Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Glycerol dehydratase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

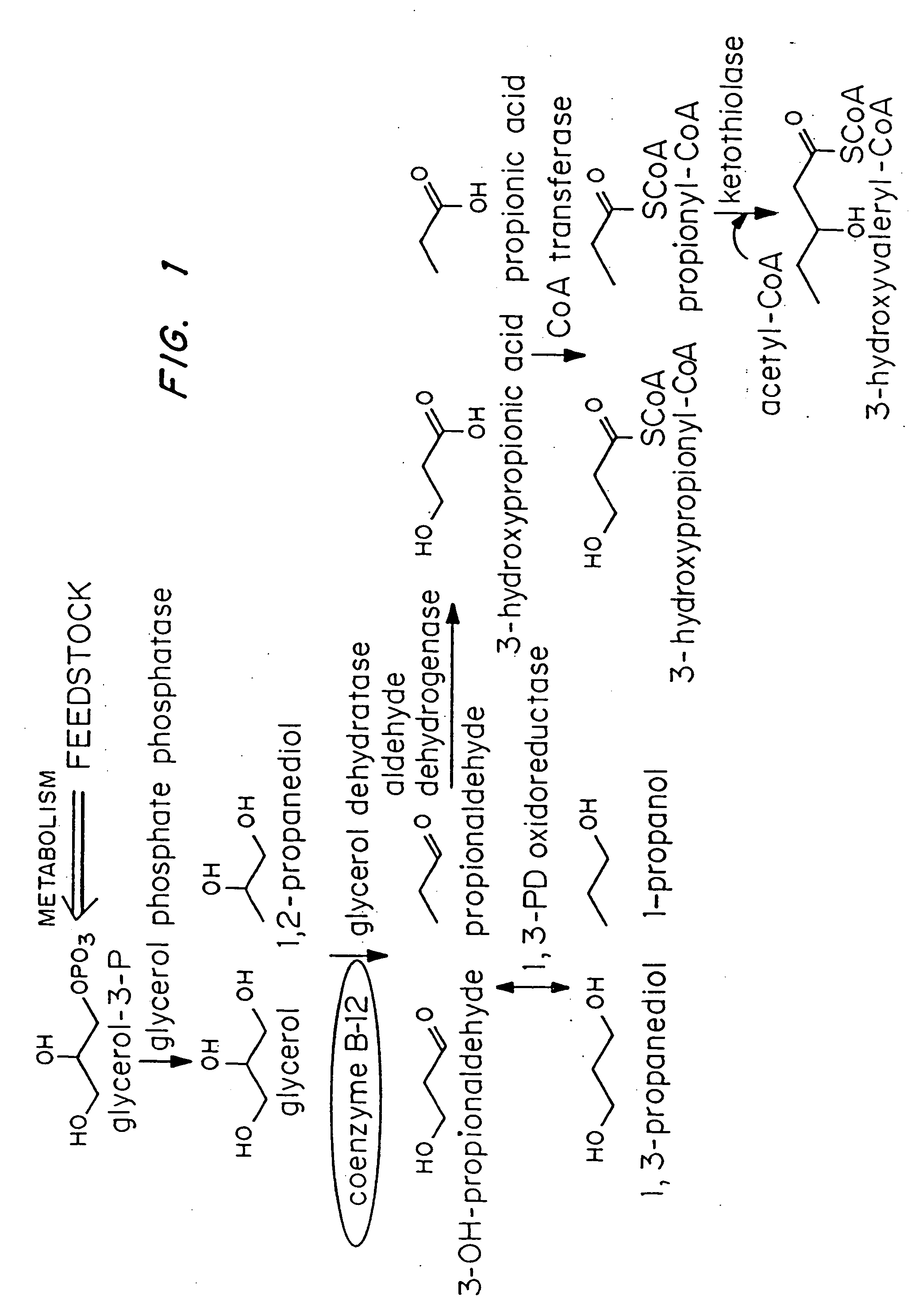

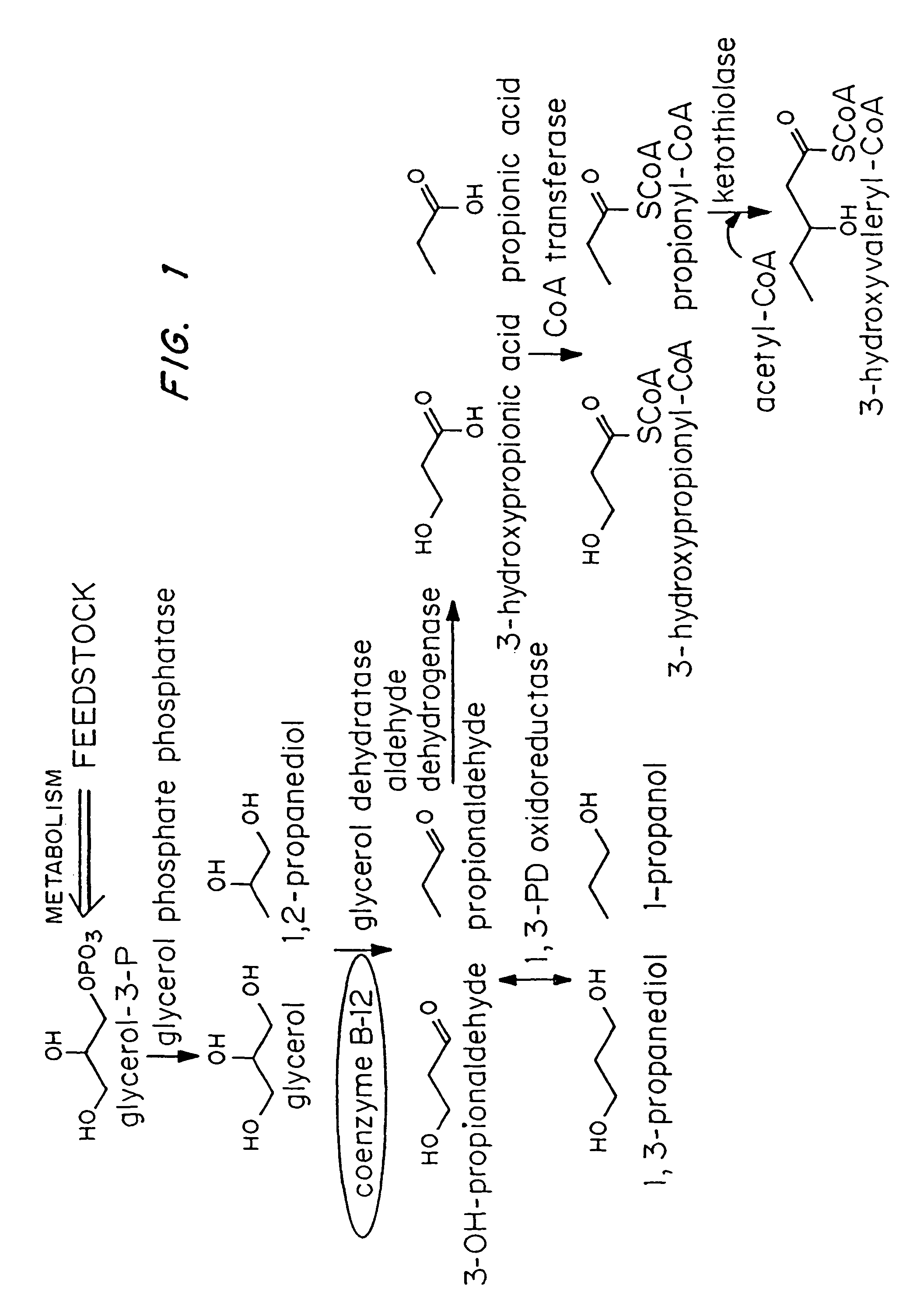

In enzymology, a glycerol dehydratase (EC 4.2.1.30) is an enzyme that catalyzes the chemical reaction glycerol ⇌ 3-hydroxypropanal + H₂O Hence, this enzyme has one substrate, glycerol, and two products, 3-hydroxypropanal and H₂O. This enzyme belongs to the family of lyases, specifically the hydro-lyases, which cleave carbon-oxygen bonds. The systematic name of this enzyme class is glycerol hydro-lyase (3-hydroxypropanol-forming).

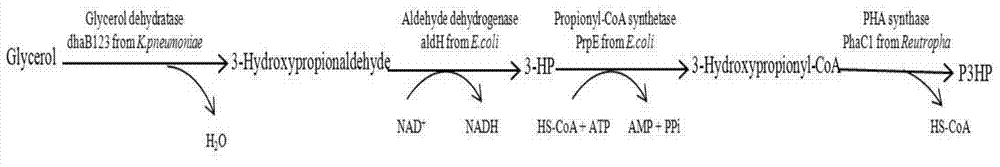

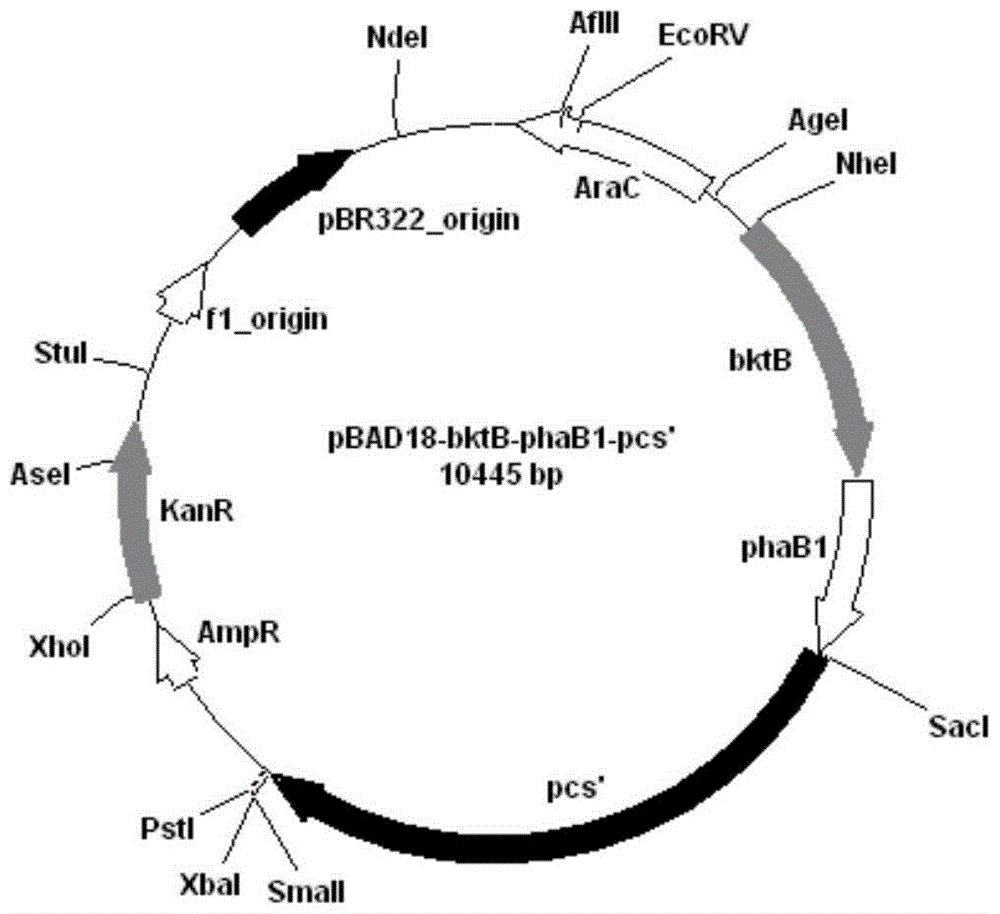

Polyhydroxyalkanoate production from polyols

InactiveUS20050239179A1Promote recoveryProduct can be usedBacteriaMicroorganism based processes3-Hydroxypropionic acidPropanoic acid

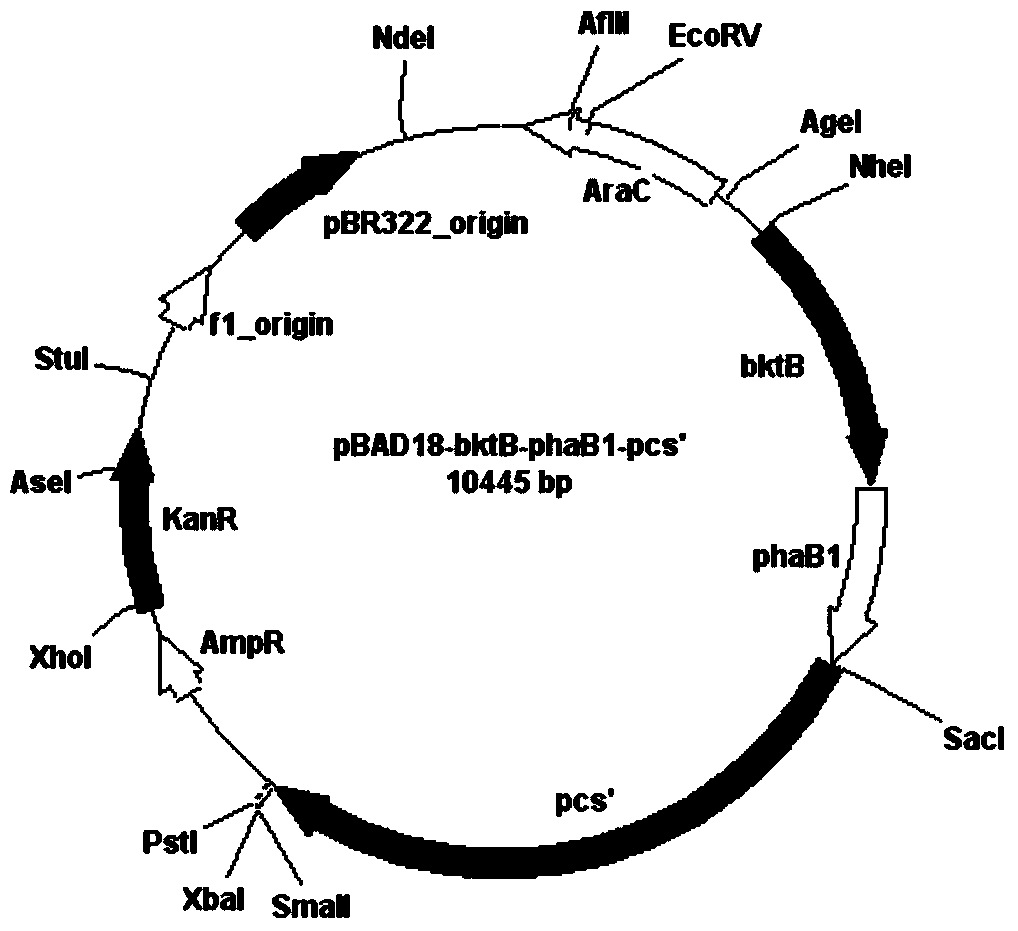

Organisms are provided which express enzymes such as glycerol dehydratase, diol dehydratase, acyl-CoA transferase, acyl-CoA synthetase β-ketothiolase, acetoacetyl-CoA reductase, PHA synthase, glycerol-3-phosphate dehydrogenase and glycerol-3-phosphatase, which are useful for the production of PHAs. In some cases one or more of these genes are native to the host organism and the remainder are provided from transgenes. These organisms produce poly (3-hydroxyalkanoate) homopolymers or co-polymers incorporating 3-hydroxypropionate or 3-hydroxyvalerate monomers wherein the 3-hydroxypropionate and 3-hydroxyvalreate units are derived from the enzyme catalysed conversion of diols. Suitable diols that can be used include 1,2-propanediol, 1,3 propanediol and glycerol. Biochemical pathways for obtaining the glycerol from normal cellular metabolites are also described. The PHA polymers are readily recovered and industrially useful as polymers or as starting materials for a range of chemical intermediates including 1,3-propanediol, 3-hydroxypropionaldehyde, acrylics, malonic acid, esters and amines.

