Recombinant klebsiella expressed by kalamycin resistance gene promoter and use thereof

A technology of Klebsiella and kanamycin, applied in the field of genetic engineering, can solve the problems of no cost advantage, low product fermentation intensity, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

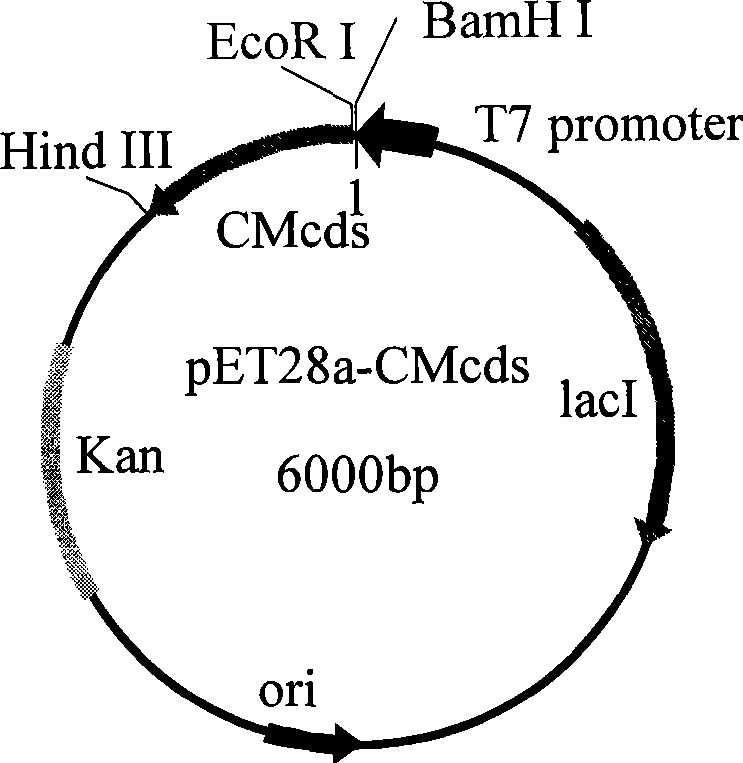

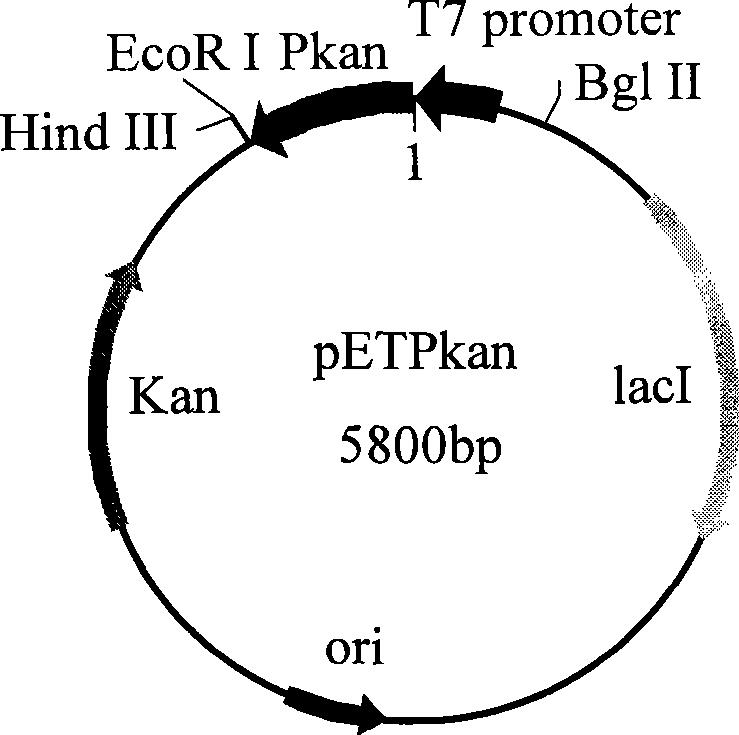

[0058] Embodiment 1: Construction of plasmid pETPkan:

[0059] The plasmid pET28a was used as a template for PCR amplification, and the primers used were as follows:

[0060] P1: 5'-cgc aga tct GTA TCT CAG TTC GGT GTA GG-3'

