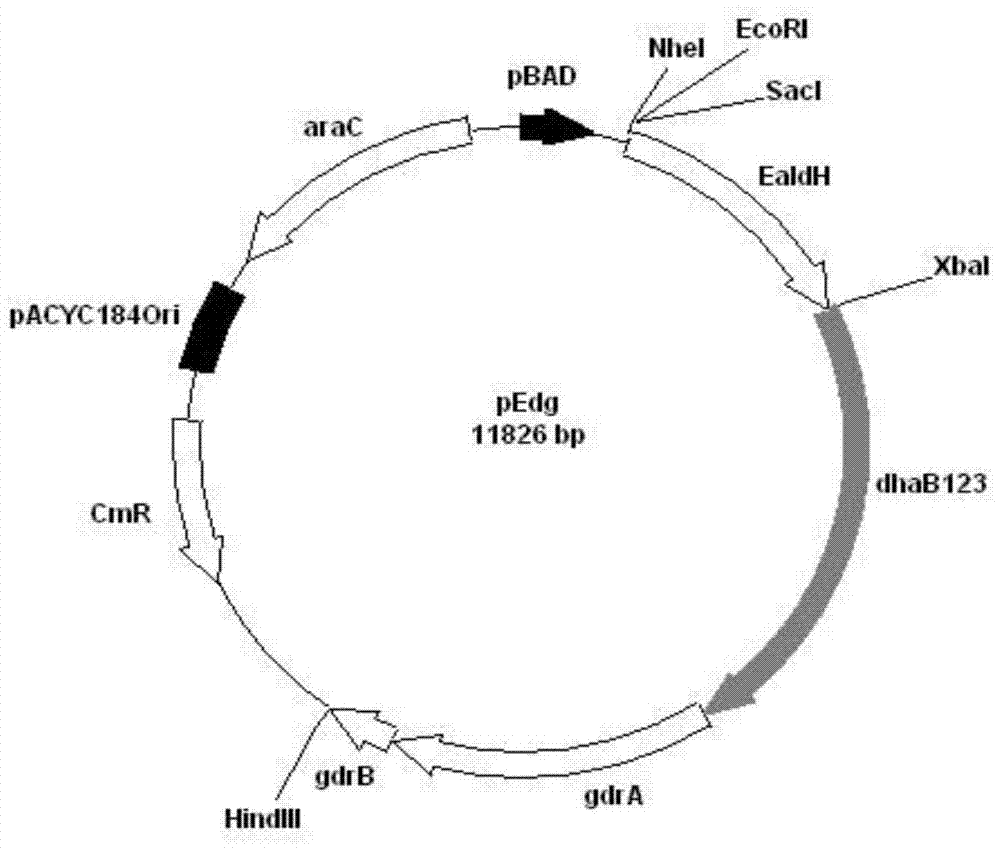

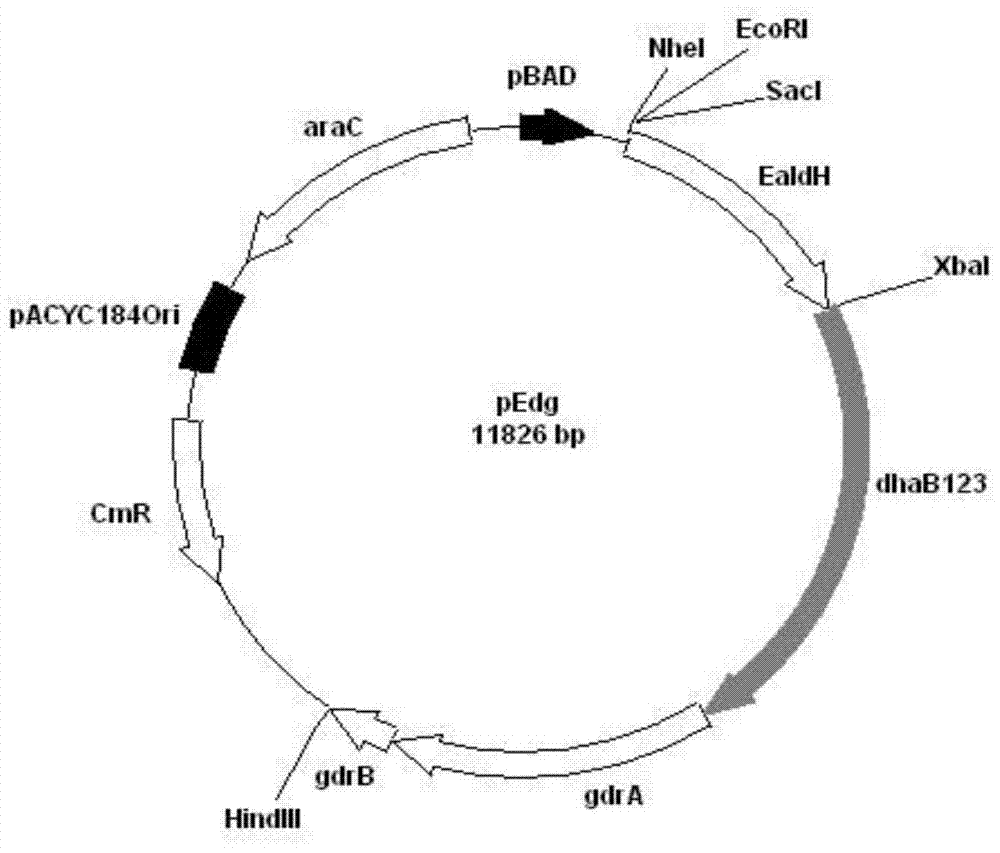

Recombination klebsiella pneumonia capable of co-producing 3-HP and P3HP, and preparation method and application thereof

ActiveCN103497922AReduce synthesisIncrease productionBacteriaMicroorganism based processes3-Hydroxypropionic acidK pneumoniae

The invention discloses recombination klebsiella pneumonia capable of co-producing 3-HP and P3HP, and a preparation method and application thereof. The recombination bacterium is obtained by introducing glycerol dehydratase gene, glycerol dehydratase reactivation enzyme gene, aldehyde dehydrogenase gene, propionyl coenzyme A synthetase gene and polyhydroxyalkanoate synthetase gene into a host recombination klebsiella pneumonia in which 1, 3-propylene glycol oxidoreductase gene and aldehyde reductase / alcohol dehydrogenase gene are knocked out. According to the technical scheme, the production cost of 3-hydroxypropionic acid and poly(3-hydroxypropionic acid) is reduced, and 3-hydroxypropionic acid and poly(3-hydroxypropionic acid) can be synthesized at the same time by taking a same thallus as the host.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Clostridium perfringen glycerol dehydrase gene, and its 1,3-propylene glycol producing method

The invention relates to new glycerin dehydrase gene cloning and its expression in relative host. The enzyme gene is cloned form clostridium perfringens which can transform the glycerin into 3-hydroxyl propionic aldehyde at normal biological chemical reacting condition. Based on the invention, it can recombine the 1,3-propylene glycol redox enzyme relative gene into Escherichia coli to gain a new metabolism engineering fungus which can be transformed into 1, 3-propylene glycol by fermenting tapioca hydrolyzate, glucose, or glycerol.

Owner:南宁中诺生物工程有限责任公司

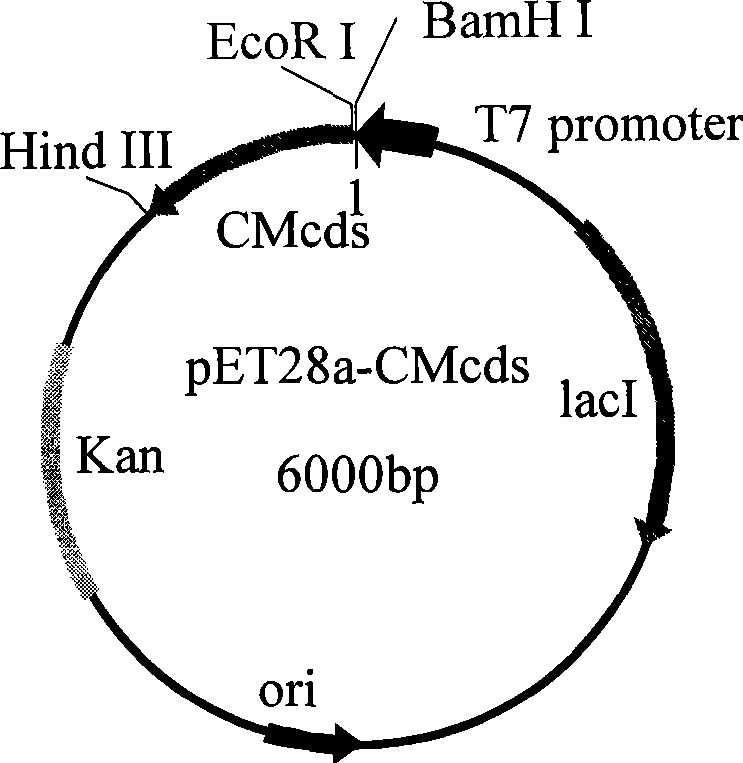

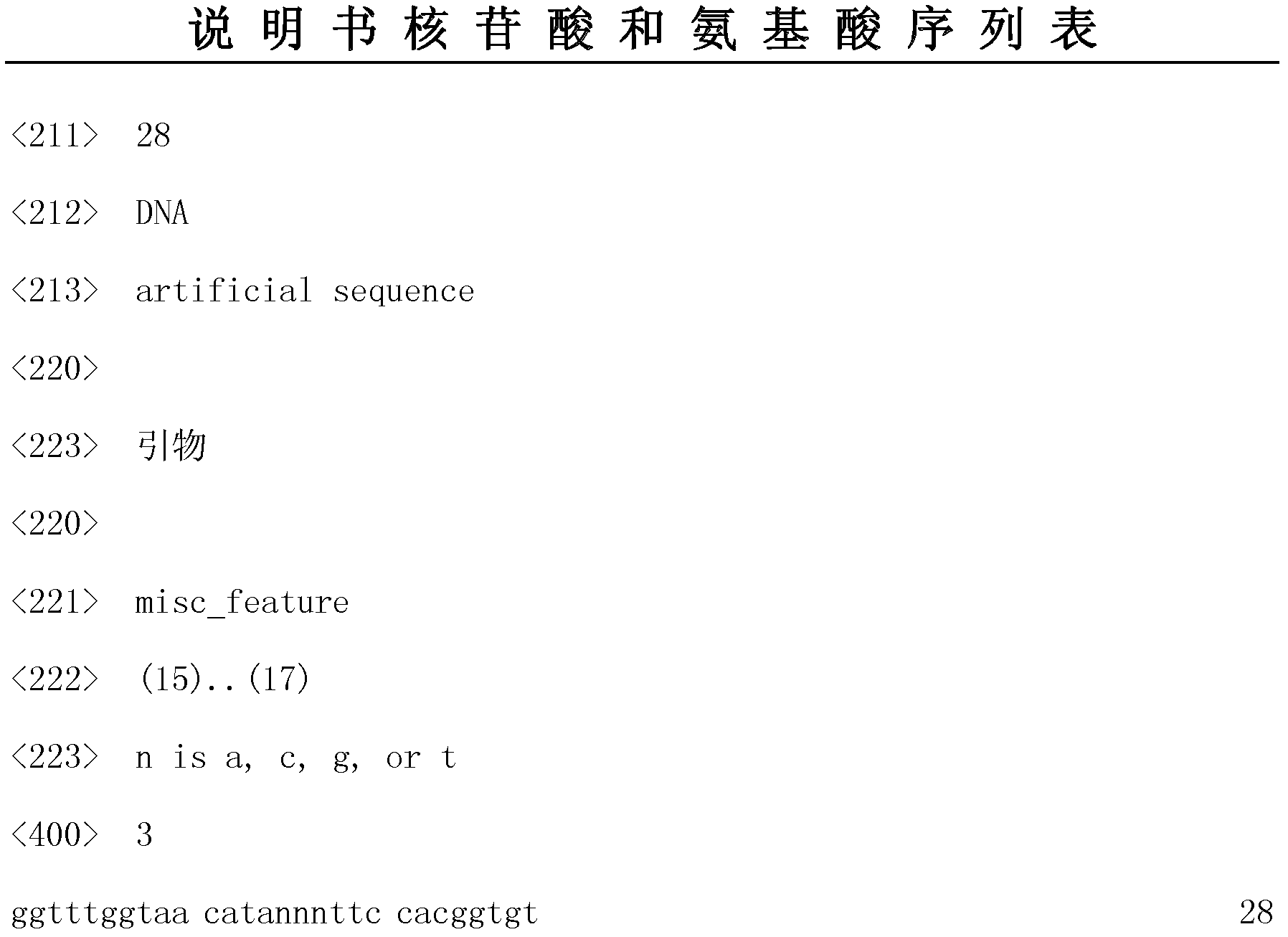

1,3-propylene glycol redex enzyme isoenzyme variant gene gln202ala and uses thereof

