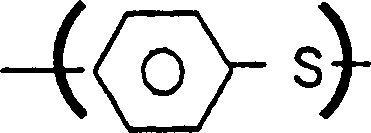

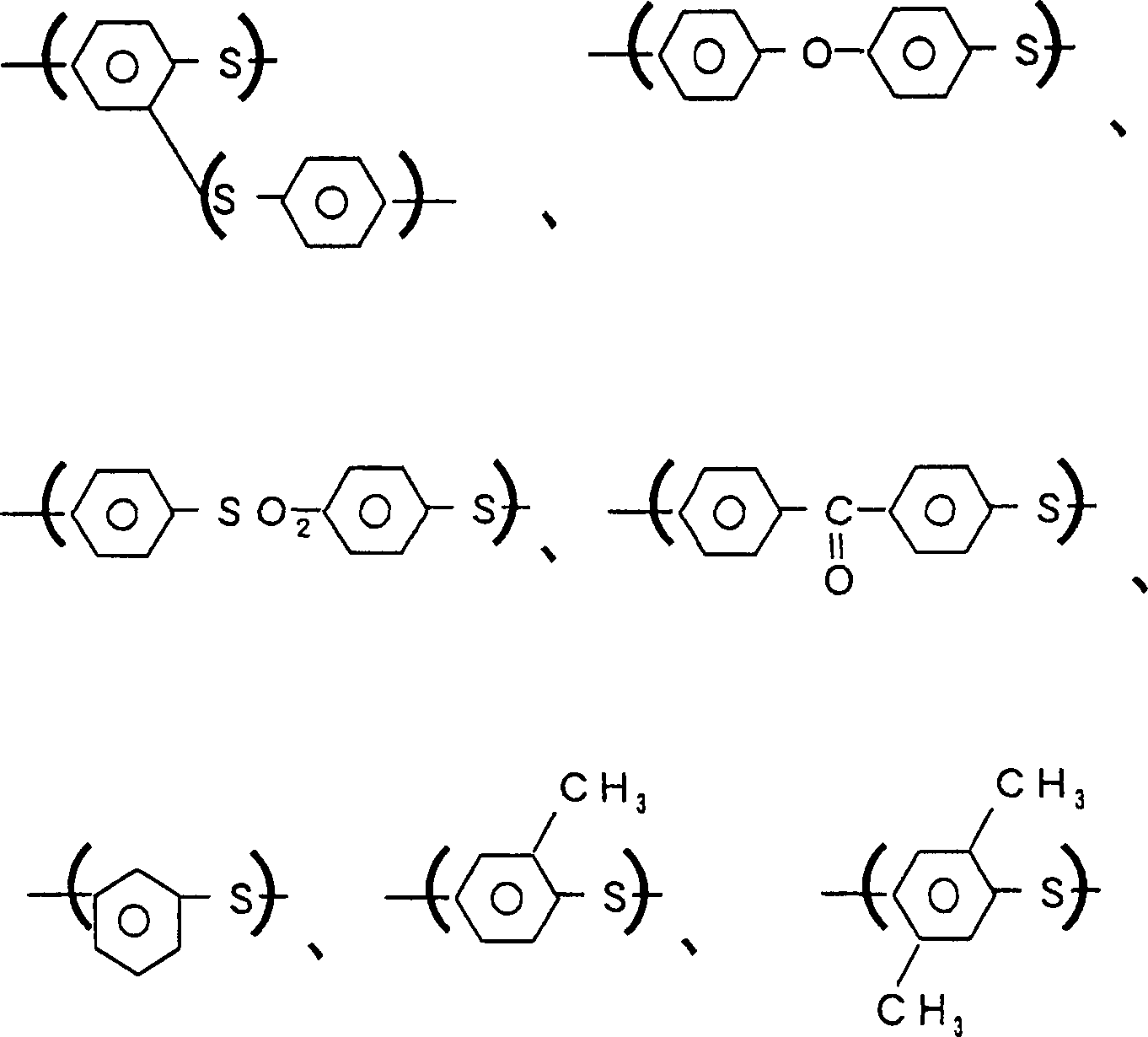

Polyphenylene sulfide resin compositions

A technology of polyphenylene sulfide resin and composition, which is applied in the field of polyphenylene sulfide resin composition, and can solve the problems such as the reduced degree of freedom in the design of molded parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-30、 comparative example 1-7

[0208] According to the combination and amount of Table 1-3, from the above (1) PPS resin group, (2) glass fiber group, (3) filler group other than glass fiber, (4) amorphous resin group, (5) ) silane compound and (6) antioxidant materials are selected, mixed, and pelletized with a twin-screw extruder PCM equipped with a three-hole linear die at a resin temperature of 310°C to produce a PPS resin combination. matter particles. The pellets of these PPS resin compositions were molded into moldings for each evaluation test, and the cooling crystallization temperature, the amount of chloroform extract, laser transmittance, heat distortion temperature, and laser welding strength and warpage were evaluated respectively, and Table 1- 3 shows the results.

Embodiment 31-52

[0210] As above, according to the combination and amount in Table 4, from the above (1) PPS resin group, (2) glass fiber group, (3) filler group other than glass fiber, (4) amorphous resin group , the silane compound of (5), and the antioxidant of (6) are selected from each material, mixed, respectively, with a twin-screw extruder PCM equipped with a three-hole linear die, and pelletized at a resin temperature of 310°C, thereby producing PPS resin composition particles.

[0211] For the particles of these PPS resin compositions, the cooling crystallization temperature, the amount of chloroform extract, the laser transmittance, the heat distortion temperature, and the laser welding strength and warpage were measured respectively, and the results shown in Table 4 were obtained.

Embodiment 53-55

[0213] According to the combination and amount in Table 5, each material from the above (1) PPS resin group, (2) glass fiber group, (5) silane compound, (6) antioxidant, (7) elastomer group Select, mix, and pelletize with a twin-screw extruder PCM equipped with a three-hole linear die at a resin temperature of 310° C., thereby producing PPS resin composition pellets. The cooling crystallization temperature, chloroform extract content, laser transmittance, heat distortion temperature, and laser welding strength, warpage, and cold and heat resistance were measured for these PPS resin composition particles, and the results shown in Table 5 were obtained. In Table 5, the results of Examples 5 and 27 above are collectively described.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com