Recombination klebsiella pneumonia capable of co-producing 3-HP and P3HP, and preparation method and application thereof

A technology for Klebsiella pneumoniae and pneumonia, which is applied in the field of recombinant Klebsiella pneumoniae and its preparation, and can solve problems such as simultaneous synthesis of 3-HP and P3HP that have not yet been found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1. Strain construction

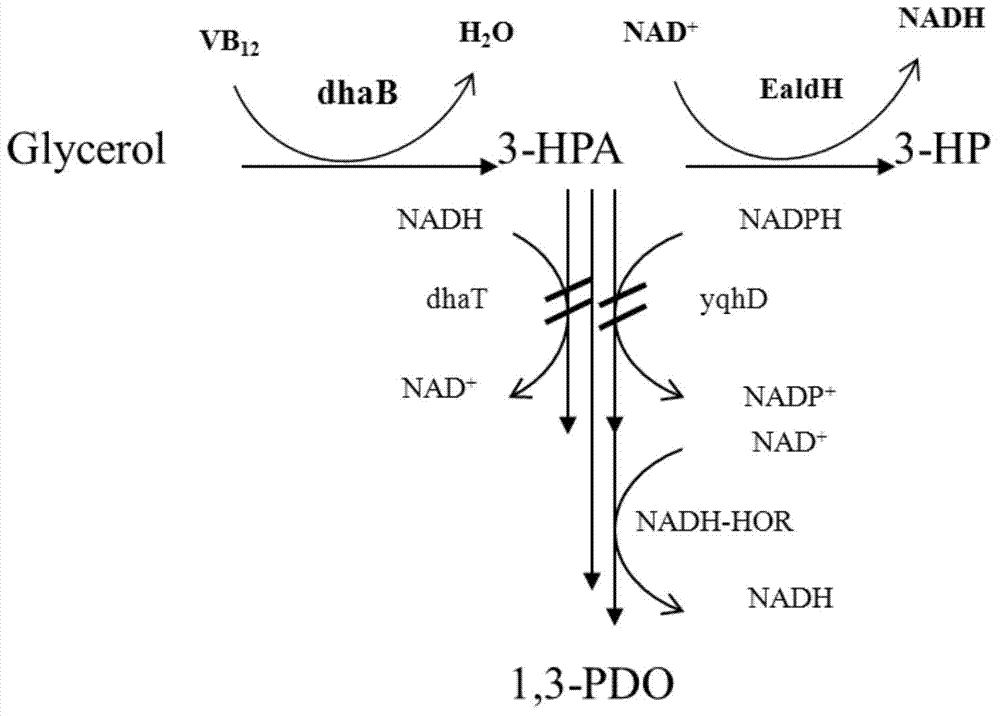

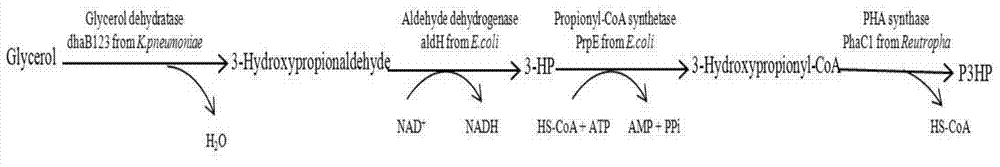

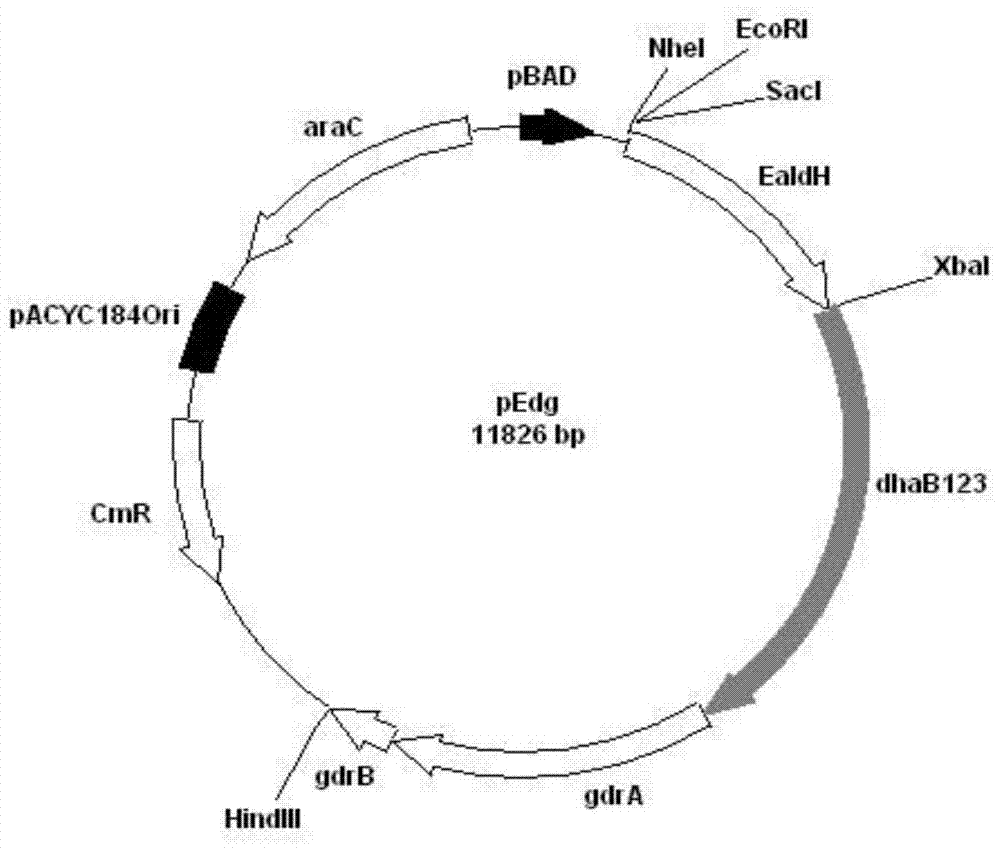

[0069] By over-expressing endogenous K. pneumoniae (K. penumoniae) strains with deletion of 1,3-propanediol dehydrogenase gene (dhaT) and aldehyde reductase / alcohol dehydrogenase gene (yqhD) Glycerol dehydratase gene (dhaB123) and glycerol dehydratase reactivation enzyme gene (gdrAB), as well as exogenous aldehyde dehydrogenase gene (aldH), propionyl-CoA synthase gene (prpE) and polyhydroxy fatty acid synthase gene ( phaC) Realize the co-production of 3-HP and P3HP using glycerol as the carbon substrate.

[0070] Those skilled in the art should understand that the above-mentioned K. penumoniae gene deletion experiments are carried out in accordance with standard molecular cloning techniques in each step; the above-mentioned five over-expressed genes are co-cloned into K. pneumoniae In K. penumoniae, each step is performed according to standard molecular cloning techniques.

[0071] 1.1 Gene knockout

[0072] Design primers using the 1,3-propan...

Embodiment 2

[0109] Example 2. SDS-PAGE to identify the expression and optimization of the target protein