InactiveCN101173292AHigh catalytic activityOxidoreductasesFermentationDrug biotransformationPropanediol

The invention discloses a 1, 3-propanediol oxidation reductase isozyme variant gene Gln202Ala and the use. Mediated random mutation of fallible PCR technology is used for screening and getting 1, 3-propanediol oxidation reductase isozyme variant gene. Codon CAG of glutamine of No. 202 in the gene is mutated into a codon GCG of Alanine, thereby getting 1, 3-propanediol oxidation reductase isozyme variant gene Gln202Ala. The nucleotide sequence of the mutated gene is SEQID No.1, which can encode 1, 3-propanediol oxidation reductase isozyme mutations. The variant gene Gln202Ala is reassembled for expressing 1, 3-propanediol oxidation reductase isozyme mutations through gene engineering technology, which is used for catalyzing hydroxy-propionaldehyde and producing 1, 3-propanediol. The invention has the advantages of improving activity by 1.5 to 2 times and providing wide application prospect for chemical raw material 1, 3-propanediol of biotransformation.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Process for the biological production of 1,3-propanediol with high titer

The present invention provides an improved method for the biological production of 1,3-propanediol from a fermentable carbon source in a single microorganism. In one aspect of the present invention, an improved process for the conversion of glucose to 1,3-propanediol is achieved by the use of an E. coli transformed with the Klebsiella pneumoniae dha regulon genes dhaR, orfY, dhaT, orfX, orfW, dhaB1, dhaB2, dhaB3, and orfZ, all these genes arranged in the same genetic organization as found in wild type Klebsiella pneumoniae. In another aspect of the present invention, an improved process for the production of 1,3-propanediol from glucose using a recombinant E. coli containing genes encoding a G3PDH, a G3P phosphatase, a dehydratase, and a dehydratase reactivation factor compared to an identical process using a recombinant E. coli containing genes encoding a G3PDH, a G3P phosphatase, a dehydratase, a dehydratase reactivation factor and a 1,3-propanediol oxidoreductase (dhaT). The dramatically improved process relies on the presence in E. coli of a gene encoding a non-specific catalytic activity sufficient to convert 3-hydroxypropionaldehyde to 1,3-propanediol.

Owner:DUPONT US HLDG LLC

1,3-propylene glycol genetically engineered bacterium and method for producing 1,3-propylene glycol by converting same

ActiveCN103789248AImprove conversion rateBacteriaMicroorganism based processesEngineered geneticPropanediol

The invention relates to a 1,3-propylene glycol genetically engineered bacterium and a method for producing 1,3-propylene glycol by mixing and converting the 1,3-propylene glycol genetically engineered bacterium, and belongs to the field of biotechnology. A PCR (Polymerase Chain Reaction) technology is used for cloning a 1,3-propylene glycol oxidation-reduction enzyme dhaT gene derived from lactobacillus brevis (Lactobacillibrevis CICC6239) so as to construct a genetically engineered strain E.coli-pSE-dhaT which is capable of efficiently and actively expressing the 1,3-propylene glycol oxidation-reduction enzyme (1,3-propanedioldehydrogenase, PDOR). The experiment proves that the enzymatic activity of the 1,3-propylene glycol oxidation-reduction enzyme expressed by the recombinant bacteria is increased by 16 times; the engineered bacterium and the lactobacillus brevis are mixed, stand still and are converted to glycerin, and the conversation rate from the glycerin to the 1,3-propylene glycol can reach 80.6%.

Owner:JIANGSU UNIV

Method for the production of 1,3-propanediol by recombinant organisms compising for vitamin B12 transport

Recombinant organisms are provided comprising genes encoding genes encoding glycerol dehydratase, 1,3-propanediol, 1,3-propanediol oxidoreductase, a gene encoding vitamin B12 receptor precursor (BtuB), a gene encoding vitamin B12 transport system permease protein (BtuC) and a gene encoding vitamin B12 transport ATP-binding protein (BtuD). The recombinant microorganism is contacted with a carbon substrate and 1,3-propanediol is isolated from the growth media.

Owner:EI DU PONT DE NEMOURS & CO +1

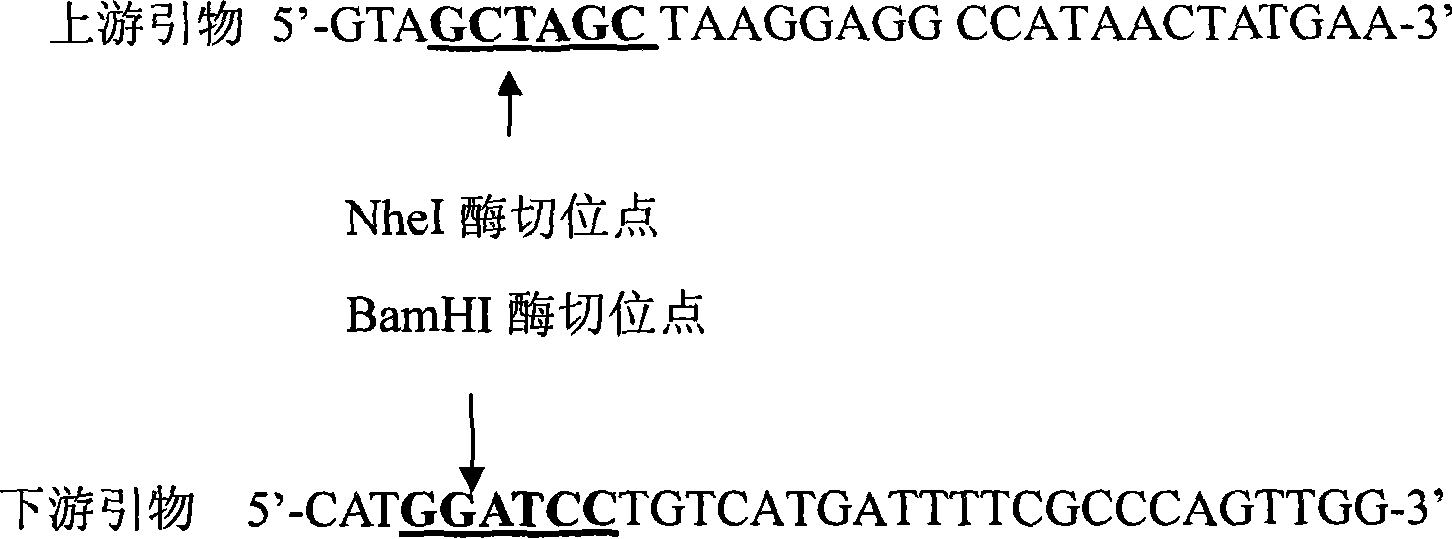

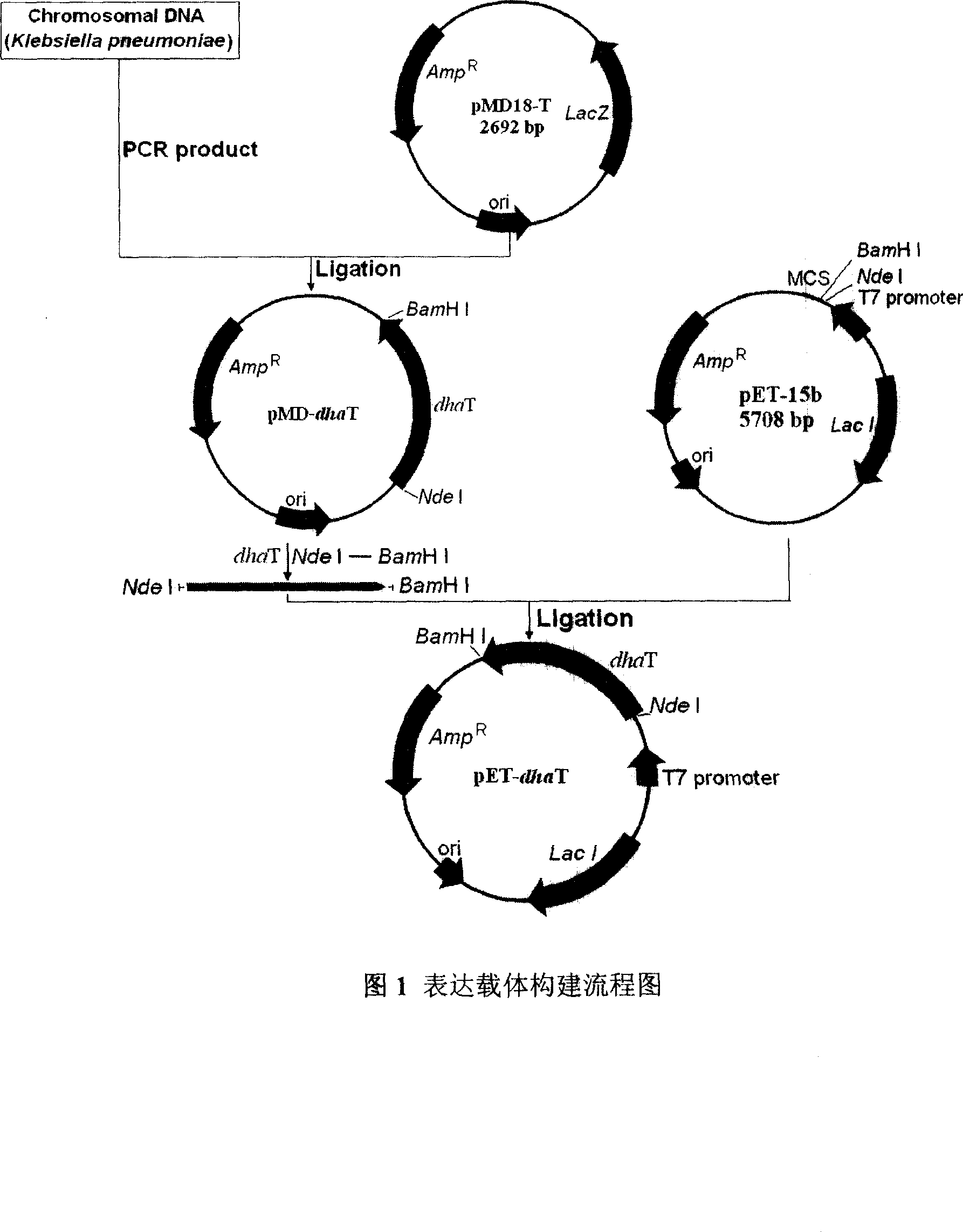

Engineering bacterium producing 1,3-methyl glycol oxidoreductase and preparation method for the enzyme

The invention discloses a preparing method of restructuring strain in biological technical domain, which comprises the following steps: adopting PCR technique; cloning dhaT gene from pneumonic klebsiella DSM 2026; constructing bacillus coli expressing carrier pET-dhaT with dhaT gene; transferring into bacillus coli DH5 alpha; proceeding plasmid reproduction; extracting recombinant plasmid; transferring to bacillus coli BL21(DE3); getting recombination gene engineering strain E. coli-pET-dhaT to express 1, 3-propanediol oxidoreductase (PDOR). This strain can get stable PDOR under the condition of non-antibiotic selective pressure.

