Hair iron having buffer member

a technology of hair iron and buffer member, which is applied in the direction of curling irons, curling-tongs, hair equipments, etc., can solve the problems of hair damage and hair not being fixed smoothly, and achieve the effect of straightening smoothly and preventing thermal deformation of hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

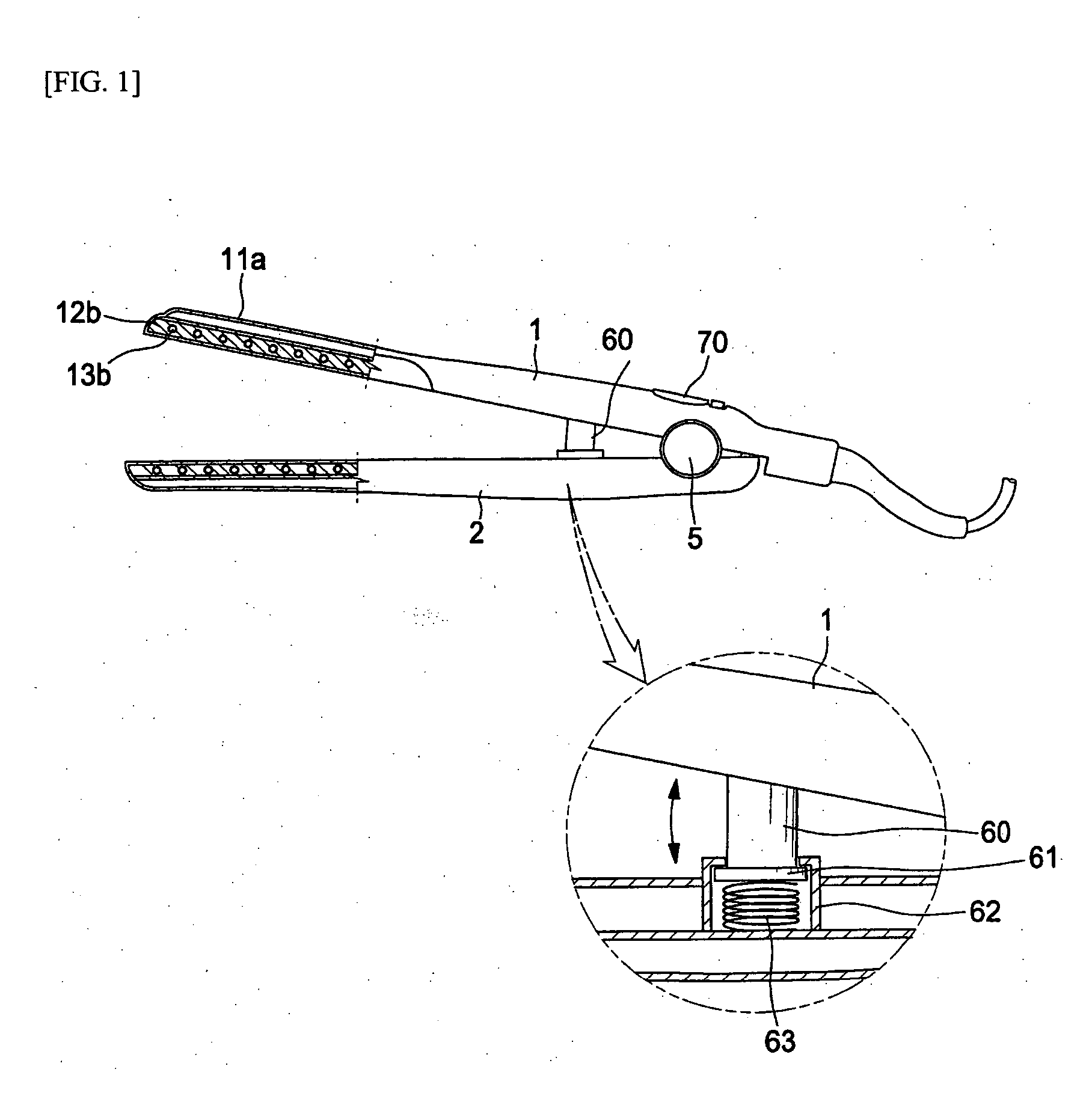

[0014] Hereunder the invention is described in more detail, referring to the attached drawings.