Owner:CJ CHEILJEDANG CORP

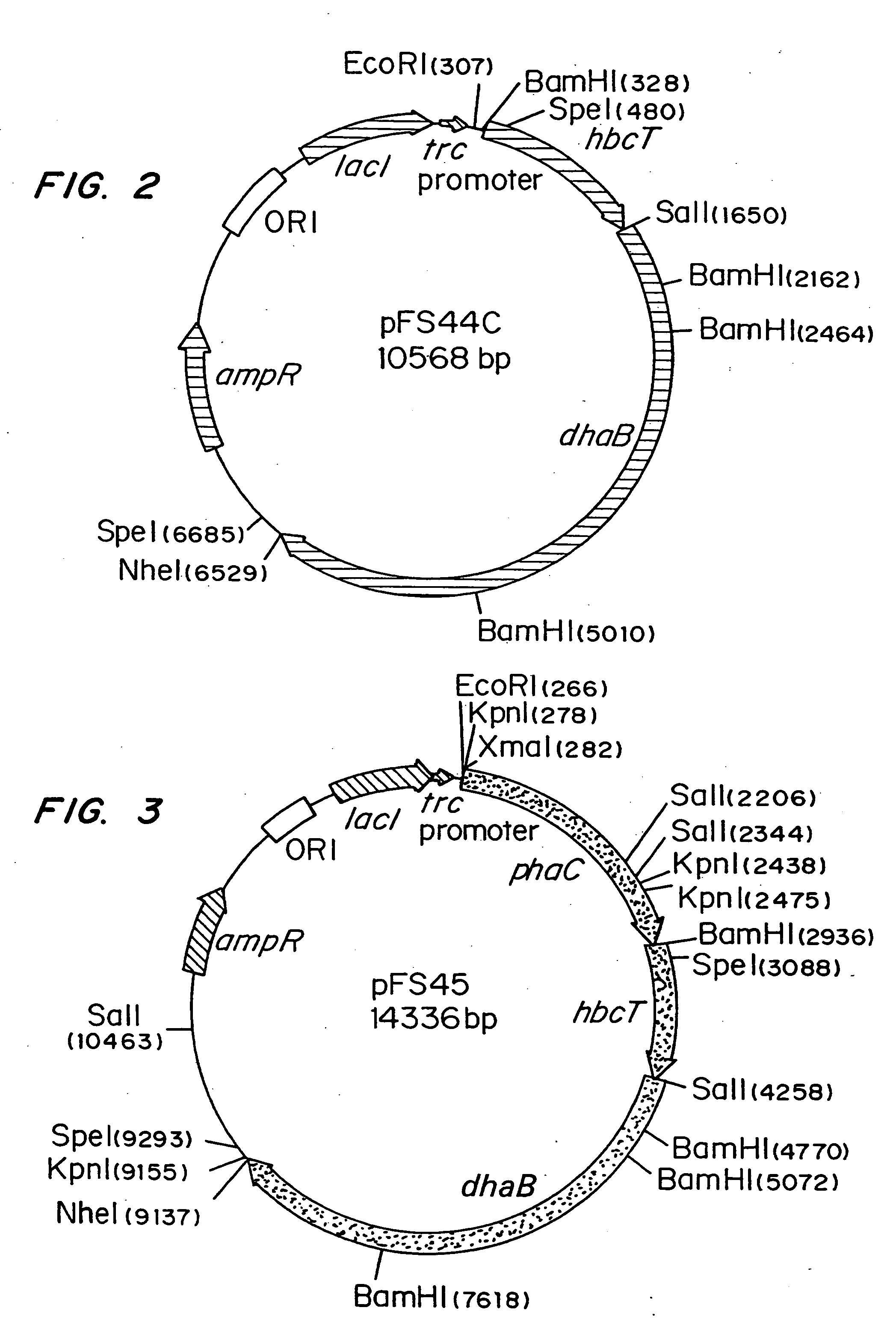

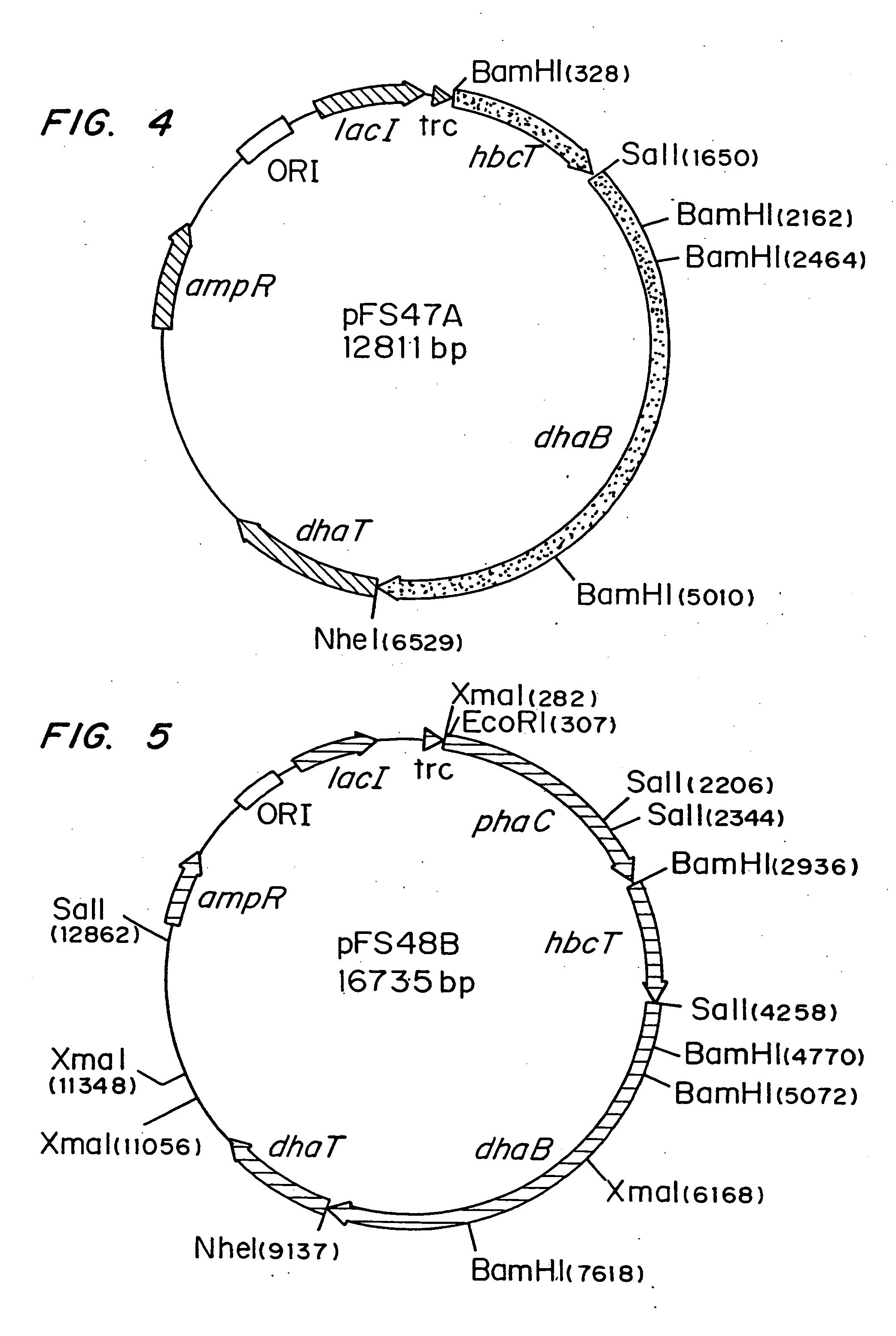

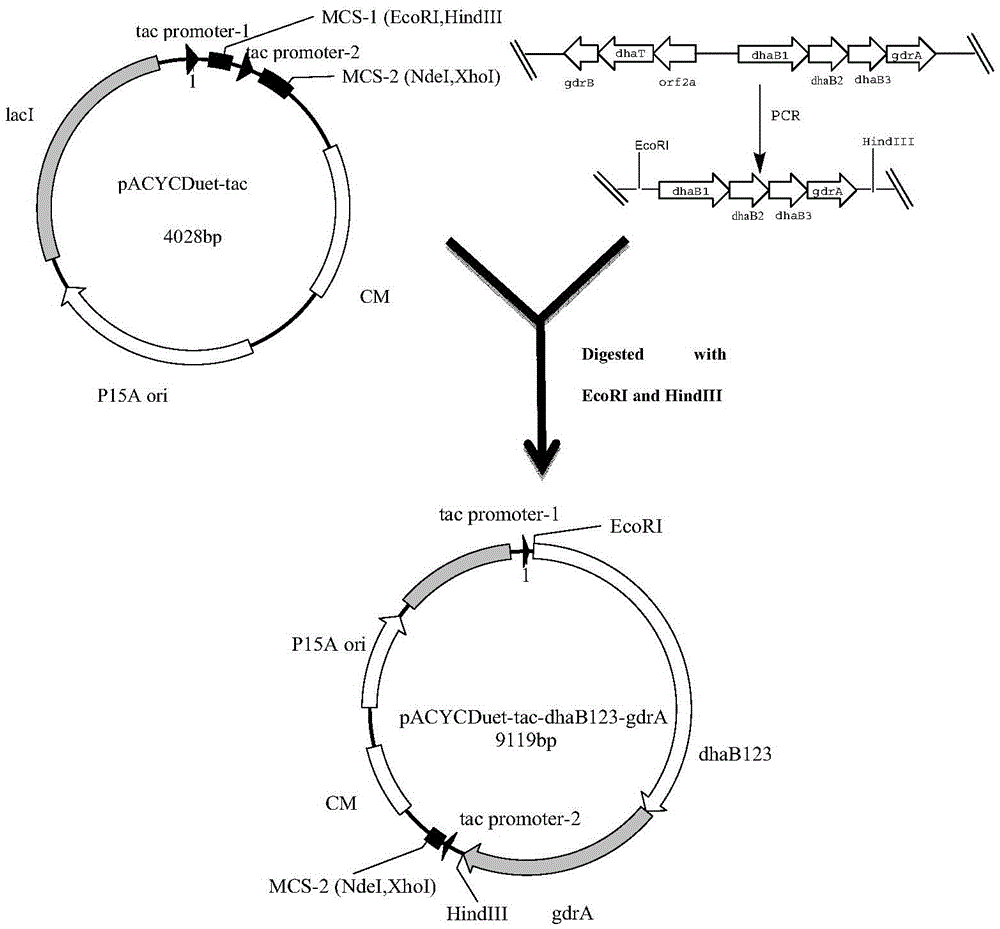

Method for the production of 1,3-propanediol by recombinant organisms comprising genes for coenzyme B12 synthesis

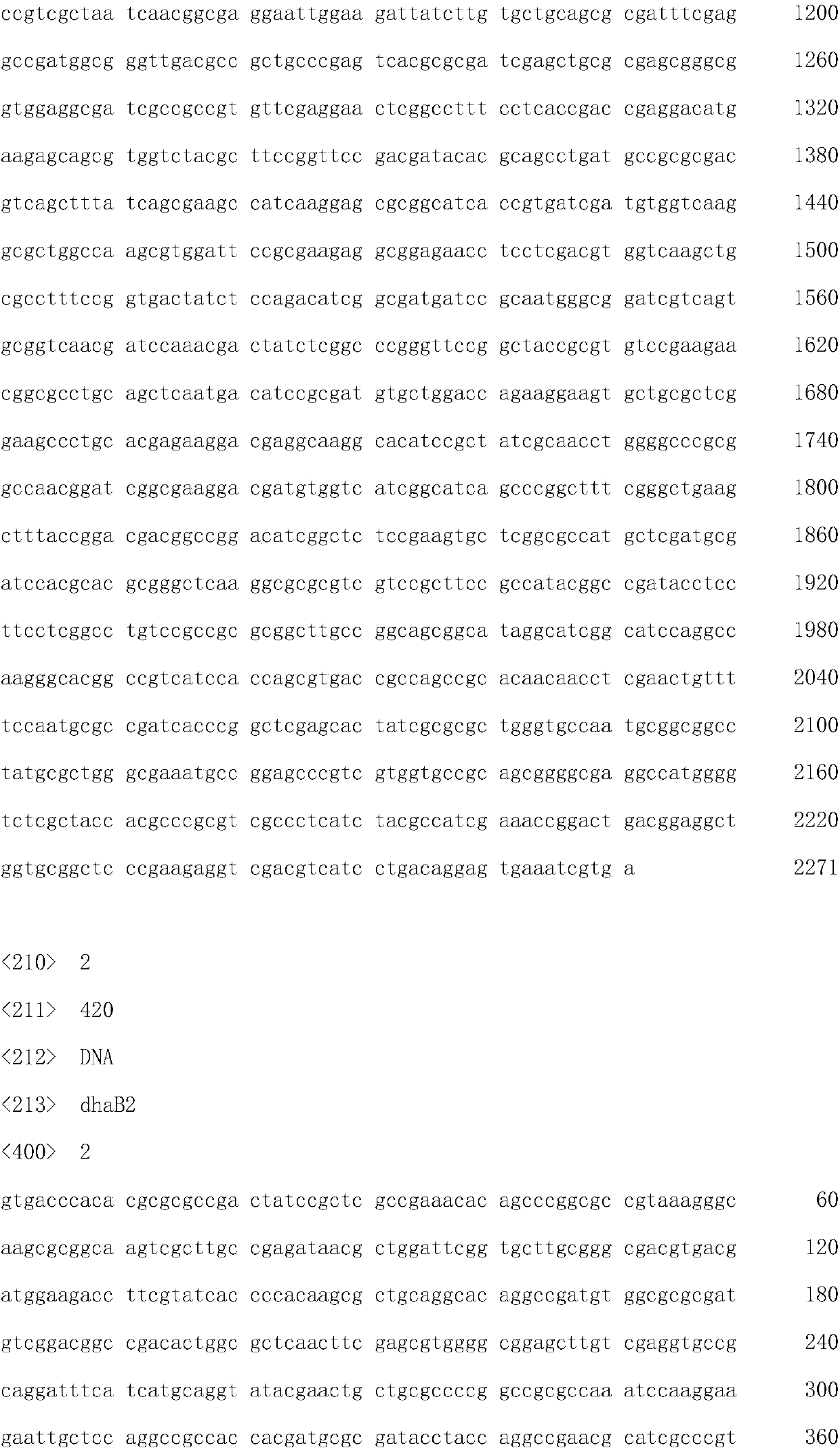

Recombinant organisms are provided comprising genes encoding aquacobalamin reductase, cob(II)alamin reductase, cob(I)alamin adenosyltransferase, glycerol dehydratase and 1,3-propanediol oxidoreductase activities useful for the production of 1,3-propanediol from a variety of carbon substrates. More specifically the following nucleotide sequences are provided: btuR, encoding the E. coli cob(I)alamin adenosyltransferase enzyme; cobA, encoding the Salmonella typhimurium cob(I)alamin adenosyltransferase enzyme; cobO, encoding the Pseudomonas denitrificans cob(I)alamin adenosyltransferase enzyme; dhaB1, encoding the α subunit of the Klebsiella glycerol dehydratase enzyme; dhaB2, encoding the β subunit of the Klebsiella glycerol dehydratase enzyme; dhaB3, encoding the γ subunit of the Klebsiella glycerol dehydratase enzyme; dhaT, encoding Klebsiella oxidoreductase enzyme; the yciK gene isolated from E. coli; the glucose isomerase promoter sequence from Streptomyces; and the N-terminal amino acid sequence for cob(II)alamin reductase from Pseudomonas denitrificans.

Owner:EI DU PONT DE NEMOURS & CO

Method For Producing 3-Hydroxypropionaldehyde

InactiveUS20080131945A1High conversion ratioHigh yieldOrganic compound preparationOrganic chemistry methodsGlycerolDiol Dehydratase

A method for producing 3-hydroxypropionaldehyde from glycerin in high conversion ratio is provided. The method is characterized by comprising a step of dehydrating glycerin using a microbial cell and / or a treated microbial cell containing diol dehydratase and / or glycerol dehydratase, and optionally diol dehydratase reactivating factor and / or glycerol dehydratase reactivating factor, under conditions so as to give a value (X / Y2) calculated by dividing a catalytic amount [X (U / g glycerin)] of diol dehydratase and / or glycerol dehydratase by square of glycerin concentration [Y (g / 100 ml)] within a range of 10 to 8,000, to produce 3-hydroxypropionaldehyde.

Owner:NIPPON SHOKUBAI CO LTD

Method for producing 1,3-propylene glycol through fermentation via recombinant microbes

PendingCN106906248AAddressing Biosecurity IssuesLow costMicroorganism based processesFermentationPhosphoric acidBacterial strain

The invention provides a method for producing 1,3-propylene glycol through fermentation via recombinant microbes. According to the invention, an endogenous dihydroxypropanone phosphatein phosphatase gene hdpA is over-expressed in Corynebacterium glutamicum to reinforce removal of phosphoric acid from dihydroxypropanone phosphatein so as to produce dihydroxypropanone; exogenous glycerol dehydrogenase is introduced to convert dihydroxypropanone into glycerin; and glycerin finally produces 1,3-propylene glycol under the action of exogenous glycerol dehydratase and an activator thereof and alcohol dehydrogenase. Corynebacterium glutamicum can use different cheap raw materials for fermentation, and cheap corn steep liquor can be used as a nutritional component to replace expensive yeast powder, so cost for raw materials is further reduced, and the problems in biosecurity and tolerance of the bacterial strain to a substrate and a product are overcome; and thalli obtained in the process of fermentation can be used as a product for a feed additive. The method provided by the invention produces few by-products and can further simplify the separating process of 1,3-propylene glycol.

Owner:GUANGDONG TSINGDA SMART BIOTECH CO LTD

Polyhydroxyalkanoate production from polyols

Organisms are provided which express enzymes such as glycerol dehydratase, diol dehydratase, acyl-CoA transferase, acyl-CoA synthetase β-ketothiolase, acetoacetyl-CoA reductase, PHA synthase, glycerol-3-phosphate dehydrogenase and glycerol-3-phosphatase, which are useful for the production of PHAs. In some cases one or more of these genes are native to the host organism and the remainder are provided from transgenes. These organisms produce poly (3-hydroxyalkanoate) homopolymers or co-polymers incorporating 3-hydroxypropionate or 3-hydroxyvalerate monomers wherein the 3-hydroxypropionate and 3-hydroxyvalerate units are derived from the enzyme catalysed conversion of diols. Suitable diols that can be used include 1,2-propanediol, 1,3 propanediol and glycerol. Biochemical pathways for obtaining the glycerol from normal cellular metabolites are also described. The PHA polymers are readily recovered and industrially useful as polymers or as starting materials for a range of chemical intermediates including 1,3-propanediol, 3-hydroxypropionaldehyde, acrylics, malonic acid, esters and amines.