Owner:HUAQIAO UNIVERSITY

A kind of 1,3-propanediol-producing genetically engineered bacteria and its preparation method and application

InactiveCN101260379BImprove stabilityHigh final concentrationBacteriaMicroorganism based processesMicroorganism1,3-Propanediol

The invention belongs to the field of biochemical industry and discloses a 1,3-propanediol-producing genetically engineered bacterium as well as a preparation method and application thereof. The strain is named Klebsiella pneumoniae ATCC 25955-pUC18-yqhD-TetR, which is composed of the 1,3-propanediol oxidoreductase isoenzyme gene yqhD from Escherichia coli and the tetracycline resistance gene TetR from the plasmid pHY300PLK, and inserted into the vector pUC18 , obtained by transforming Klebsiella pneumoniae ATCC25955. The bacteria can significantly improve the ability of glycerol to convert 1,3-propanediol, improve the utilization ability and conversion rate of the substrate glycerol, increase the final concentration of the product 1,3-propanediol, and shorten the fermentation time, which is convenient for microbial fermentation. Industrial production of 1,3-propanediol.

Owner:NANJING TECH UNIV

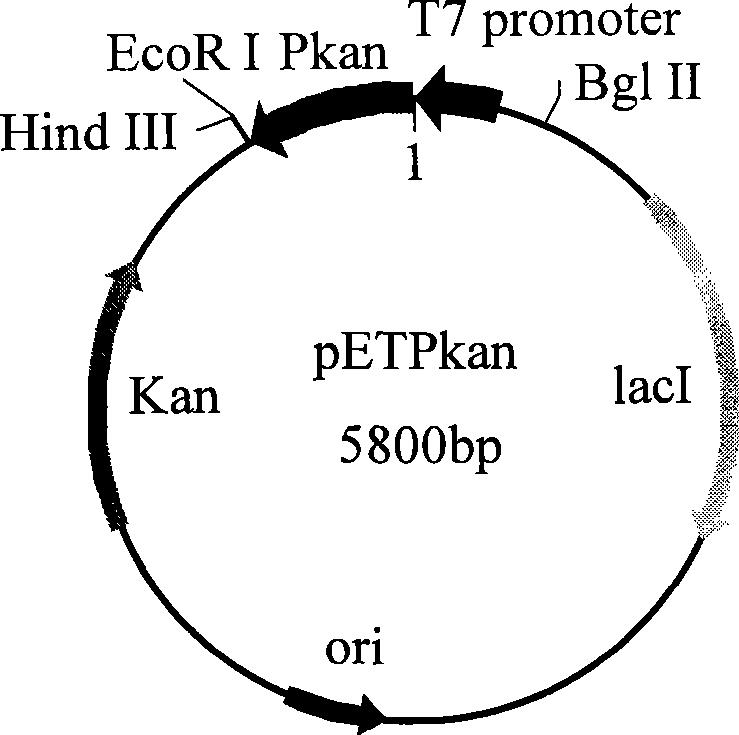

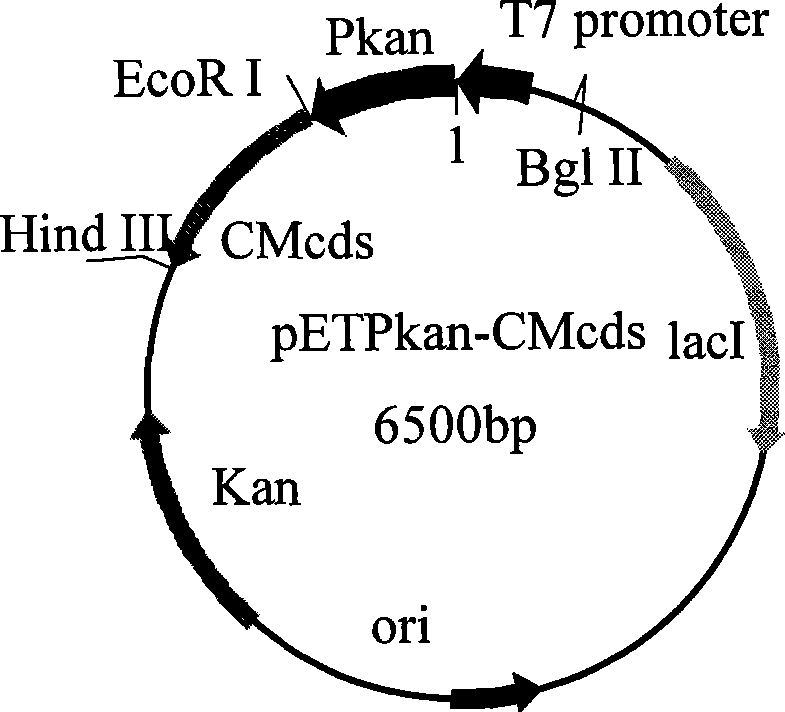

Recombinant klebsiella expressed by kalamycin resistance gene promoter and use thereof

The invention relates to a recombinant klebsiella which starts subexpression with kanamycin resistant gene and the application thereof, which belongs to the technical field of gene engineering. The invention provides a recombinant klebsiella to improve the yield of 1,3-propanediol(PDO) and the classification and nomenclature of the recombinant klebsiella is klebsiella (klebsiella sp.) pETPkan-dhaT, the recombinant klebsiella has been preserved at China Center for Type Culture Collection (CCTCC) with an accession number of CCTCC NO:M 208135. The application is to use the gene dhaT from klebsiella 1,3-propanediol redox enzyme to construct a klebsiella expression vector pETPkan-dhaT; to introduce the klebsiella expression vector into the klebsiella to obtain the recombinant klebsiella pETPkan-dhaT, and to enhance the expression of dhaT gene and realize that the accumulation of an intermediate product 3-glyceraldehyde decreases obviously, and the yield of 1,3- PDO increases by 16.9 percent than the counterpart during the course that the recombinant klebsiella has glycerol as a substrate. The method lays a solid foundation for the high yield of 1,3- PDO or the yield of 1,3- PDO klebsiella gene engineering with glucose as a substrate.

Owner:JIANGNAN UNIV

Method for producing 1,3-propanediol from whole-cell mixed conversion glycerinum

ActiveCN108060203AIncrease profitReduce accumulationMicroorganism based processesFermentation1,3-PropanediolBio engineering

The invention belongs to the technical field of bioengineering and specifically relates to a method for producing 1,3-propanediol from whole-cell mixed conversion glycerinum. The method for producing1,3-propanediol from the whole-cell mixed conversion glycerinum disclosed by the invention comprises the following specific steps: firstly, preparing clostridium butyricum XYB11 thallus and E.coli-Cb-dhaT thallus; then mixing the two kinds of thallus according to a certain proportion to obtain mixed whole cells; finally, adding the mixed whole cells into a conversion solution containing glycerinumand oscillating and converting to obtain 1,3-propanediol under the certain condition. By means of the method for producing the 1,3-propanediol from whole-cell mixed conversion glycerinum disclosed bythe invention, 3-HPA accumulation in a metabolic pathway is reduced, a utilization rate of the glycerinum is improved, and a 1,3-PD yield is increased; enzyme activity of 1,3-propanediol oxidordeuctase in the E.coli-Cb-dhaT can reach 98U / mg; a conversion rate of the glycerinum can reach 84.9%. The whole cell preparation method disclosed by the invention has the advantage of simpleness; only washing the thallus again is needed, a complex enzyme separating and purifying process is avoided, enzyme is fixed in the cells, reaction conditions are moderate, production cost is reduced, and a wide industrial application prospect is achieved.

Owner:镇江百泰生物科技有限公司

Method for producing clostridium perfringens glycerin anhydrase incitant gene and 1,3-propanediol thereof

InactiveCN101265474ASignificant progressBacteriaMicroorganism based processesEscherichia coliEnzyme Gene

The invention relates to the clone of a novel glycerol dehydratase activating factor gene and the expression thereof in related host. The activating factor gene, cloned from clostridium perfringens, can activate an inactive glycerol dehydratase under normal biochemical reaction conditions and recover the enzyme activity of the glycerol dehydratase, and can also enable the glycerol dehydratase to be difficult to be inactivated when the glycerol dehydratase is transformed to glycerin in the reaction. On the basis of the invention, related enzyme genes, such as the glycerol dehydratase, 1, 3-propanediol oxidoreductase, can be restructured to colon bacillus so as to get novel metabolic engineering bacteria. The metabolic engineering bacteria transform starch, glycerin or glucose to 1, 3-propanediol through fermentation.

Owner:南宁中诺生物工程有限责任公司

Recombined bacterial strain for modifying specificity of 1,3-propanediol redoxase coenzyme and application thereof

InactiveCN101643739AIncrease productionBacteriaMicroorganism based processesMicrobiologyBacterial strain

The invention relates to a recombined bacterial strain for modifying the specificity of a 1,3-propanediol redoxase coenzyme and an application of the recombined bacterial strain to 1,3-propanediol preparation, belonging to the technical field of biological engineering. The recombined bacterial strain is characterized in that the specificity of the 1,3-propanediol redoxase coenzyme is modified by rational design to obtain a mutant enzyme; and a recombinant expression vector in a gene sequence containing the mutant enzyme is constructed and converted into a host cell to obtain a recombined bacterial strain. Compared with an original bacterial strain, the invention has the advantage that the 1,3-propanediol yield is improved by 10-50 percent by utilizing the recombined bacterial strain for fermentation.

Owner:DALIAN UNIV OF TECH

Recombination klebsiella pneumonia capable of co-producing 3-HP and P3HP, and preparation method and application thereof

ActiveCN103497922BReduce synthesisIncrease productionBacteriaMicroorganism based processesK pneumoniae3-Hydroxypropionic acid

The invention discloses recombination klebsiella pneumonia capable of co-producing 3-HP and P3HP, and a preparation method and application thereof. The recombination bacterium is obtained by introducing glycerol dehydratase gene, glycerol dehydratase reactivation enzyme gene, aldehyde dehydrogenase gene, propionyl coenzyme A synthetase gene and polyhydroxyalkanoate synthetase gene into a host recombination klebsiella pneumonia in which 1, 3-propylene glycol oxidoreductase gene and aldehyde reductase / alcohol dehydrogenase gene are knocked out. According to the technical scheme, the production cost of 3-hydroxypropionic acid and poly(3-hydroxypropionic acid) is reduced, and 3-hydroxypropionic acid and poly(3-hydroxypropionic acid) can be synthesized at the same time by taking a same thallus as the host.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

