Refrigeration cycle device and control method therefor

A technology of circulation device and control valve, which can be used in fluid circulation arrangement, heating and ventilation control system, irreversible circulation compressor, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0033] (refrigeration cycle)

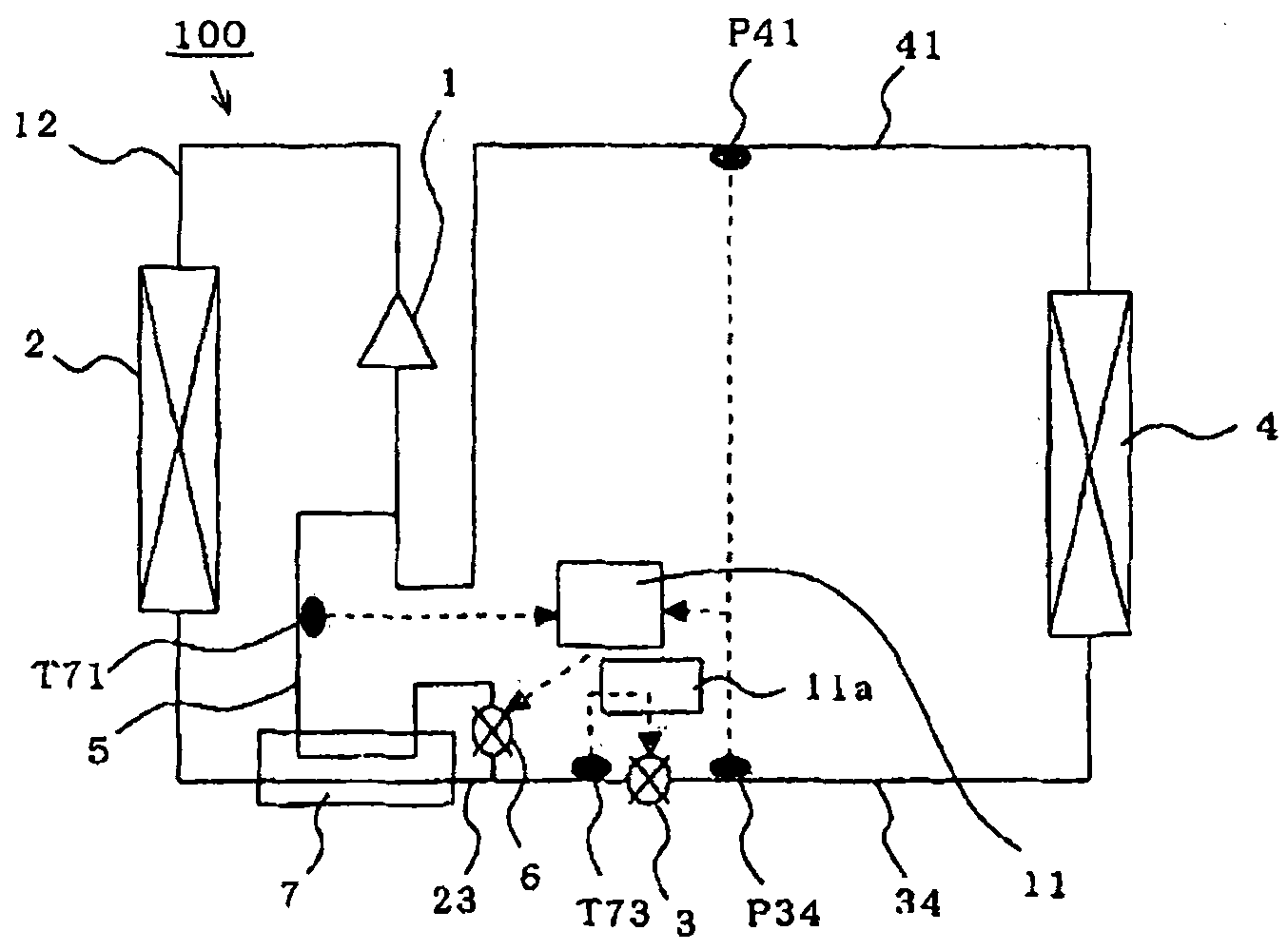

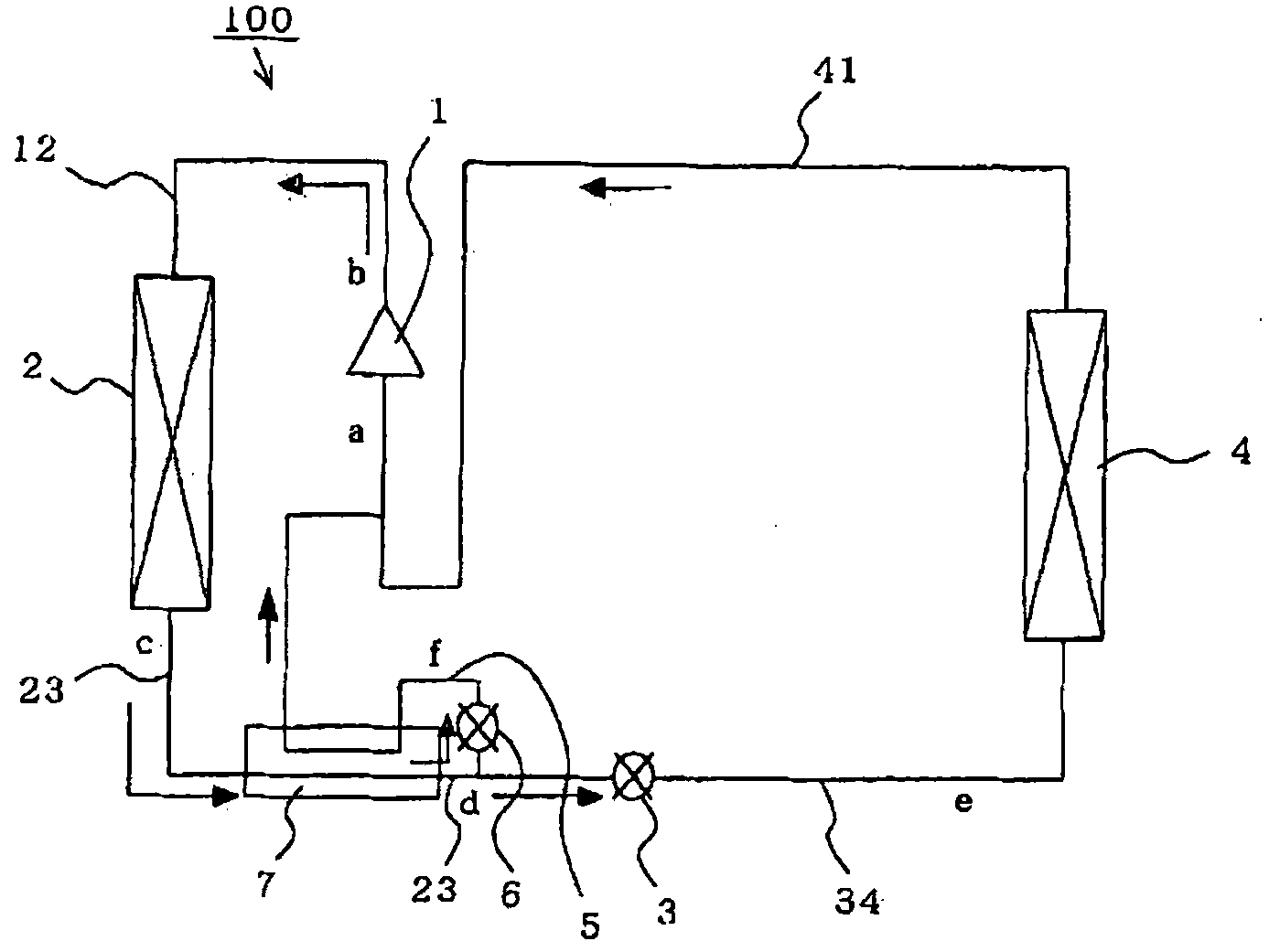

[0034] figure 1 It is a refrigerant circuit diagram explaining the structure of the refrigeration cycle apparatus concerning Embodiment 1 of this invention. exist figure 1Among them, the refrigeration cycle apparatus 100 has a main circuit including a compressor 1 for compressing refrigerant, a condenser 2 for condensing the compressed refrigerant, and an expansion valve (such as an electronic expansion valve) for expanding the condensed refrigerant. flow control valve, capillary tube, etc.) 3, evaporator 4 for evaporating the expanded refrigerant, high temperature and high pressure piping 12 connecting compressor 1 and condenser 2, medium temperature and high pressure piping 23 connecting condenser 2 and expansion valve 3, connecting The low-temperature and low-pressure piping 34 connecting the expansion valve 3 and the evaporator 4 , and the medium-temperature and low-pressure piping 41 connecting the evaporator 4 and the compressor 1 .

[0...

Embodiment approach 2

[0048] (Embodiment 2: Control Method)