Owner:CJ CHEILJEDANG CORP

Recombination klebsiella pneumonia capable of co-producing 3-HP and P3HP, and preparation method and application thereof

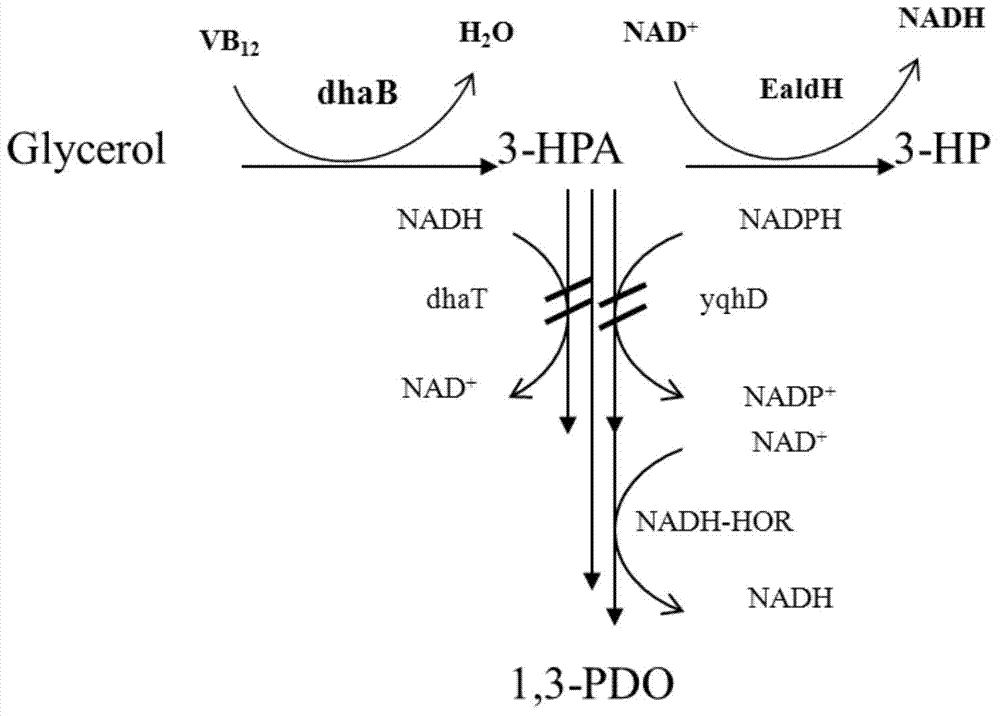

ActiveCN103497922AReduce synthesisIncrease productionBacteriaMicroorganism based processes3-Hydroxypropionic acidK pneumoniae

The invention discloses recombination klebsiella pneumonia capable of co-producing 3-HP and P3HP, and a preparation method and application thereof. The recombination bacterium is obtained by introducing glycerol dehydratase gene, glycerol dehydratase reactivation enzyme gene, aldehyde dehydrogenase gene, propionyl coenzyme A synthetase gene and polyhydroxyalkanoate synthetase gene into a host recombination klebsiella pneumonia in which 1, 3-propylene glycol oxidoreductase gene and aldehyde reductase / alcohol dehydrogenase gene are knocked out. According to the technical scheme, the production cost of 3-hydroxypropionic acid and poly(3-hydroxypropionic acid) is reduced, and 3-hydroxypropionic acid and poly(3-hydroxypropionic acid) can be synthesized at the same time by taking a same thallus as the host.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

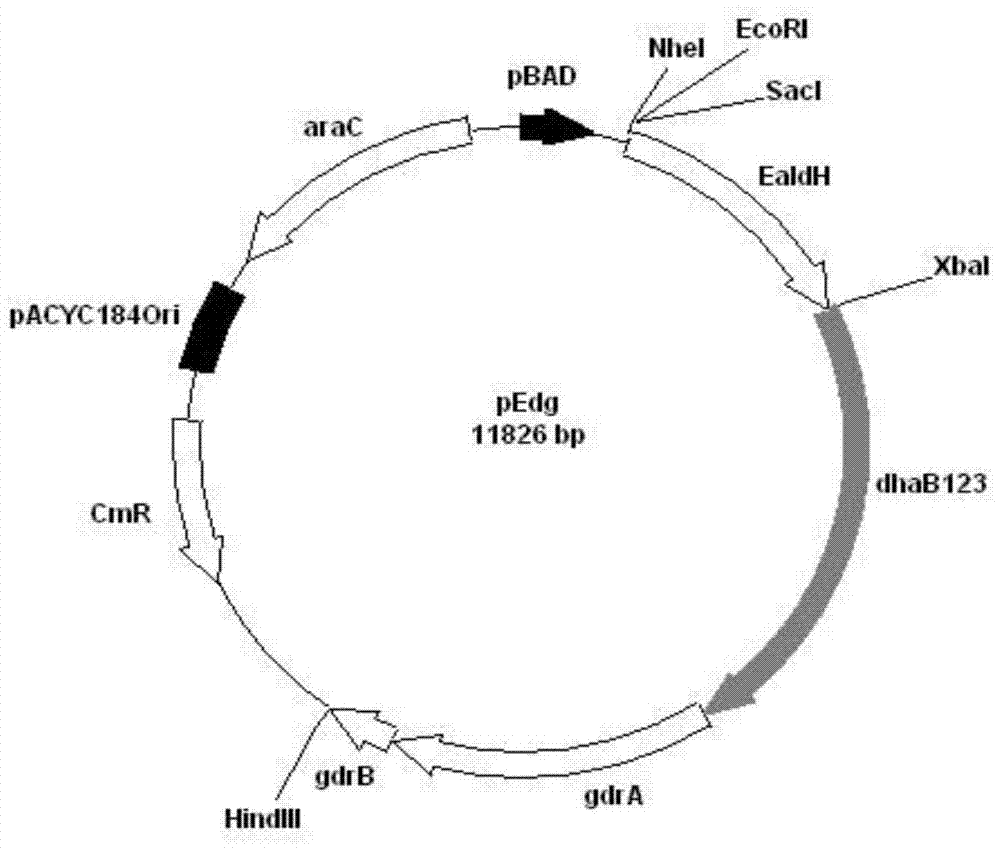

Recombinant Escherichia coli and application of recombinant Escherichia coli in synthesizing 3-hydroxypropionic acid

ActiveCN105567622AIncrease productionBacteriaMicroorganism based processesEscherichia coli3-Hydroxypropionic acid

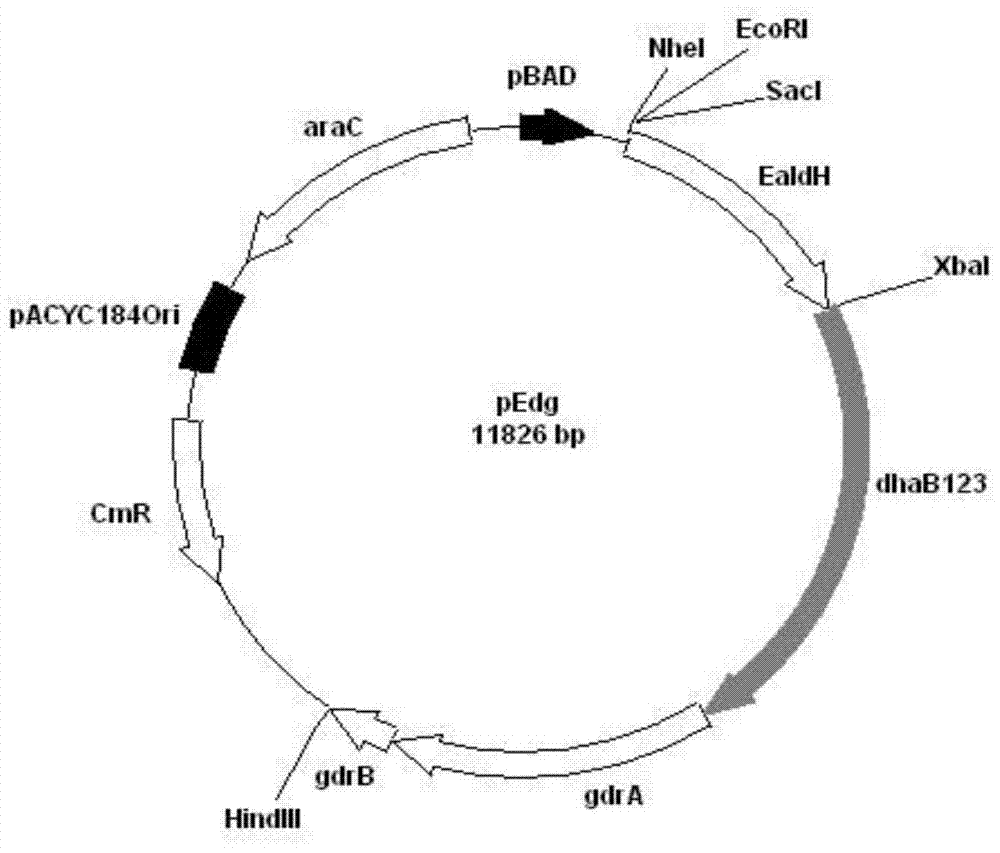

The invention discloses recombinant Escherichia coli and application of the recombinant Escherichia coli in synthesizing 3-hydroxypropionic acid. The recombinant Escherichia coli is formed by glycerol dehydratase genes dhaB123, glycerol dehydratase reactivating factor genes gdrA, alpha-oxoglutarate semialdehyde dehydrogenase mutant coding genes TUkgsadh and glycerol-3-phosphate dehydrogenase coding genes gpdl which are guided into host bacteria. By means of the gene knockout technique, the yield of byproduct 1,3-propylene glycol is reduced, and meanwhile, cofactors NAD+ of aldehyde dehydrogenase are regenerated. Thus, the yield of the 3-hydroxypropionic acid is improved by 1.5 times.

Owner:ZHEJIANG UNIV OF TECH

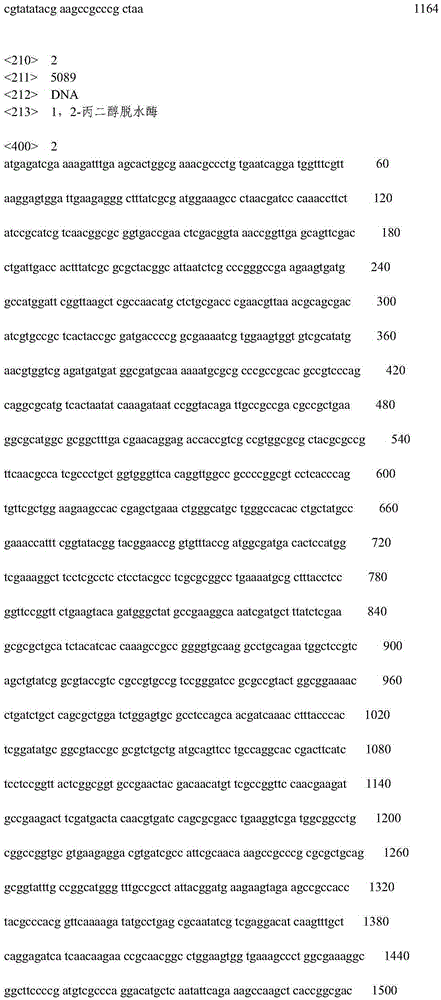

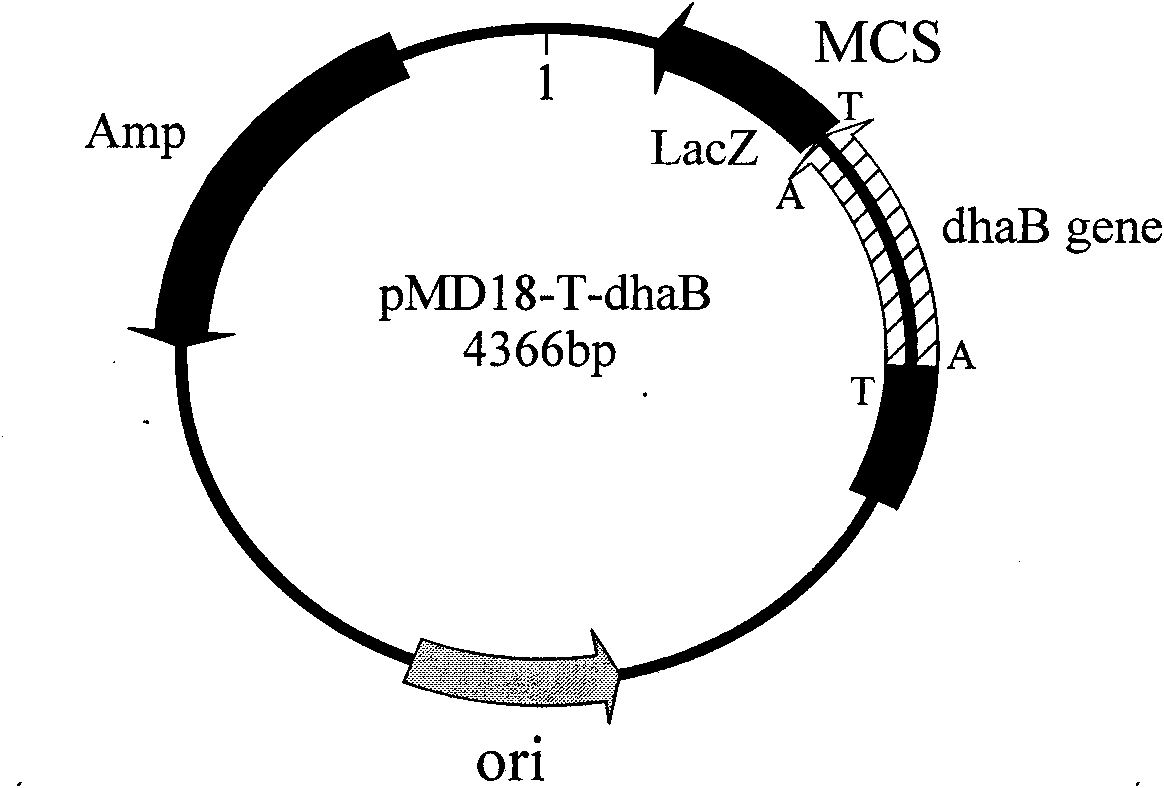

Clostridium perfringen glycerol dehydrase gene, and its 1,3-propylene glycol producing method

The invention relates to new glycerin dehydrase gene cloning and its expression in relative host. The enzyme gene is cloned form clostridium perfringens which can transform the glycerin into 3-hydroxyl propionic aldehyde at normal biological chemical reacting condition. Based on the invention, it can recombine the 1,3-propylene glycol redox enzyme relative gene into Escherichia coli to gain a new metabolism engineering fungus which can be transformed into 1, 3-propylene glycol by fermenting tapioca hydrolyzate, glucose, or glycerol.

Owner:南宁中诺生物工程有限责任公司

Method for co-production of 1,3-propanediol and glutamic acid through recombined corynebacterium glutamicum

ActiveCN105400831ALow costTake advantage ofBacteriaMicroorganism based processesGlycerolProcessing cost

The invention discloses a method for co-production of 1,3-propanediol and glutamic acid through recombined corynebacterium glutamicum. In order to obtain the recombined corynebacterium glutamicum, the method comprises the following steps that 1, the encoding gene of 1,3-propanediol dehydrogenase is introduced into the corynebacterium glutamicum; 2, 1,2-propanediol dehydratase and the encoding gene of an activity factor of the 1,2-propanediol dehydratase are introduced into the corynebacterium glutamicum, or glycerol dehydratase and the encoding gene of an activity factor of the glycerol dehydratase are introduced into the corynebacterium glutamicum. By the adoption of the method, the corynebacterium glutamicum is used as a production strain, so that the problem of biological safety is solved, and the thallus processing cost is lowered. According to the method, in the production process that the glutamic acid and the 1,3-propanediol are fully coupled, reducing power can be fully utilized. The yield of the glutamic acid is not lowered, and meanwhile extremely-high mass conversion rate of the 1,3-propanediol to glycerinum is obtained. Moreover, the number of reaction by-products is small, and the separating process is simple and convenient.