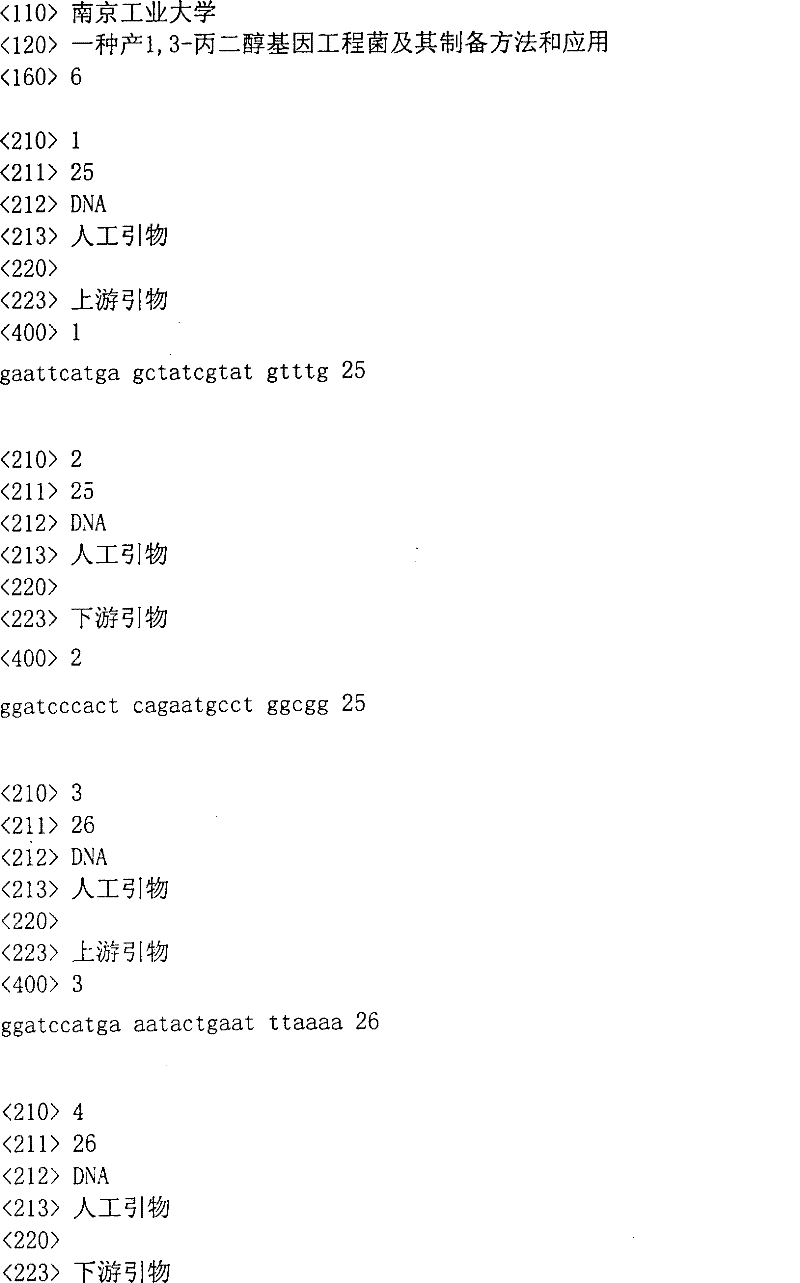

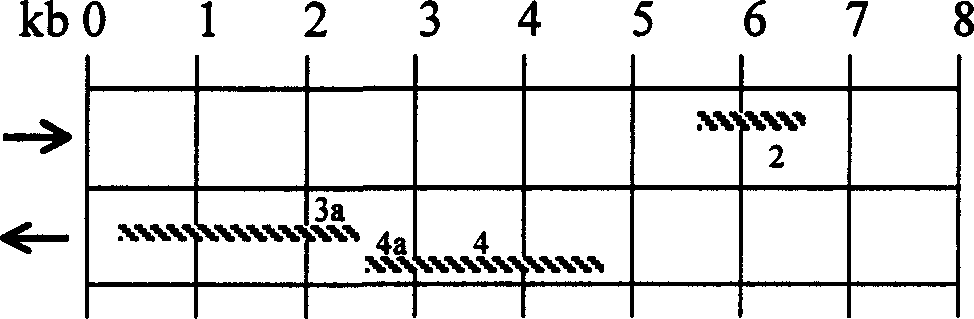

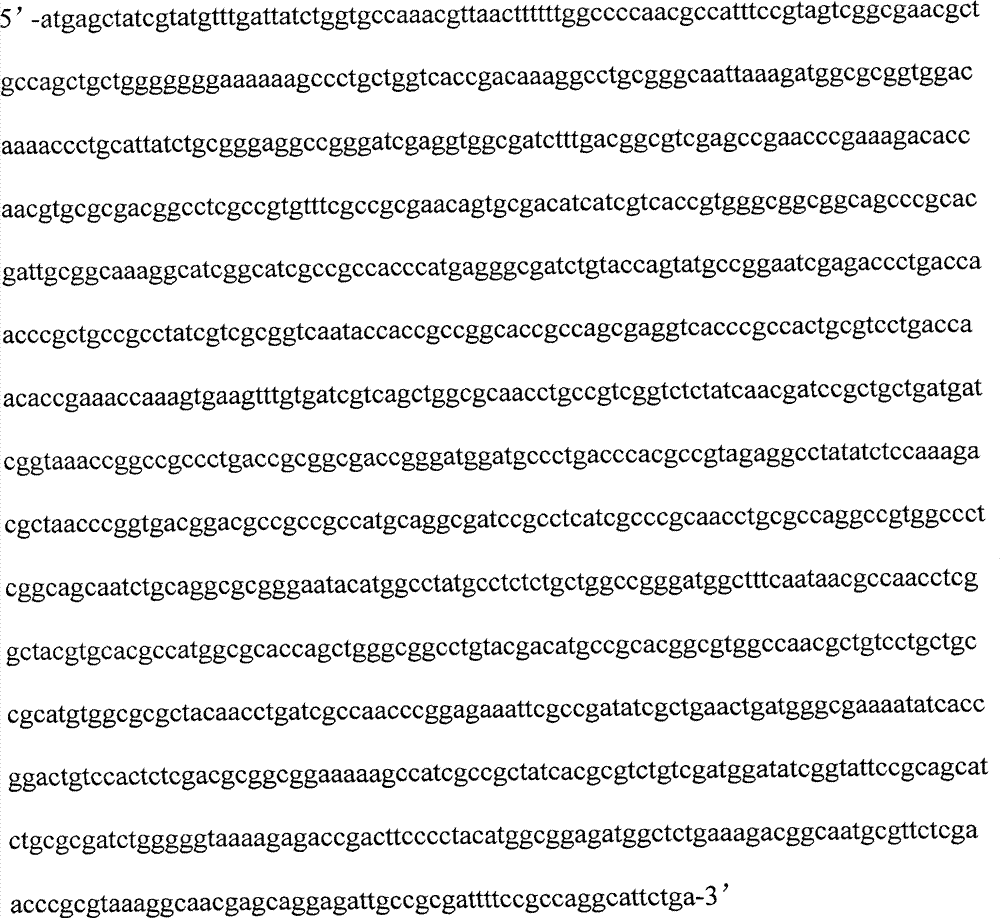

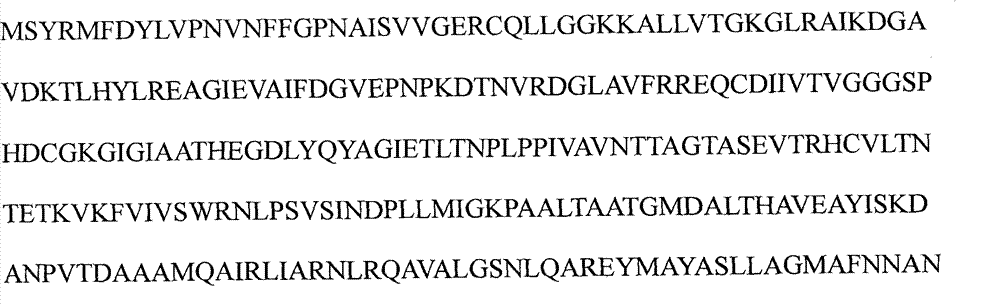

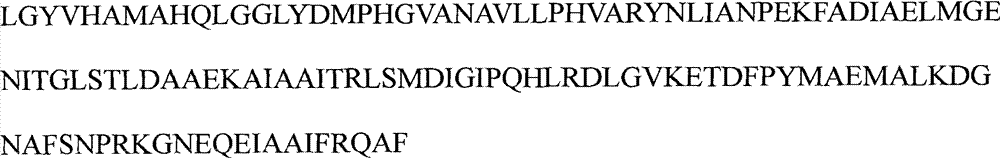

Gene for coding, 1,3-propylene glycol reductase in E.aero strain

A coded 1,3-propylene-glycol redox enzyme gene of Eaero strain high-yielding mutant strain of aerogens 1.3-PD with number CGMCC 0532. The total length of the dhaT gene is 1164bp which codes 387 amino acid proteins, it begins with ATG initial codon and ends with TGA condon. The molecular weight of expressed protein is 43Kda and enzyme activity is 39muM / mg.

Owner:迟乃玉

Method for the production of 1,3-propanediol by recombinant organisms comprising genes for coenzyme B12 synthesis

Recombinant organisms are provided comprising genes encoding cob(II)alamin reductase, cob(I)alamin adenosyltransferase, glycerol dehydratase and 1,3-propanediol oxidoreductase activities useful for the production of 1,3-propanediol from a variety of carbon substrates.