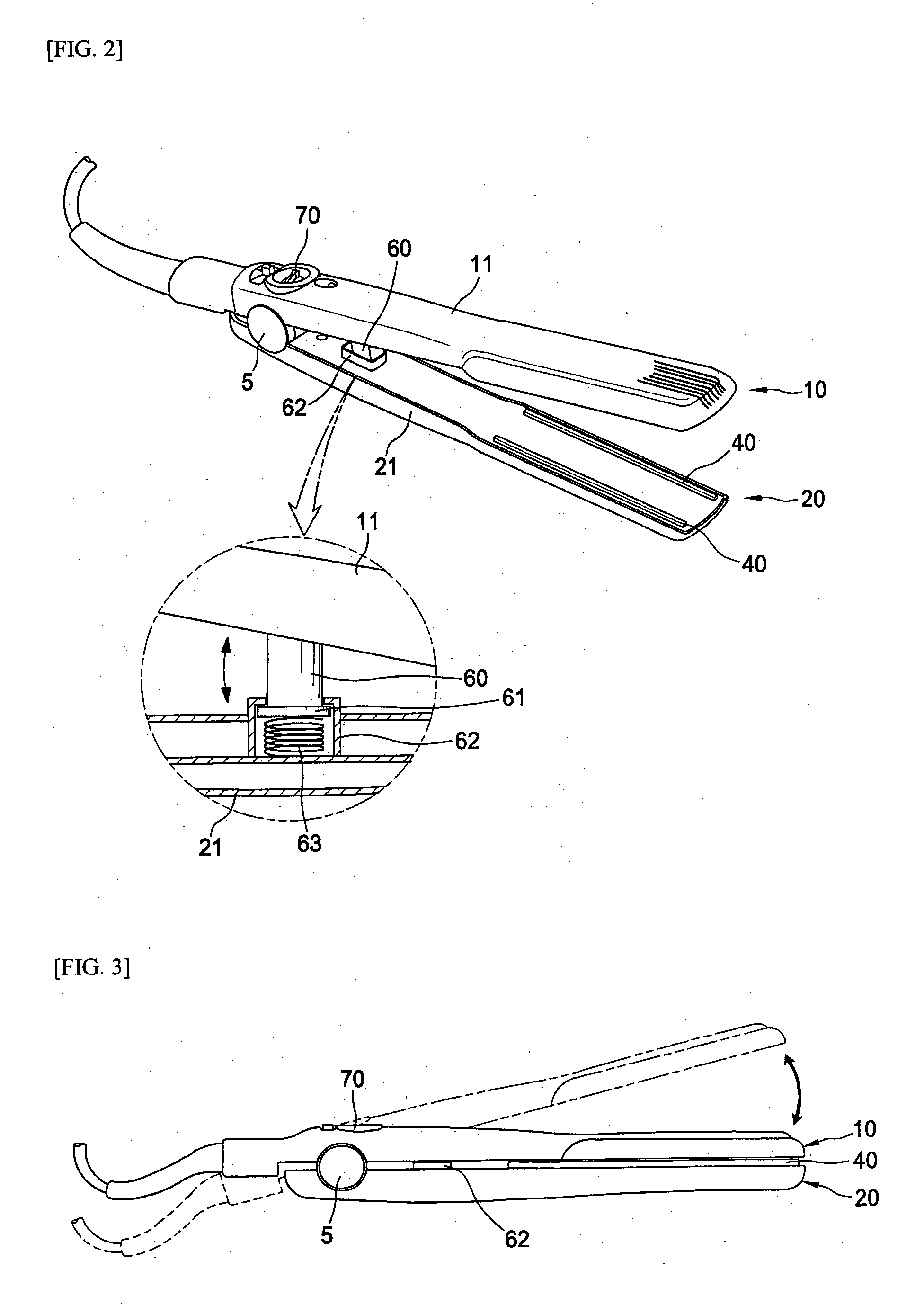

[0015]FIG. 2 shows the hair iron of the present invention, which is laid open. FIG. 3 shows the hair iron of the present invention, which is shut. FIG. 4 shows the cross-section of the hair iron of the present invention. And, FIG. 5 shows another embodiment of the hair iron of the present invention. The present invention is characterized by a hair iron comprising a first pressing member 10 and a second pressing member 20 having steel plates 12, 22, in which thermal wire heaters 13, 23 are built in, respectively, wherein a buffer member 40 is attached to the steel plate 22 attached to the second pressing member 20.

[0016] The buffer member 40 is made of heat-resistant silicon or silver. The buffer member 40 may be either attached on the surface of the steel plate 22 or inserted in a groove 22a formed on the surface of the steel plate 22. Although not shown in the drawings, the buffer membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com