Owner:GUANGDONG TSINGDA SMART BIOTECH CO LTD

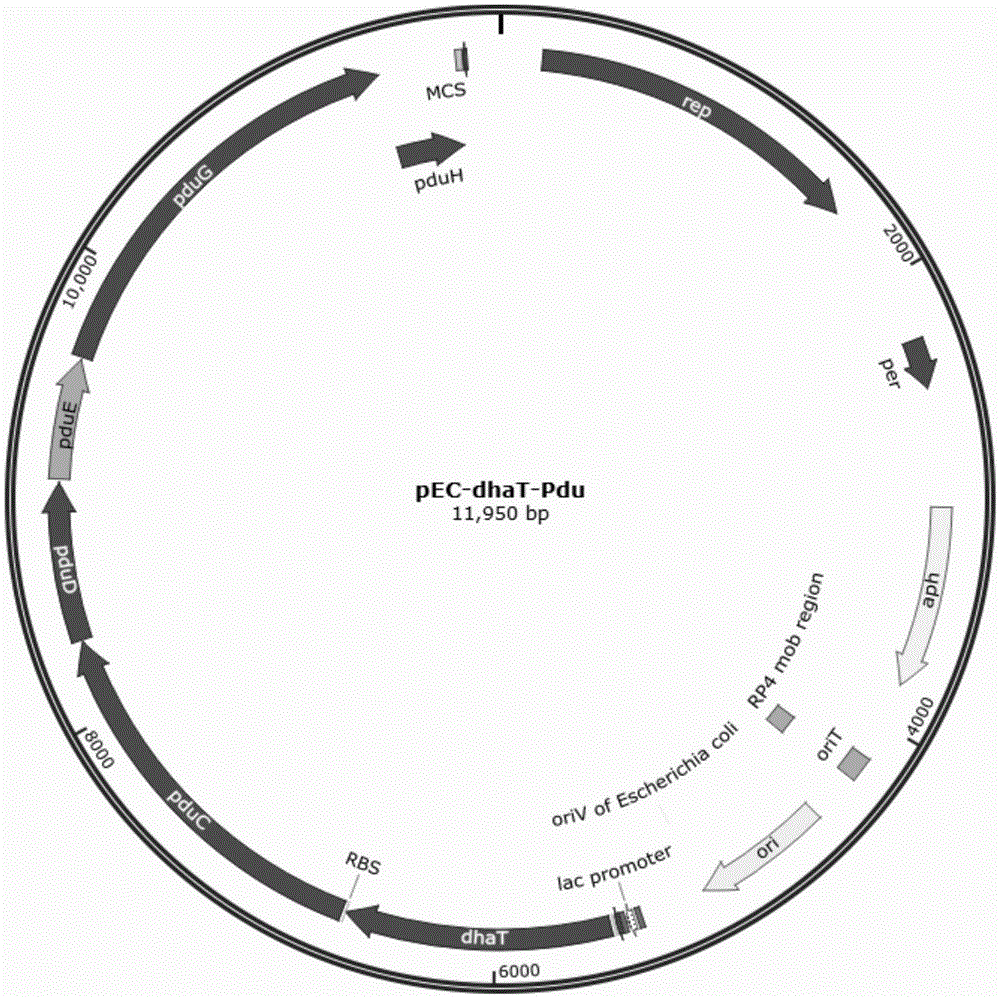

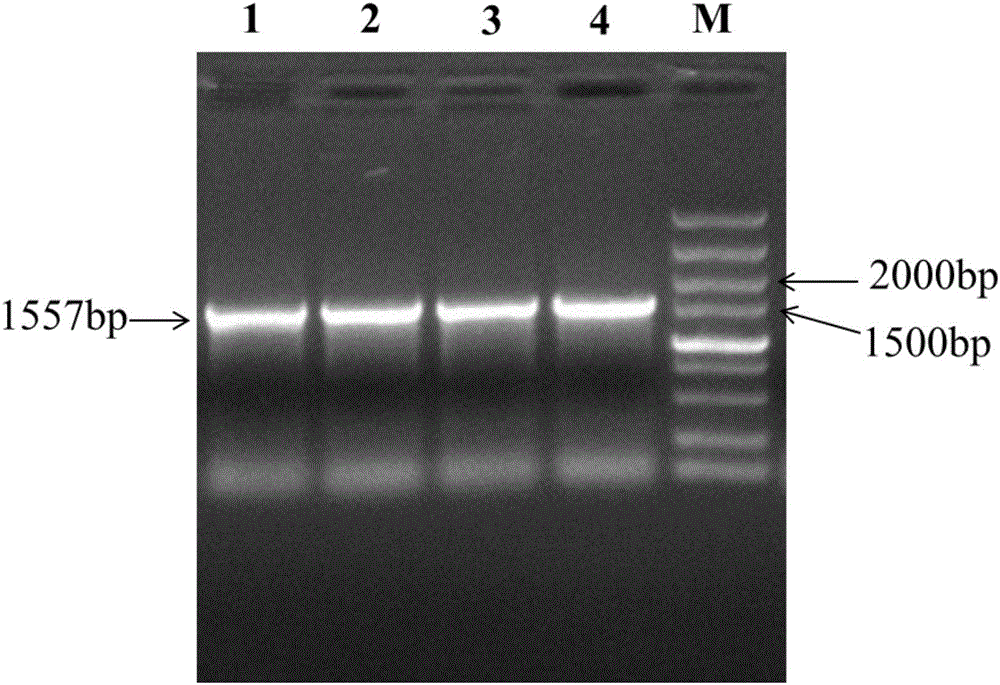

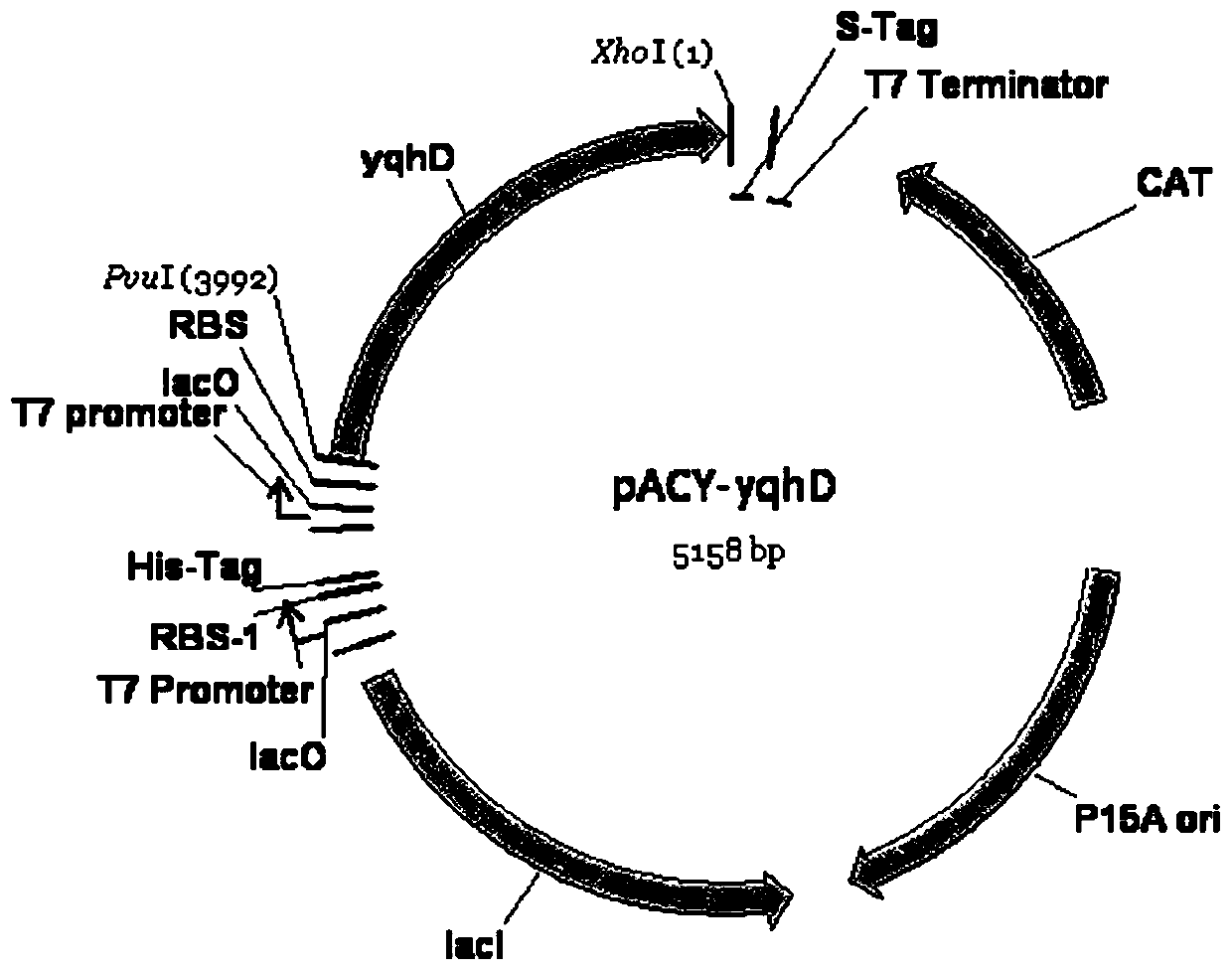

Glycerol dehydratase gene, vector, engineering bacteria and application thereof

The invention provides a glycerol dehydratase gene for coding glycerol dehydratase, a recombinant vector containing the gene, a recombinant gene engineering bacteria obtained by the transformation ofthe recombinant vector and an application thereof for preparing the recombinant glycerol dehydratase. The glycerol dehydratase gene can obtain an intracellular expression recombinant plasmid or a secretory expression recombinant plasmid by connection and construction with an expression vector, then the intracellular expression recombinant plasmid or the secretory expression recombinant plasmid isrespectively and correspondingly transformed to an escherichia coli strain and obtains the recombinant escherichia coli which contains recombinant glycerol dehydratase, and can recombine the escherichia coli to carry out biocatalysis and transformation for an enzyme source. As an enzyme for transformation, the recombinant glycerol dehydratase can respectively adopt glycerol, 1, 2-propylene glycolor alcohol as primer and carry out transformation reaction so as to prepare corresponding 3-hydroxypropionaldehyde, propionaldehyde or aldehyde and the like.

Owner:ZHEJIANG UNIV OF TECH

Method for the production of 1,3-propanediol by recombinant organisms compising for vitamin B12 transport

Recombinant organisms are provided comprising genes encoding genes encoding glycerol dehydratase, 1,3-propanediol, 1,3-propanediol oxidoreductase, a gene encoding vitamin B12 receptor precursor (BtuB), a gene encoding vitamin B12 transport system permease protein (BtuC) and a gene encoding vitamin B12 transport ATP-binding protein (BtuD). The recombinant microorganism is contacted with a carbon substrate and 1,3-propanediol is isolated from the growth media.

Owner:EI DU PONT DE NEMOURS & CO +1

3-hydracrylic-acid-producing recombinant Corynebacterium glutamicum strain, and construction method and application thereof

ActiveCN105950529ASolving Tolerance IssuesAddress biosecurityBacteriaMicroorganism based processes3-Hydroxypropionic acidGlycerol

The invention relates to a 3-hydracrylic-acid-producing recombinant Corynebacterium glutamicum strain, and a construction method and application thereof. The construction method of the recombinant Corynebacterium glutamicum strain comprises the following steps: in a Corynebacterium glutamicum strain, overexpressing an endogenous dihydroxyacetone phosphate phosphatase gene hdpA, and overexpressing a glyceroldehydrogenase gene gldA, a glycerol anhydrase and activating factor gene pduCDEGH and a 3-hydroxypropylaldehyde dehydrogenase gene aldH. When the recombinant strain is used for producing 3-hydracrylic acid by fermentation, the Corynebacterium glutamicum strain can perform fermentation by using different cheap raw materials, thereby further lowering the raw material cost. The 3-hydracrylic-acid-producing recombinant Corynebacterium glutamicum strain solves the problems of biosafety and acid tolerance. The strain in the fermentation process can be used in a feed additive as a product. The method can generate fewer byproducts, so that the separation process of the end product 3-hydracrylic acid is simplified.

Owner:GUANGDONG TSINGDA SMART BIOTECH CO LTD

B12 dependent dehydratases with improved reaction kinetics

InactiveUS20080293119A1Improve stabilitySugar derivativesMicrobiological testing/measurementOligonucleotide-Directed MutagenesisPropanediol