Owner:EI DU PONT DE NEMOURS & CO +1

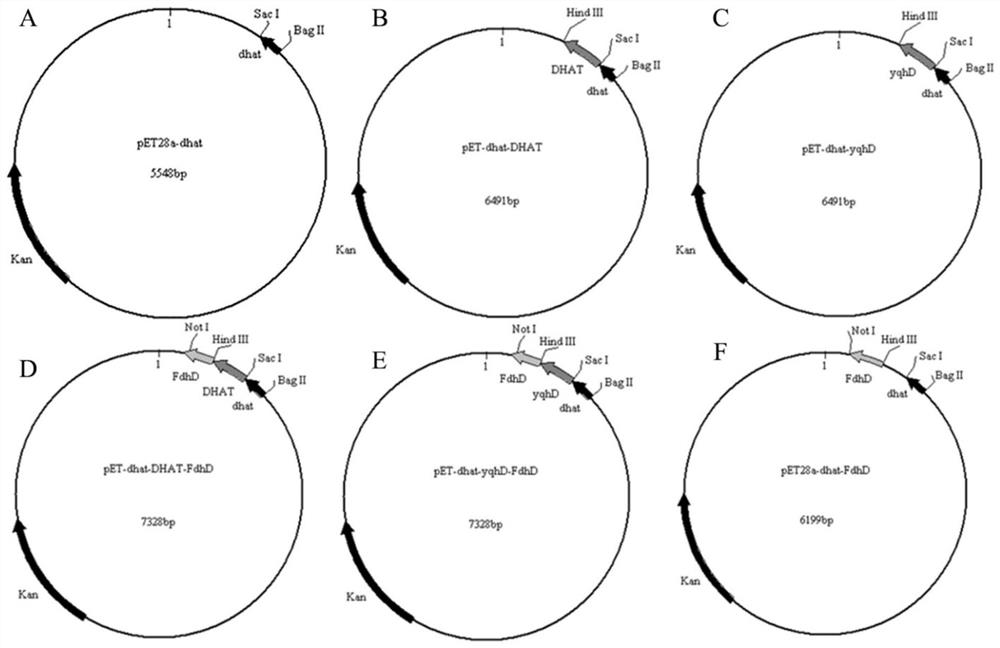

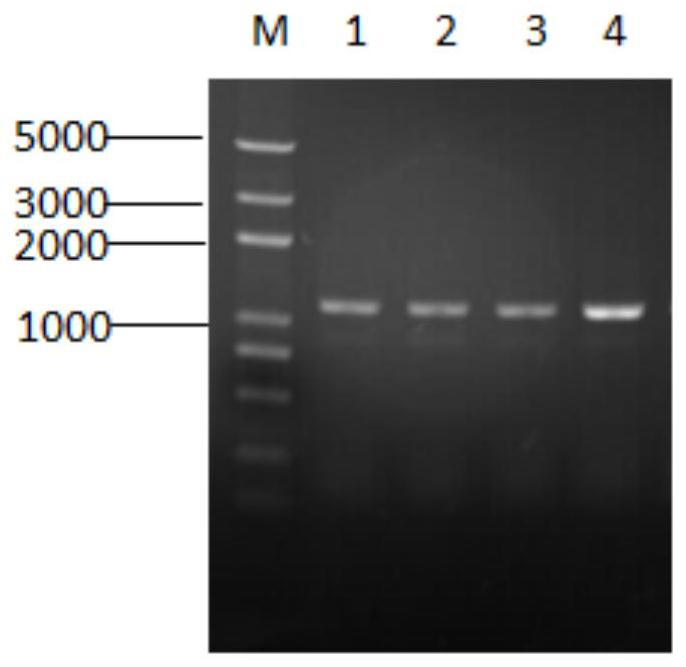

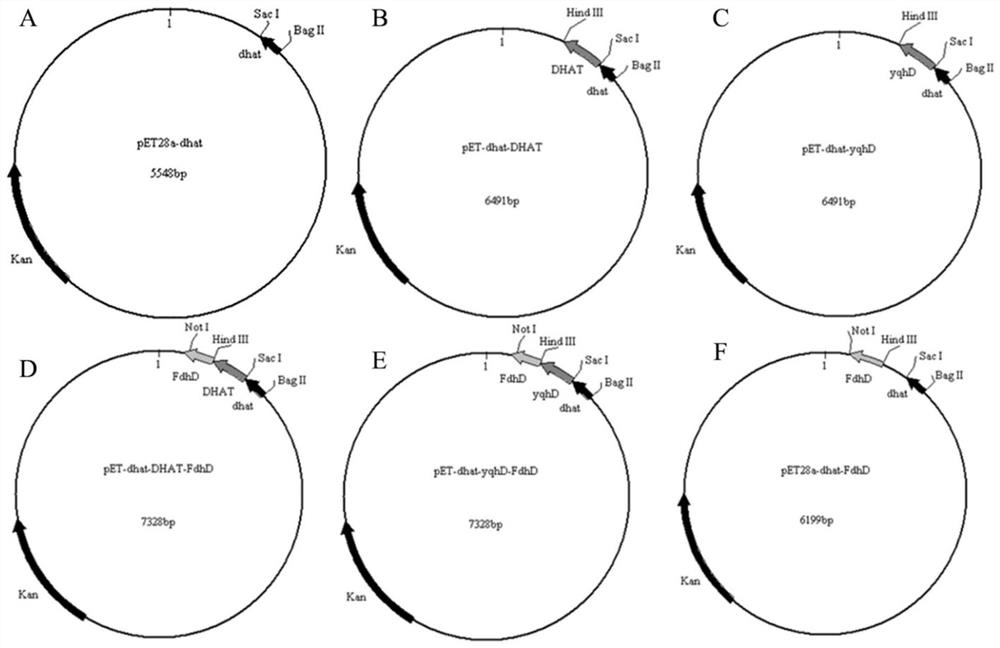

Genetic engineering strain for efficiently producing 1,3-propanediol, construction method for genetic engineering strain and application of genetic engineering strain

ActiveCN111996157AHigh glycerol toleranceImprove induction abilityBacteriaMicroorganism based processesNADH regenerationBatch fermentation

The invention relates to a genetic engineering strain for efficiently producing 1,3-propanediol, a construction method for the genetic engineering strain and application of the genetic engineering strain. According to the genetic engineering strain, the construction method therefor and the application of the genetic engineering strain, the enzyme activity of 1,3-propanediol oxidoreductase is improved through strengthening expression of the 1,3-propanediol oxidoreductase in Klebsiella pneumoniae, meanwhile, a NADH regeneration way is constructed, thus, the accumulation of 3-hydroxypropanal is lowered, the conversion of the 1,3-propanediol from the 3-hydroxypropanal is strengthened, and thus, the yield of the 1,3-propanediol is increased. The enzyme activity of the genetic engineering strain, i.e., the 1,3-propanediol oxidoreductase, constructed by the method is 3.25 to 3.5 times that of a starting strain; and the enzyme activity of formate dehydrogenase is 0.414U / mg to 0.45U / mg. Throughcarrying out fed-batch fermentation for 29 hours by employing the genetic engineering strain constructed by the method, the yield of the 1,3-propanediol is increased by 43.89%-97.93% compared with that of the starting strain; and due to a dual-gene synergistic effect, the output and yield of the 1,3-propanediol are increased remarkably.

Owner:QILU UNIV OF TECH

A kind of genetic engineering bacteria for efficient production of 1,3-propanediol and its construction method and application

ActiveCN111996157BHigh glycerol toleranceImprove induction abilityBacteriaMicroorganism based processesNADH regenerationBatch fermentation

The invention relates to a genetically engineered bacterium capable of efficiently producing 1,3-propanediol and a construction method and application thereof. The present invention strengthens the expression of 1,3-propanediol oxidoreductase in Klebsiella pneumoniae to enhance the enzymatic activity of 1,3-propanediol oxidoreductase, and simultaneously constructs a NADH regeneration pathway to reduce the accumulation of 3-hydroxypropionaldehyde, Enhances the conversion of 3-hydroxypropionaldehyde to 1,3-propanediol, thereby increasing the yield of 1,3-propanediol. The enzymatic activity of the 1,3-propanediol oxidoreductase of the genetically engineered bacteria constructed by the present invention is 3.25-3.5 times that of the starting strain; the enzymatic activity of the formate dehydrogenase is 0.414-0.45 U / mg. Using the genetically engineered bacteria constructed by the present invention to carry out fed-batch fermentation for 29 hours, the yield of 1,3-propanediol is increased by 43.89%-97.93% compared with the starting strain, and the synergistic effect of the double genes significantly increases the yield of 1,3-propanediol and yield.

