Recombination klebsiella pneumonia capable of co-producing 3-HP and P3HP, and preparation method and application thereof

A technology for Klebsiella pneumoniae and pneumonia, which is applied in the field of recombinant Klebsiella pneumoniae and its preparation, and can solve problems such as simultaneous synthesis of 3-HP and P3HP that have not yet been found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

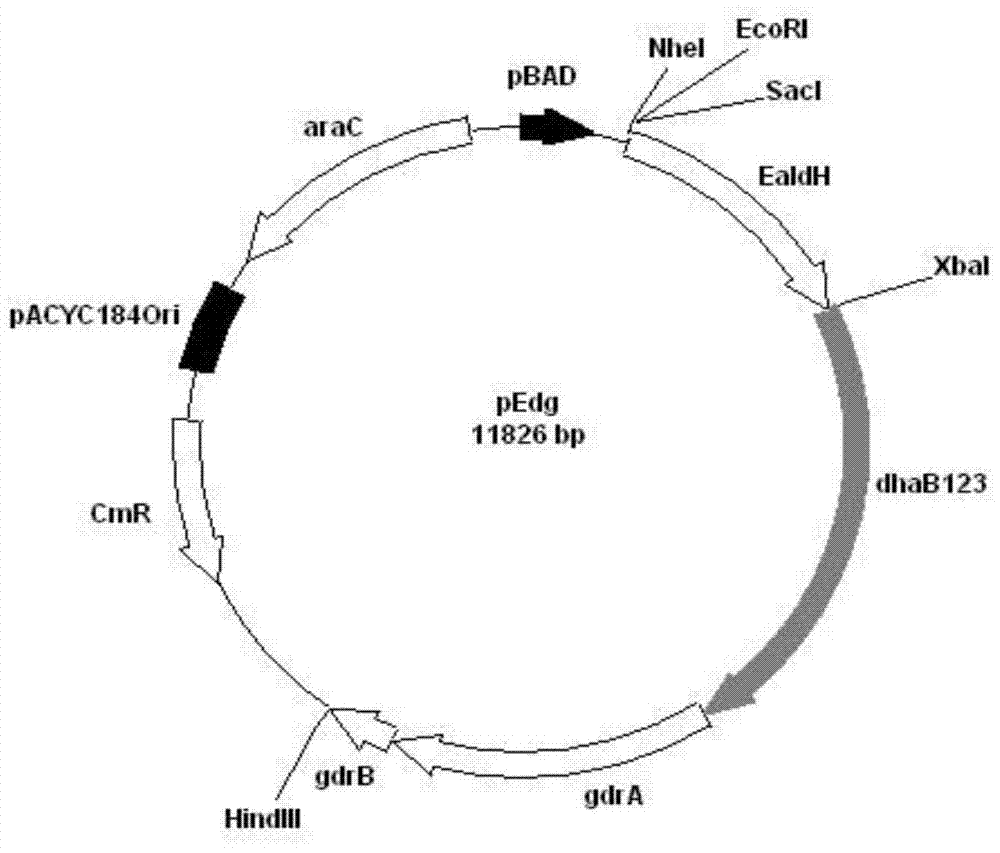

[0068] Example 1. Strain construction

[0069] By overexpressing endogenous Klebsiella pneumoniae (K. Glycerol dehydratase gene (dhaB123) and glycerol dehydratase reactivating enzyme gene (gdrAB), and exogenous aldehyde dehydrogenase gene (aldH), propionyl-CoA synthetase gene (prpE) and polyhydroxy fatty acid synthase gene ( phaC) realizes the biocoproduction of 3-HP and P3HP using glycerol as the carbon substrate.

[0070] Those skilled in the art should understand that the deletion experiments of the above-mentioned K. In K. penumoniae, all steps were carried out according to standard molecular cloning techniques.

[0071] 1.1 Gene knockout

[0072] Primers were designed using about 500 base fragments upstream and downstream of the 1,3-propanediol dehydrogenase gene (dhaT) (Gene ID: 7946507) of the wild strain of Klebsiella pneumoniae (K. , 3-propanediol dehydrogenase gene (dhaT) upstream and downstream fragments, and then use the recovery kit to recover the target gene ...

Embodiment 2

[0109] Example 2. SDS-PAGE identifies the expression and optimization of the target protein

[0110] Inoculate the activated engineered Klebsiella pneumoniae into 20 mL of liquid medium (containing 100 μg·mL -1 Chloramphenicol and 100 μg·mL -1 kanamycin), 37°C, 180rpm shaking culture, OD 600 When it reached 0.6, a certain concentration of arabinose was added to the bacterial solution, and then the temperature was adjusted to 30°C for 3 hours to induce the expression of the target protein. The induced culture was taken out, and the cells were collected by centrifugation at 12000 g for 10 min, and the cells of the cells were washed once with 0.05 mol / L phosphate buffer (pH 7.0). Then add 1mL phosphate buffer, break the cells, take 10μL supernatant and add an equal volume of 2×SDS-PAGE loading buffer, bathe in boiling water for 5min, centrifuge at high speed instantaneously, and detect by 10% SDS-PAGE electrophoresis, the target protein can be detected express the situation ( ...

Embodiment 3

[0111] Embodiment 3. Shake flask fermentation test of recombinant bacterial strain

[0112] Inoculate the activated recombinant strain into a 250mL shake flask containing 50mL of M9 modified liquid medium at a ratio of 1:100 (containing 100μg·mL -1 Chloramphenicol and 100 μg·mL -1 Kanamycin), cultured with shaking at 37°C and 180rpm. OD 600 When it reaches about 0.6, add 0.05% arabinose, after that, add arabinose and antibiotic every 12h, and stop the fermentation 48h after arabinose induction.

[0113] Take 1 mL of fermentation broth, centrifuge at 15,000 rpm for 10 min at 4°C, take the supernatant, and detect the fermentation product by high performance liquid chromatography. Gas chromatography( Figure 6 ) confirmed that 3-hydroxypropionic acid was obtained; and compared with the non-knockout bacteria, the production of 3-hydroxypropionic acid increased, and the production of by-product 1,3-propanediol decreased. The 3-hydroxypropionic acid production of the non-knocko...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com