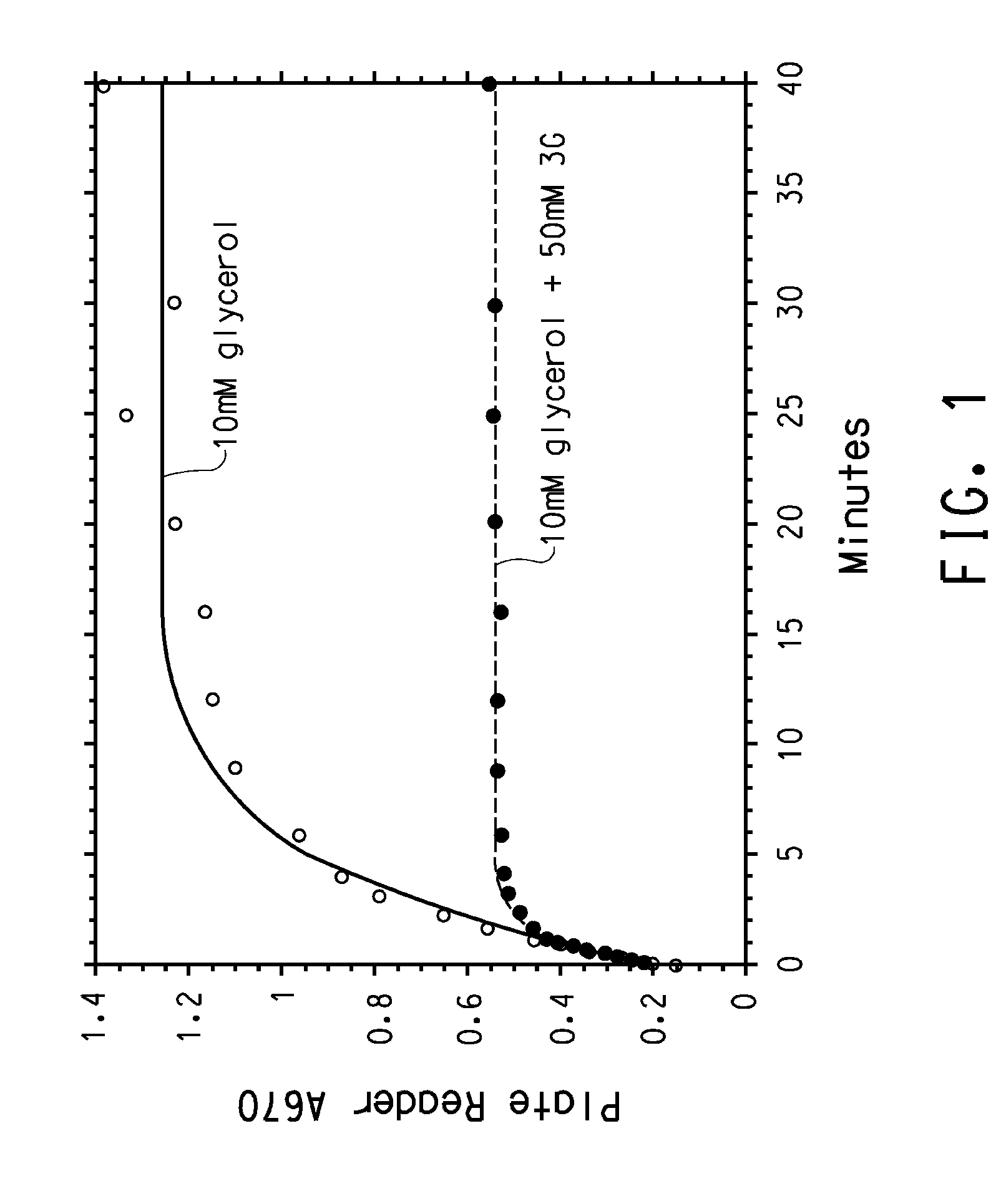

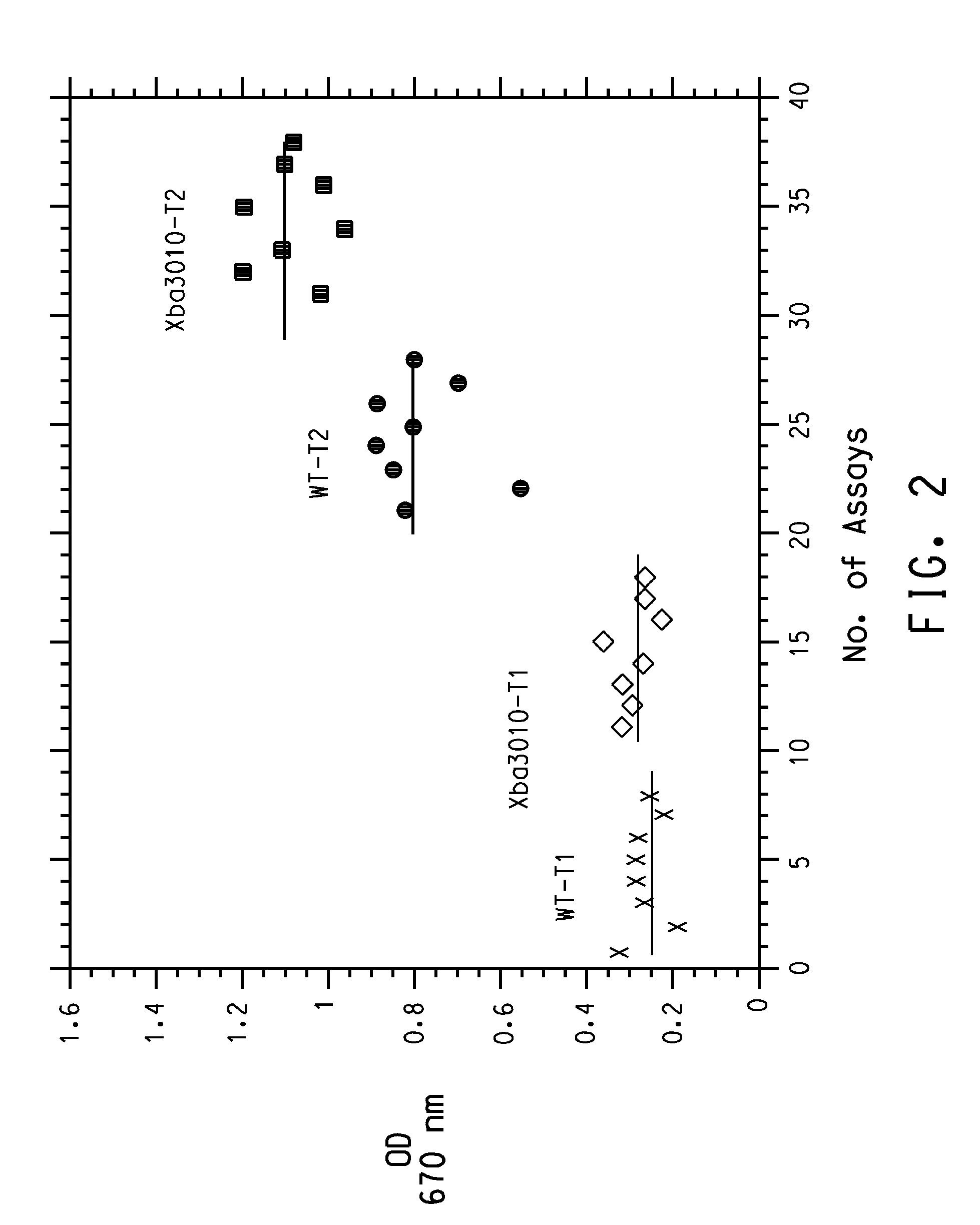

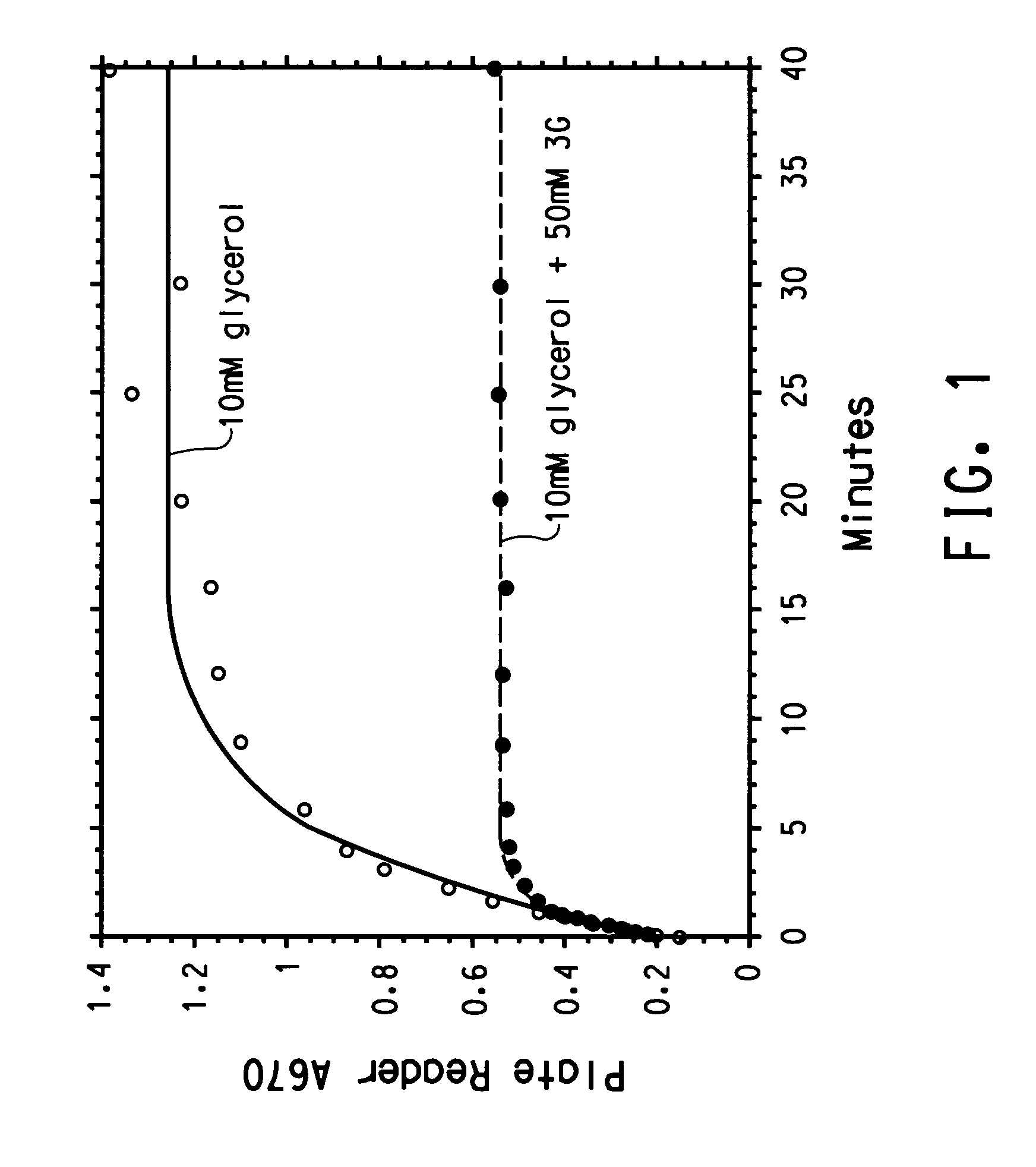

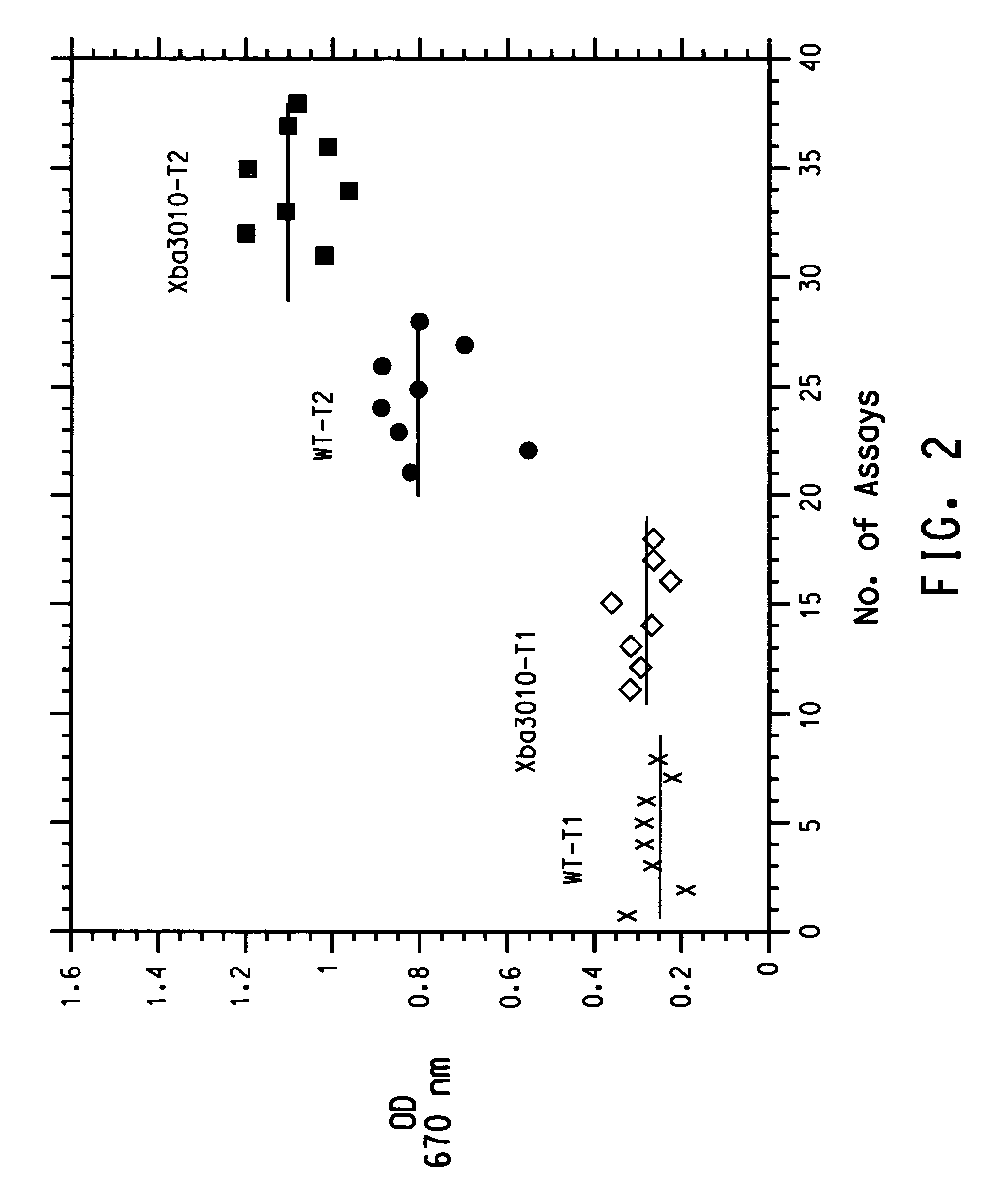

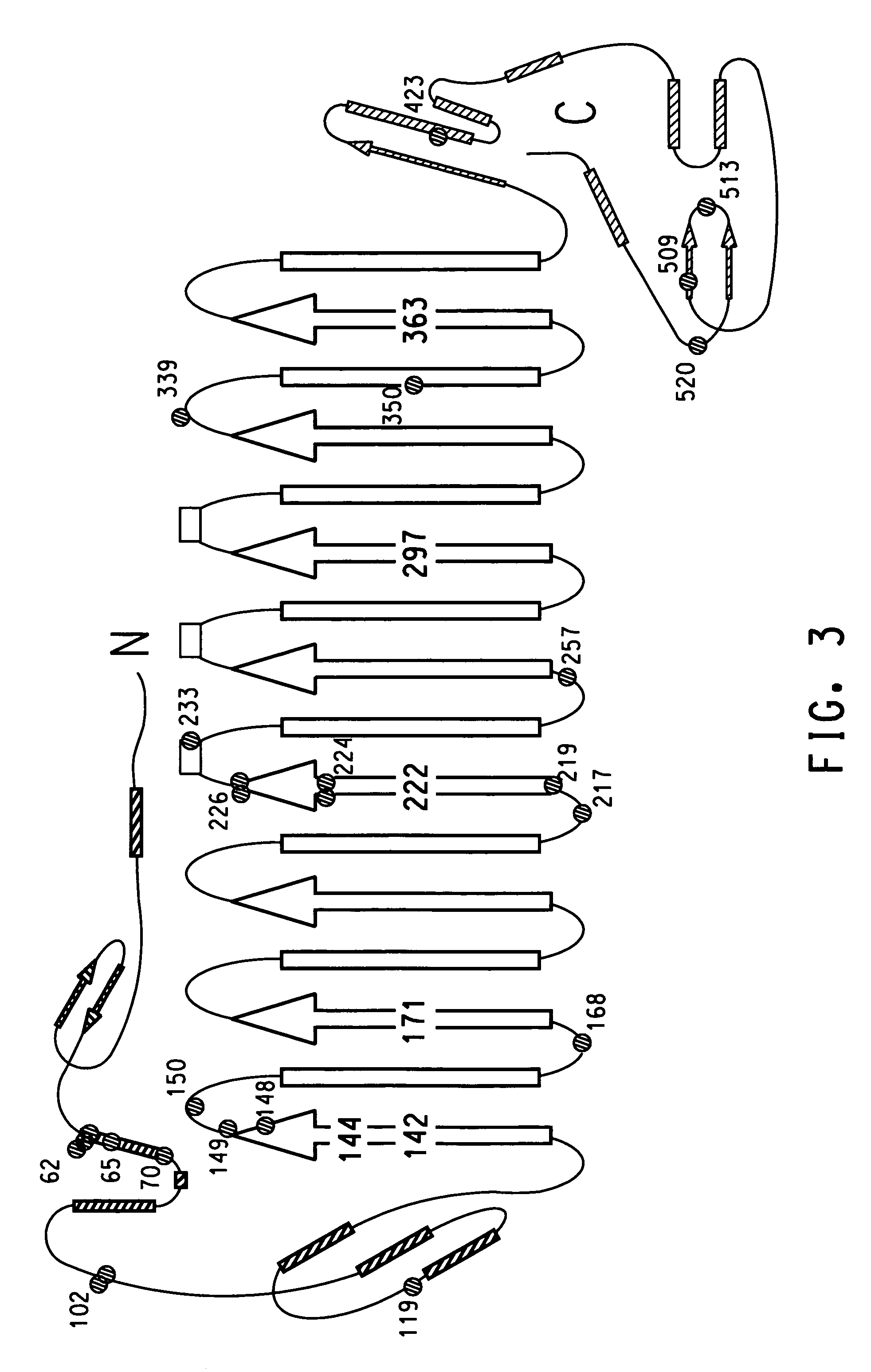

Sequences of B12-dependent dehydratases with improved reaction kinetics are presented. Use of these B12-dependent dehydratases reduce the rate of the enzyme's suicide inactivation in the presence of glycerol and 1,3-propanediol. The enzymes were created using error-prone PCR and oligonucleotide-directed mutagenesis to target the DhaB1 gene, which encodes the α-subunit of glycerol dehydratase. Mutants with improved reaction kinetics were rapidly identified using high throughput assays.

