Engineering bacterium producing 1,3-methyl glycol oxidoreductase and preparation method for the enzyme

A genetically engineered bacteria and purpose technology, applied in the direction of oxidoreductase, biochemical equipment and methods, botanical equipment and methods, etc., can solve the problems of cost and production capacity not reaching industrial production, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

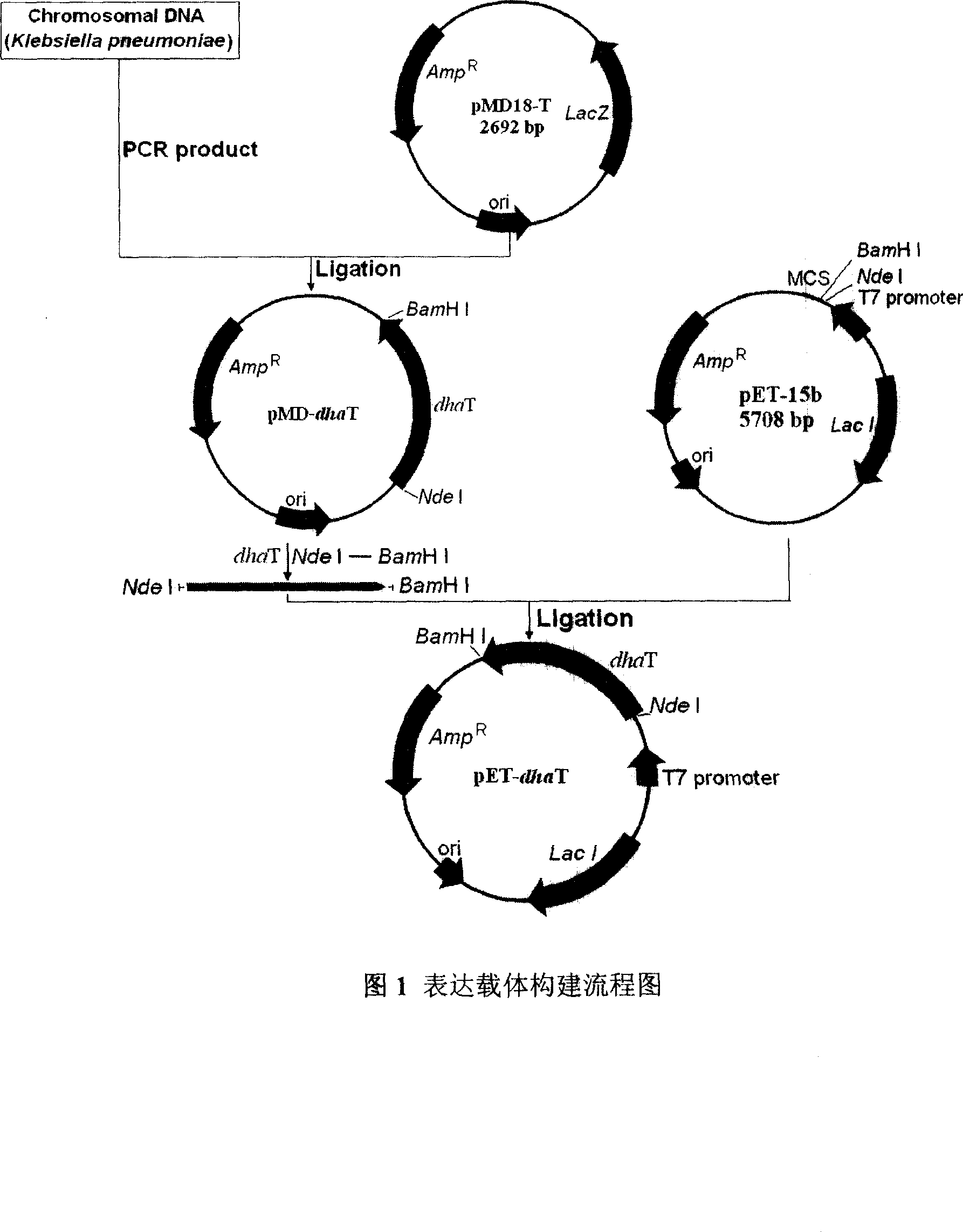

Method used

Image

Examples

Embodiment 1

[0026] The genetically engineered bacterium BL21(DE3)-pET-dhaT containing 1,3-propanediol oxidoreductase of 10-25% glycerol preserved at -70°C was taken out, and a small amount of bacterial liquid was inoculated into the culture medium of LB containing Amp, 25 Activate at -39°C for 6-12 hours on a shaker.

[0027] Then inoculate the activated bacterial liquid in (1-5% inoculum size) LB medium containing 0-150 μg / mL Amp, culture in a fermenter at 25-39°C for 0.5-2h, add inducer to the final concentration, if When IPTG is used as an inducer, it is 0.05-1mM, and lactose is used as 2-200mM for induction; continue to ferment at 15-28°C for 3-12h.

[0028] The fermented liquid was centrifuged at 6000rpm at 1°C for 10min to collect the thallus, and the binding buffer (20mM Na 3 PO 3 , 0.5M NaCl, pH 7.5-8.5) or Tris buffer (pH 7.3-8.5) to suspend, add 10 mg / mL lysozyme in an amount of 1 / 10 volume of the added binding buffer, ice-bath for 30min, shake at 4°C Shake for 10 minutes; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com