Owner:QILU UNIV OF TECH

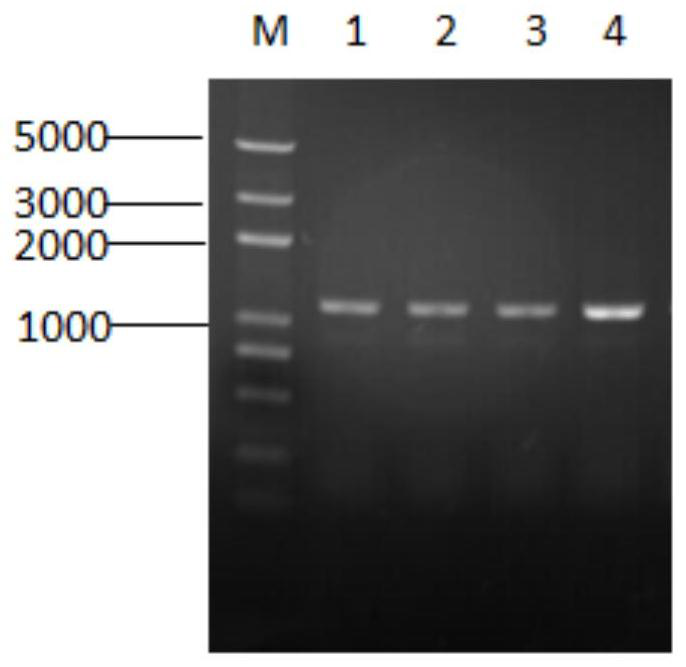

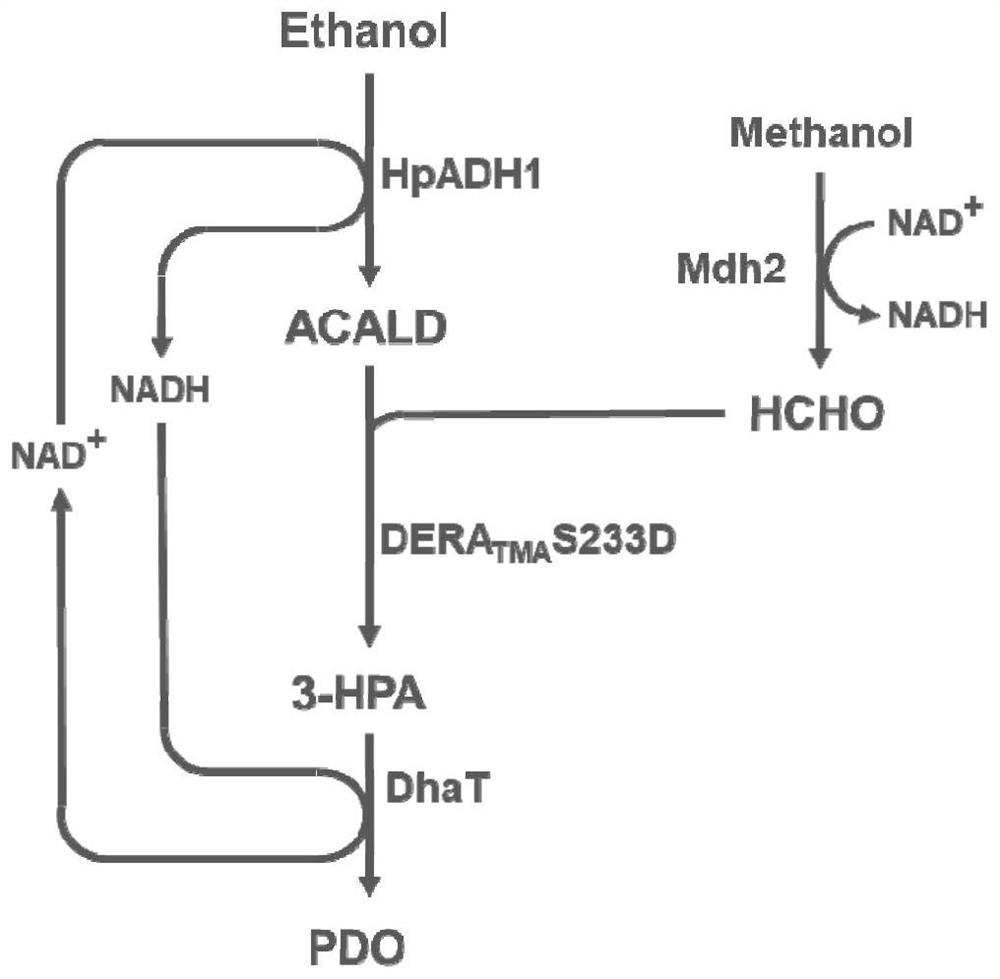

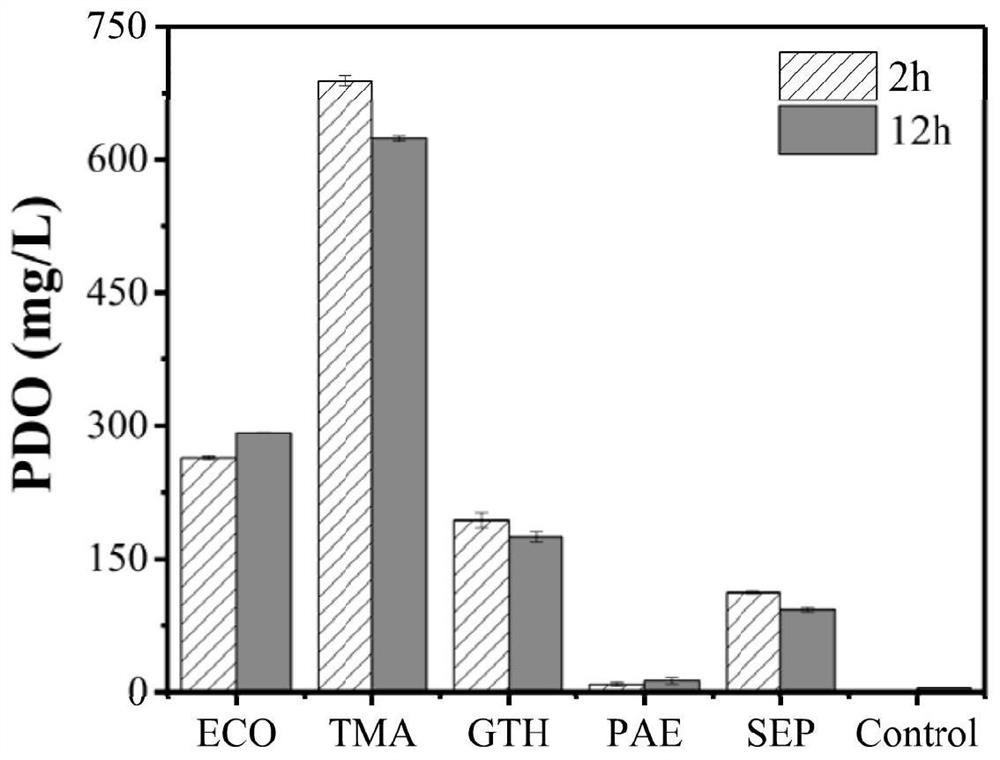

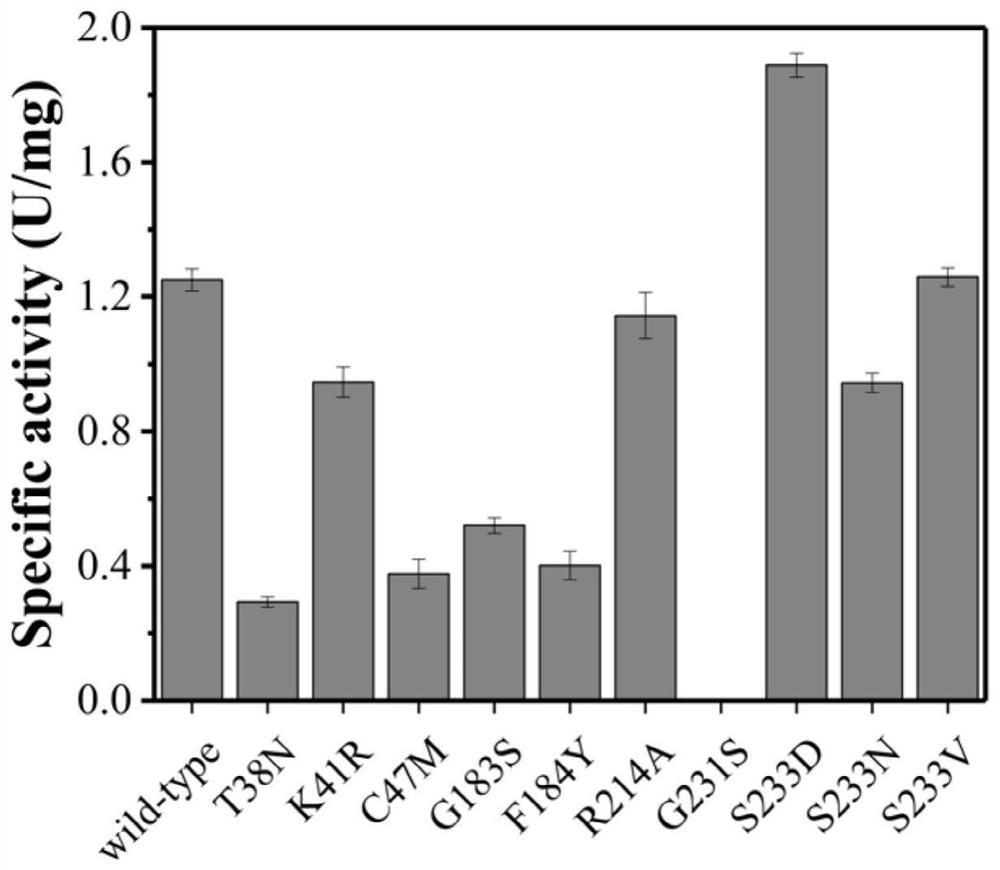

Aldolase mutant and its application in production of 1, 3-propylene glycol

ActiveCN112921021AIncrease productionIncrease vitalityFungiBacteriaEscherichia coliEthanol dehydrogenase

The invention relates to the technical field of synthetic biology and microbial fermentation, in particular to modification of deoxyribose-5-phosphate aldolase through semi-rational design and overexpression of four enzymes in recombinant escherichia coli, namely methanol dehydrogenase, ethanol dehydrogenase, deoxyribose-5-phosphate aldolase, 1, 3-propylene glycol oxidoreductase or 1, 3-propylene glycol oxidoreductase isozyme, to construct unnatural 1, 3-propylene glycol from methanol, a formaldehyde-carbon compound, ethanol and acetaldehyde. The activity of the DERATMAS233D mutant screened by the invention is improved by 51% compared with that of a wild type enzyme; When the conversion from formaldehyde and ethanol to PDO by using escherichia coli, the yield of PDO is increased by 21.8%; when the formaldehyde and the acetaldehyde are converted into the PDO, the yield of the PDO is increased by 9.2%, the synthesis route of the PDO is greatly shortened, and the yield of the PDO is increased.

Owner:BEIJING UNIV OF CHEM TECH

Clostridium perfringen glycerol dehydrase gene, and its 1,3-propylene glycol producing method

The invention relates to new glycerin dehydrase gene cloning and its expression in relative host. The enzyme gene is cloned form clostridium perfringens which can transform the glycerin into 3-hydroxyl propionic aldehyde at normal biological chemical reacting condition. Based on the invention, it can recombine the 1,3-propylene glycol redox enzyme relative gene into Escherichia coli to gain a newmetabolism engineering fungus which can be transformed into 1, 3-propylene glycol by fermenting tapioca hydrolyzate, glucose, or glycerol.