[0061] P2: 5'-cgc gaa ttc AAC ACC CCT TGT ATT ACT G-3'

[0062]The PCR method is as follows: Add to the 50 μL reaction system: 1.5 μL of 10 mol / L primers P1 and P2, 5 μL of 2 mmol / L dNTP, 5 μL of 10×ExTaq Buffer, 0.5 μL of 5U / μL ExTaq DNA polymerase, 1 μg of template, and Make up 50 μL with double distilled water; PCR conditions are: denaturation at 95°C for 5 minutes, 1 minute at 54°C, extension at 72°C for 2 minutes, denaturation at 94°C for 1 minute, cycle 30 times;

[0063] The purified reaction product was analyzed by agarose gel electrophoresis, and the target band appeared in the loading lane, and the target fragment of about 0.5 kb was recovered with the PCR fragment recovery kit; the purified target fragment was double-digested with Bgl II and ...

Embodiment 2

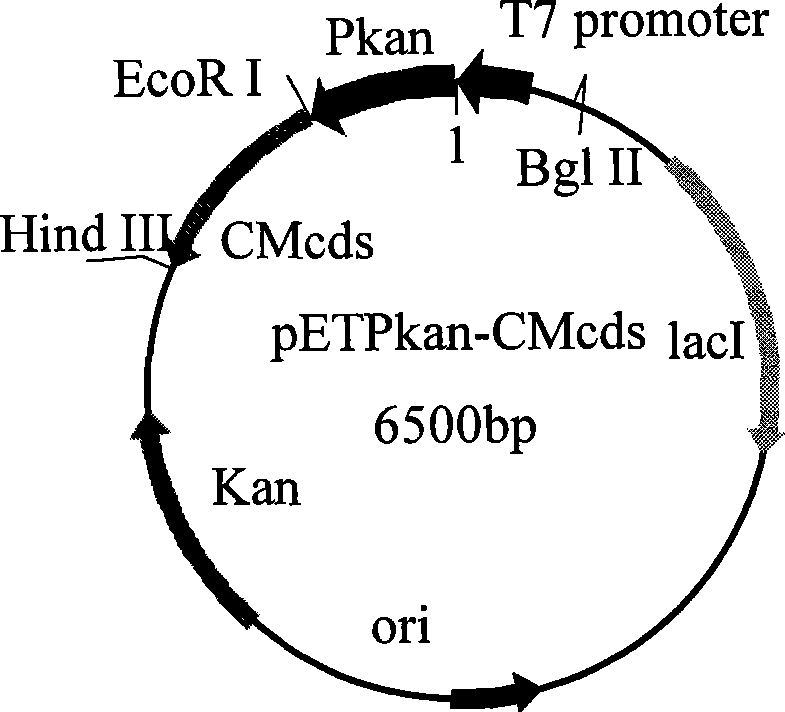

[0064] Embodiment 2: Construction of plasmid pETPkan-CMcds:

[0065] Take a cryopreserved BL21 / pET28a-CMcds, inoculate it in 20 mL of LB medium containing 50 μg / mL kanamycin and culture overnight at 37°C, extract the plasmid pET28a-CMcds, and perform double digestion with EcoR I and Hind III, The gel recovery kit recovers the target fragment with a size of about 0.7kb. At the same time, the plasmid pETPkan is extracted, digested with EcoR I and Hind III, recovered and purified. use T 4 Ligase ligated the two enzyme-cleaved and purified fragments, and the ligated product was transformed into Escherichia coli JM109 competent cells, and the transformed product was spread on an LB agar plate containing 50 μg / mL kanamycin and 25 μg / mL chloramphenicol, and cultured overnight at 37°C ;Plasmids were extracted, digested with EcoR I and Hind III respectively, and positive clones were identified by agarose gel electrophoresis. The positive recombinants were stored in LB containing 20% ...

Embodiment 3

[0066] Embodiment 3: plasmid pETPkan-CMcds transforms Klebsiella:

[0067] The plasmid pETPkan-CMcds was transformed into Klebsiella competent cells, and the transformants were spread on LB agar plates containing 50 μg / mL kanamycin and 25 μg / mL chloramphenicol, and cultured overnight at 37°C; a large number of single colonies were found.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com