Owner:EI DU PONT DE NEMOURS & CO

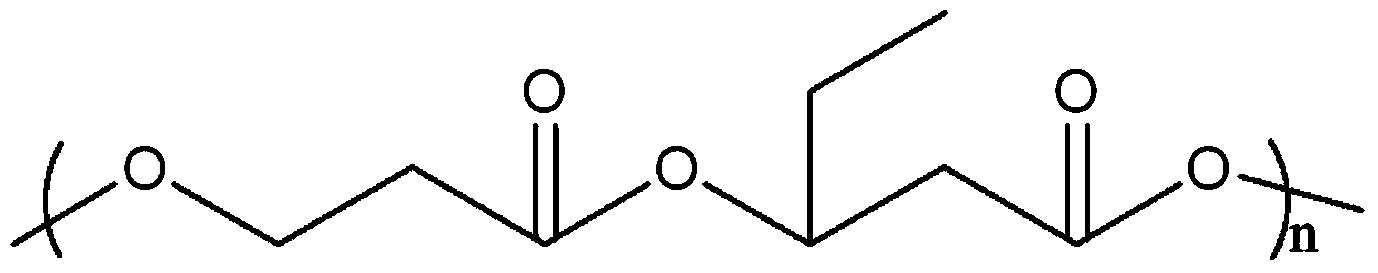

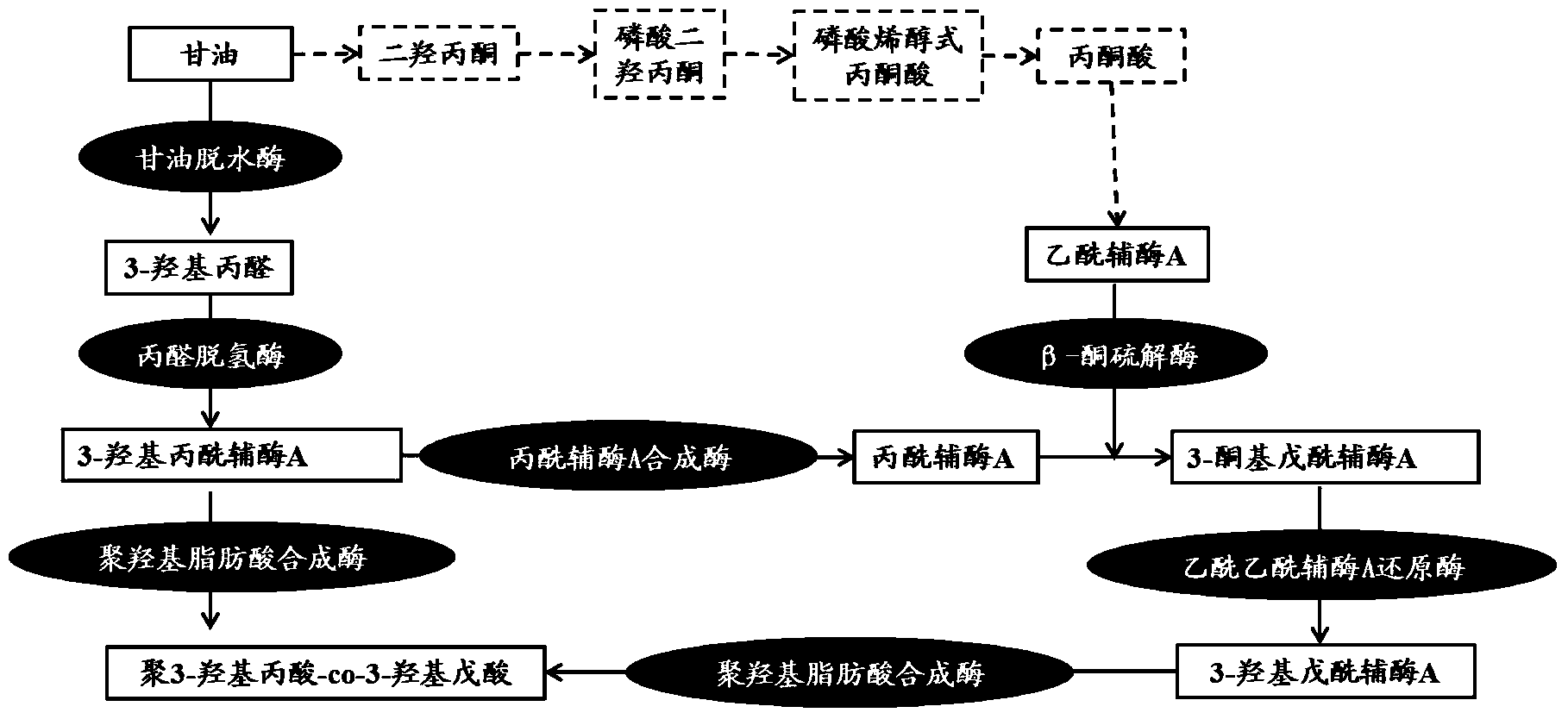

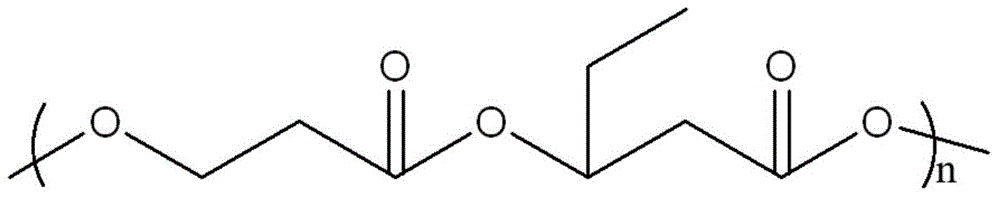

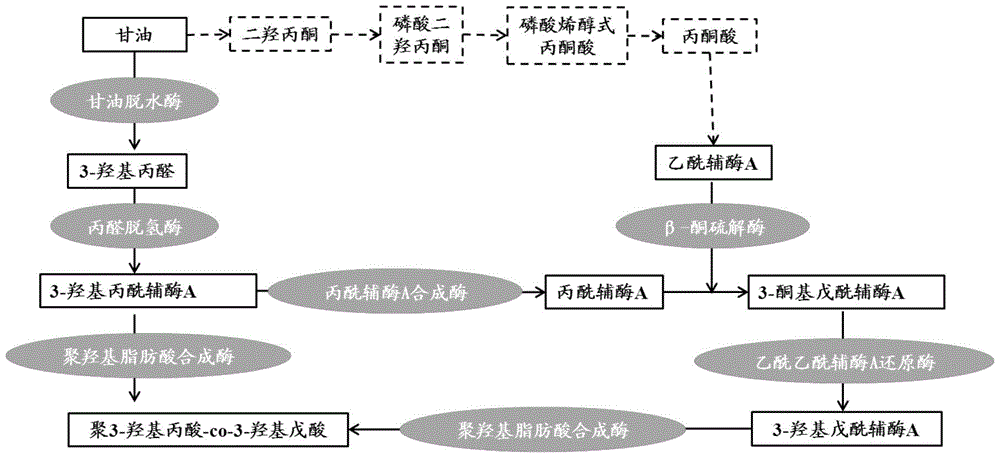

Poly-3-hydroxy propionic acid copolymer and production method thereof

ActiveCN104046659AHigh melting pointReduce crystallinityBacteriaMicroorganism based processes3-Hydroxypropionic acidPropanoic acid

The invention discloses a poly-3-hydroxy propionic acid copolymer and a production method thereof and belongs to the technical field of genetic engineering. According to the poly-3-hydroxy propionic acid copolymer and the production method thereof, a glycerol dehydratase gene and a glycerol dehydratase re-activating enzyme gene are integrated with a host strain genome by a gene integration technology, a polyhydroxy fatty acid synthase gene, a propionaldehyde dehydrogenase gene, a beta-ketoacyl coenzyme A thiolase gene, an acetoacetyl coenzyme A reductase gene and a propionyl coenzyme A synthetase gene are introduced, and a recombinant gene engineering strain has the ability of biologically synthesizing poly-3-hydracrylic acid-co-3-hydroxyvaleric acid. According to the poly-3-hydroxy propionic acid copolymer and the production method thereof, the poly-3-hydracrylic acid-co-3-hydroxyvaleric acid is obtained in a biosynthesis manner for the first time; compared with poly-3-hydracrylic acid, the obtained poly 3-hydracrylic acid-co-3-hydroxyvaleric acid has a higher melting point and lower crystallinity, has good degradability and can serve as a packaging material, a medical implant material, a drug sustained-release material and an electrochemical material.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

B12 -dependent dehydratases with improved reaction kinetics

InactiveUS7410754B1Facilitated reaction kineticsMicrobiological testing/measurementFermentationOligonucleotide-Directed MutagenesisMutant

Sequences of B12-dependent dehydratases with improved reaction kinetics are presented. Use of these B12-dependent dehydratases reduce the rate of the enzyme's suicide inactivation in the presence of glycerol and 1,3-propanediol. The enzymes were created using error-prone PCR and oligonucleotide-directed mutagenesis to target the DhaB1 gene, which encodes the α-subunit of glycerol dehydratase. Mutants with improved reaction kinetics were rapidly identified using high throughput assays.

Owner:EI DU PONT DE NEMOURS & CO

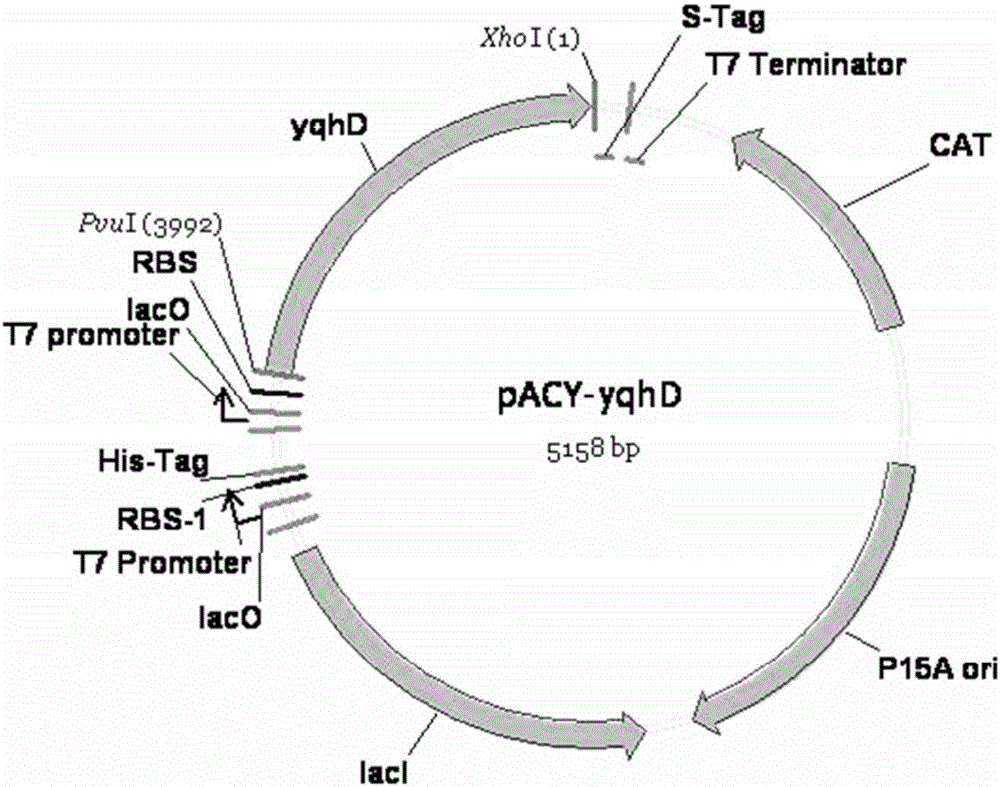

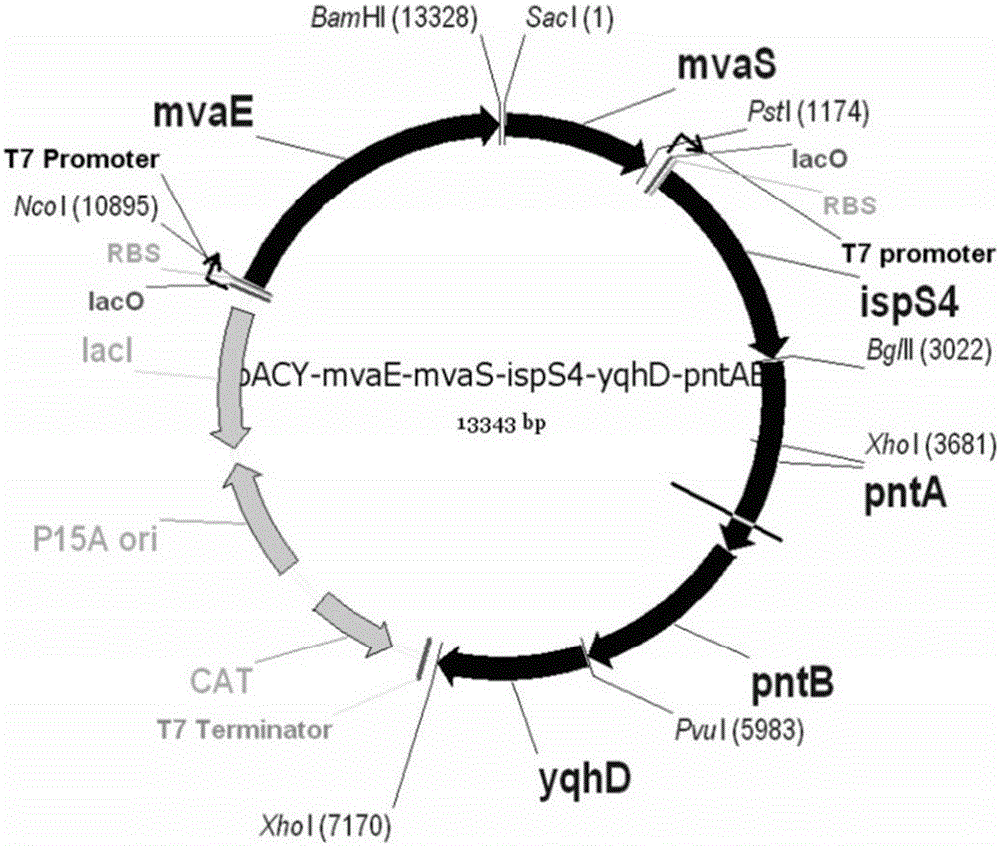

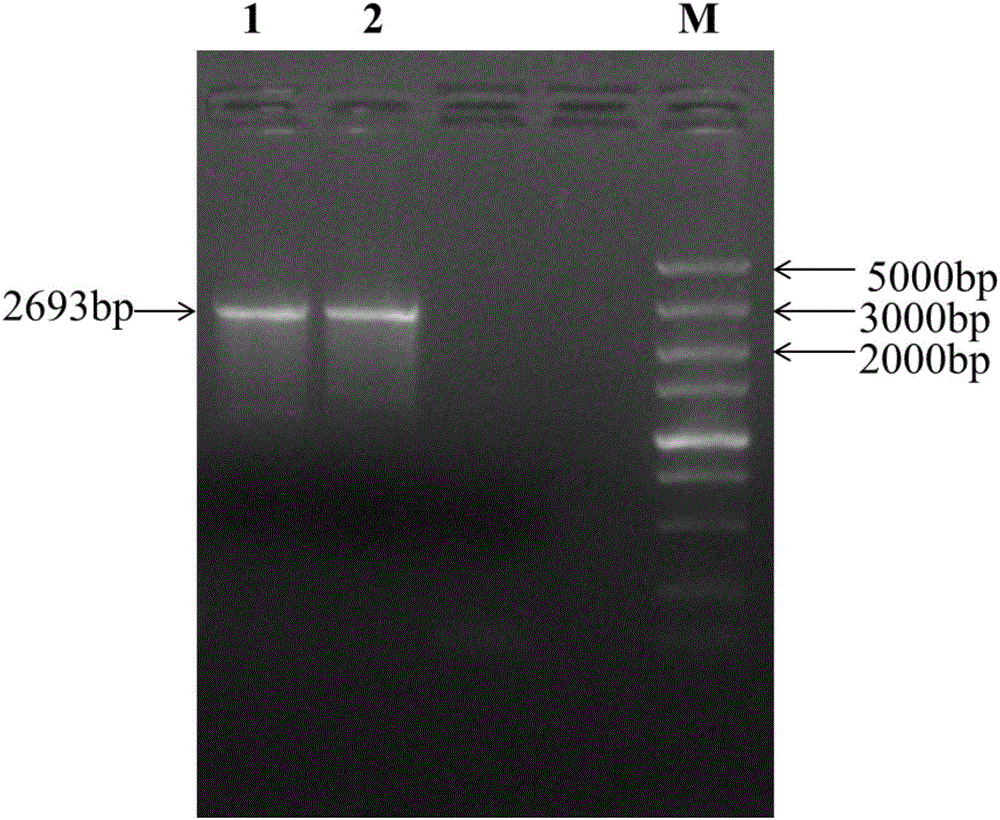

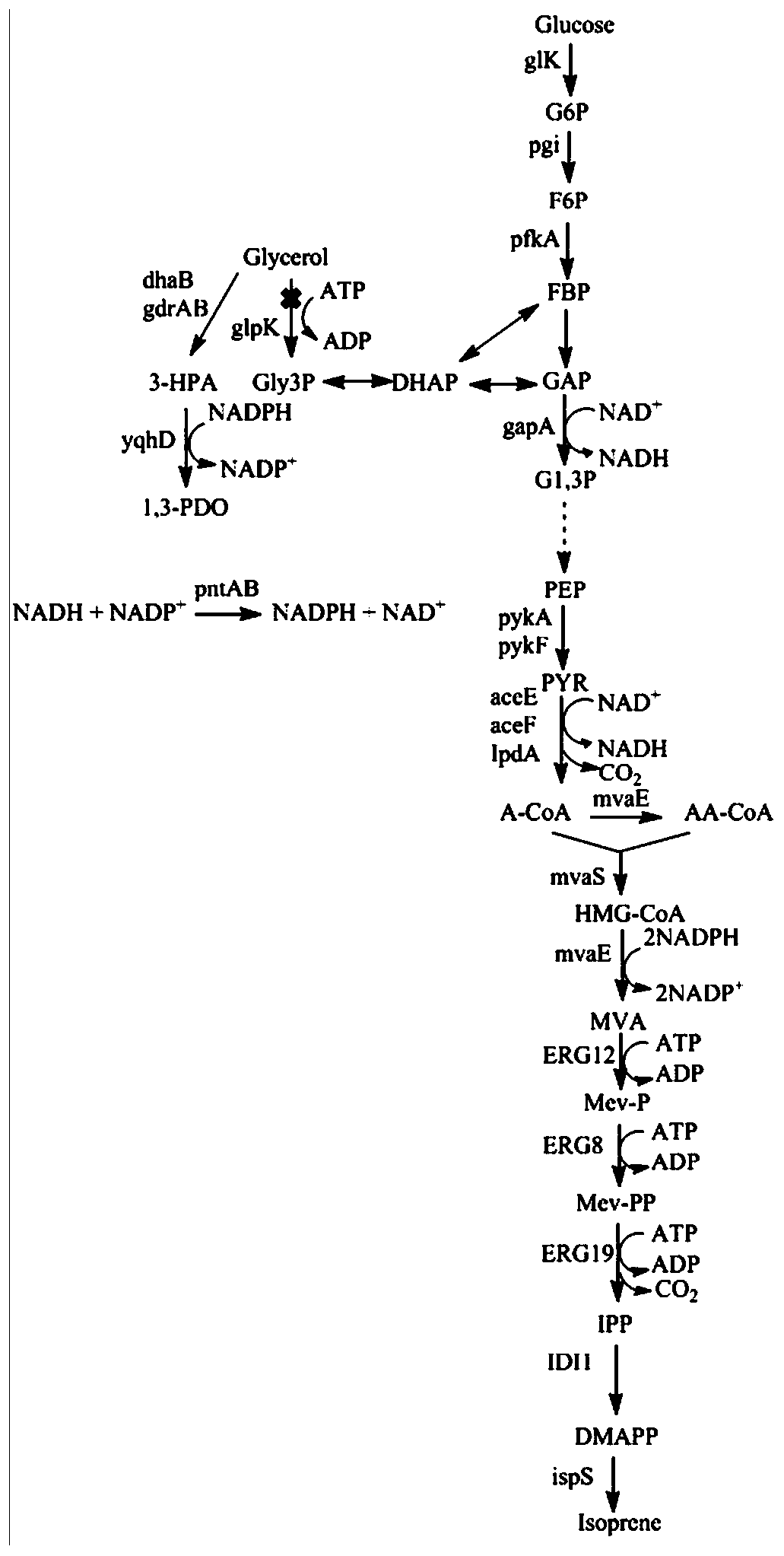

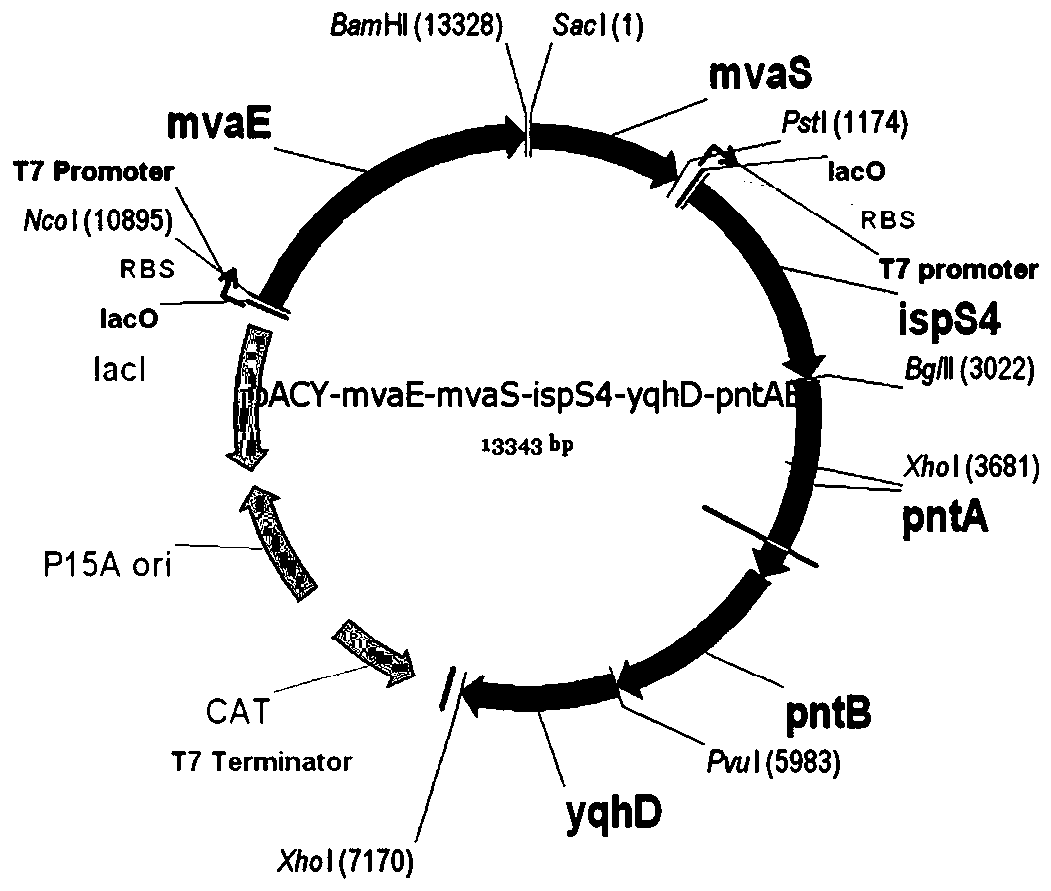

Genetic engineering strain capable of coproducing isoprene and 1,3-propylene glycol and establishment method and application thereof