Owner:南宁中诺生物工程有限责任公司

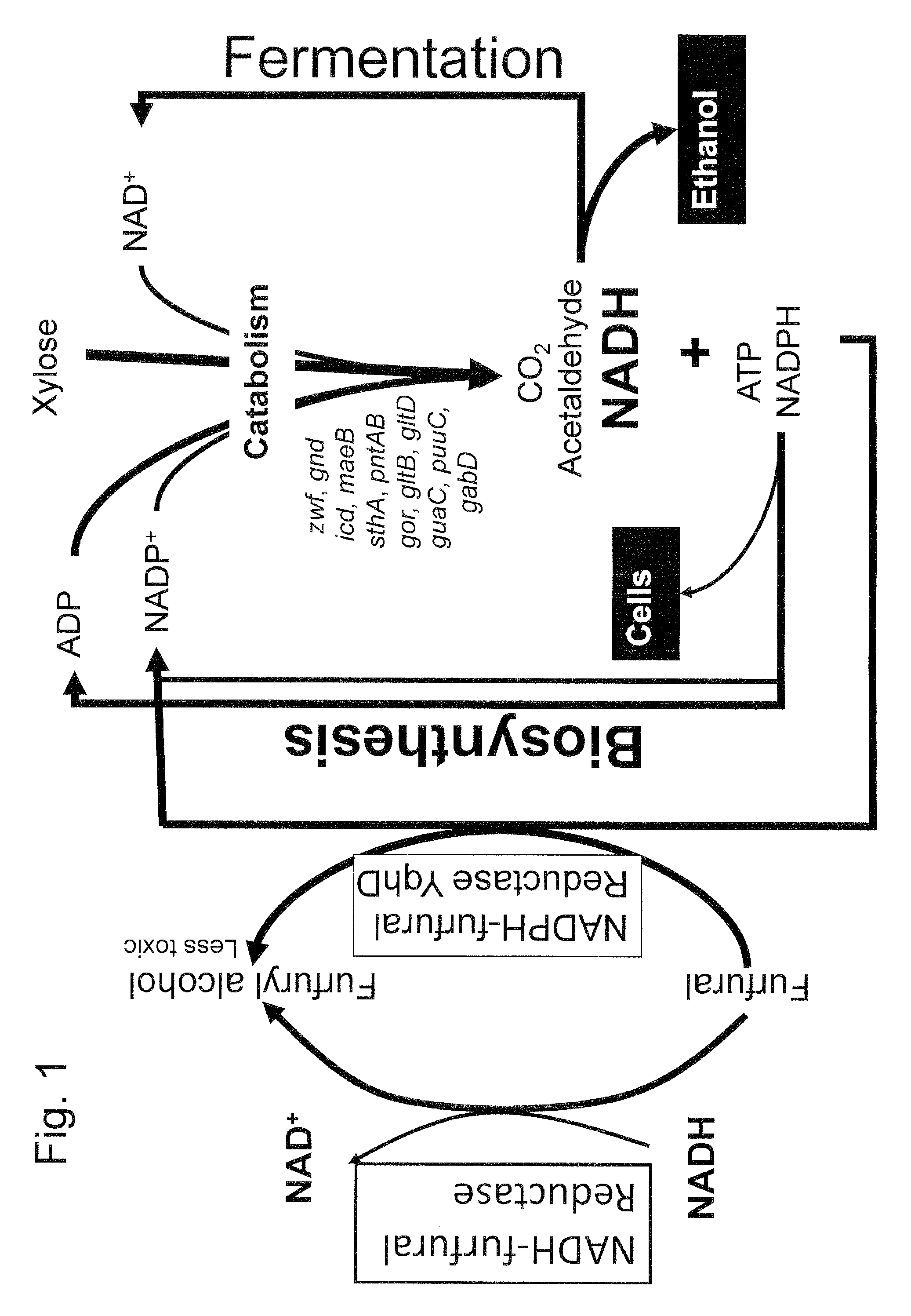

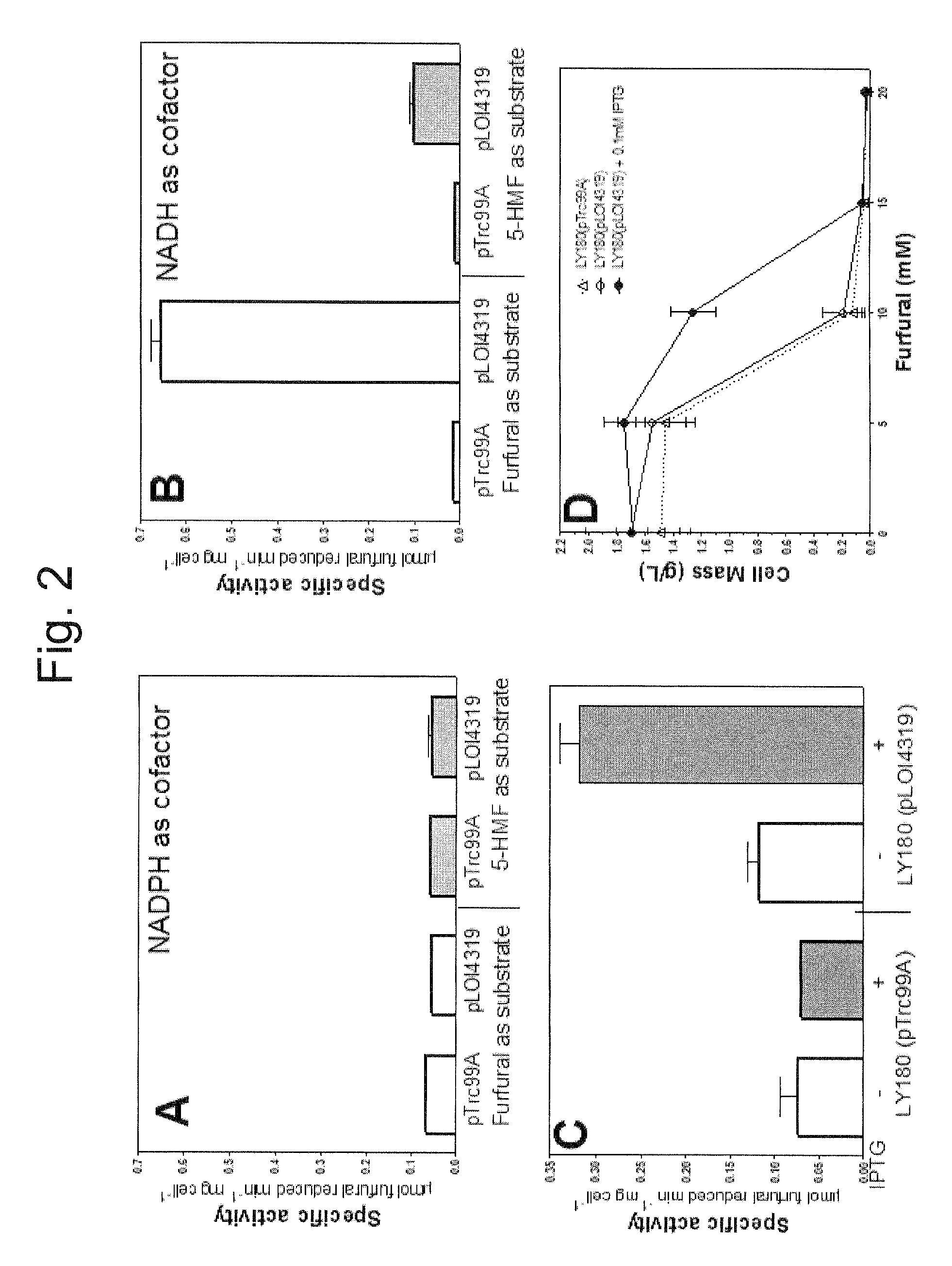

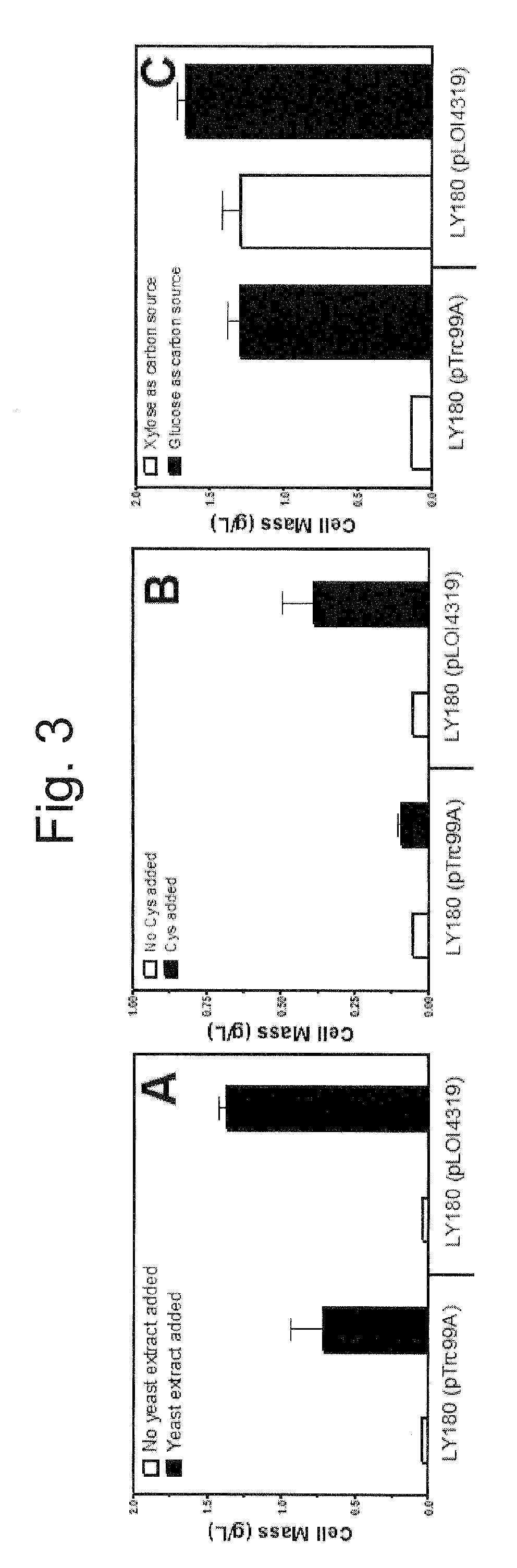

Over-expression of NADH-dependent oxidoreductase (fucO) for increasing furfural or 5-hydroxymethylfurfural tolerance

The subject invention pertains to the discovery that the NADH-dependent propanediol oxidoreductase (FucO) can reduce furfural. This allows for a new approach to improve furfural tolerance in bacterial and / or yeast cells used to produce desired products. Thus, novel biocatalysts (bacterial, fungal or yeast cells) exhibiting increased tolerance to furfural and 5-hydroxymethylfurfural (5-HMF) are provided as are methods of making and using such biocatalysts for the production of a desired product.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

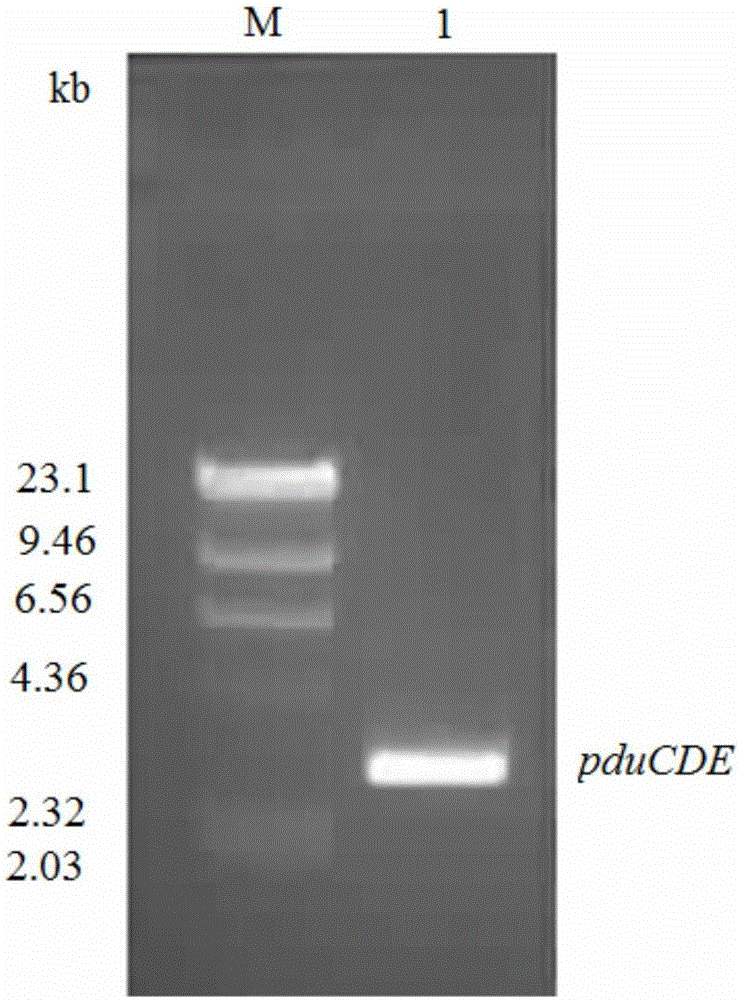

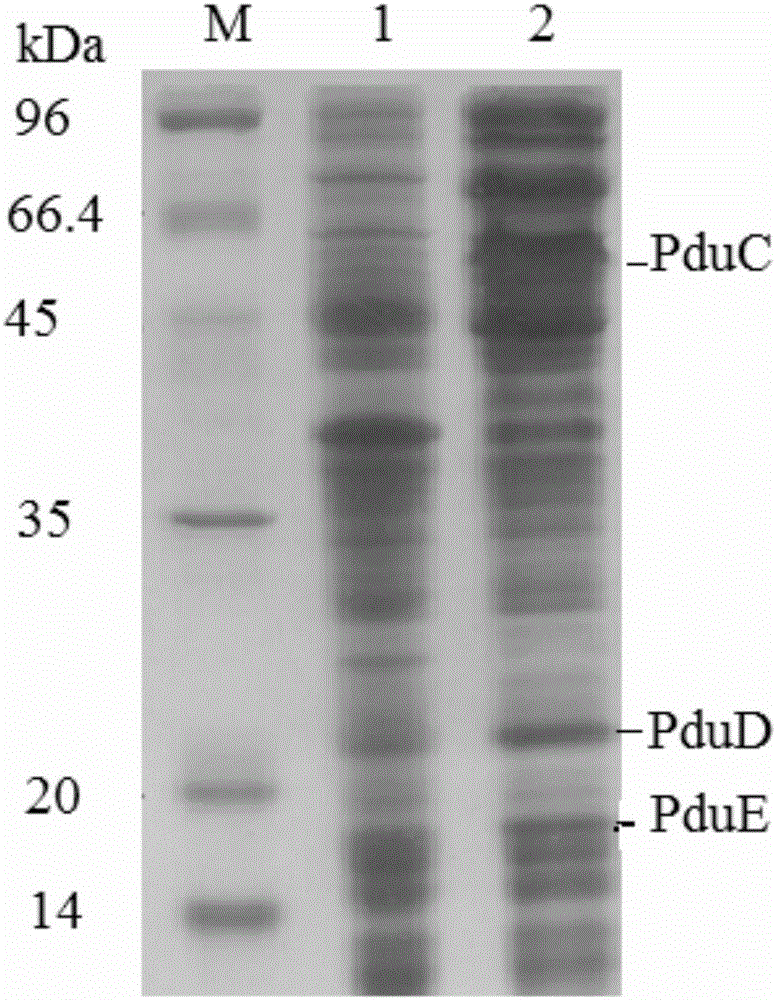

Application of dioldehydrase gene pduCDE

InactiveCN105695496AVigorousSave resource costBacteriaMicroorganism based processes3-Hydroxypropionic acidEscherichia coli

The invention discloses application of dioldehydrase gene pduCDE, and particularly discloses application of engineering bacteria containing the gene to preparation of 3-hydroxypropionic acid, 1,3-propylene glycol and 3-hydroxypropionic acid with fermented glycerinum. The gene is expressed successfully in escherichia coli for the first time, and an encoded enzyme of the gene can be used for catalyzing dehydration of the glycerinum to generate 3-hydroxy-propionaldehyde. On the basis of the application, a 1,3-propylene oxidordeuctase gene or an adlehyde dehydrogenase gene can be recombined into escherichia coli, and recombinant bacteria can transform the glycerinum into 1,3-propylene glycol or 3-hydracrylic acid through fermentation.