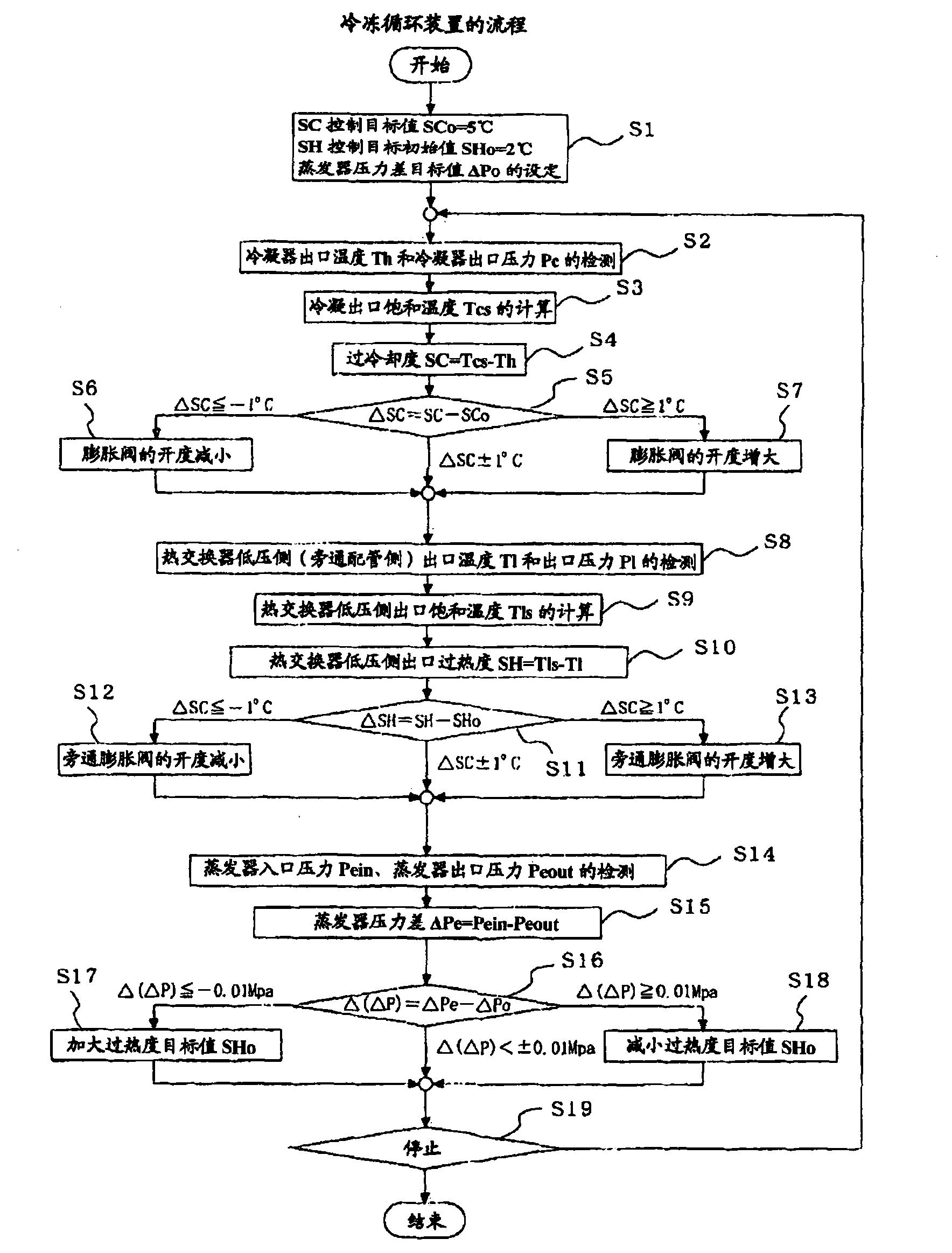

[0049] Below, refer to figure 2 Control of the expansion valve 3 and the bypass expansion valve 6 by the control mechanism of the refrigeration cycle apparatus shown in Embodiment 1 will be described.

[0050] figure 2 It is a flowchart showing the degree of supercooling control and the degree of superheating control of the control means for explaining the control method of the refrigeration cycle apparatus according to Embodiment 2 of the present invention.

[0051] exist figure 2 First, the subcooling degree control unit 11a and the superheating degree control unit 11b respectively set initial values for the supercooling degree target value SCo and the superheating degree target value SHo (for example, SCo=5°C, SHo=2°C) (S1) . This initial value is a value (a positive value equal to or greater than 0) that is appropriately adjusted according to the installation conditions and the type of refrigeration device, and is stored in ...

Embodiment approach 3

[0102] (refrigeration cycle)

[0103] Figure 5 It is a refrigerant circuit diagram explaining the structure of the refrigeration cycle apparatus concerning Embodiment 3 of this invention. exist Figure 5 In the refrigerating cycle device 200, the gas-liquid separator 8 is added to the low-temperature and low-pressure piping 34 in the refrigerating cycle device 100 (Embodiment 1), and the gas (steam) separated in the gas-liquid separator 8 is provided. A pipe (hereinafter, referred to as "gas pipe") 10 that supplies the compressor 1 is provided.

[0104] A flow control valve (hereinafter referred to as "gas flow control valve") 9 is provided in the middle of the gas piping 10, and a gas flow control valve inlet pressure sensor P89 is installed on the upstream side of the gas flow control valve 9 respectively. The downstream side of the valve 9 is provided with a gas flow control valve outlet pressure sensor P91.

[0105] Except for the above structure, the rest is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com