ActiveCN106350476AReduce consumptionBalance metabolismBacteriaMicroorganism based processesBiotechnologyHMG-CoA reductase

The invention discloses a genetic engineering strain capable of coproducing isoprene and 1,3-propylene glycol and an establishment method and application thereof, and belongs to the technical field of genetic engineering. In the genetic engineering strain, a glycerol dehydratase gene and a glycerol dehydratase gene reactivating enzyme gene are integrated, a glycerol kinase gene is knocked out, and HMG-CoA reductase, HMG-CoA synthetase, mevalonate kinase, phosphomevalonate kinase, pyrophosphomevalonate decarboxylase, IPP isomerase, isoprene synthetase, aldehyde reductase and transhydrogenase are overexpressed. According to the invention, through genetic engineering, a metabolic way capable of coproducing the isoprene and the 1,3-propylene glycol is successfully established in escherichia coli; by the establishment method, redox cofactors in cells of the genetic engineering strain are metabolized in a balanced way, and the yield in coproducing the isoprene and the 1,3-propylene glycol through glucose and glycerol fermentation is increased.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

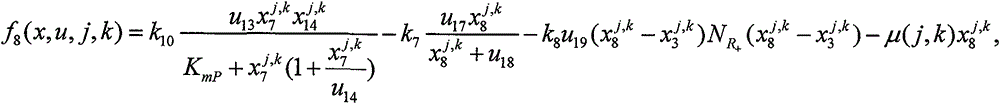

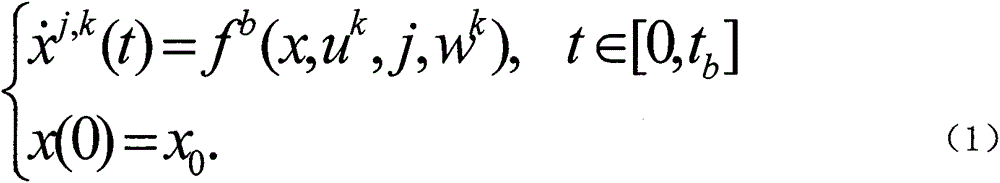

Path particle swarm optimization algorithm of gene controlled nonlinear dynamical system

ActiveCN105912830AImprove stabilityImprove computing efficiencyInformaticsSpecial data processing applicationsGlycerolNonlinear dynamical systems

The invention relates to a path particle swarm optimization algorithm of a gene controlled nonlinear dynamical system. Ordering x(t)=(x1,x2, and the like,x14) <T> belonging to a set of R<14> to be a state variable, and an admissible set is a formula, wherein x1, x2, and the like, x5 respectively represent extracellular biomass, glycerol, 1,3-PD, acetic acid, and ethanol; x6, x7, and the like, x14 respectively represent intracellular glycerol, concentration of 3-HPA, concentration of 1,3-PD, mR, free regulation protein concentration R, mGDHt, concentration of glycerol dehydratase GDHt, mPDOR, and concentration of 1-3-PD oxidordeuctase PDOR. The optimization algorithm gives most possible path identification of a glycerol dissimilation reaction, and a new definition of extracellular relative error is introduced, and an obtained result is good in stability. The optimization algorithm adds a plurality of determining conditions, so the optimization algorithm fits actual problems of continuous fermentation, and operation efficiency and accuracy are improved.

Owner:南京宁创经纬智能技术有限公司

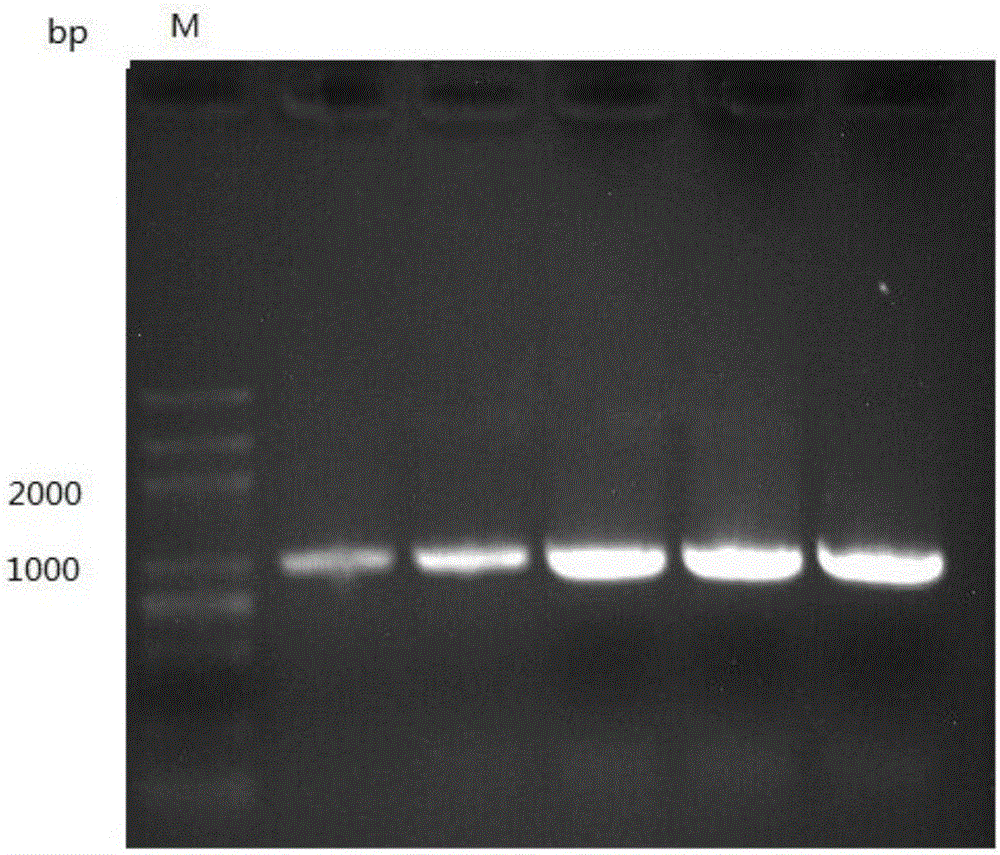

Genetically engineered bacterium used for producing 3-hydroxypropionic acid (3-HP) by fermentation, constructing method and application of genetically engineered bacterium

PendingCN106479947AIncrease productionStrong industrial application valueBacteriaMicroorganism based processesBiotechnology3-Hydroxypropionic acid

The invention discloses a genetically engineered bacterium used for producing 3-hydroxypropionic acid (3-HP) by fermentation, a constructing method and application of the genetically engineered bacterium. An acetaldehyde dehydrogenase gene in Saccharomyces cerevisiae and a glycerol dehydratase gene in Klebsiella pneumoniae are connected onto a prokaryotic expression vector pET30a(+) so as to construct a Pet30a-ALDH-DHAB double-gene prokaryotic expression vector, and then the constructed Pet30a-ALDH-DHAB double-gene prokaryotic expression vector is transformed in to an escherichia coli BL21(DE3) competent cell to construct the genetically engineered bacterium used for effectively producing the 3-HP by fermentation. The problems of high energy consumption and sever pollution in chemical industrial synthesis of the 3-HP and the problem of low yield rate in microbial fermentation production of the 3-HP are solved. By utilizing the genetically engineered bacterium to produce the 3-HP by fermentation, a yield of the 3-HP can reach to 8.443g / L, and a production process is simple and convenient for industrialized application.

Owner:XUZHOU UNIV OF TECH

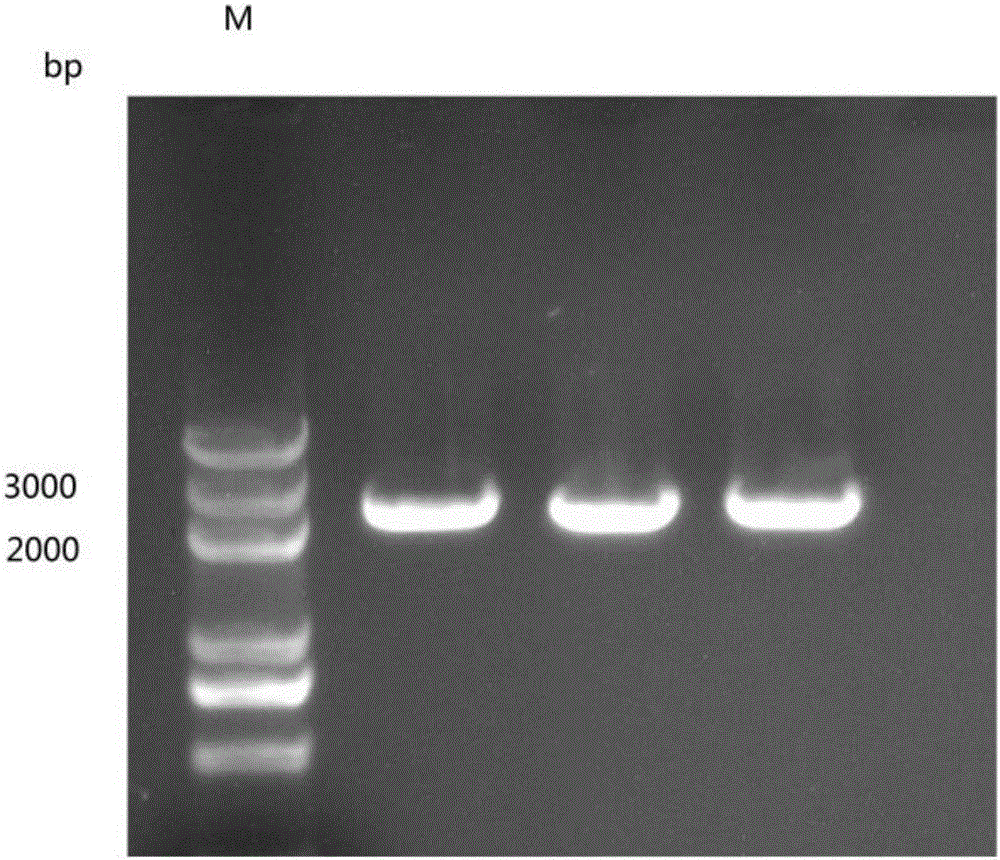

Engineering bacterium capable of co-producing long-chain dicarboxylic acid and 1,3-propylene glycol and building method thereof

ActiveCN106636156AIncrease productionImprove use valueMicroorganism based processesNucleic acid vectorDicarboxylic acidBiology

The invention relates to an engineering bacterium capable of co-producing long-chain dicarboxylic acid and 1,3-propylene glycol and a building method thereof. The engineering bacterium is prepared by transforming a recombinant plasmid. The recombinant plasmid is prepared by the following steps: performing PCR (Polymerase Chain Reaction) amplification to obtain a glycerol dehydratase gene, and connecting the glycerol dehydratase gene with a promoter pGAPg obtained by PCR amplification in an overlapping way to obtain a pGAPg-GD segment; performing PCR amplification to obtain a 1,3-propanediol dehydrogenase gene, connecting the 1,3-propanediol dehydrogenase gene with the promoter pGAPp obtained by the PCR amplification in the overlapping way to obtain a pGAPp-PDE segment; performing PCR amplification to obtain a terminator gene, and preparing a two-way terminator segment; separately connecting the segments to obtain the recombinant plasmid. By adopting the engineering bacterium built by the method, co-expression of a plurality of genes is realized; moreover, the yield of the long-chain dicarboxylic acid is 10g / L, and the yield of the 1,3-propylene glycol generated by transforming glycerine is 13g / L, being remarkably higher than current reported values.

Owner:QILU UNIV OF TECH

Gene regulation continuous fermentation hybrid power system

InactiveCN105740599AStructural Optimal Control ProblemChemical processes analysis/designFermentationScientific theoryMathematical model

The invention relates to a gene regulation continuous fermentation hybrid power system. The system solves a glycerin microorganism fermentation control problem by utilizing an optimal scientific theory. The glycerin microorganism fermentation control problem comprises control factors; and the control factors comprise biomass, extracellular glycerin, extracellular 1,3-PD, acetic acid, ethanol, intracellular glycerin, intracellular 3-HPA, intracellular 1,3-PD, mR, free regulatory proteins R, MGDHt, glycerol dehydratase GDHt, MPDOR and 1,3-PD oxidordeuctase PDOR. According to the gene regulation continuous fermentation hybrid power system, balance is found between mathematical modeling and numerical value accuracy, a possible metabolism path is proposed, a 14-dimension nonlinear hybrid power system with discrete path parameters and continuous system parameters for continuous fermentation is established, and an optimal control problem is structured by using a constraint condition.

Owner:HUZHOU TEACHERS COLLEGE

Method for producing clostridium perfringens glycerin anhydrase incitant gene and 1,3-propanediol thereof

InactiveCN101265474ASignificant progressBacteriaMicroorganism based processesEscherichia coliEnzyme Gene

The invention relates to the clone of a novel glycerol dehydratase activating factor gene and the expression thereof in related host. The activating factor gene, cloned from clostridium perfringens, can activate an inactive glycerol dehydratase under normal biochemical reaction conditions and recover the enzyme activity of the glycerol dehydratase, and can also enable the glycerol dehydratase to be difficult to be inactivated when the glycerol dehydratase is transformed to glycerin in the reaction. On the basis of the invention, related enzyme genes, such as the glycerol dehydratase, 1, 3-propanediol oxidoreductase, can be restructured to colon bacillus so as to get novel metabolic engineering bacteria. The metabolic engineering bacteria transform starch, glycerin or glucose to 1, 3-propanediol through fermentation.

Owner:南宁中诺生物工程有限责任公司

Preparation method of recombinant organism 3-hydracrylic acid

The invention relates to a preparation method of 3-hydracrylic acid, which can be explained by the production of 3-hydracrylic acid (3-HP) from glycerol in a bacterial host. 3-HP is a useful raw material for production of a polymeric material. A genetic engineering bacteria host of two enzymes is enough to produce 3-HP. One enzyme is glycerol dehydratase and the other enzyme is acetaldehyde dehydrogenase. The recombinant microorganism host, which is allowed to be established, can synthesize 3-HP from glycerol or glucose used as a starting material. Glycerol or glucose is converted and then transformed into 3-HP.