[0110] The activated engineered Klebsiella pneumoniae was inoculated into 20mL liquid culture medium (containing 100μg·mL -1 Chloramphenicol and 100μg·mL -1 Kanamycin), 37℃, 180rpm shaking culture, OD 600 When it reaches 0.6, add a certain concentration of arabinose to the bacterial solution, then adjust the temperature to 30°C and continue culturing for 3 hours to induce the expression of the target protein. Take out the induced culture, centrifuge at 12000g for 10 min to collect the bacterial cells, and wash the bacterial cells once with 0.05 mol / L phosphate buffer (pH 7.0). Then add 1mL phosphate buffer to disrupt the cells, take 10μL of supernatant and add an equal volume of 2×SDS-PAGE loading buffer, boiling water bath for 5min, instantaneous high-speed centrifugation, 10% SDS-PAGE electrophoresis detection, you can detect the target protein Express the situation ( Figure 5 ), whe...

Embodiment 3

[0111] Example 3. Shake flask fermentation test of recombinant strain

[0112] Inoculate the activated recombinant strain at a ratio of 1:100 into a 250mL shake flask containing 50mL of M9 modified liquid medium (containing 100μg·mL -1 Chloramphenicol and 100μg·mL -1 Kanamycin), shaking culture at 37°C and 180rpm. OD 600 When it reaches about 0.6, add 0.05% arabinose, after that, add arabinose and antibiotics every 12h, and terminate the fermentation 48h after arabinose is induced.

[0113] Take 1 mL of fermentation broth, centrifuge at 15000 rpm at 4°C for 10 min, take the supernatant, and detect the fermentation product by high performance liquid chromatography. Gas chromatography( Image 6 ) It was confirmed that 3-hydroxypropionic acid was obtained; and the production of 3-hydroxypropionic acid was increased, and the production of by-product 1,3-propanediol was decreased compared with the genetically engineered bacteria related to the synthesis of knockout by-products. The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com