Owner:南宁中诺生物工程有限责任公司

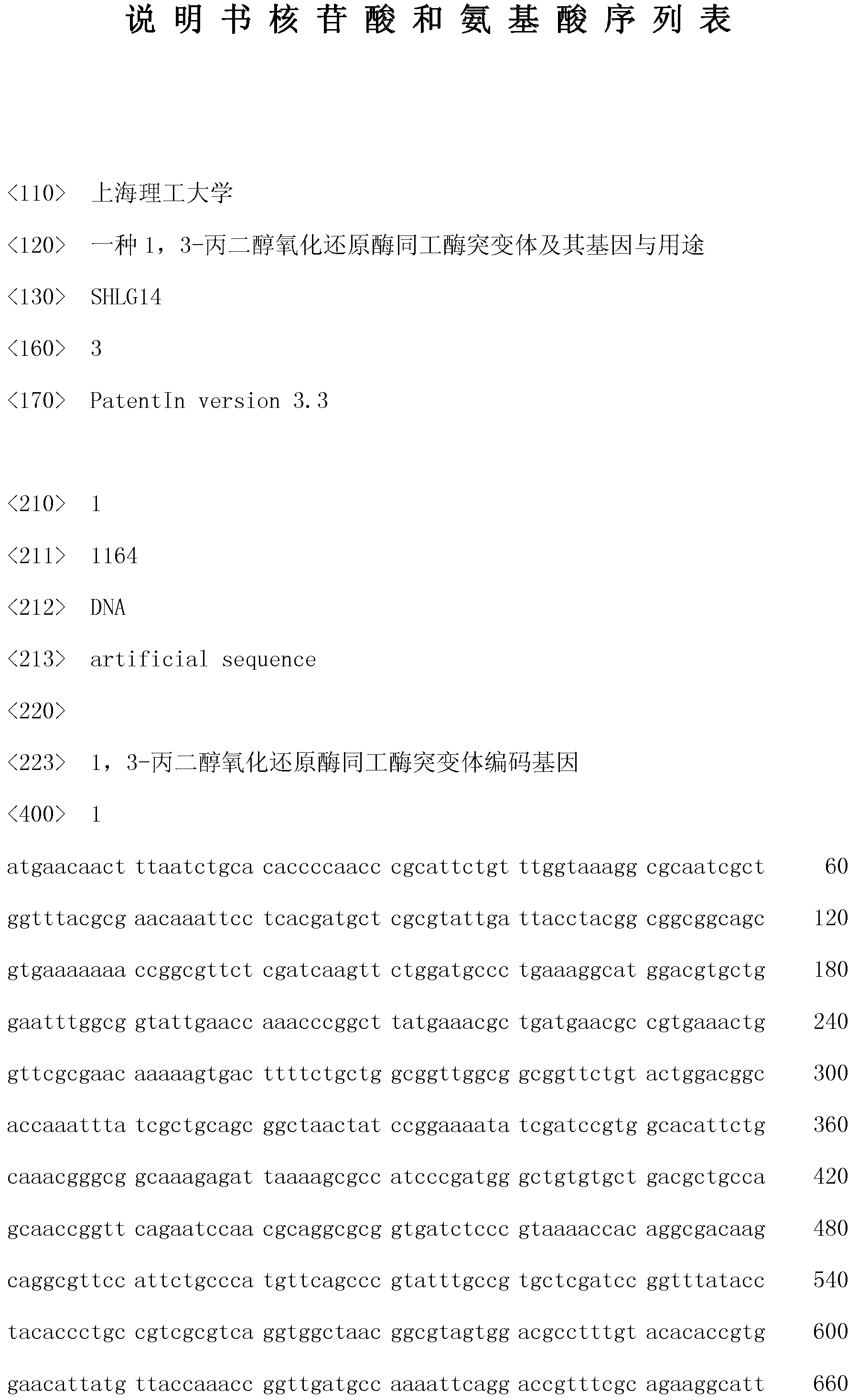

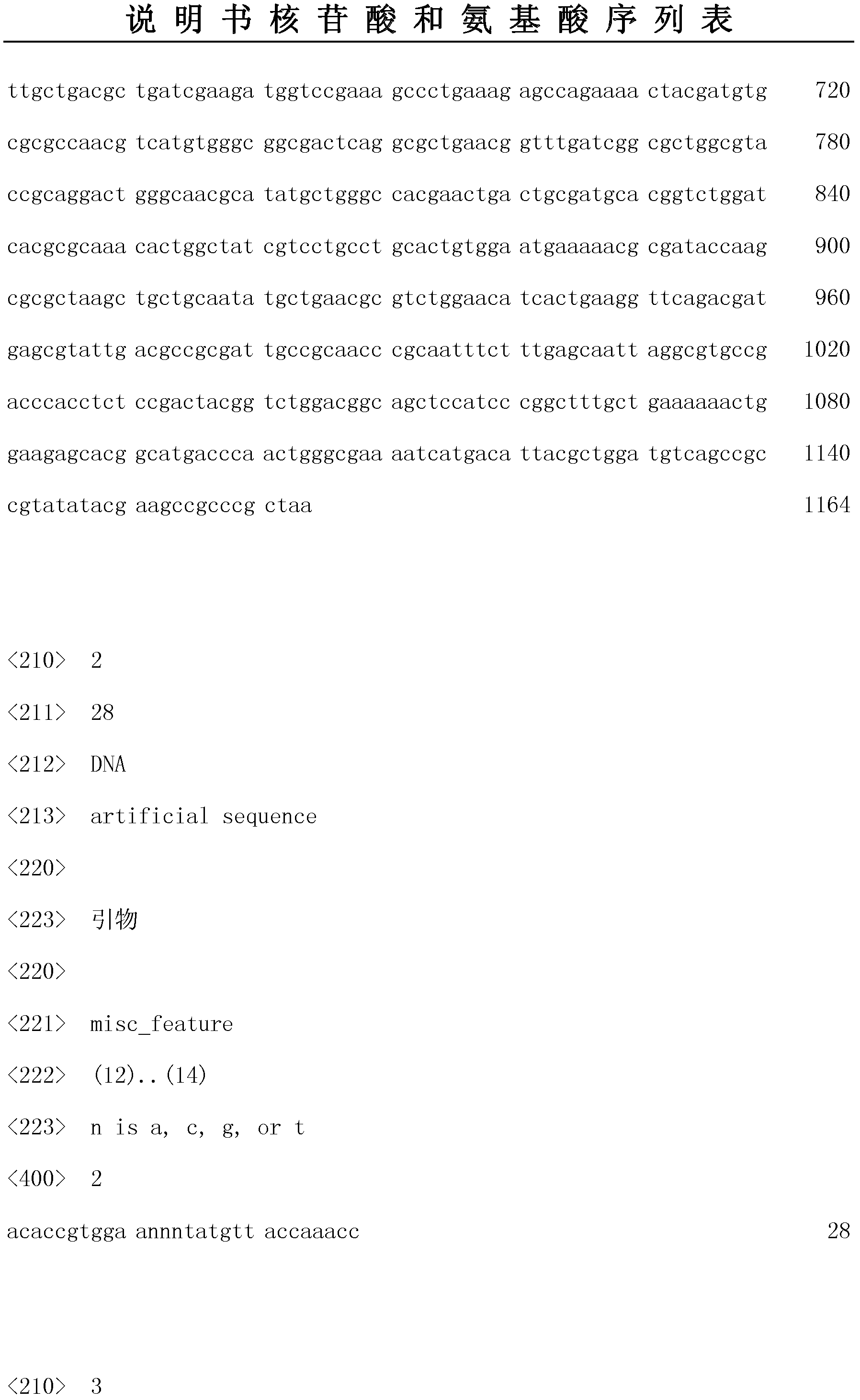

1,3-propylene glycol oxidoreductase isozyme mutant, and gene and application thereof

The invention discloses a 1,3-propylene glycol oxidoreductase isozyme mutant, and a gene and application thereof. The 1,3-propylene glycol oxidoreductase isozyme mutant, provided by the invention, has activity for catalyzing 3-hydroxypropionaldehyde to generate 1,3-propylene glycol, and is 1,3-propylene glycol oxidoreductase isozyme containing Q202H mutation. A variant gene is measured by an enzyme kinetics curve; in comparison with the 1,3-propylene glycol oxidoreductase isozyme mutant, the catalysis efficiency is remarkably improved, and the wide application prospect is provided for biological production of 1,3-propylene glycol.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for the production of 1,3-propanediol by recombinant organisms compising for vitamin B12 transport

Recombinant organisms are provided comprising genes encoding genes encoding glycerol dehydratase, 1,3-propanediol, 1,3-propanediol oxidoreductase, a gene encoding vitamin B12 receptor precursor (BtuB), a gene encoding vitamin B12 transport system permease protein (BtuC) and a gene encoding vitamin B12 transport ATP-binding protein (BtuD). The recombinant microorganism is contacted with a carbon substrate and 1,3-propanediol is isolated from the growth media.

Owner:EI DU PONT DE NEMOURS & CO +1

Recombined bacterial strain for modifying specificity of 1,3-propanediol redoxase coenzyme and application thereof

Owner:DALIAN UNIV OF TECH

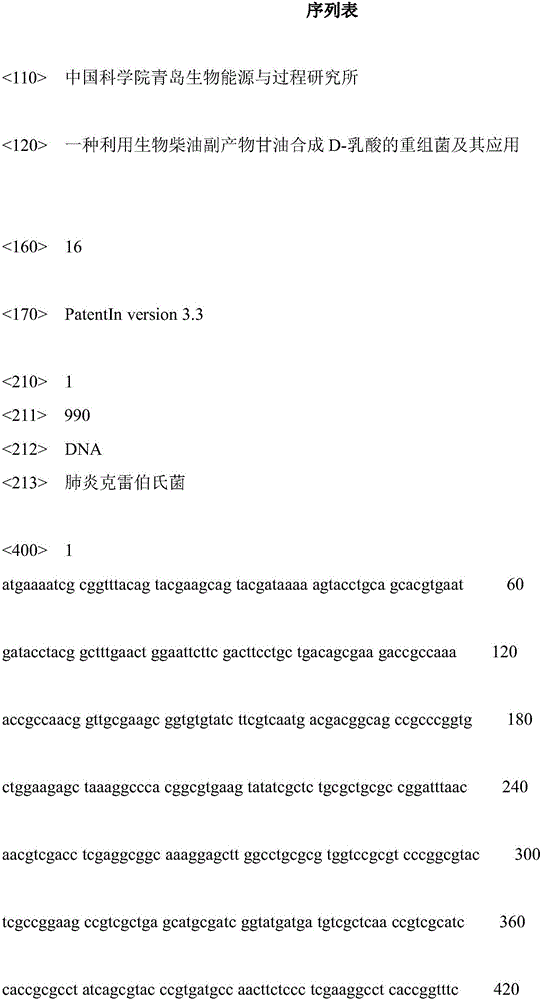

Recombinant bacterium for synthesizing D-lactic acid by adopting biodiesel by-product, namely, glycerol and applications of recombinant bacterium

InactiveCN106434505AImprove conversion rateCost advantageBacteriaMicroorganism based processesK pneumoniaeBiodiesel

The invention discloses a recombinant bacterium for synthesizing D-lactic acid by adopting the biodiesel by-product, namely, glycerol and applications of the recombinant bacterium, belonging to the field of genetic engineering. For the recombinant bacterium provided by the invention, the dehydrogenase gene of D-lactic acid, namely, ldhA is introduced into the host, namely, recombinant Klebsiella pneumoniae with the 1,3-propanediol oxidoreductase gene dhaT and the aldehyde reductase / alcohol dehydrogenase gene yqhD knocked out, and thus the engineering strain is obtained. D-lactic acid is synthesized by taking the biodiesel by-product, namely, glycerol as the substrate, in the shake flask level, the yield and conversion rate respectively achieve 12.7g / L and 50.4%, the optical purity is 100%, and the recombinant bacterium has the advantages that the optical purity and conversion rate are high, and the production cost is low.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Process for the biological production of 1,3-propanediol with high titer

The present invention provides an improved method for the biological production of 1,3-propanediol from a fermentable carbon source in a single microorganism. In one aspect of the present invention, an improved process for the conversion of glucose to 1,3-propanediol is achieved by the use of an E. coli transformed with the Klebsiella pneumoniae dha regulon genes dhaR, orfY, dhaT, orfX, orfW, dhaB1, dhaB2, dhaB3, and orfZ, all these genes arranged in the same genetic organization as found in wild type Klebsiella pneumoniae. In another aspect of the present invention, an improved process for the production of 1,3-propanediol from glucose using a recombinant E. coli containing genes encoding a G3PDH, a G3P phosphatase, a dehydratase, and a dehydratase reactivation factor compared to an identical process using a recombinant E. coli containing genes encoding a G3PDH, a G3P phosphatase, a dehydratase, a dehydratase reactivation factor and a 1,3-propanediol oxidoreductase (dhaT). The dramatically improved process relies on the presence in E. coli of a gene encoding a non-specific catalytic activity sufficient to convert 3-hydroxypropionaldehyde to 1,3-propanediol.

Owner:DUPONT US HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com