Owner:XINCHANG GUANYANG TECH DEV

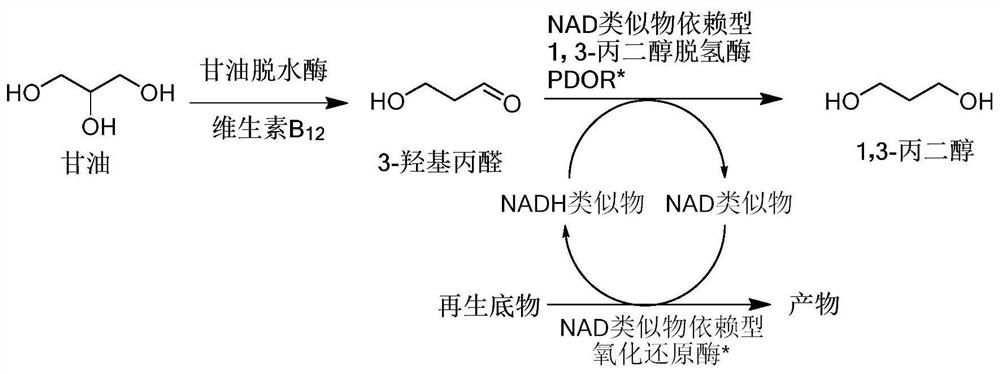

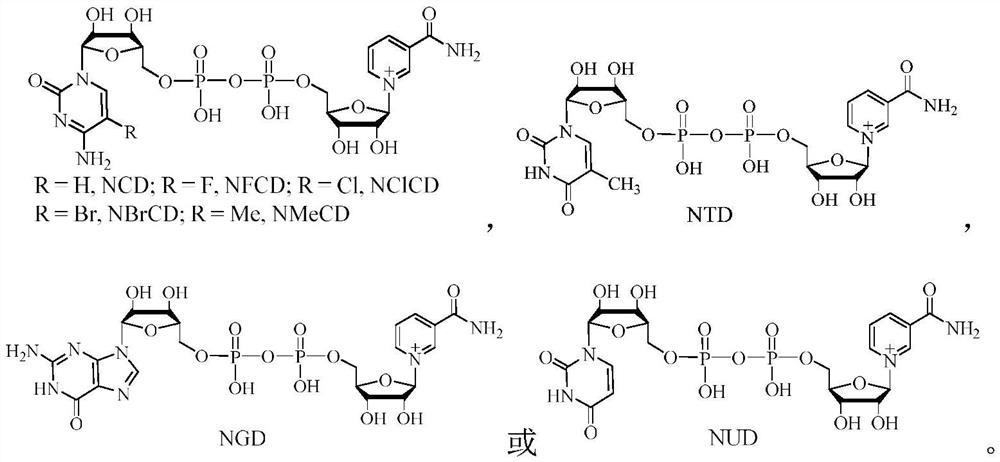

Method for producing 1,3-propanediol by biologically catalyzing glycerol

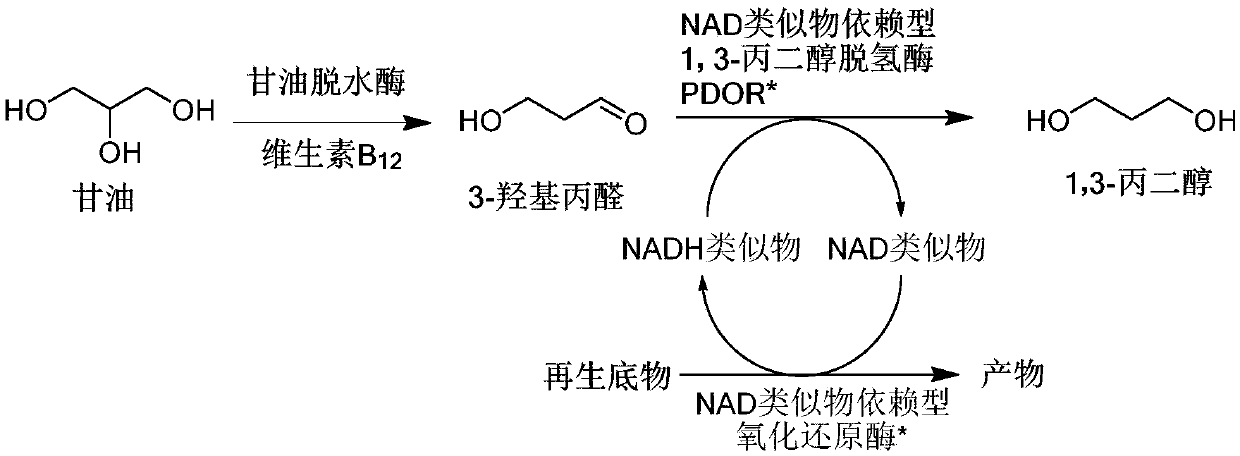

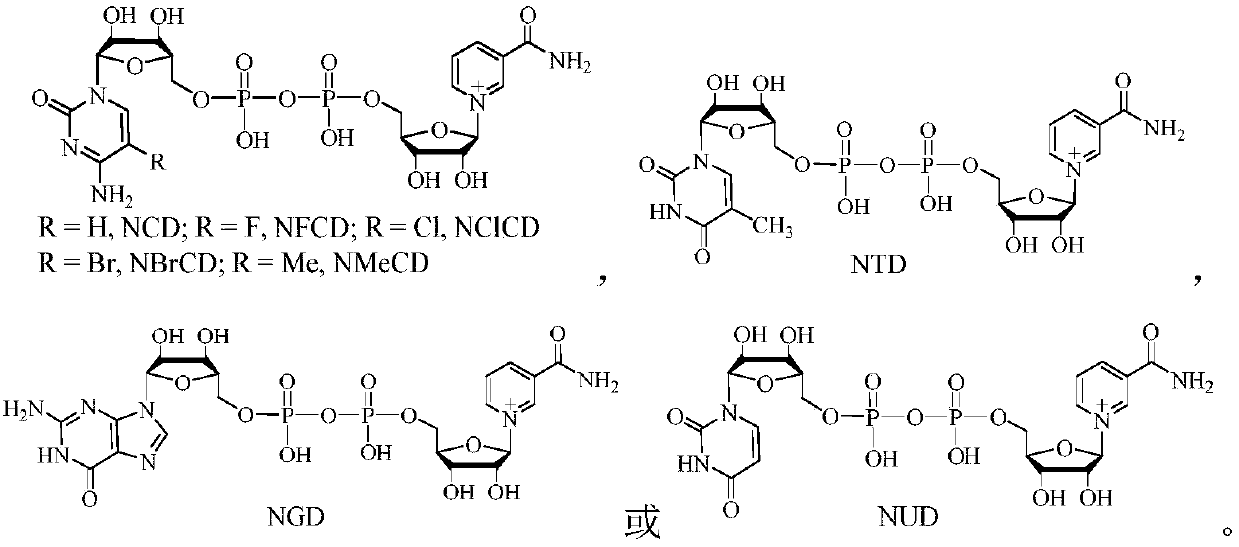

The invention discloses a method for producing 1,3-propanediol by biologically catalyzing glycerol. According to the method, firstly, the glycerol is converted to an intermediate 3-hydroxypropionaldehyde through glycerol dehydratase, and under coupling catalysis of nicotinamide adenine dinucleotide (NAD) analog dependent 1,3-propanediol dehydrogenase and NAD analogue dependent oxidoreductase of regenerative NAD analogs, the intermediate produces the 1,3-propanediol. The catalytic system can be used for catalyzing the glycerol as a biodiesel by-product in an extracellular cell-free system or amicroorganism to produce the 1,3-propanediol, so that the production cost of the 1,3-propanediol is obviously reduced, and the product yield is increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

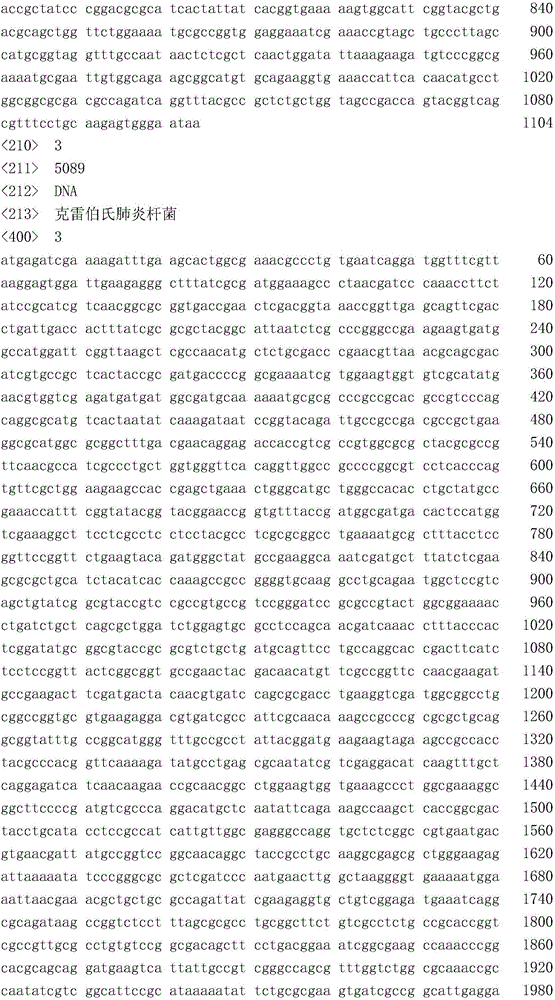

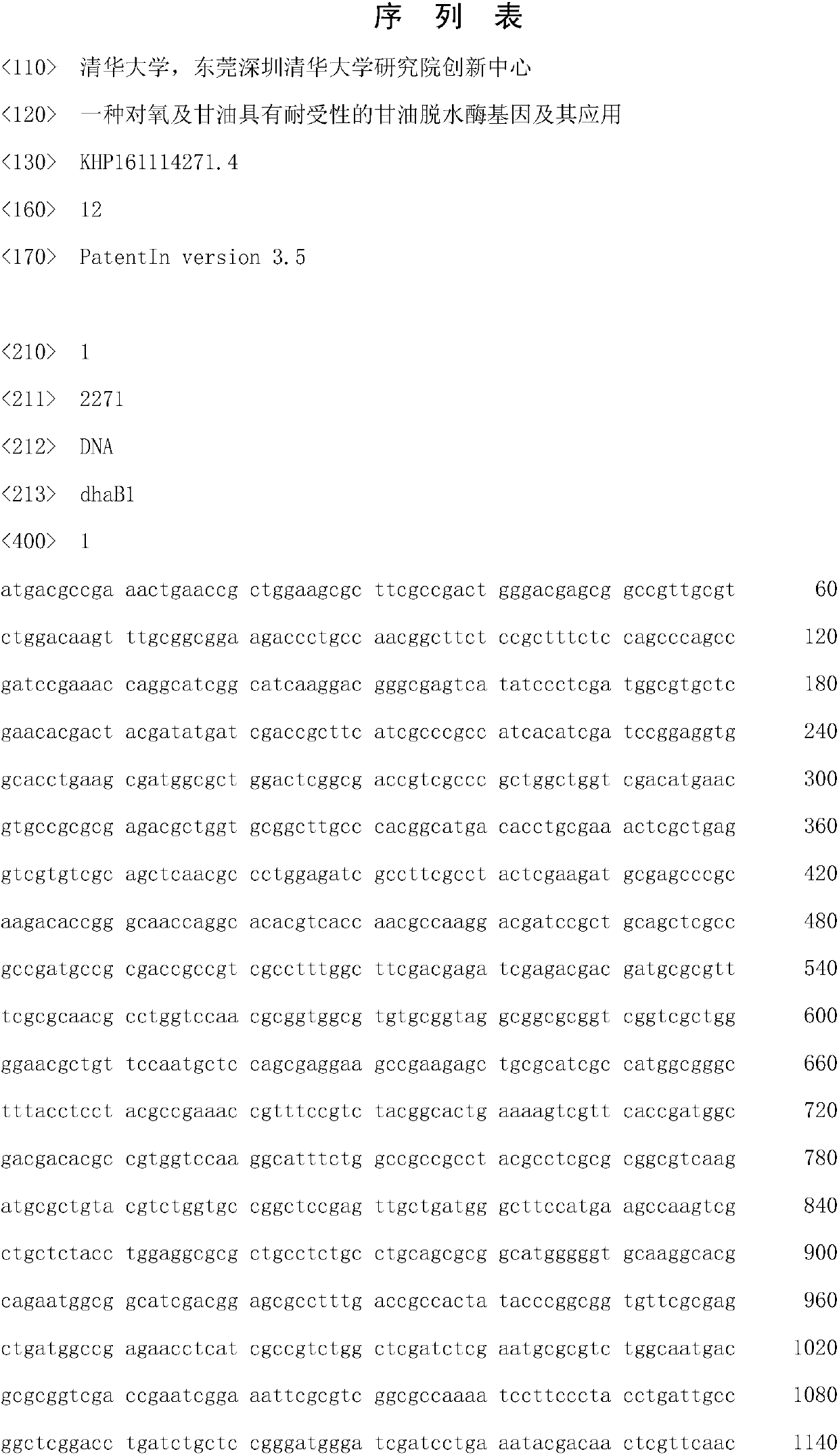

Glycerol dehydratase gene resistant to oxygen and glycerin and application thereof

InactiveCN105950642AHigh catalytic activityReduce inhibitionGenetic engineeringFermentationNucleotideGlycerol

The invention provides a glycerol dehydratase gene resistant to oxygen and glycerin and application thereof. The glycerin dehydratase gene dhaB1B2 derives from lotaustralin root nodule bacteria and only includes two subunits including a big alpha subunit and a small beta subunit, and nucleotide sequences of the subunits are shown as SEQ ID NO.1-2. The glycerin dehydratase gene dhaB1B2 has very high catalytic activity, and the enzyme activity inhibiting effect on the glycerin and the oxygen is far lower than those of other existing known B12-dependent glycerol dehydratases. In addition, the glycerol dehydratase gene can remarkably increase the yields of 1,3-propylene glycol and 3-hydracrylic acid and has a broad application prospect.

Owner:TSINGHUA UNIV +1

Recombination klebsiella pneumonia capable of co-producing 3-HP and P3HP, and preparation method and application thereof

ActiveCN103497922BReduce synthesisIncrease productionBacteriaMicroorganism based processesK pneumoniae3-Hydroxypropionic acid

The invention discloses recombination klebsiella pneumonia capable of co-producing 3-HP and P3HP, and a preparation method and application thereof. The recombination bacterium is obtained by introducing glycerol dehydratase gene, glycerol dehydratase reactivation enzyme gene, aldehyde dehydrogenase gene, propionyl coenzyme A synthetase gene and polyhydroxyalkanoate synthetase gene into a host recombination klebsiella pneumonia in which 1, 3-propylene glycol oxidoreductase gene and aldehyde reductase / alcohol dehydrogenase gene are knocked out. According to the technical scheme, the production cost of 3-hydroxypropionic acid and poly(3-hydroxypropionic acid) is reduced, and 3-hydroxypropionic acid and poly(3-hydroxypropionic acid) can be synthesized at the same time by taking a same thallus as the host.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

A kind of poly-3-hydroxypropionic acid copolymer and production method thereof

ActiveCN104046659BReduce crystallinityHigh melting pointBacteriaMicroorganism based processes3-Hydroxypropionic acidEnzyme Gene

The invention discloses a poly-3-hydroxy propionic acid copolymer and a production method thereof and belongs to the technical field of genetic engineering. According to the poly-3-hydroxy propionic acid copolymer and the production method thereof, a glycerol dehydratase gene and a glycerol dehydratase re-activating enzyme gene are integrated with a host strain genome by a gene integration technology, a polyhydroxy fatty acid synthase gene, a propionaldehyde dehydrogenase gene, a beta-ketoacyl coenzyme A thiolase gene, an acetoacetyl coenzyme A reductase gene and a propionyl coenzyme A synthetase gene are introduced, and a recombinant gene engineering strain has the ability of biologically synthesizing poly-3-hydracrylic acid-co-3-hydroxyvaleric acid. According to the poly-3-hydroxy propionic acid copolymer and the production method thereof, the poly-3-hydracrylic acid-co-3-hydroxyvaleric acid is obtained in a biosynthesis manner for the first time; compared with poly-3-hydracrylic acid, the obtained poly 3-hydracrylic acid-co-3-hydroxyvaleric acid has a higher melting point and lower crystallinity, has good degradability and can serve as a packaging material, a medical implant material, a drug sustained-release material and an electrochemical material.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

A kind of method of biocatalytic glycerol production 1,3-propanediol

The invention discloses a method for biocatalyzing glycerin to produce 1,3-propanediol. The method first converts glycerol to the intermediate 3-hydroxypropanal by glycerol dehydratase, and the intermediate is in the NAD analog-dependent 1,3-propanediol dehydrogenase and the NAD analog-dependent oxidoreductase of the renewable NAD analog With coupling catalysis, 1,3‑propanediol is also produced. The system can be used in an extracellular cell-free system or in microorganisms to catalyze biodiesel by-product glycerol to produce 1,3-propanediol, which can significantly reduce the production cost of 1,3-propanediol and increase the product yield.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for the preparation of 3-hydroxypropanal method for preparing 3-hydroxyl propionaldehyde

InactiveCN101333546AIncrease profitIncrease productivityMicroorganism based processesFermentationFiltrationGlycerol

The invention discloses a process for preparing 3-hydroxy-propionaldehyde, which adopts a two-stage process of cultivating microbial thalli firstly and then utilizing the thalli to transform glycerol, and the process comprises the following steps of: (1) preparing an MRS culture medium containing glucose or fructose for cultivating microorganisms that contain glycerol anhydrase and can secrete the 3-hydroxy-propionaldehyde to the outside of cells, and acquiring mass thalli; and (2) utilizing the thalli to serve as a biocatalyst for transforming the glycerol so as to produce the 3-hydroxy-propionaldehyde. The process has advantages of simple separation process, only needing the thalli separation in the transformation process, having no byproduct, saving separation and purification costs, reusable thalli after filtration, washing and activation, reducing the transformation time and improving the production efficiency.

Owner:HUAQIAO UNIVERSITY

Method for the production of 1,3-propanediol by recombinant organisms comprising genes for coenzyme B12 synthesis

Recombinant organisms are provided comprising genes encoding cob(II)alamin reductase, cob(I)alamin adenosyltransferase, glycerol dehydratase and 1,3-propanediol oxidoreductase activities useful for the production of 1,3-propanediol from a variety of carbon substrates.

Owner:EI DU PONT DE NEMOURS & CO +1

Genetically engineered bacteria for co-production of isoprene and 1,3-propanediol and its construction method and application

ActiveCN106350476BRealize joint productionHigh yieldBacteriaMicroorganism based processesEscherichia coliBiotechnology

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com